Have you ever considered the game-changing potential of servo press technology in manufacturing? In this article, we’ll explore how these advanced machines are revolutionizing the industry, offering unparalleled precision, efficiency, and versatility. Our expert insights will reveal the key advantages of servo presses and how they can transform your production process. Get ready to discover the future of metal forming and take your manufacturing to the next level.

The stamping industry has seen the emergence of a new generation of presses that address the limitations of traditional mechanical presses.

The solution lies in the use of servo motors as direct power sources for presses, resulting in a highly precise and easily controlled slider motion.

The servo press offers several advantages such as controlled slider speed, versatility, energy efficiency, and environmental friendliness. It is considered the third generation punch and the current trend in stamping industry development.

The programmable control capabilities of the servo motor allow for advanced precision control, including controlling the position of the press slider.

Servo punches are used in production lines such as drawing, blanking, bending, cold forging, embossing, and die testing.

AC servo motor drive technology is a research focus in advanced forging equipment and a new direction of development for international presses.

The AC servo press offers several benefits including high productivity, flexibility, precision, energy efficiency, and environmental sustainability, reflecting the future trend of forging machine tool development.

As industries such as iron and steel, non-ferrous metallurgy, aerospace, high-speed railways, shipping, nuclear power, wind energy, and military demand higher performance parts, the need for advanced stamping equipment grows.

Mechanical presses have limitations such as a fixed stroke, difficulty in controlling pressure, and poor adaptability to processes due to fixed motion characteristics of the slider.

The servo press addresses these challenges by providing a flexible press that meets the demanding requirements of modern industries.

Servo refers to a feedback control system for mechanical displacement and acceleration, whose main function is to accurately track the input displacement or angular displacement with the output mechanical displacement. Servo stamping technology refers to a feedback control system/follow-up system used to precisely follow the stamping process.

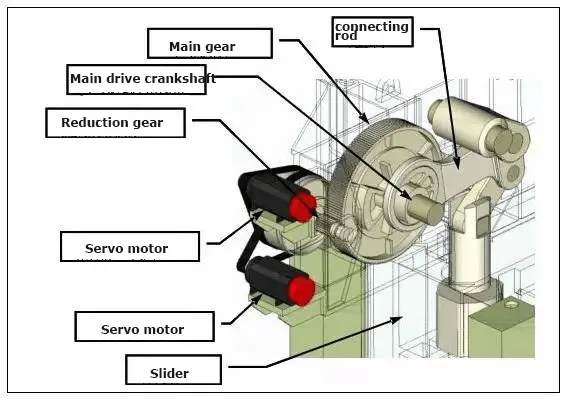

A servo press is a type of press that is powered and controlled by a servo motor. The servo motor drives the eccentric gear, allowing for movement of the slider.

With the use of advanced electrification control, the servo press can be programmed to control the stroke, speed, and pressure of the slider with precision. This allows for the nominal tonnage of the press to be reached at low speeds.

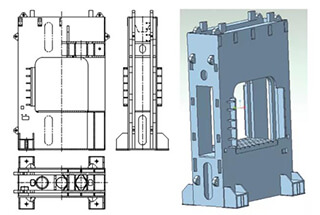

The structure of an AC servo press consists of a main drive system, an actuator, and an auxiliary mechanism. The main drive system transfers energy from the servo motor to the actuator, and can be achieved through various transmission modes such as gear transmission, belt transmission, screw transmission, or hydraulic transmission.

The actuator drives the reciprocating motion of the slider to complete the forging process and can take the form of a crank slider mechanism or a crank wedge mechanism.

The auxiliary mechanism enhances the reliability of the AC servo press and expands its process applications, with common components including balance cylinders, brakes, jacking devices, and position detection devices.

The main drive system of the servo press can be divided into two types based on the driving mode of the servo motor: direct drive and drive with a reducer. Direct drive utilizes a low-speed, high-torque servo motor directly connected to the actuator, resulting in a simple structure, high transmission efficiency, and low noise.

However, its limited torque restricts its use to small tonnage servo presses.

The widely used main drive system in commercial servo presses employs a deceleration mechanism and a force-increasing mechanism, which can take three different transmission structures: motor deceleration crank connecting rod, motor deceleration crank elbow rod, and motor deceleration screw elbow rod.

This approach allows for a high-speed, low-torque servo motor to drive large tonnage presses, making it the current trend in the development of servo presses.

Table 1 Comparison of project parameters

| Project | Robot automatic line | Automatic line of single arm manipulator | Crossbar double arm transmission high speed line | Single slider multi station production line | |

|---|---|---|---|---|---|

| Single line automation cost | About 12 million yuan | About 20 million yuan | About 30 million yuan | About 15 million yuan | |

| Line speed / SPM | 5~10 | 6~12 | 10~15 | 12~25 | |

| Production applicability | Multi variety and small batch | Multi variety, medium batch | Multiple varieties and large quantities | Variety, mass | |

| Production flexibility | high | commonly | commonly | low | |

| Production stability | low | commonly | high | ||

| Mold change time/min | 15 | 15 | 5 | 5 | |

| Requirements for press | Operation mode | Single time | Single time | Single, continuous | continuity |

| Press spacing / M | 6.5~8 | 6~9 | 4.5~7 | / | |

| Slider stroke | Small | more | large | large | |

| Mold height | Small | more | large | large | |

As shown in Table 1, the beat of the cross bar double arm transmission high-speed line is between 10 to 15 strokes per minute (SPM). By using a servo press, the beat of the high-speed line can be increased to a maximum of 18 SPM.

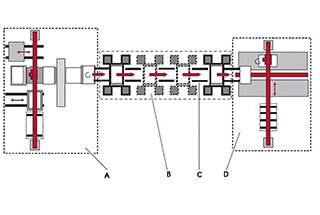

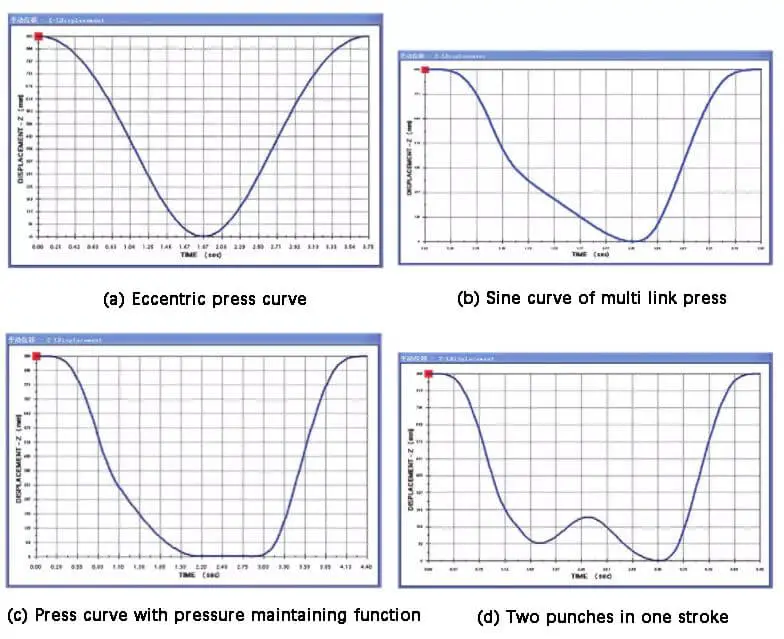

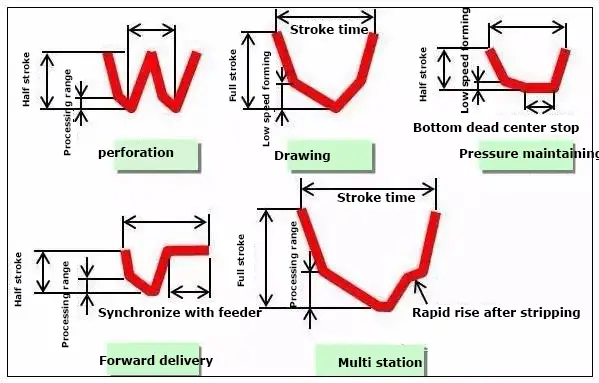

As illustrated in Figure 1, the servo press has the ability to set different curves depending on the specific situation.

Fig. 1 Servo press can set different curves

Figure 2 displays the power flow during the acceleration and deceleration phases.

Fig. 2 Current flow direction of servo motor during operation

As depicted in Figure 3, the low drawing speed reduces the impact on the die, leading to an improvement in die life and a reduction in die cost.

Fig. 3 Schematic diagram of drawing speed

Reducing the size of equipment can decrease the investment in plant, infrastructure, and other facilities. As shown in Figure 4, using the four-sequence press as an example, a traditional mechanical press production line consists of one multi-link press and three eccentric presses, requiring a foundation length of approximately 25 meters. In comparison, a production line consisting of four servo presses would only require a foundation length of approximately 16 meters.

Fig. 4 Comparison between traditional mechanical press and servo press

The stroke length can be set to the minimum required for production, and the appropriate forming speed for the processing content can be maintained.

1) Full stroke mode → bottom dead center precision can reach ± 0.02mm.

2) Half stroke mode (pendulum mode) → bottom dead center accuracy can reach ± 0.02mm, improving SPM.

3) Reverse mode → lower dead center accuracy up to ± 001mm.

The closed-loop feedback control ensures the accuracy of the bottom dead center, reducing the formation of burrs in the product and preventing the generation of defective products.

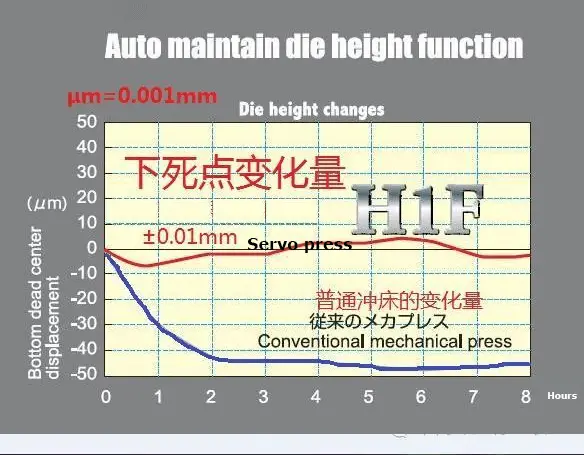

Servo unique auto die height correction function:

The position change of the slider can be measured and corrected to ±0.01mm of the preset value through the use of a linear grating scale in each stroke, ensuring a high degree of accuracy in the bottom dead center.

Linear grating ruler position ↓

The servo bottom dead center has an automatic correction function which ensures the accuracy of the bottom dead center at ±0.01mm even after prolonged production, thereby ensuring a high yield of products.

The low noise mode, which reduces the contact speed between the slider and the sheet metal, significantly reduces noise compared to a traditional mechanical press.

Additionally, the die experiences minimal vibration, leading to an extended service life.

Users can use this feature to create a customized slider movement mode that is suitable for their processing technology, thereby improving the accuracy and stability of the products.

This leads to an extended die life and productivity, as well as quiet blanking and the ability to process a wider range of materials, including magnesium alloys.

The servo press can be used for processes such as blanking, stretching, embossing, and bending, and can provide performance curves for different materials. The ability to pause the slider while maintaining pressure improves the quality of the formed workpiece.

The traditional mechanical press’s energy-consuming components like the flywheel and clutch have been eliminated, resulting in fewer driving parts and a simplified mechanical transmission structure.

The need for lubricating oil is reduced and the stroke is controllable. The reduced motor consumption leads to a significant decrease in operating costs.

The servo punch is mainly utilized in production processes such as drawing, blanking, bending, cold forging, embossing, and die testing.

Thanks to its utilization of PLC control, digital technology, and feedback control methods, the servo punch offers advanced precision control. This includes the ability to control the position of the press slider.

The monitoring system and compensation control enable the position of the slider to be controlled with an accuracy of ±0.01mm. The motion mode can be programmed, allowing for control of the slider’s speed and trajectory.

This reduces stamping speed, noise, and vibration, improving the stamping work environment and extending the lifespan of the die.

Additionally, the output force of the slider can be controlled with a precision of ±1.6% of the maximum output force. This allows for the formation of large panels using high-strength steel and aluminum alloy plates in the automobile industry.

Difficult-to-form materials such as magnesium alloy, aluminum alloy, and titanium alloy can be made easier to form through the combination of die design and peripheral system control.

Toggle type servo structure

Crankshaft direct drive servo structure

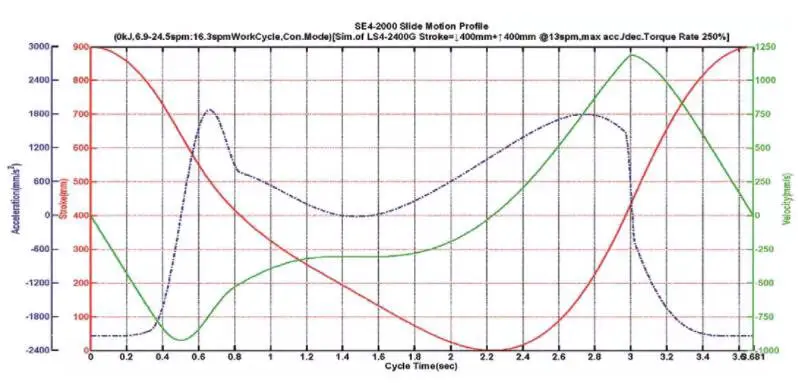

Figure 5 depicts the Schuler double servo bottom drive multi-station press.

Fig. 5 Schuler double servo bottom drive press

The double servo bottom drive press is powered by two separate groups of servo motors, one on the left and one on the right. These motors drive the four guide columns on each side, allowing for the movement of the sliding block.

The independent transmission mechanisms on both the left and right sides enable the table to have large dimensions on both sides, making it suitable for large tables and high tonnage presses, as shown in Figure 6.

Fig. 6 Double servo multi station press

The double servo bottom drive press uses the precise control of two groups of servo motors to achieve synchronous movement of the slider on both the left and right sides.

In the event of an eccentric load on the slider, the parallelism of the slider can be adjusted through electrical control, making it more flexible and adaptable to meet user requirements.

Compared to ordinary presses, the bottom drive press has better eccentric load strength and precision curves. While still meeting accuracy requirements, it offers improved resistance to eccentric loads and a larger area for eccentric load application.

As the competition in the manufacturing industry becomes increasingly intense, there is a growing demand for servo presses to produce high-precision and high-quality products efficiently.

The servo press offers several benefits, including compounding, high efficiency, precision, flexibility, low noise, energy efficiency, and environmental sustainability, which aligns with the future trend of forging machine development.

The servo press has the ability to adjust the stroke and forming speed to meet different production requirements, ensuring the accuracy of the bottom dead center and reducing the occurrence of product burrs. Additionally, the small die vibration improves the die life.

The design of the servo press represents a departure from traditional mechanical presses, as it eliminates the flywheel, clutch, and brake, reducing machine operating costs.

Servo presses will play an increasingly important role in key manufacturing industries such as electronics and automotive, as well as other precision manufacturing fields.

First, it depends on the required accuracy of the servo press.

Accuracy refers to the degree of accuracy in which the pressure and position reach the specified point to stop. It is related to the resolution of the driver, the resolution of the pressure transmitter, the accuracy of the servo motor, and the response speed of the equipment.

With the mature and integrated control of the servo motor and the driver, the repeat accuracy of the servo press is getting higher and higher, and its application field is getting wider and wider.

If high accuracy is required for the servo press, the focus should be on the configuration when choosing.

Second, it depends on the structure of the servo press.

Generally, the structure of the servo press produced by manufacturers is not single. The most common structures are four-column, single-column, arch type, horizontal, and frame structures.

The four-column structure is economical and practical, while the single-column and arch structures are mainly designed for easy operation.

The horizontal structure is commonly used for longer products, and the frame structure has the advantage of occupying a larger tonnage.

Therefore, the selection of the structure should be based on the size and structure of the product.

The functions of the servo press include forging, stamping, assembly, assembly, pressing, forming, flanging, and shallow pulling.

Different functions have different structural differences, so it is necessary to choose the appropriate servo press according to the requirements of the product process.

The stamping industry is set to experience significant changes with the emergence of servo punch, a product that promises to greatly enhance the competitiveness of stamping companies and positively impact the development of various stamping industries.

However, despite its potential benefits, the technology remains expensive and unstable due to most manufacturers not having fully mastered the core technology of servo punch.

As a result, it is difficult for low-value stamping companies to invest in expensive servo presses, especially during the current economic slowdown and reduced benefits of the automobile-based manufacturing industry.

Nevertheless, with the expected improvement of the economy in the future, the market demand for servo presses is anticipated to be huge, and leading manufacturers are expected to develop cost-effective and stable servo presses in the next 5-10 years to boost the overall competitiveness of stamping companies.

The use of an AC servo motor to drive a press can significantly enhance the equipment’s flexibility, intelligence, and operational characteristics, which is the direction of development for the next generation of forming equipment.

As related technologies advance and competition with imported products intensifies, the market price of servo technology is expected to decrease rapidly, leading to wider adoption in the field of forming equipment.