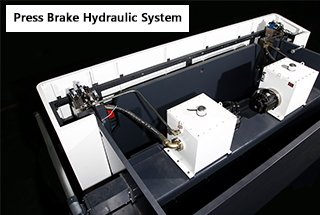

Ever wondered what keeps a CNC press brake running smoothly? The answer lies in the hydraulic oil. This essential fluid ensures optimal performance and longevity of the machine. Our article dives into the types of hydraulic oil best suited for different temperatures, the importance of regular maintenance, and tips for avoiding common pitfalls. By understanding these key elements, you’ll be equipped to maintain your press brake efficiently and prevent costly breakdowns. Ready to master your machine’s maintenance? Read on to learn more!

The hydraulic oil used in this CNC press brake should have a viscosity of 4 ° E ~ 5 ° E (EN viscosity) at 50 ℃ or 45 ~ 68 centistoke (kinematic viscosity) at 40 ℃.

It is recommended to use N68 anti-wear hydraulic oil in summer and N46 anti-wear hydraulic oil in winter.

It is essential to ensure the cleanliness of the hydraulic system. Most hydraulic system failures occur due to unclean oil.

Before filling oil, clean the oil tank to ensure there are no impurities in the tank.

After cleaning the oil tank, fill it with fine-filtered (10um) hydraulic oil. See the “Technical Parameters of Machine Tool” for the oil tank capacity of the machine.

Note that newly purchased hydraulic oil is not clean hydraulic oil.

After the oil tank is filled for the first time and works for 500 hours, the tank must be cleaned and replaced with new, fine-filtered hydraulic oil.

In the future, the oil tank should be cleaned and replaced every 2000 hours.

It is not recommended to operate the press brake machine at low temperatures (below -5 ℃). If it must be used, the machine should run under no-load for a period of time. An oil heater can be installed in the circuit if necessary.

Under normal working conditions, the oil temperature should not exceed 70 ℃. In special environments, an oil cooler can be installed according to actual needs (the oil tank has an interface).

Maintenance of the CNC press brake machine is crucial, particularly with regards to maintaining and replacing hydraulic oil.

It’s important to keep an eye on the oil’s usage and replace it regularly.

Regarding the first-time use of the CNC press brake, how often does the hydraulic oil need to be replaced and how can the machine be properly maintained?

During operation, the pollution level of the hydraulic oil used in the system should not fall below the specified requirements.

Typically, three months after the hydraulic bending machine has been put into operation for the first time, the hydraulic oil should be filtered or replaced and the oil tank should be cleaned.

In the future, it’s usually recommended to change the oil once a year. The oil should be tested every three months and any deteriorated or seriously polluted oil should be replaced promptly.

It’s advisable to use the specified brand of hydraulic oil and not mix different brands.

In addition to replacing the hydraulic oil, the following maintenance points should also be considered:

Reasons for oil leakage in a press brake machine include:

Generally, oil heating is not necessary, except in extreme low temperature conditions. If the temperature becomes too high, the oil will become thin and this will result in inconsistent pressure transmission and impact the machine’s operation.

#46 Anti-wear hydraulic oil should be used. Using #46 ordinary hydraulic oil may result in overheating and cause damage to the valve and cylinder seals.

It is generally recommended to replace the hydraulic oil once or twice a year, and to check the oil every month. If the oil appears white or black, it should be replaced immediately.