Have you ever wondered how everyday objects like pots, cups, and even car parts are shaped so precisely? This article explores the fascinating differences between mechanical and hydraulic presses. You’ll learn how each type of press works, their unique applications, and which one is best suited for various tasks. Get ready to uncover the secrets behind these powerful machines!

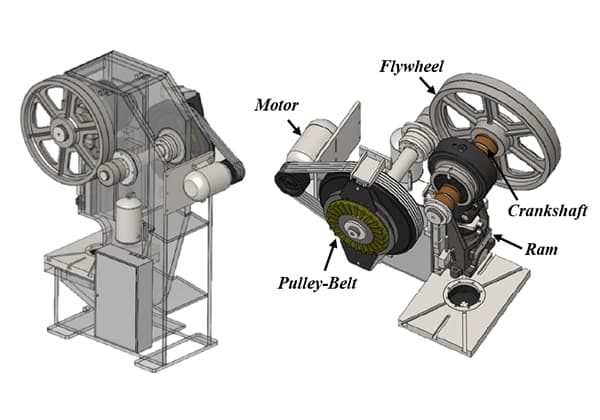

The design principle of a mechanical press is to convert circular motion into linear motion. The flywheel, driven by the main motor, engages the clutch which drives the gear, crankshaft (or eccentric gear), and connecting rod to achieve linear motion of the slider. The motion from the main motor to the connecting rod is circular in nature.

The hydraulic oil press (a type of hydraulic press machine) operates by using special hydraulic oil as the working medium and a hydraulic pump as the power source. The force of the pump drives the hydraulic oil into the cylinder/piston through the hydraulic pipeline. There are several sets of seals in the cylinder/piston, which are different in each location, but serve the same purpose of preventing hydraulic fluid from leaking. The hydraulic oil then circulates through the tank via a check valve, causing the cylinders/pistons to cycle and complete a specific mechanical action, resulting in productivity.

Now, let’s examine the differences between the mechanical press and hydraulic press.

(1) Punch press applies rapid downward pressure with an inertia force, whereas hydraulic press exerts static pressure with a slower downward force. If a larger elongation is required, it’s better to use a hydraulic press.

(2) Punch presses have rigid speed control and cannot be adjusted, whereas hydraulic presses are equipped with stepless speed control and the pressure can be changed at any time, making it easier to control. The degree of deformation of the material is referred to as the amount of elongation. Possible cracking may occur during hydraulic press punching if the elongation is large.

(3) For small emblems or silver jewelry, an ordinary mechanical press is a better choice due to its low elongation pressure and high efficiency. On the other hand, products with large elongation, such as deeper pots and cups, are better suited for hydraulic presses. Punching machines are more suitable for blanking.

(4) Punch presses use mechanical transmission with a crank-slide structure, while hydraulic presses use hydraulic transmission.

(5) The most significant difference between the mechanical press and hydraulic press is that they are used for different purposes and are different types of process equipment. Punch presses are mainly used for sheet metal cutting, while hydraulic presses are mainly used for sheet metal forming.

Punching machines are commonly used in the stamping and forming of hardware parts for a wide range of industries, including electronics, communications, computers, household appliances, furniture, transportation (automobiles, motorcycles, bicycles), and more.

Hydraulic presses are widely used in the processing of auto parts and in various industries for shaping, punching, calibrating, shoemaking, handbag production, rubber molding, pressing of shaft and bushing parts, embossing, bending of sheet metal parts, stretching of sheaths, production of washing machines, electric motors, automotive motors, air conditioning motors, micro motors, servo motors, wheel manufacturing, shock absorbers, motorcycles, and machinery.

These are the differences between hydraulic and mechanical presses. Both types of machines have their own advantages. It is my belief that as technology advances, the future of automation equipment will become increasingly intelligent.