Ever wondered how everyday metal objects withstand wear and tear? This article uncovers the fascinating world of metal surface treatment processes. From improving durability to adding special functions, discover how these techniques transform ordinary materials into extraordinary components. Dive in to learn about the science behind surface modification, alloying, conversion films, and coatings, and how they revolutionize modern engineering.

The surface treatment process is a procedure that uses the technologies of modern physics, chemistry, metallography, heat treatment, and other disciplines to modify the condition and properties of the surface of a component and optimize its combination with the core material to meet the predetermined performance requirements.

Function of surface treatment:

It can be divided into four categories: surface modification technology, surface alloying technology, surface conversion film technology and surface coating technology.

1. Surface quenching

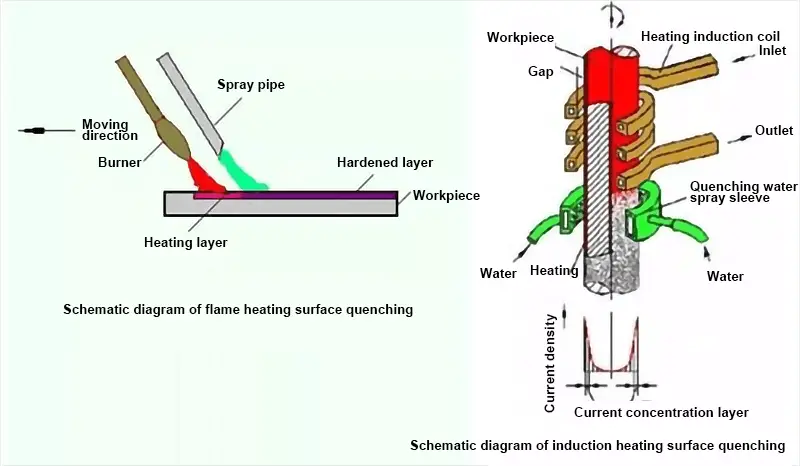

Surface quenching refers to the heat treatment method of austenitizing the surface layer by rapid heating and quenching to strengthen the surface of parts without changing the chemical composition and core structure of steel.

The main methods of surface quenching are flame quenching and induction heating.

The common heat sources are oxyacetylene or oxypropane flame.

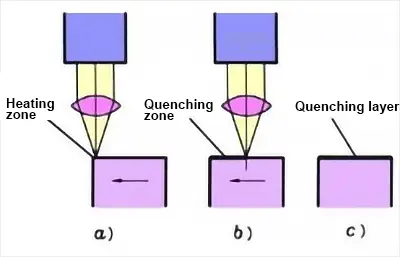

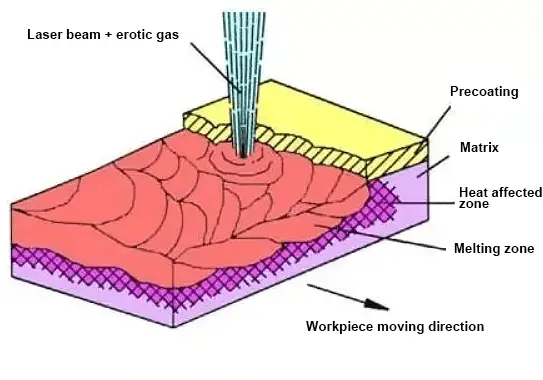

2. Laser surface strengthening

Laser surface strengthening is the process of using a focused laser beam to irradiate the surface of a workpiece, heating the extremely thin surface material to a temperature above the phase transformation temperature or melting point in a very short time. The material is then rapidly cooled to harden and strengthen the workpiece surface.

Laser surface strengthening can be divided into laser phase transformation strengthening treatment, laser surface alloying treatment and laser cladding treatment.

Laser surface strengthening has a small heat-affected zone, small deformation, and convenient operation. It is mainly used for locally strengthening parts, such as blanking dies, crankshafts, cams, camshafts, spline shafts, precision instrument guide rails, high-speed steel cutters, gears, and cylinder liners of internal combustion engines.

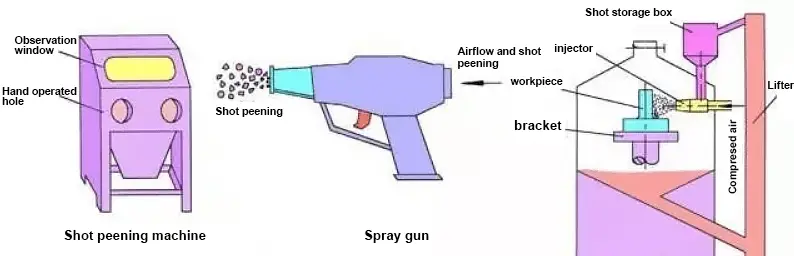

3. Shot peening

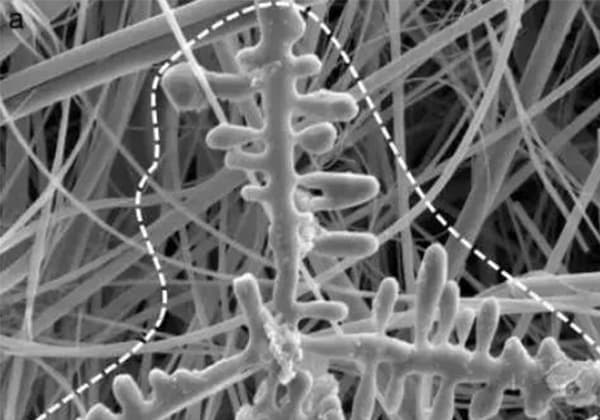

Shot peening is a strengthening technology that involves spraying a large number of high-speed moving particles onto the surface of parts. This process creates countless small impacts on the metal surface, inducing plastic deformation in the surface and subsurface regions of the parts to achieve strengthening.

Function:

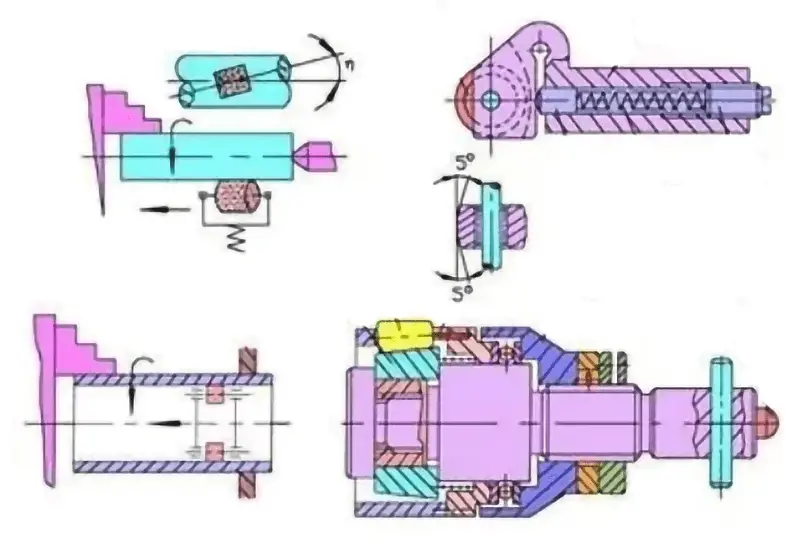

4. Rolling

Rolling is a surface treatment process in which hard rollers or rolls are pressed onto the rotating workpiece surface at room temperature and move along the bus direction to plastically deform and harden the workpiece surface, so as to obtain an accurate, smooth, and strengthened surface or specific pattern.

Application: cylindrical surface, conical surface, plane and other parts with relatively simple shape.

5. Wire drawing

Wire drawing is a surface treatment method that involves making the metal pass through a die under external force, compressing the metal cross-sectional area, and obtaining the required cross-sectional area shape and size, which is called a metal wire drawing process.

Wire drawing can be made into straight lines, random lines, ripples and spiral lines according to the needs of decoration.

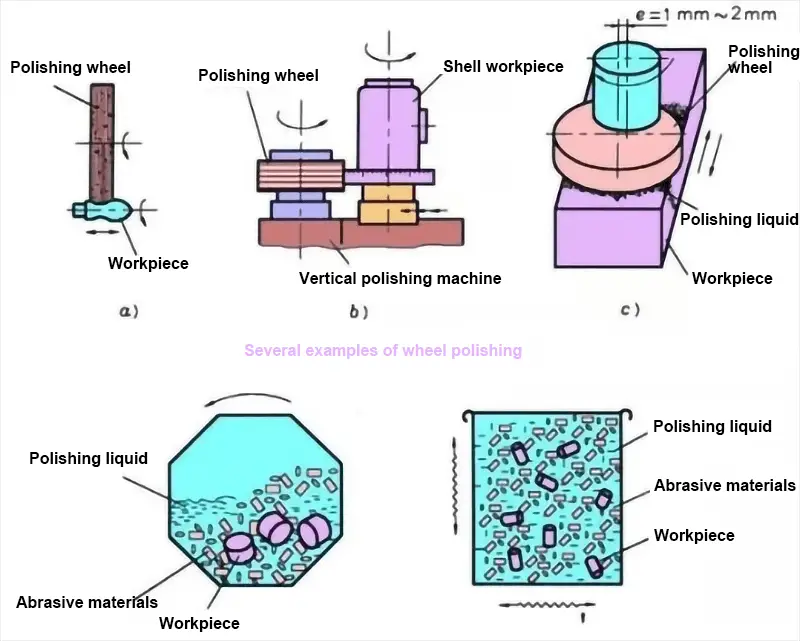

6. Polishing

Polishing is a finishing method used to modify the surface of parts. Generally, it can only achieve a smooth surface and cannot improve or even maintain the original machining accuracy. With different pre-processing conditions, the Ra value (a measure of surface roughness) after polishing can reach 1.6 to 0.008 μm.

It is generally divided into mechanical polishing and chemical polishing.

Chemical surface heat treatment

The typical process of surface alloying technology is chemical surface heat treatment.

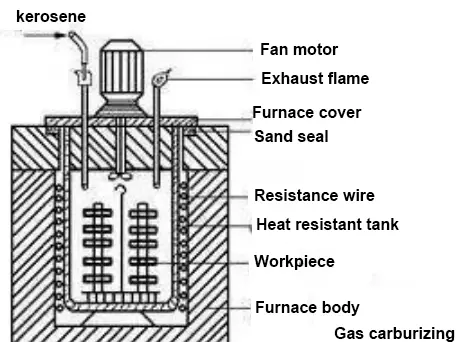

It is a heat treatment process that involves placing the workpiece in a specific medium for heating and insulation. This allows the active atoms in the medium to penetrate the surface of the workpiece and change the chemical composition and organization. This process alters the surface of the workpiece, which in turn changes its performance.

Compared to surface quenching, chemical surface heat treatment not only changes the surface structure of steel but also alters its chemical composition.

Carburizing and nitriding can be categorized into multiple elements and other elements depending on the different elements used.

The chemical heat treatment process comprises three fundamental stages: decomposition, absorption, and diffusion.

The two primary methods of chemical surface heat treatment are carburizing and nitriding.

| Comparison | Carburization | Nitridation |

| Objective | Improve the surface hardness, wear resistance and fatigue strength of the workpiece, while maintaining good toughness of the heart. | Improve the surface hardness, wear resistance and fatigue strength of the workpiece, and improve the corrosion resistance. |

| Material | Low carbon steel containing 0.1 ~ 0.25% C. High carbon reduces the toughness of the core. | It is medium carbon steel containing Cr, Mo, Al, Ti and V. |

| Common method | Gas carburizing, solid carburizing and vacuum carburizing | Gas nitriding method, ion nitriding method |

| temperature | 900~950℃ | 500~570℃ |

| Surface thickness | Generally 0.5 ~ 2mm | Not more than 0.6 ~ 0.7mm |

| Purpose | It is widely used in mechanical parts such as aircraft, automobile and tractor; Such as gear shaft, camshaft, etc. | It is used for parts with high wear resistance and precision requirements and heat-resistant, wear-resistant and corrosion-resistant parts. Such as small shaft of instrument, light load gear and important crankshaft, etc. |

1. Blackening and phosphating

Blackening:

The process of heating steel or steel parts to a suitable temperature in air, steam, or chemicals to form a blue or black oxide film on their surface is known as “blueing.” The steel or steel parts can also turn blue during the process.

Phosphating:

Phosphating is a process in which a workpiece made of steel, aluminum, or zinc is immersed in a phosphating solution (usually an acid phosphate-based solution) and a crystalline phosphate conversion film insoluble in water is deposited on the surface.

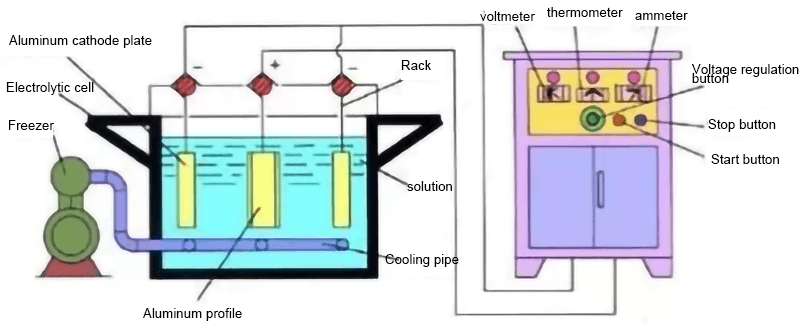

2. Anodic oxidation

It mainly refers to the process of creating an oxide coating on the surface of aluminum and its alloys.

During anodizing, aluminum or aluminum alloy parts are immersed in an acidic electrolyte and act as the anode under the influence of external current. This results in the formation of an anti-corrosion and oxidation film that is firmly combined with the substrate on the surface of the parts.

This oxide film possesses unique properties such as protection, decoration, insulation, and wear resistance.

Before anodizing, polishing, degreasing, cleaning and other pretreatment shall be carried out, followed by washing, coloring and sealing.

Application: it is commonly used in the protective treatment of some special parts of automobiles and aircraft, as well as the decorative treatment of handicrafts and daily hardware products.

1. Thermal spraying

Thermal spraying involves heating and melting metal or non-metallic materials and continuously blowing them onto the surface of the workpiece with compressed gas. This creates a coating that is firmly combined with the substrate, enabling the surface of the workpiece to acquire the necessary physical and chemical properties.

Thermal spraying technology can improve the wear resistance, corrosion resistance, heat resistance and insulation of materials.

Applications: aerospace, atomic energy, electronics and other cutting-edge technologies in almost all fields.

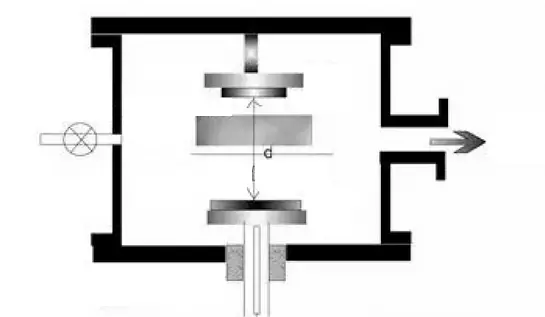

2. Vacuum plating

Vacuum plating is a surface treatment process that involves depositing various metal and non-metallic films on a metal surface through distillation or sputtering under vacuum conditions.

Vacuum plating can produce very thin surface coatings. Additionally, it offers advantages such as high speed, good adhesion, and less pollution.

Principle of vacuum sputter plating

According to different processes, vacuum plating can be divided into vacuum evaporation, vacuum sputtering and vacuum ion plating.

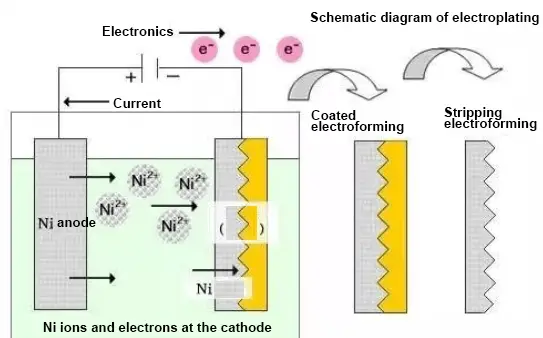

3. Electroplating

Electroplating is an electrochemical and redox process.

To illustrate nickel plating: metal parts are immersed in a solution of metal salt (NiSO4) as the cathode, while the metal nickel plate serves as the anode. Upon connecting the DC power supply, a metal nickel coating will be deposited on the parts.

Electroplating methods are classified as either ordinary electroplating or special electroplating.

4. Vapor deposition

Vapor deposition technology is a novel coating technology that uses physical or chemical methods to deposit vapor phase substances containing deposition elements onto the surface of materials. This creates thin films.

Vapor deposition technology is categorized into physical vapor deposition (PVD) and chemical vapor deposition (CVD) based on the different principles of the deposition process.

Physical vapor deposition (PVD)

Physical vapor deposition is a technology that involves vaporizing materials into atoms, molecules, or ions by physical methods under vacuum conditions. A thin film is subsequently deposited on the surface of materials through the vapor process.

Physical deposition technology comprises three fundamental methods: vacuum evaporation, sputtering, and ion plating.

Chemical vapor deposition (CVD)

Chemical vapor deposition is a process that involves forming metal or compound films on the surface of a substrate through the interaction between mixed gas and the substrate surface at a specific temperature.

Chemical vapor deposition films are widely used in various industries such as mechanical manufacturing, aerospace, transportation, and coal chemical industries. These films possess unique properties, including good wear resistance, corrosion resistance, heat resistance, and electrical and optical properties.