Have you ever wondered how a CNC lathe can create such precise parts? In this article, we’ll explore the fascinating world of CNC lathes, focusing on the number of axes they use and how these axes determine their capabilities. By the end, you’ll understand how these machines achieve such incredible precision.

To process highly precise parts, the spatial positions of the worktable and cutter on a CNC lathe must be defined with accurate coordinate values, and the movement in multi-dimensional space must be represented with digital computing information.

This movement axis is referred to as the CNC axis.

In this discussion, we will cover the number of axes in a CNC lathe and how to identify them.

Related reading: What Is a Lathe?

A CNC lathe, or computer numerical control lathe, is a type of mechanical equipment that can be controlled by computer program to perform high-precision operations around various axes.

The number of axes is a component of a CNC lathe, and each CNC machine has one or more axes, with different combinations for different types of CNC machines.

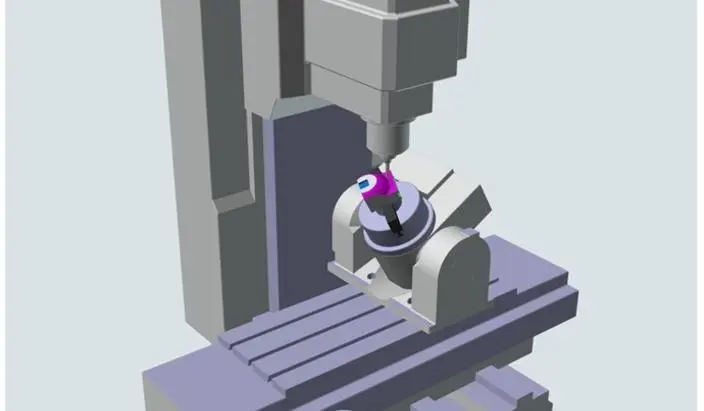

For instance, a four-axis milling machine can have XYZA or XYZB axes, while a foam cutter may have an XYUV axis. Lathes typically have an XZ axis. This article will mainly focus on the number of axes in a CNC lathe and how to identify them.

The CNC lathe’s number of axes determines the type of work it can perform, the level of detail it can cut, and the position it can manipulate the workpiece. CNC machining uses CAD technology to automatically shape and cut parts, and the number of axes determines the types of motion the CNC machine tool can perform.

The reference to axes describes the mechanical equipment running along multiple axis points. NC machining involves removing materials from the workpiece until the desired results are achieved.

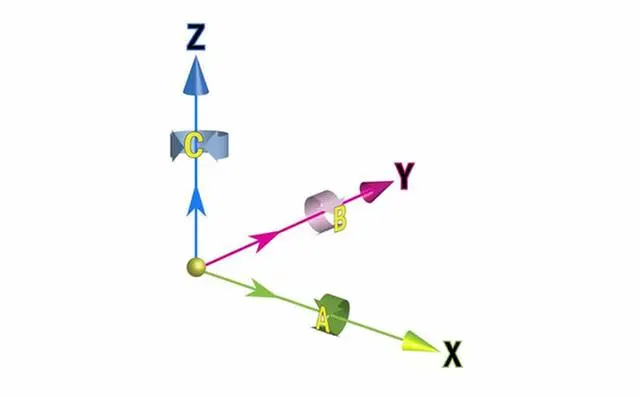

In general, a CNC machine tool has at least three axes running along the XYZ plane: X axis represents the vertical plane, Y axis represents the horizontal plane, and Z axis represents the depth.

The number of axes indicates the work that can be completed, the degree of detail of the workpiece that can be cut, and the position that can be controlled. Ordinary milling machines typically have three axes, also known as machining centers.

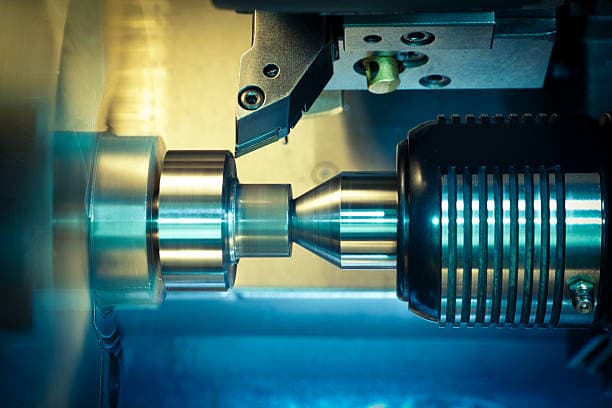

CNC lathes typically have two axes and a spindle on which parts are fixed for rotation. However, with technological advancements, lathes with additional milling heads are also available.

The number of axes in a CNC system is determined by the system itself. Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard.

However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. The exact number of axes is determined by the system’s function.

How many CNC lathes are there?

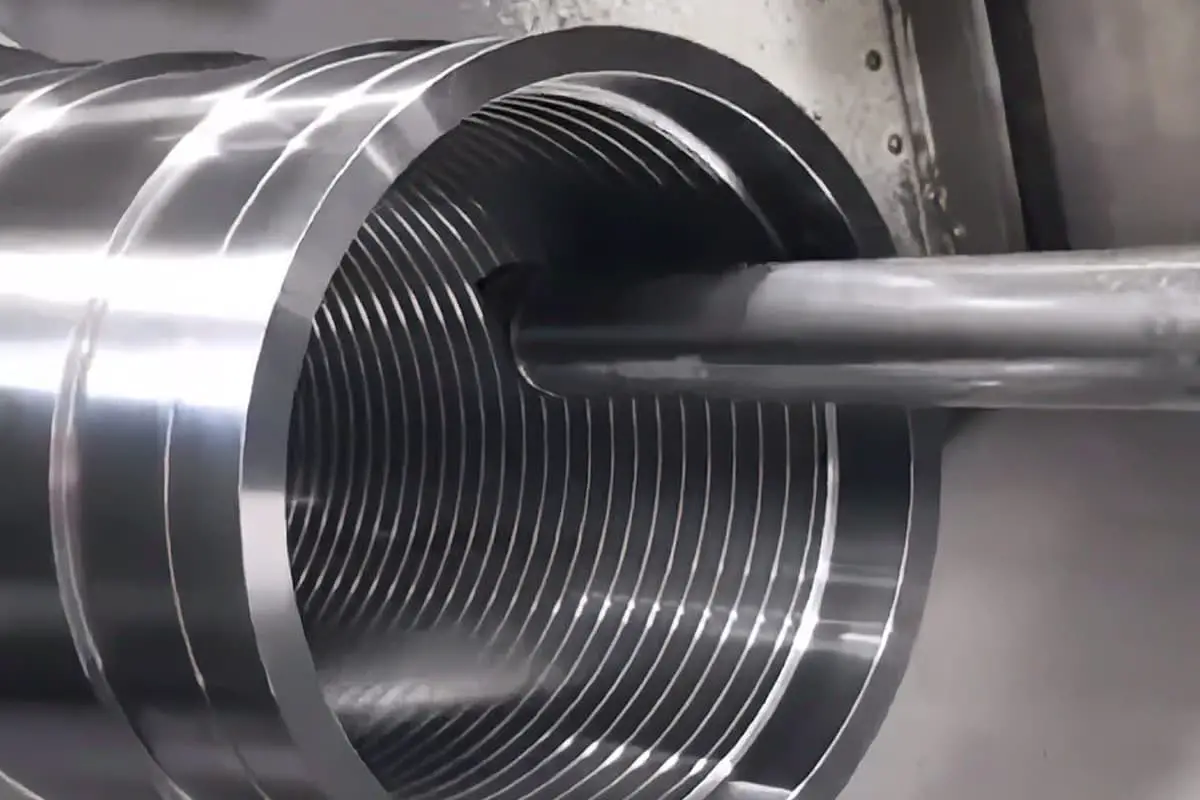

The Z axis is parallel to the axis on the workpiece, allowing the tool to move along the side of the material as the part rotates about the Z axis (C). The movement along the Z axis determines the length of the job.

The X axis is perpendicular to the Z axis, allowing the tool to move back and forth along the X axis to determine the diameter of the part.

The C axis is defined as the rotary table in the center of the workbench, which rotates 360 degrees around the Z axis. The front end of the shaft is a rotary head that can also rotate 360 degrees around the Z axis, becoming the C axis.

Related reading: 4-Axis and 5-Axis CNC Machining Basics

1. Rotary motion:

The rotary motion around the X, Y and Z axes is represented by A, B and C respectively, and the positive direction is determined according to the right-hand screw rule.

2. Additional axis:

The movement of the additional axis is represented by U, V, W, P, Q and R.

The rotation of the additional shaft is indicated by D, E and F.

Related reading: 5 Axis Machining

On a CNC lathe, the Z axis is located horizontally on the operator’s left side. By convention, the Z axis is referred to as being near or far from the main axis. Some CNC lathes also have a Y axis, which allows the carriage to be adjusted for off-axis live tool drilling.

The CNC lathe is primarily used for processing reverse rolling parts, with the cutting tool only requiring lateral and longitudinal movements.

As a result, CNC lathes typically only control the X and Z axes, making them typical two-axis CNC equipment. However, some CNC lathes may also have a Y axis.