Have you ever wondered about the fascinating history behind the lathe, a machine tool that has revolutionized manufacturing? In this captivating blog post, we’ll take you on a journey through time, exploring the lathe’s remarkable evolution and its profound impact on various industries. From its humble beginnings to its modern-day sophistication, discover how this versatile tool has shaped our world and continues to play a vital role in precision machining.

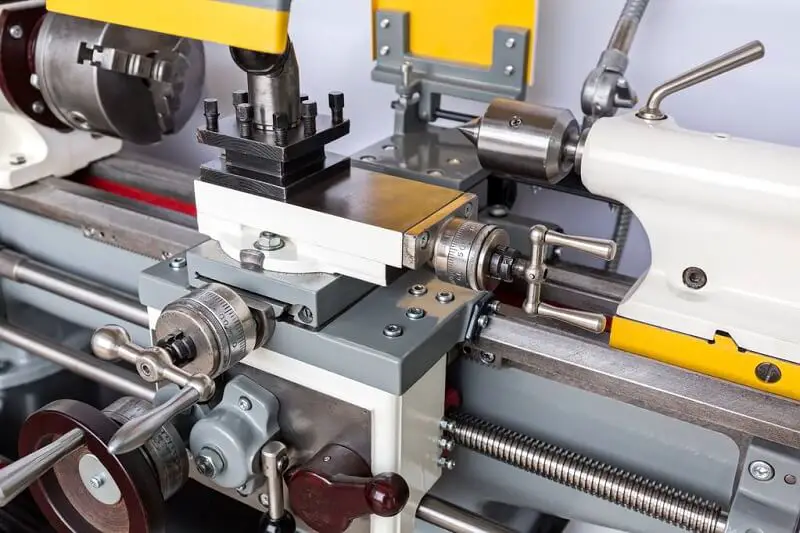

A lathe is a machine tool that primarily employs a turning tool to rotate a workpiece. In addition, bits, reamers, taps, thread dies, and knurling can also be utilized on the lathe for specific processing.

Lathes are predominantly utilized for machining shafts, discs, sleeves, and other workpieces with rotating surfaces. They are the most commonly used type of machine tool in machinery manufacturing and repair shops.

Well, after popularizing science, the topic of “Mother of the Machine” should be discussed – the past and present life of the lathe.

The first prototype of the machine tool, the lathe, was created by our ancestors approximately 2,000 years ago to make working with tools easier.

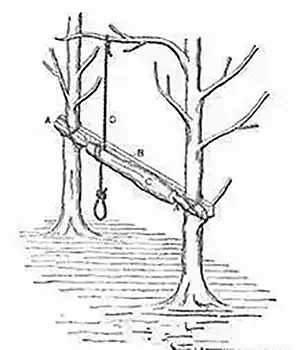

During the 13th century, the development of machine tools continued and it became necessary to find alternative methods of operation as hanging it on a tree was no longer feasible. This led to the creation of the “pedal lathe”, which used a foot pedal to rotate the crankshaft and drive the flywheel. This in turn powered the spindle, causing it to rotate, and was also known as a flexible bar lathe.

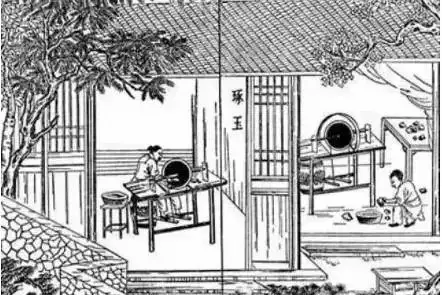

During the same period in China, the Ming dynasty published a remarkable book named “Tian Gong Kai Wu”, which documented the technologies of the Ming dynasty and the dynasty before it, demonstrating the meaning of “the wisdom of the ancients”.

The book also described the structure of a grinding machine, which employed a similar principle to the European medieval foot-operated machine. This machine used the pedal method to rotate a metal plate and utilized sand and water to shape jade.

Structure of a grinding machine from Tian Gong Kai Wu

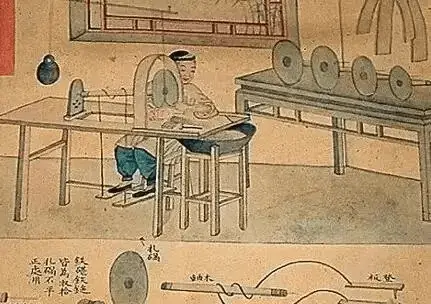

from Tian Gong Kai Wu

This process is similar to modern machining techniques such as boring, where a specialized tool, called a steelyard, is used to remove small amounts of material from the inner jade. It is remarkable to consider the level of skill and expertise possessed by ancient craftsmen.

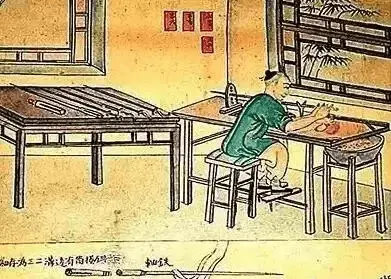

from Tian Gong Kai Wu

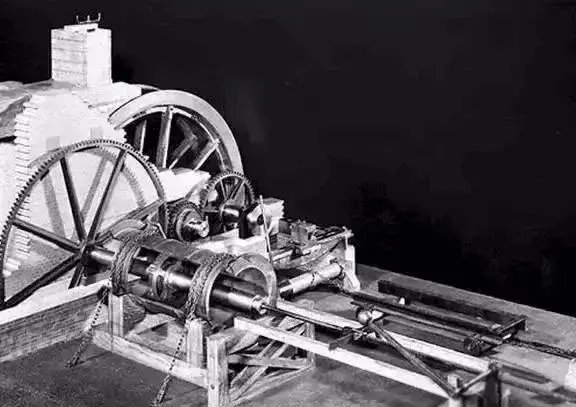

In 1774, the British inventor Wilkinson created the world’s first true boring machine, the barrel boring machine.

The barrel boring machine invented by Wilkinson was initially utilized for forging firearms. In 1775, Wilkinson utilized the cylinder bored by this machine to construct a new version of Wattner’s leaky cylinder, which met the specifications required for Watt’s steam engine.

To accommodate the boring of larger cylinders, he built a cylinder boring machine powered by a water wheel in the same year, which greatly contributed to the advancement of steam engines.

Wilkinson’s cylinder boring machine, designed for forging larger cylinders, marked a turning point in the evolution of machine tools. From then on, the machine tool was driven by a steam engine through the use of a crankshaft. The mutual assistance between the machine tool and steam engine facilitated their concurrent development and ushered in a dynamic era of industrial revolution.

It is important to mention Henry Maudslay, the British inventor known as the “Father of the Lathe”. Maudslay is to the lathe what James Watt is to the steam engine.

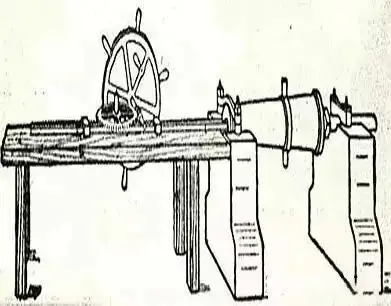

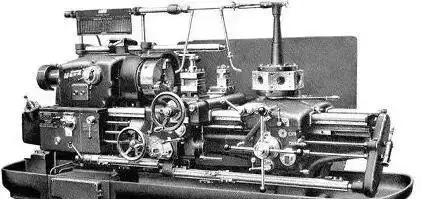

In 1797, Maudslay created the world’s first thread-cutting lathe, which featured a screw and a polished rod. This modern lathe, equipped with a sliding tool post, could produce threads of varying pitches.

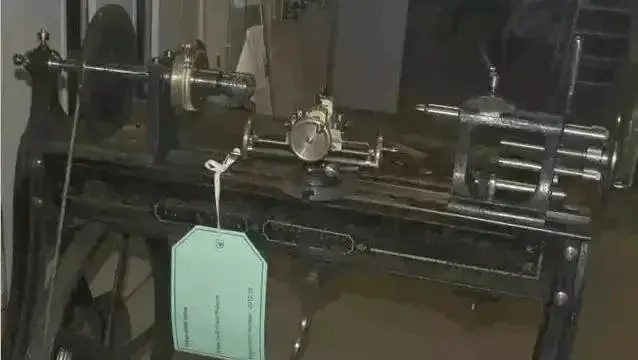

Maudslay 1797 lathe

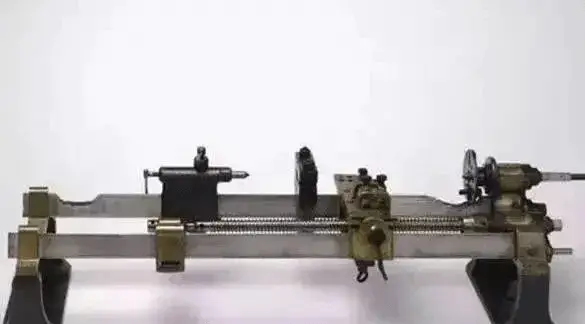

Maudslay continued to refine the lathe and in 1800, he made a significant improvement by replacing the triangular iron bar frame with a solid cast iron bed and the idler wheel with interchangeable gear pairs.

This allowed for the production of threads of varying pitches without the need to change the screw. This prototype of the modern lathe, known as the epoch-making tool-frame lathe, played a crucial role in the English Industrial Revolution.

Maudslay 1800 lathe

To be precise, Maudslay did not invent the lathe, but rather re-invented it based on the work of his predecessors and added the capability for automatic cutting. Nevertheless, it was Maudslay’s reimagination that made the lathe widely popular and gave birth to the lathe as we know it today.

The rapid development of all types of machine tools

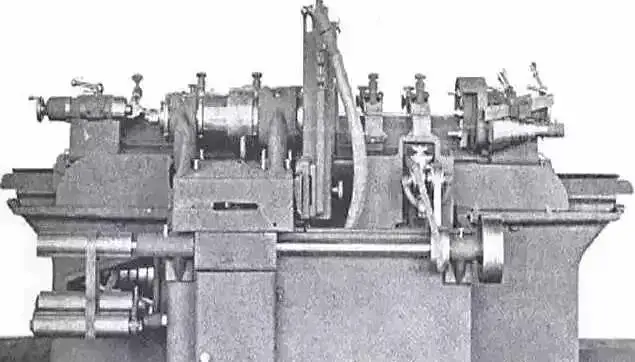

In the 19th century, with the growth of various industries, the demand for various types of machine tools increased. In 1817, Roberts created the gantry lathe, and in 1818, Whitney from the United States invented the world’s first general-purpose milling machine.

Roberts gantry lathe

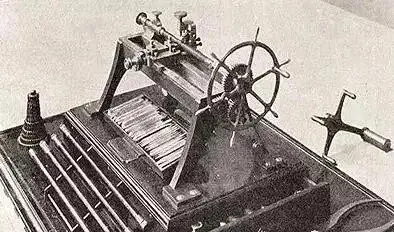

To further enhance mechanization and automation, in 1845, Fitch from the United States created the turret lathe. In 1848, rotary lathes were introduced in the United States, and in 1873, Spencer from the United States developed a single-spindle automatic lathe. This was quickly followed by the invention of a three-spindle automatic lathe.

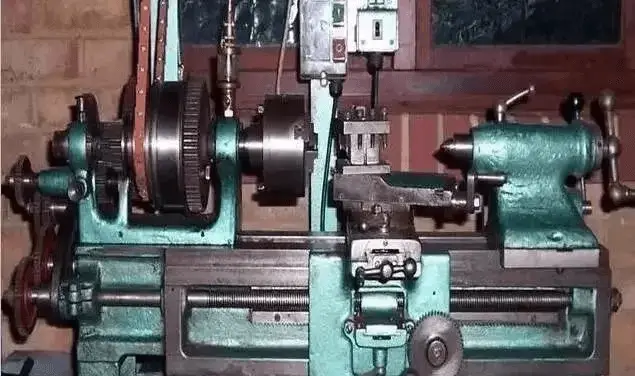

By the early 20th century, lathes with gearboxes powered by a single motor became available.

Spencer machine tools

In 1900, the American company Norton utilized emery and corundum to produce a large and wide grinding wheel, as well as a sturdy and heavy-duty grinder. This marked a major step forward in the development of grinders and elevated machinery manufacturing technology to a new level of precision.

The Industrial Revolution was a period of explosive growth and development. During this time, machine tools were constantly evolving and improving to increase the efficiency of industry and production. The inventors of these machine tools played a crucial role in shaping the world.

With the advent of high-speed tool steel and the widespread use of electric motors, machine tools underwent another epoch-making upgrade, transitioning from steam power to electric power. This demonstrates the remarkable progress that humanity has made over hundreds of years, moving from human power, to water power, to steam power, and finally to electric power.

1910, old British lathe

After World War I, the development of various high-efficiency automatic lathes and specialized lathes accelerated rapidly due to the demands of the munitions, automobile, and other machinery industries.

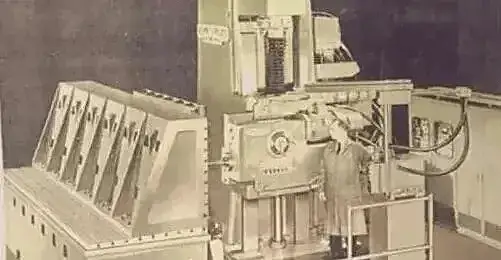

In the late 1940s, to enhance the productivity of small batch workpieces, lathes equipped with hydraulic profiling devices were introduced. At the same time, multi-tool lathes were also developed.

Electric machine tool after World War II

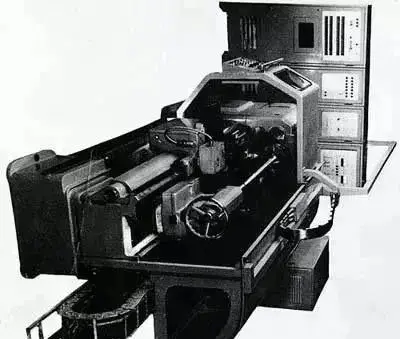

In the mid-1950s, program-controlled lathes equipped with punched cards, latch plates, and dials were developed. The use of CNC technology in lathes began in the 1960s and by the 1970s, microprocessors were directly integrated into CNC machines, further advancing the popularization and rapid development of CNC machine tools, which has continued to evolve until present day.

Early CNC machine tools

The Evolution of Chinese Lathes: From Belt Lathes to Five-Axis Lathes

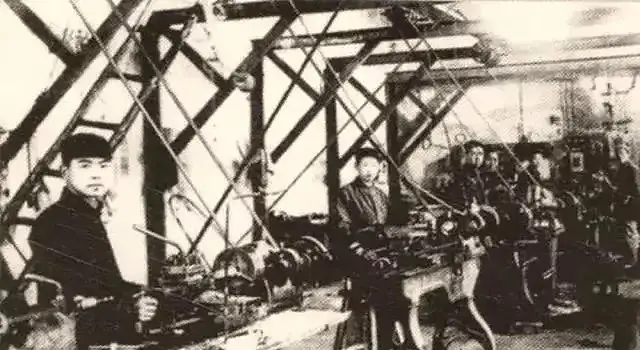

Due to historical reasons, China missed out on the first three industrial revolutions. The real development of Chinese lathes started after the establishment of the People’s Republic of China. At the beginning of the new China, the equipment manufacturing industry, including machine tools, was almost nonexistent.

Through the tireless efforts of the workers, China’s first batch of machine tools was successfully produced under the challenging conditions of poverty and lack of resources.

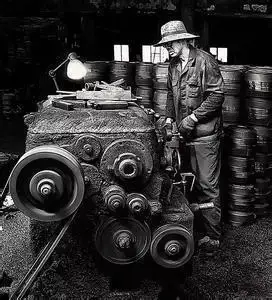

In 1949, the first lathe in New China, a six-foot belt lathe, was finally manufactured at the Shenyang No. 1 Machine Tool Plant.

The workers in the picture are operating a belt lathe

The arrival of this batch of machine tools and subsequent mass production significantly supported the country’s industrialization and resulted in many subsequent production marvels.

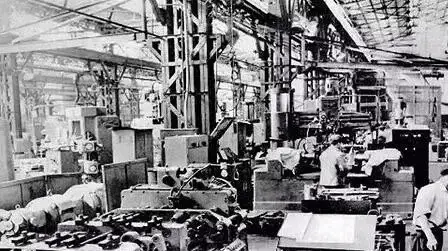

Machining Workshop of Shenyang No.1 Machine Tool Plant

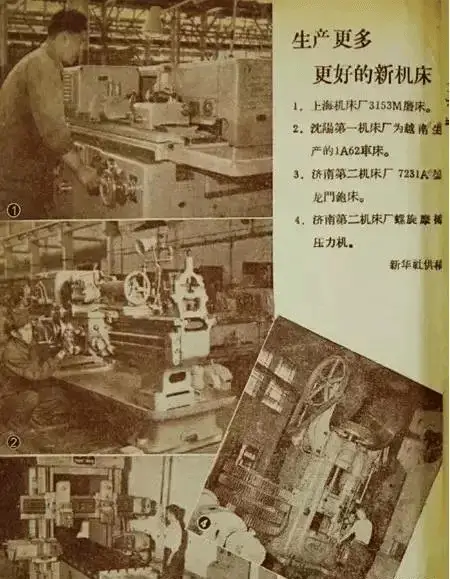

During the “First Five-Year Plan” period, the government renovated some machinery repair plants and established new enterprises, identifying 18 key production enterprises that became known as the “Eighteen Arhats” in the machine tool industry. With technical support from the Soviet Union, these “Eighteen Arhat Factories” continuously developed new machine tools.

For instance, after Shenyang No. 1 Machine Tool Plant produced the first lathe in New China in 1949, it went on to develop China’s first C620-1 horizontal lathe in 1955 and started mass production.

In the same year, Dalian Machine Tool Plant began producing a new machine tool, a universal shovel, and Shanghai Machine Tool Plant successfully trial-produced a new cylindrical grinder. In 1956, Ji’er Machine Tool mass-produced a planer and spiral friction press (the factory had previously developed China’s first large planer and first large mechanical press in 1953 and 1955, respectively).

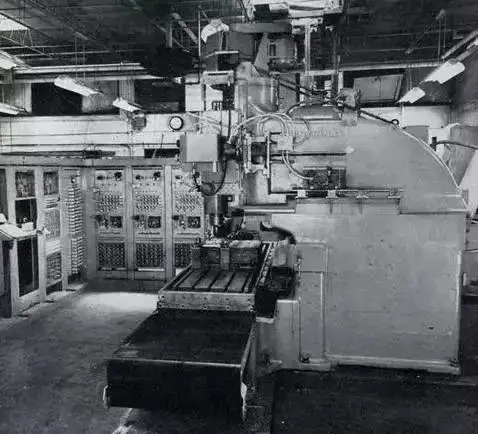

In the summer of 1958, the first CNC milling machine of New China was finally developed – the X53K1. It was jointly created by Tsinghua University and Beijing First Machine Tool Factory and was also the first CNC machine in Asia.

New China’s first CNC milling machine was finally born–X53K1

The successful development of the X53K1 marked a great leap forward in the history of China’s machinery industry and signaled a shift from manual labor to technology-driven machining. However, due to foreign technology blockades and domestic limitations, China’s CNC technology did not advance significantly for nearly 30 years.

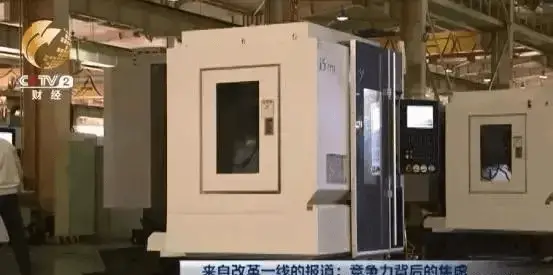

After the implementation of reforms and opening up, China experienced a resurgence in the development of the machine tool industry, and the types and models of machine tools became increasingly diverse. To date, a wide range of lathes including vertical, horizontal, multi-axis, CNC car, turning and milling compound, and more have been developed.

In 2012, Shenyang Machine Tool Company independently developed and designed the first “i5 CNC system” with network intelligence capabilities and successfully brought it to market. This marked the end of China’s dependence on imports for high-grade CNC machine tool systems.

Today, China has been the world’s largest machine tool market for eight consecutive years and is the only country in the world to produce all categories of machine tools.

The increasing development of CNC lathes has made them the trend in the industry. However, conventional lathes are still expected to exist for a certain period of time, as they are more cost-effective and time-saving for small-volume orders.

The transition towards an intelligent transformation of machine substitutions to “dominate the world” will take a relatively long time to complete. Nevertheless, the eventual phasing out of conventional lathes from the market is inevitable.