Have you ever wondered how complex metal parts are precisely crafted? CNC machining is the answer. This article explains how computer-controlled tools shape materials like metal into intricate components with high accuracy and efficiency. You’ll discover the types of CNC machines, their benefits and drawbacks, and the detailed steps involved in the CNC machining process. By the end, you’ll understand why CNC machining is essential for modern manufacturing and how it ensures quality and precision in creating everything from aerospace parts to medical devices.

Numerical Control (NC) refers to the method of controlling the movement and processing operations of machine tools using digitized information. Numerical Control Machine Tools, often abbreviated as NC machine tools, are machine tools equipped with an NC system. Computerized Numerical Control (CNC) is a method where a general-purpose computer directly controls the movement and processing operations of machine tools.

By changing the corresponding control program, the control function of the CNC system can be changed without altering the hardware circuit, thus making the CNC system highly versatile and flexible. This is the direction of development for NC technology, and it has found widespread application in production.

Numerical Control Machining refers to a method of part processing on NC machine tools. The process of NC machine tool machining is generally consistent with traditional machine tool processing, but due to the unique characteristics of NC machining, there are notable changes in the NC machining process compared to general machining processes.

CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it.

Metal is the most commonly used material in CNC machining, and the end result is a finished product or part.

This process is known as subtractive manufacturing, and computer applications are used to control machine tool movements for better CNC machining. The most common types and processing processes for CNC machine tools include milling, turning, grinding, and EDM.

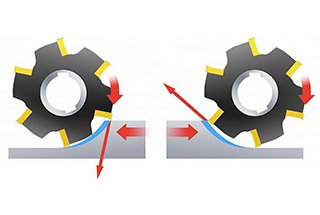

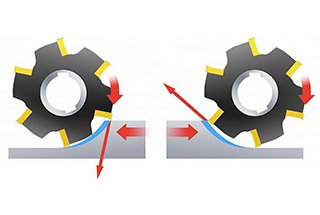

Milling uses a rotary cutter to remove material from the workpiece surface by moving along 3, 4, or 5 axes. This process is used to quickly process complex geometric shapes and precision parts with metal by cutting or trimming the workpiece.

Turning, on the other hand, involves using a lathe to manufacture parts with cylindrical features. The workpiece rotates on the shaft and contacts the precision turning tool to form circular edges, radial and axial holes, grooves, and grooves.

Compared to traditional hand machine machining, CNC machining is much faster, with high dimensional accuracy and minimal errors. The finished product meets the design’s computer code.

CNC manufacturing can be used to manufacture final products and components, but it is usually cost-effective only for short-term production of low batches, making it an ideal rapid prototyping manufacturing method.

NC milling is a process that utilizes rotary cutters to remove materials. The workpiece can either remain stationary while the tool moves onto it or enter the machine tool at a predetermined angle.

The complexity and speed of the forming process depend on the number of moving axes the machine has. The more axes a machine has, the faster and more intricate the process can be.

3-axis NC milling is still one of the most widely used and popular machining processes.

In 3-axis machining, the workpiece remains stationary, and the rotary cutter cuts along the X, Y, and Z axes.

This machining method is relatively simple and can produce products with a simple structure. However, it is not suitable for machining complex geometries or products with intricate components.

Since cutting can only be performed on three axes, the processing speed may be slower than that of 4-axis or 5-axis NC machining. This is because the workpiece may need to be manually repositioned to achieve the desired shape.

4-axis NC milling adds a fourth axis to the motion of the cutting tool, enabling rotation around the X axis.

This method involves the use of four axes: the X-axis, Y-axis, Z-axis, and A-axis (rotating around the X-axis).

Most 4-axis CNC machines also have the capability to rotate the workpiece, known as the B-axis. This allows the machine to function both as a milling machine and a lathe.

If you require drilling on the side of a part or on the surface of a cylinder, 4-axis CNC machining is the ideal choice.

It significantly enhances the machining process and achieves high accuracy in machining.

5-axis NC milling has an additional rotation axis compared to 4-axis NC milling.

The fifth axis is typically the B-axis, which rotates about the Y-axis.

Some 5-axis CNC machines also allow for rotation of the workpiece, known as the B-axis or C-axis.

Due to the high versatility of 5-axis NC machining, it is often used for manufacturing complex and precise parts, such as medical components like artificial limbs or bones, aerospace parts, titanium parts, oil and gas mechanical parts, military products, and more.

A complete CNC machining process includes the following steps: process analysis based on the part processing drawing, determination of machining plans, process parameters and displacement data; writing the part processing program sheet with the prescribed program codes and formats; program input or transmission; trial operation, tool path simulation, etc., of the machining program input or transmitted to the NC unit; automatic operation of the machine tool through correct operation, first sample trial cutting; inspection of the processed parts.

The CNC machining program is a sequence of instructions that drives the NC machine tool to carry out machining, and it is the application software of the NC machine tool. The main tasks of CNC programming include part drawing analysis, process design, machining route planning, and machine tool auxiliary function determination. It is an important stage in CNC machining.

The content and steps of CNC programming are shown in below:

Part drawing analysis -> Determine the process route for processing -> Tool path calculation -> Writing programs -> Program input -> Program verification and trial cutting

The methods of NC program compilation include manual programming and automatic programming.

1) Manual programming refers to the method of programming where the entire process, from analyzing part drawings, formulating process procedures, calculating tool motion trajectories, writing part processing program sheets, preparing control media to program checking, is all completed manually. For parts with less complex geometric shapes, simple calculations, and few machining programs, manual writing is easy to implement.

Manual programming is the basis for compiling machining programs and is also the main method for on-site machining debugging of NC machine tools. It is a basic skill that machine tool operators must master.

For parts with complex shapes, such as parts with non-circular curves and tabular curve contours, manual programming is tedious, the program volume is huge, the possibility of errors is high, the efficiency is low, and manual programming is not up to the task, so automatic programming should be adopted.

2) Automatic programming refers to the method where most or part of the program writing work for NC machine tools is done by a computer. Automatic programming reduces the labor intensity of programmers, improves the efficiency and quality of programming, and solves the programming problems of complex parts that manual programming cannot handle.

Depending on the different ways of information input and processing methods, automatic programming methods are mainly divided into language programming and graphic interactive programming.

Language programming uses a certain high-level language to define the geometric shape of the part and the feed path, with the computer completing complex geometric calculations, or selecting tools, fixtures, and cutting quantities through a technology database. The more famous NC programming systems include APT (Automatically Programmed Tools).

Language programming does not provide an intuitive description of the geometric shape of the part, it is an early programming method used by NC machine tools, and it has gradually been replaced by graphic interactive programming methods.

Graphic interactive programming is based on a certain CAD/CAM software, where the machining graphic definition and process parameter setting are completed through human-computer interaction, and then the programming software automatically processes to generate the tool trajectory and CNC machining program.

Graphic interactive programming is currently the most commonly used method, with typical software systems including Mastercam, UG, Pro/E, and other CNC programming systems.

Compared to traditional mechanical machining, the advantages of CNC machining are:

The shape of the parts processed by CNC machine tools mainly depends on the processing program. When the workpiece changes, a new program can be reprogrammed to process the parts, making it particularly suitable for single-piece, small-batch production, and prototype testing. Additionally, the controllable movement of CNC machining enables it to complete complex surface machining that is difficult or impossible for ordinary machine tools.

CNC machine tools have higher precision than ordinary machine tools. During the machining process, the automatic machining mode of CNC machine tools can avoid errors caused by human factors, resulting in good dimensional consistency, high precision, and very stable machining quality for the same batch of parts.

The adjustment range of the spindle speed and feed rate of CNC machine tools is much larger than that of ordinary machine tools. The rigidity of the machine tool is high, allowing for large cutting quantities, thus effectively saving machining time. The rapid movement speed of the moving parts of the CNC machine tool shortens positioning and non-cutting time.

CNC machine tools move according to coordinates, saving auxiliary operations such as line drawing and reducing auxiliary time. The workpiece is often installed in a simple positioning and clamping device, which shortens the design and manufacturing cycle of process equipment, thus speeding up the production preparation process.

On CNC machine tools with a tool magazine and an automatic tool changer, the part can complete multiple continuous machining processes with a single clamping, reducing the turnover time of semi-finished products and making the improvement in production efficiency more apparent.

The labor intensity is low. The machining of parts by CNC machine tools is done automatically according to a pre-programmed program. The operator’s main tasks are program editing, program input, loading and unloading parts, preparing tools, observing the machining status, and inspecting parts, without the need for heavy repetitive manual operations.

Therefore, the labor intensity is significantly reduced, and the machine tool operator’s work tends towards intellectual operations. In addition, CNC machine tools generally process in an enclosed manner, which is clean and safe.

Programmatic control machining makes it convenient to change varieties. Also, multi-sequence machining on one machine simplifies the management of the production process, reduces the number of management personnel, and can achieve unmanned production. Using CNC machine tools for machining can accurately calculate the working hours of a single product and reasonably arrange production.

CNC machine tools use digital information and standard code processing to control machining, creating conditions for the automation of the production process and effectively simplifying the transmission of information between inspections, work fixtures, and semi-finished products.

① Reduce the number of tooling required and eliminate the need for complex tooling to process parts with intricate shapes.

If you need to alter the shape or size of a part, simply modify the processing program for that part, making it ideal for the development and modification of new products.

② Machining quality is consistent with high accuracy and repeatability, making it suitable for the stringent machining requirements of aircraft.

④ It can efficiently handle complex profiles that are difficult to process using conventional methods, and can even work on parts that cannot be seen during processing.

The downside of NC machining is that the cost of the machinery and equipment is quite high, and maintenance personnel must have a high level of expertise.

CNC machining is currently the most widely used machining method.

When conducting CNC machining, it’s important to not only understand its characteristics but also the steps involved in the process in order to improve machining efficiency.

What are the steps involved in CNC machining?

Based on the machining drawings provided by the customer, the machining personnel can analyze the shape, dimensional accuracy, surface roughness, material of the part, type of blank, and heat treatment status. This information is used to choose the machine tools and tools, determine the positioning and clamping device, machining method, sequence, and cutting parameters.

When determining the machining process, consideration must be given to the control capabilities of the CNC machine tool being used. This will maximize the efficiency of the machine tool and result in a more efficient machining path, reducing tool travel time and shortening machining hours.

To calculate the motion trajectory of the center of the tool path, the geometric dimensions of the machined parts and the set programming coordinate system are taken into account. This results in the determination of all tool position data.

Most CNC systems have the capabilities for linear interpolation and circular arc interpolation. For the processing of relatively simple planar parts, such as those made up of lines and circular arcs, the starting and ending points of geometric elements, the center of circular arcs (or the radius), and the coordinate values of the intersection or tangent points are calculated.

If the NC system does not have tool compensation capabilities, the coordinate values of the motion path for the tool center must be calculated.

For parts with more complex shapes, such as those made up of non-circular curves and surfaces, the actual curves or surfaces must be approximated using straight segments (or arc segments) and the coordinate values of their nodes must be calculated based on the required machining accuracy.

Based on the tool path for the part, the data for tool movement and the determined process parameters and auxiliary actions are calculated.

The programmer then writes the part processing program in sections, following the functional instructions and program section format specified by the NC system being used.

Considerations should be given to:

By following these three steps during CNC machining, the machining process can be carried out more efficiently.

The performance characteristics of CNC machine tools determine the application scope of CNC machining. For CNC machining, the objects can be divided into three categories according to their suitability.

1) Most suitable category:

Parts with high machining precision, complex shape, and structure, especially those with complex curves and surface contours, or parts with non-open cavities. These parts are difficult to machine and inspect with general machine tools, and it is difficult to guarantee the machining quality; parts that must be completed in one clamping for multiple operations.

2) More suitable category:

Expensive parts with difficult-to-obtain blanks that cannot be scrapped. These parts are prone to substandard or scrapped parts when processed on ordinary machine tools.

For reliability, they can be selected for machining on CNC machine tools; parts with low efficiency, high labor intensity, and difficult quality control when processed on general machine tools; parts used for model changes and performance testing (requiring good dimensional consistency); multi-variety, multi-specification, single-piece and small-batch production parts.

3) Unsuitable category:

Parts that rely entirely on manual positioning; parts with very unstable machining allowances if the CNC machine tool does not have an online inspection system that can automatically check and adjust the part position coordinates; parts that must use specific process equipment, rely on templates, and sample parts for machining; parts that need to be produced in large quantities.

With the improvement of CNC machine tool performance, the perfection of functions, the reduction of costs, the continuous improvement of the performance of CNC machining tools and auxiliary tools, and the continuous improvement of CNC machining technology, the use of CNC machine tools with high automation, high precision, and concentrated operations for large-scale production is gradually increasing.