Imagine the heart-stopping moment when a hydraulic press’s sliding block unexpectedly falls. This article explores crucial safety measures to prevent such incidents, ensuring the stability and reliability of hydraulic presses. From hydraulic locking devices to safety claws, learn about innovative solutions that safeguard both machinery and operators. Dive into the detailed mechanisms and practical applications, and discover how these systems can protect your workplace from catastrophic failures.

With the rapid development of aviation, aerospace, energy, automobile, household appliances, and other industries, the production and usage of hydraulic presses have increased significantly in factories.

As the society evolves towards humanization, the safety system of hydraulic presses is required to be safe, stable, and reliable while being humane. The safety protection measures used in hydraulic press applications are particularly crucial.

This post aims to discuss briefly several safety protection measures to prevent the sliding block of a hydraulic press from falling off.

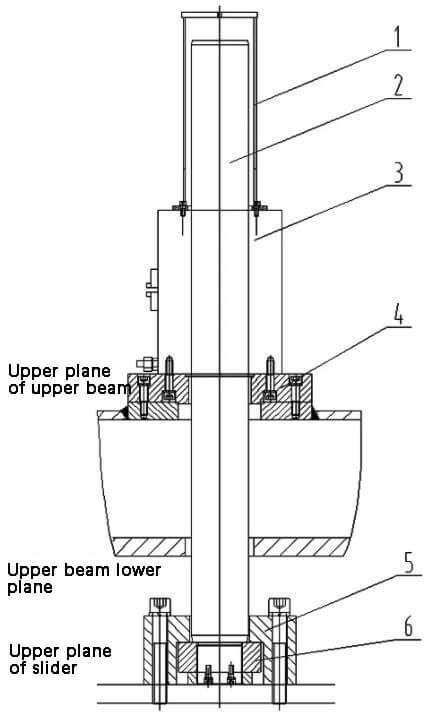

The hydraulic locking device for the slider is typically installed on the top surface of the slider and the bottom surface of the upper crossbeam, or on the side of the column, as depicted in Figure 1.

Fig. 1 Schematic diagram of slider locking device

The slider locking device is composed of several components including the upper support, lower support, locking bolt, impact block, hydraulic oil cylinder, limit switch, screw, washer, and others.

To install, the lower support is fixed onto the upper plane of the sliding block using screws and washers, while the hydraulic oil cylinder is connected to the upper support. The locking bolt and striker are then attached to the piston rod of the oil cylinder, and the upper support is secured onto the lower plane of the upper crossbeam using screws and washers.

When the impact block makes contact with the limit switch, the switch sends a message indicating whether the device is locked or unlocked in place. For a physical representation of the slider locking device, please refer to Figure 2.

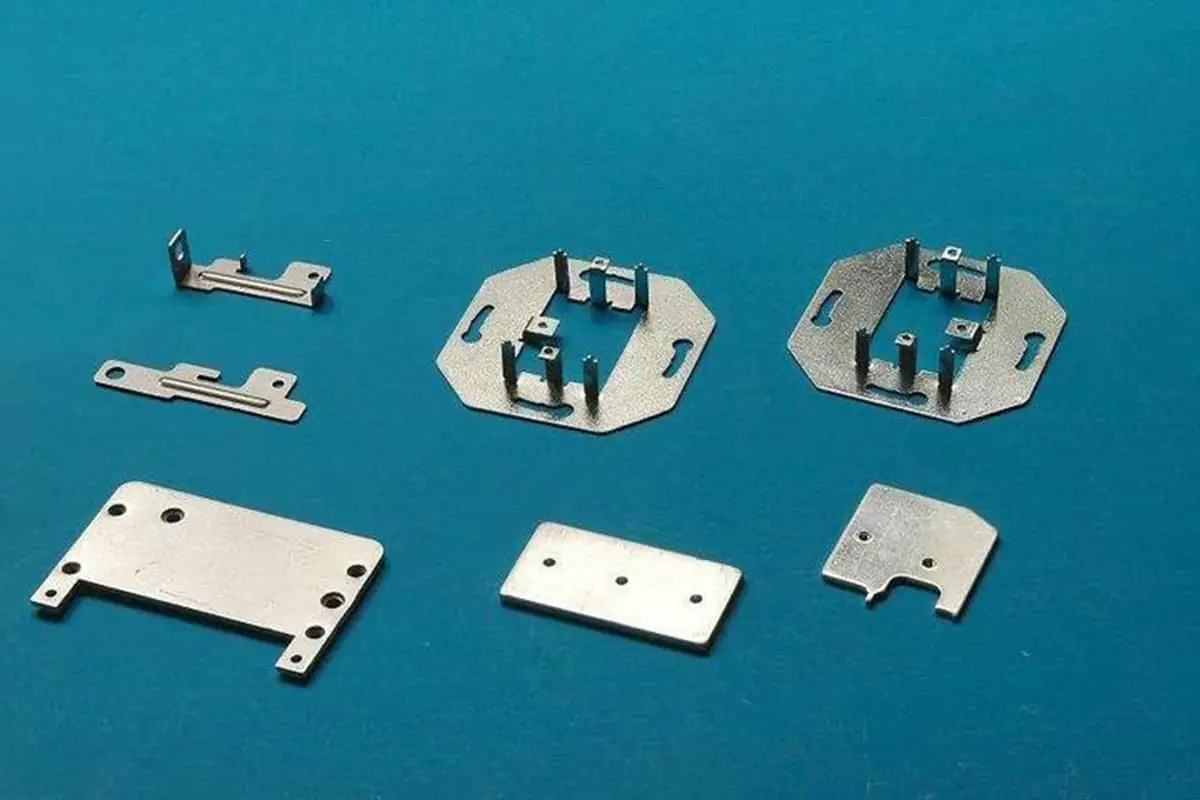

Fig. 2 Physical drawing of slider locking device

Locking Action: When the main slider is in the upper limit position, pressing the locking button will activate the locking device and lock the main slider automatically.

However, if the main slider is not in the upper limit position, pressing the locking button will cause the slider to rise to the upper limit position first, and then automatically lock.

Release Action: If the slider is in the upper limit position and the locking device is engaged, pressing the release button will immediately unlock and release the slider.

If the locking device is engaged but the slider is not in the upper limit position, pressing the release button will cause the slider to slowly return to the upper limit position before unlocking and releasing.

To prevent the sliding block from falling out of control, a double support safety circuit is installed in the lower chamber of the piston main oil cylinder to ensure safety.

Figure 3 shows the schematic diagram of the hydraulic double support safety circuit. The circuit comprises the support valve, solenoid ball valve, solenoid valve, overflow valve, and pipeline system.

When the solenoid ball valve (2) and solenoid valve (3) are not energized, the support valve (1) and support valve (4) remain closed, preventing the oil in the lower chamber of the oil cylinder from flowing back to the oil tank. This ensures that the sliding block does not move downwards.

Fig. 3 Schematic diagram of the hydraulic double support safety circuit

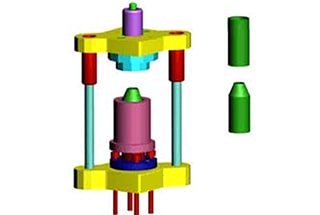

Figure 4 displays the structural diagram of the rotary safety bolt device.

The fixing ring (2) is secured to the pillar (1) using a set screw, and the support (6) is fastened to the front of the pillar using a screw and washer. The rotating arm (4) is attached to the support (6) via the pin shaft (5), and the pillar (1) is inserted into the circular hole at the outer end of the rotating arm (4). Additionally, the spring (3) supports the weight of the fixing ring (2).

The limit switch (7) is positioned on the front of the column.

The rotating arm (4) can revolve around the pin shaft (5) as the center. By screwing the column (1) into the worktable or outwards of the column, it sends a signal to the limit switch (7) and interlocks with the action of the host.

Fig. 4 Structural diagram of rotary safety bolt

To begin the operation, rotate column (1) to the outside of the column through the rotating arm (4) and fix it firmly. Once this is done, the limit switch (7) will send a signal and the press can enter into the working mode normally.

During the repair of the mold or the press, screw the strut (1) into the working table area and press it onto the working table with the weight of the slider and the mold. The strut (1) will support the weight of the sliding block, mold, piston rod, plunger rod, and other moving parts. If the limit switch (7) does not send a signal, the press cannot enter any working mode to ensure the safety of the operator.

The safety bolt device is generally located at the diagonal front of the column, which is convenient for rotational operation. It can also be set at the inner side of the column, and the structural forms are relatively diverse. The specific structural form of the safety bolt can be reasonably selected according to the specific situation.

Fig. 5 is a schematic diagram of the safety claw device.

Fig. 5 Schematic diagram of safety claw device

The rack (1) is positioned using a flat key (2) and fixed onto the side of the sliding block with screws and washers.

The claw (4) is assembled onto the bracket (5) using a pin shaft, while the oil cylinder (6) is mounted onto the same bracket (5) with screws and washers. The claw (4) is connected to the piston rod of the oil cylinder (6) via a connecting rod (7), a spring (8), etc.

The bracket (5) is securely fixed onto the inner side of the column using screws and washers.

The oil cylinder (6) has a rod cavity to feed oil, which drives the claw (4) to release. At the same time, the limit switch (3) sends a signal, allowing the slider to move downward.

The oil cylinder (6) also has a rod cavity for oil discharge. When the claw (4) is reset by the spring (8), it locks onto the rack (1) and securely holds the slider in place.

If the limit switch (3) does not send a signal, the slider cannot move downward, thus ensuring the operator’s safety.

A Sitema safety locking device can effectively prevent the sliding block from falling off, as shown in Figure 6. Sitema (3) is installed and fixed on the upper plane of the upper beam using a connecting plate (4), screws, washers, etc. The pull rod (1) passes through Sitema (3) and the upper beam and is connected to the sliding block through nuts (6) and flanges (5). Additionally, a protective cover (2) is installed on the upper surface of Sitema (3).

Fig. 6 Sitema safety locking device

The Sitema safety clamping device is used to ensure personnel protection and prevent accidents in case of load-bearing machine failure when improving the connection between the load and tool. It provides accident protection in case of leakage or failure of the hydraulic or pneumatic pressure system.

The safety clamping device is designed to keep the slider in any position within the stroke in a mechanically stable and reliable manner.

The self-reinforcing clamping device is based on a design principle that ensures a very high level of safety. As shown in Figure 7, the pull rod (1) is surrounded by several wedge-shaped clamping jaws (3), and each wedge-shaped clamping jaw is enclosed within a frame (2) assembled with a guide rail lining (4) and a drive lining (5).

Fig. 7 Structural principle diagram of Sitema

When pressure (P) is applied to the piston (8), the spring (6) compresses and holds the wedge claw in a raised position, allowing the pull rod (1) to move freely.

When pressure is released from the piston (8), the safety clamping device immediately takes effect. The spring applies pressure to the wedge clamping claw (3), which then secures the pull rod (1) to fix the load device.

However, the clamping force is not generated until the load force moves the pull rod (1).

Because of the self-reinforcement of the static friction force on the pull rod (1), the wedge-shaped clamping claw (3) moves to the clamping position and stops at position (7) after traveling a distance of “e” (approximately 5-15mm, depending on the design diameter).

This motion is referred to as phase A in the force/path.

The above briefly discusses several common safety measures to prevent the sliding block of a hydraulic press from falling off.

However, there are many other safety protection measures for hydraulic presses, such as setting up a safety light curtain at the front and rear of the machine, installing two-hand operation buttons, emergency stop buttons, and interlocking functions of the hydraulic and electrical systems. These measures will not be described in detail here.

Currently, the safety protection measures of hydraulic presses are essentially perfect and meet the safety requirements of social and human development for hydraulic presses.