Imagine a welding technique that offers precision, minimal thermal distortion, and high-speed processing. Laser welding brings these advantages to the table, revolutionizing the manufacturing industry. This article delves into the fundamental principles of laser welding, its benefits and limitations, and the types of materials best suited for this process. By the end, you’ll understand how laser welding can enhance efficiency and quality in various applications. Dive in to discover the key aspects and transformative potential of this advanced welding technology.

(1) A small processing range can offer better control over energy input, leading to reduced thermal stress, a smaller heat affected zone, and smaller thermal deformation.

(2) Welds that are narrow and smooth require fewer post-weld treatment processes, or none at all.

(3) The fast cooling speed and fine weld structure result in excellent performance of the welded joint.

(4) The process has a high processing speed and short working cycle.

(5) Micro welding and long-distance transmission can be accomplished without the use of a vacuum device, making it ideal for mass automatic production.

(6) Laser welding is easy to integrate with other processing methods, such as bending, punching, and assembly, and is well-suited for automatic production.

(7) The production process is easily controlled, as the sensor system monitors the process in real-time to guarantee welding quality.

(8) Laser welding does not require contact with the workpiece, thus avoiding any contact stress.

Although laser welding has many advantages and is a promising welding method, it also has certain limitations.

(1) The welding thickness is limited and is mainly suitable for thin materials.

(2) The workpiece must be clamped with high accuracy, and the clearance should be kept to a minimum. This often requires precision welding fixtures, which can be relatively expensive.

(3) Accurate positioning is critical, and programming requirements are relatively high.

(4) Welding materials with high reflectivity and high thermal conductivity, such as aluminum and copper alloys, can be challenging.

(5) Rapid solidification of the weld can lead to gas retention and may result in porosity and brittleness.

(6) The equipment is costly, and for small batch production or production with complex positioning and processes, the cost-effectiveness may not be optimal.

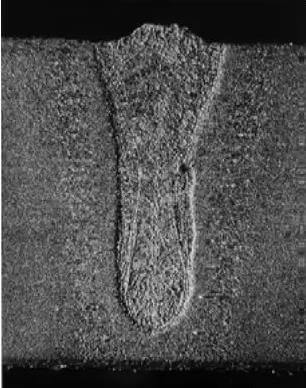

Laser deep penetration welding requires the laser beam to have a high energy density, typically greater than 10 kW/mm2. This results in not only melting of the metal, but also the formation of metal vapor.

The pressure created by the generated metal vapor in the molten pool causes it to displace the liquid metal. As the metal continues to melt and the metal vapor decreases, a narrow and fine metal vapor hole is formed.

The hole is surrounded by the liquid molten metal, and as the laser beam moves forward, the hole moves with it. The liquid metal behind the hole continues to solidify, forming the weld.

1. Key hole

2. Molten metal

3. Welds

4. Laser beam

5. Welding direction

6. Metal steam

7. Workpiece

The laser weld is characterized by its narrow and thin shape, and its depth-to-width ratio can even reach 10:1.

The laser beam is directed along the edge of the material, causing the molten material to fuse and solidify, forming a weld. The depth of the weld can range from close to zero to one millimeter, and the thickness of the material typically does not exceed 3mm, usually being less than 2mm.

1. Molten material

2. Weld

3. Laser beam

4. Welding direction

5. Workpiece

Solid-state laser heat conduction welding is primarily used for welding the corners of thin plates, such as battery shells, pacemaker shells, and some machine tool covers. This welding method results in a smooth and clean fillet weld that does not require any further processing.

Lap

Overlap welding

Crimping welding

In general, carbon steel is well suited for laser welding and the quality of the weld is dependent on the level of impurities present. High levels of sulfur and phosphorus can lead to welding cracks, making laser welding unsuitable for materials with high levels of these elements.

Both medium and high carbon steels and ordinary alloy steels can be effectively laser welded, however, preheating and post-weld treatment are necessary to relieve stress and prevent crack formation.

In general, laser welding of stainless steel is easier to produce high-quality joints compared to conventional welding methods.

Stainless steel with low thermal conductivity is more conducive to achieving deep and narrow weld penetration.

Stainless steel can be divided into four main categories: ferritic stainless steel (which can result in joint embrittlement), austenitic stainless steel (prone to hot cracking), martensitic stainless steel (known for poor weldability), and duplex stainless steel (which can be prone to embrittlement in the welding affected zone).

The high reflectivity and thermal conductivity of aluminum alloy surfaces make laser welding difficult.

For laser welding of highly reactive materials, the energy threshold performance becomes more pronounced.

The welding properties of different series and grades of aluminum alloys vary.

Aluminum alloy welding difficulties:

Aluminum has a strong oxidation capacity and is prone to oxidation in air and during welding. The resulting alumina has a high melting point and is highly stable.

Removing the oxide film is challenging and it has a significant proportion, making it difficult to separate from the surface. This can result in defects such as slag inclusion, incomplete fusion, and incomplete penetration.

The oxide film on the surface of aluminum can also adsorb a significant amount of water, leading to the formation of pores in the weld.

There are high requirements for the cleanliness of the workpiece.

Aluminum has a higher thermal conductivity and specific heat capacity.

In order to effectively weld aluminum, it is recommended to use energy sources with high concentration and power. Additionally, preheating can sometimes be used as a process measure.

Generally, the required laser power is relatively large.

Aluminum has a large linear expansion coefficient and experiences significant volume shrinkage during solidification, leading to high deformation and stress in the weldment. This can result in shrinkage cavities, shrinkage porosity, thermal cracking, and high internal stress.

Aluminum has a strong ability to reflect light and heat.

There is no noticeable change in color during the solid-liquid state transformation, making it difficult to judge during the welding process.

High-temperature aluminum has low strength and struggles to support the molten pool, making it prone to welding through.

The laser used for welding must be resistant to high reflection.

Formation of pores is common in aluminum welding. Aluminum and its alloys can dissolve a significant amount of hydrogen in the liquid state, but almost none in the solid state.

During the solidification and rapid cooling of the welding pool, hydrogen is unable to escape in time, leading to the formation of hydrogen pores.

There are high requirements for the cleanliness of the workpiece, including the drying of the workpiece and its surrounding environment.

The evaporation and burning of alloy elements during welding can result in a decrease in weld performance.

The welding process of mirror copper is similar to that of aluminum alloy, but mirror copper has a stronger ability to reflect.

The most commonly used grades in the industry are T1, T2, and T3, which have a distinctive purple appearance and are therefore also known as red copper.

Easily generated welding defects:

Use welding shielding gas to protect the welding effect:

Some welding processes require the use of a welding shielding gas to form a thin protective layer over the weld surface. This layer helps prevent the surrounding air from affecting the weld.

The primary purpose of the shielding gas is to prevent the molten metal from reacting with the air’s oxygen, water vapor, or carbon dioxide.

Common shielding gases include helium, argon, nitrogen, or a mixture of gases. The type of gas used is typically determined by the material being welded.

The shielding gas is delivered to the weld surface through a protective gas pipe or through the fixture itself.

Please note that using a shielding gas for welding three-dimensional parts may increase the difficulty of robot movement.

Prior to welding, it is essential to clearly define the welding specifications, which typically encompass the strength of the weld (such as penetration requirements, pore control requirements, crack control requirements, etc.), appearance (including flatness of the weld, oxidation level, depth-width ratio, etc.), and air tightness (withstanding air pressure).

Quality inspection:

The aim of any quality inspection is to verify that the workpiece’s performance satisfies the usage requirements.

For welding, the quality standard for laser welding primarily concentrates on the weld and the heat-affected zone produced during welding.

Welds need to meet the following two recent quality requirements:

The welding procedure specification also contains some other welding standards and welding defects.

The following figure shows different welding defects:

Quality defects of welds

Typical weld internal defects:

Incomplete fusion: excessive weld gap

Air hole: a small amount of air or bubbles mixed into the weld; crack: on the surface or inside of the weld

Quality defects in lap joints

Uneven weld shape: for example, microcracks caused by weld collapse

Molten metal splash: pits are formed on the weld surface due to the “explosion” of molten metal, which reduces the weld strength and even forms pores

Weld surface collapse and weld bottom depression: reduce the effective stress area of the weld and reduce the weld strength

Misalignment: in butt welds, misalignment results in a reduction in the effective weld area

Arc crater: reduce the effective stress area of the weld

Oxidation: reduce the oxidation resistance of stainless steel

Splash: splash objects fall on the weld or workpiece surface, reduce the surface quality and increase the follow-up treatment

Welding deformation caused by heat input: In the welding process, the heat inside the weld will be transmitted to the workpiece around the weld, resulting in a small amount of deformation. If a workpiece needs to have a large number of welds, the welding sequence shall be reasonably selected.

For carbon steel and stainless steel: