Folding loss

For mechanical folding, due to the differences in various process parameters, such as the curved surface and curved edge of the folded sheet, its dimensional accuracy will directly affect the assembly clearance of the vehicle body.

The indentation of the boundary is the most common, and its indentation value is also known as the folding loss (FV), as shown in Figure 1.

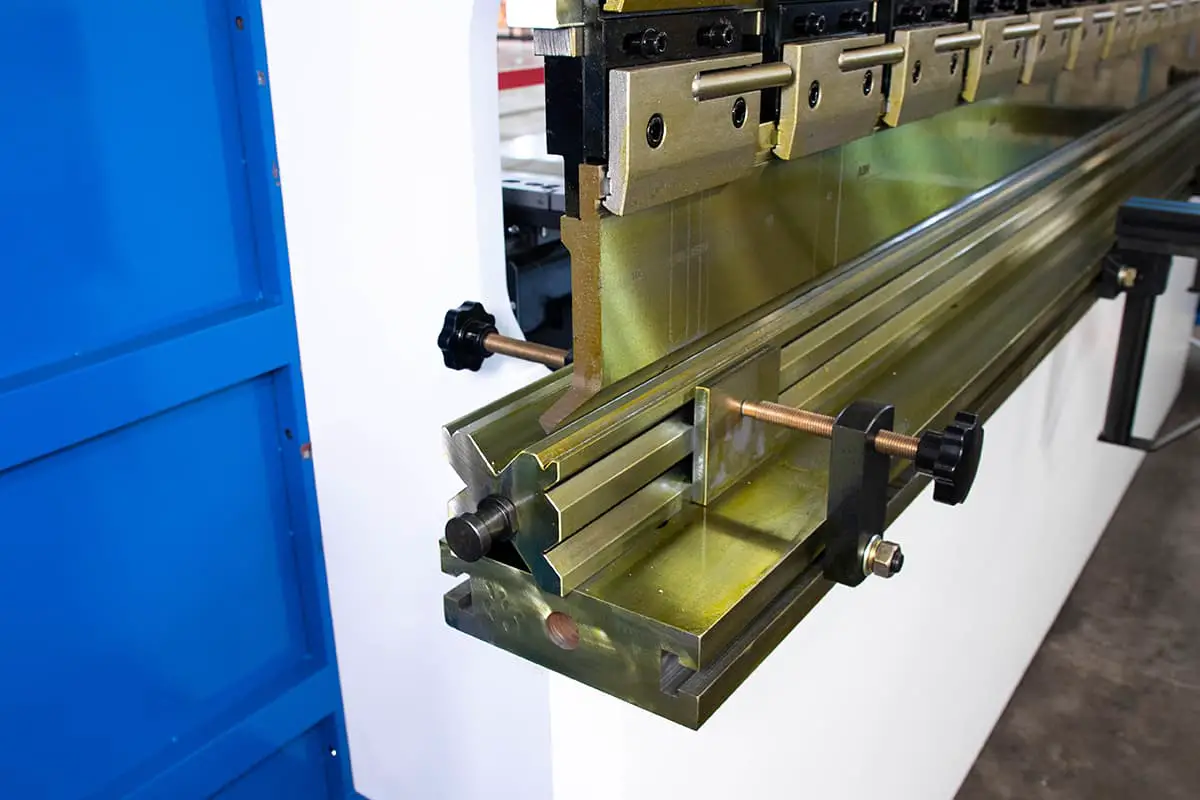

Circular arc pre–folding knife

At present, most die folding adopts a planar pre-folding knife.

There is a mature research foundation on the influence of planar pre-folding knives on dimensional accuracy.

In the actual forming and technology development process, the folding equipment supplier began to use the arc-shaped pre-folding knife on a small number of folding equipment, that is, a working surface is no longer a plane, but a curved surface with a certain curvature.

The model diagram is shown in Figure 2.

Problem object description

According to the actual situation of the door panel, the folding objects are divided into 9 kinds: curved surface edge, straight surface edge, straight face curved edge, straight face straight edge, etc.

For the parameters in the folding process, after comparing with the actual production, determine the value range of different parameters, and explore the influence of different parameters on the folding results.

See Table 1 for the parameter range.

Table 1 folding parameters

| Parameter | Parameter range sheet |

| Arc pre-folding knife type | Circular arc pre folding knife |

| Flanging length / mm | 5.5-7.5 |

| Flanging angle /° | 90-110 |

| Clearance between inner and outer plates / mm | 0.5-1.5 |

| Die arc size / mm | 1-1.3 |

| Radius of curvature of surface / mm | 100 |

| Curvature radius of part contour / mm | 100 |

| Arc radius of pre folding knife / mm | 6-8 |

Simulation experiment

Sensitivity analysis of process parameters

After investigation, four process parameters are selected for sensitivity analysis:

folding size H, inner and outer plate gap G, outer plate fillet radius R and folding opening angle θ.

Judge their influence range on hem loss.

In this post, the uniform test design table is used to judge by range method.

Uniform design is adopted. In the experimental design, the selection range of four parameters is shown in Table 2.

Table 2 selection range of process parameters

| Parameter | Value range | |

| Min | Max | |

| Flanging size H / mm | 5.5 | 7.5 |

| Clearance between inner and outer plates G / mm | 0.5 | 1.5 |

| Radius of outer plate R / mm | 0.35 | 0.75 |

| Flanging open angle θ/° | 90 | 110 |

The uniform test design table of 4 factors and 5 levels is adopted, and AutoForm is used for simulation.

Under the condition that other conditions remain unchanged, the folding type is selected as concave straight edge, the same arc pre-folding knife is used for folding, and the folding loss value FV is read.

It can be seen that the first is the folding opening angle, which has the greatest impact on the folding loss, the second is the fillet radius of the outer plate, and the third is the gap between the inner and outer plates.

The folding size has the least impact on the folding loss.

The relationship between the change of the four process parameters and the folding loss is shown in Figure 3.

As can be seen from the figure:

(1) The folding size has no significant effect on the folding loss value, and the folding loss value always fluctuates around 0.19mm.

(2) With the increase of the gap between the inner and outer plates, the folding loss first increases and then decreases, and the decreasing trend is slow;

(3) With the increase of the fillet radius of the outer plate, the folding loss first increases and then decreases, but the increasing trend is obvious, and the maximum value will be reached between 0.55 ~ 0.75mm.

(4) With the increase of the folding opening angle, the folding loss gradually decreases.

It should be noted that the type of sensitivity analysis is concave straight edge.

For other types of hem, the results of sensitivity analysis may change, and the influence law of various parameters may also change.

Response surface results

The test data are processed.

When the response surface analysis is carried out by using design expert software, the analysis results are that the primary term parameters that have a significant impact on the folding loss are: part contour curvature radius, arc radius of arc-shaped pre-folding blade, folding opening angle.

And the cross-term parameters of the second term are part contour curvature radius, and folding opening angle.

The arc radius of the arc-shaped pre-folding knife is multiplied by the folding opening angle.

Firstly, the primary term parameters are analyzed.

When the other four parameters are fixed, the value range of each parameter is selected as the abscissa and the folding loss value is selected as the ordinate, and the changing relationship between the folding loss and each parameter is drawn, as shown in Figure 4.

As can be seen in Figure 4:

(1) with the increase of the curvature radius of the part contour, the folding loss decreases;

(2) with the increase of arc curvature radius of arc-shaped pre-folding blade, the hem loss increases;

(3) with the increase of the folding opening angle, the folding loss decreases, which is the same as the result of sensitivity analysis.

In the response surface nephogram, the nephogram of the folding loss value with respect to the folding opening angle, the curvature radius of the arc-shaped pre-folding blade and the curvature radius of the part contour is made, and the results are shown in Fig. 5.

As can be seen from Figure 5:

(1) when the folding opening angle is unchanged, the folding loss decreases with the increase of the curvature radius of the part contour and increases with the increase of the curvature radius of the circular arc pre-folding knife;

(2) when the curvature radius of the part contour remains unchanged, the folding loss decreases with the increase of the folding opening angle;

(3) when the curvature radius of the circular arc pre-folding blade is unchanged, the folding loss decreases with the increase of the folding opening angle.

The above conclusion is the same as the influence trend of the previous significance parameters.

But in the cloud map of the secondary significance parameters, facing the selection of different parameter values, the folding loss can be obtained more accurately and conveniently.

Analysis of folding loss mechanism

Comparison of difference between circular arc pre-folding knife and plane knife

By using AutoForm software, read the folding loss value after the pre-folding process and the folding loss value after the final folding in the folding process of the arc pre-folding knife and plane knife.

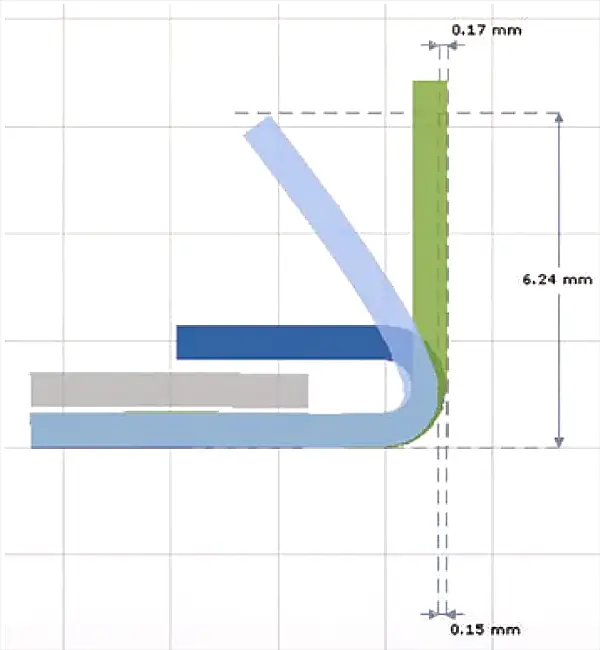

As shown in Figure 6 and Figure 7, it can be seen that after the pre-folding process is completed, that is, when the folding surface is at the same angle, the folding loss value of the circular arc pre-folding knife is 0.15mm, and the height of the outer plate flange is 6.2mm.

The folding loss value of the plane knife is 0.32mm, and the height of the outer plate flange is 5.9mm.

After the final folding process is completed, the folding loss value of the arc-shaped pre-folding knife is 0.33mm, the height of the outer plate flange is 2.41mm, the folding loss value of the plane knife is 0.39mm, and the height of the outer plate flange is 2.39mm.

Fig. 6 folding process of circular arc pre-folding knife

Fig. 7 folding process of plane knife

Compared with the planar pre-folding knife, the reason why the circular arc pre-folding knife can reduce the folding loss is that when the circular arc pre-folding knife is used, the outer plate is always in contact with the circular arc working surface point.

And the contact point will move upward along the circular arc working surface with the pre-folding.

Since the direction of the force on the sheet metal by the working face of the pre-folding knife is always perpendicular to the working face of the pre-folding knife, and the contact point points to the center of the circle, when the arc-shaped pre-folding knife is adopted, the direction of the force on the sheet metal is always parallel to the arc normal direction of the contact point.

With the change of the contact point on the working surface of the pre-folding knife, the direction of the force of the outer plate changes all the time.

The direction of the force change is conducive to slowing down the trend of the inner approach of the outer plate folding face, and finally conducive to the reduction of the folding loss value.

Analysis of the influence of the radius of circular arc pre-folding blade on the folding loss

In the response surface equation analysis, it can be obtained that the folding loss decreases with the increase of the arc curvature radius of the circular arc pre-folding blade.

The reason for this changing trend is explored.

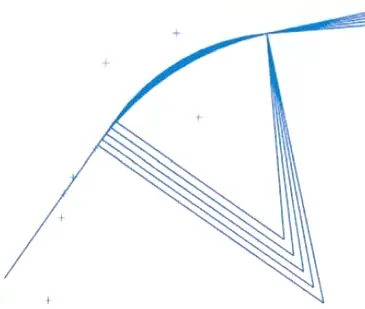

Change the arc curvature radius of the arc-shaped pre-folding knife to 6mm, 6.5mm, 7mm, 7.5mm and 8mm, and draw the corresponding arc-shaped pre-folding knife shape in UG, as shown in Figure 8.

It can be seen that when the starting and ending positions of the arc-shaped pre-folding blade are fixed, the center of the circle corresponding to the arc segment moves from inside to outside with the increase of the arc radius.

In the stress analysis of the pre-folding process of the circular arc pre-folding knife in the previous summary, the force on the folding surface of the outer plate always points to the center of the circular arc section from the contact point, that is, the uppermost end of the folding surface.

Therefore, when the force in the pre-folding process is constant, with the increase of the arc radius, the horizontal component of the force on the outer plate will increase.

And the increase of the component in this direction will increase the trend that the folding face of the outer plate approaches inward, resulting in the increase of the folding loss value.

In order to verify the accuracy of the above analysis, under the values of the process parameters, five arc-shaped pre-folding knives are used for folding simulation, and the folding loss after the pre-folding process and the final folding process are measured. See Table 3.

Table 3 folding loss of pre-folding and final folding

| Group No. | Radius of curvature of circular arc pre folding knife (mm) | Pre folding FV(mm) | Final hem FV(mm) |

| 1 | 6 | 0.281 | 0.46 |

| 2 | 6.5 | 0.3 | 0.475 |

| 3 | 7 | 0.311 | 0.481 |

| 4 | 7.5 | 0.313 | 0.477 |

| 5 | 8 | 0.318 | 0.484 |

It can be seen that when the arc radius of the arc-shaped pre-folding knife increases, the folding loss after the pre-folding process also increases.

The final folding process increases the folding loss almost the same.

Therefore, it can be inferred that the influence of the arc curvature radius of the arc-shaped pre-folding knife on the folding loss value occurs in the pre-folding stage, so as to change the direction of the force on the folding surface of the outer plate and affect the final folding loss value.

Conclusion

In this post, taking the circular arc pre-folding blade as the research object, the factors that may affect the folding loss are analyzed through AutoForm software, and the following conclusions are obtained:

- The fillet radius of the outer plate, the opening angle of the folding, the arc radius of the part contour and the arc radius of the arc-shaped pre-folding blade have a significant impact on the folding loss;

- when the arc radius of the arc-shaped pre-folding blade increases, the folding loss of the part increases;

- when the curvature radius of the part contour increases, the folding loss of the part increases;

- when the opening angle of folding increases, the folding loss of parts increases;

- when the arc-shaped pre-folding knife works, with the change of the contact point on the working surface of the pre-folding knife, the direction of the force on the outer plate changes all the time. The direction of the force change is conducive to slowing down the trend of the inner approach of the folding face of the outer plate and ultimately reducing the folding loss value.