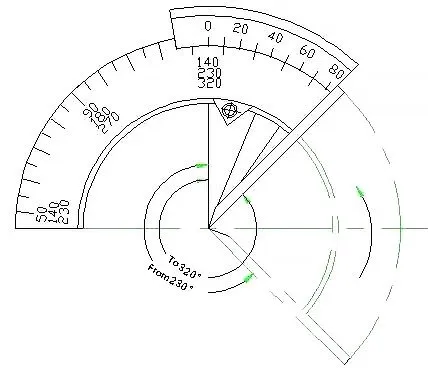

Ever wondered how to achieve precise bends in sheet metal? This article dives into using a multifunctional angle ruler for accurate measurements in bending processes. By the end, you’ll know how to measure angles from 0° to 320° with confidence, ensuring perfect bends every time. Ready to refine your metalworking skills and improve your project outcomes? Let’s get started!

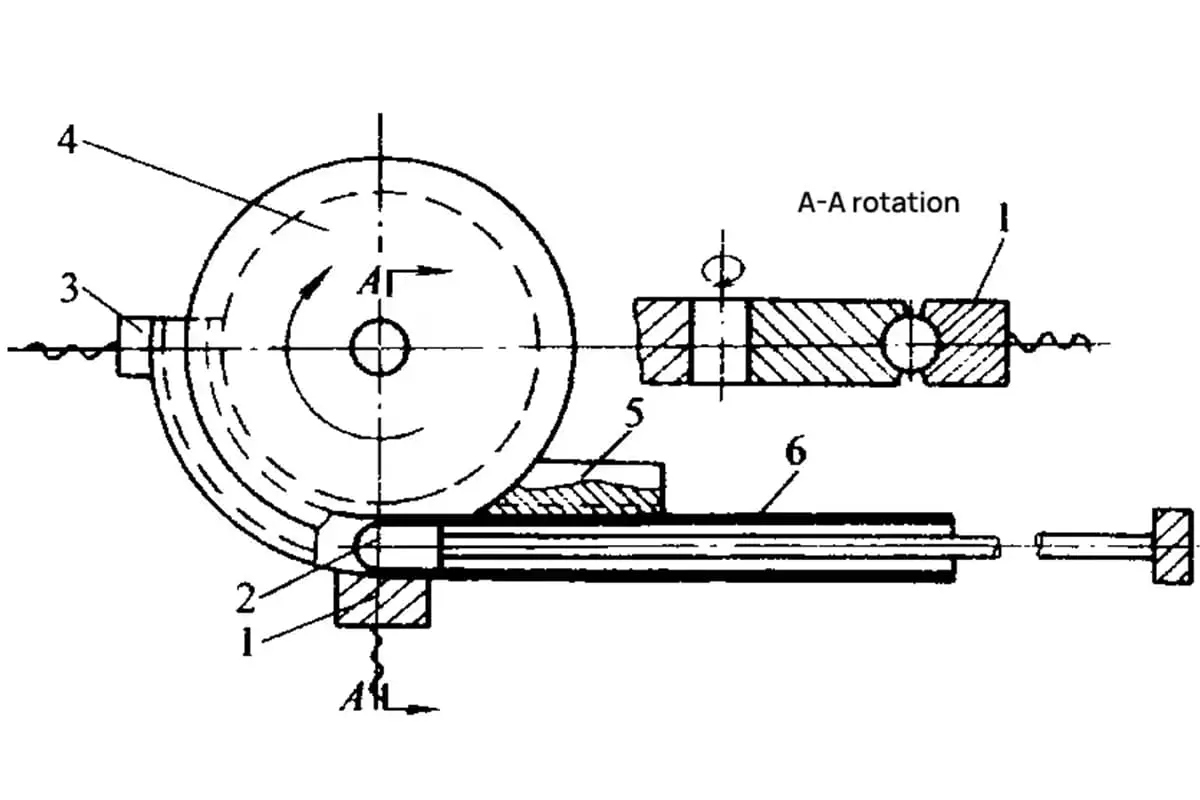

A multifunctional angle ruler is needed in sheet metal bending.

The angle ruler and straight ruler are all installed, and the measured part of the product is placed between the measuring surfaces of each ruler of the base ruler for the measurement.

The angle ruler can be removed and the ruler can be installed to connect it with the sector plate.

The measured part of the workpiece is placed between the measuring surface of the base ruler and the straight ruler for the measurement.

Remove the straighter ruler and clamping block, and only install the angle ruler, but push the angle ruler up until the intersection line of the short side and the long side of the angle ruler is aligned with the sharp edge of the base ruler.

Place the measured part of the workpiece between the measuring surface of the base ruler and the short side of the angle ruler for measurement.

Remove the angle ruler, straight ruler and clamping block, leaving only the sector plate and main ruler (with base ruler).

Place the measured part of the product between the base ruler and the measuring surface of the sector plate for measurement.

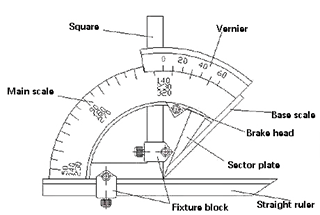

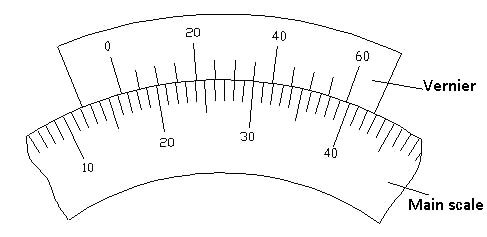

This paper introduces how to use the angle ruler when measuring the angle and how to read the universal angle ruler?

The reading method of the universal angle ruler is the same as that of the vernier caliper.

First read out the angle in front of the travel zero line, and then read out the value of the angle “minute” from the vernier.

The sum of the two is the angle value of the measured part.

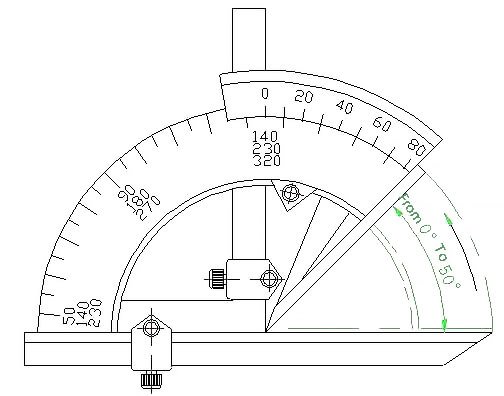

1 when the angle of the part is > 90 º ~ 180 º, the measured angle = 90 º + the reading of the angle measuring ruler.

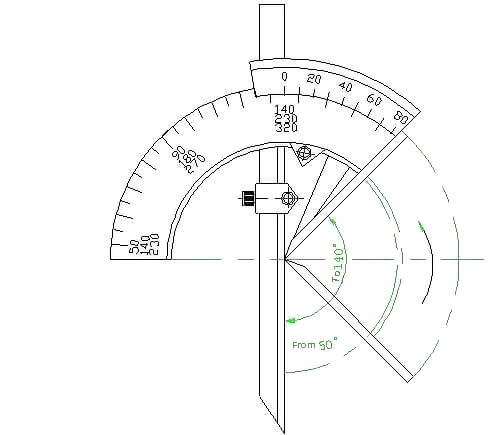

2 when the angle of the part is > 180 º ~ 270 º, the measured angle = 180 º + the reading of the angle measuring ruler.

3 when the angle of the part is > 270 º ~ 320 º, the measured angle = 270 º + the reading of the angle measuring ruler.