Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, exploring its principles, challenges, and applications. Whether you’re a curious engineer or a manufacturing enthusiast, join us on this journey to uncover the secrets behind this remarkable process.

The definition of deep drawing

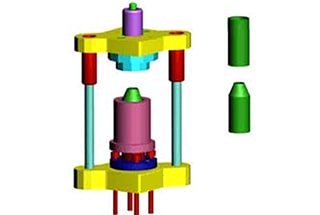

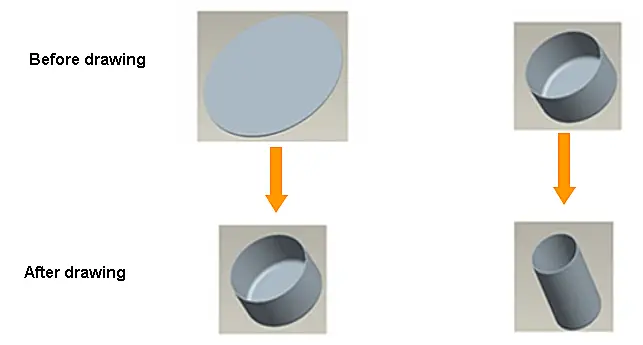

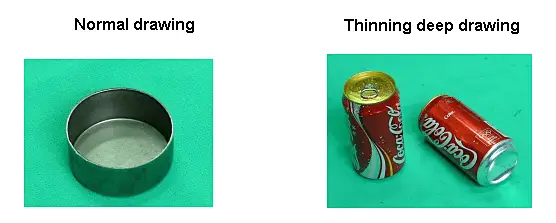

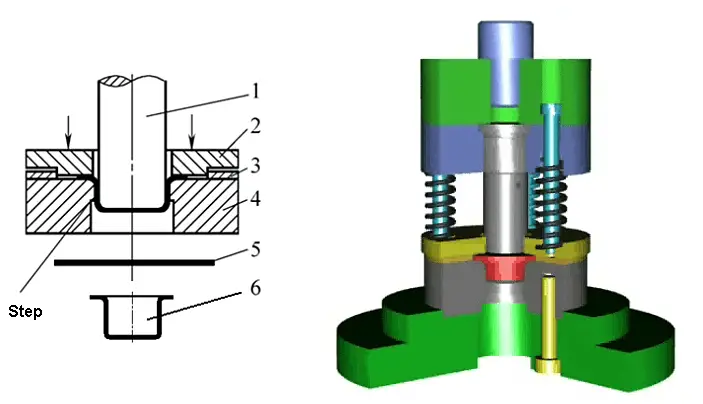

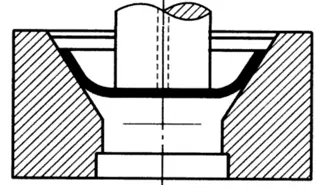

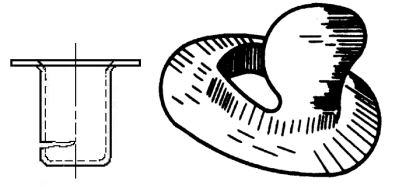

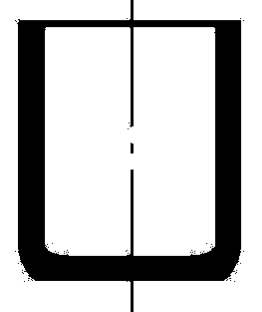

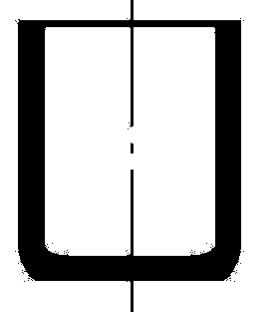

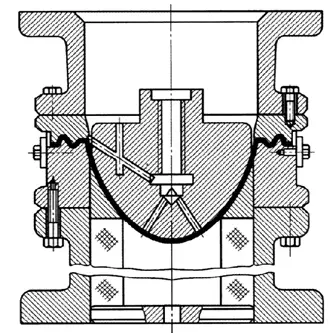

Deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press.

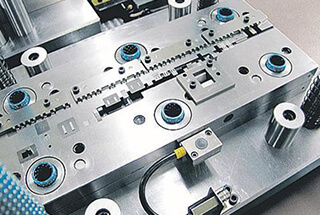

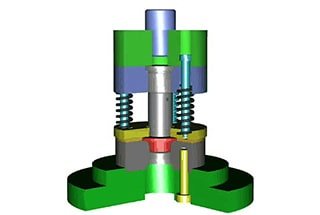

The mold for deep drawing is been called deep drawing die.

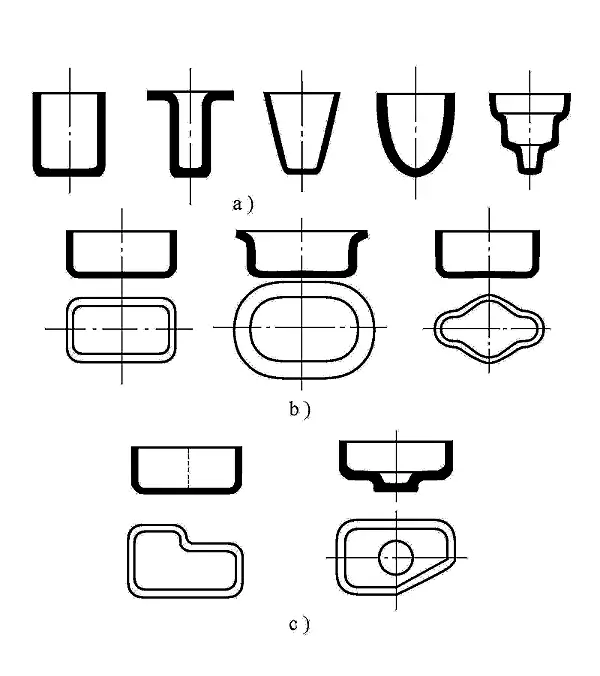

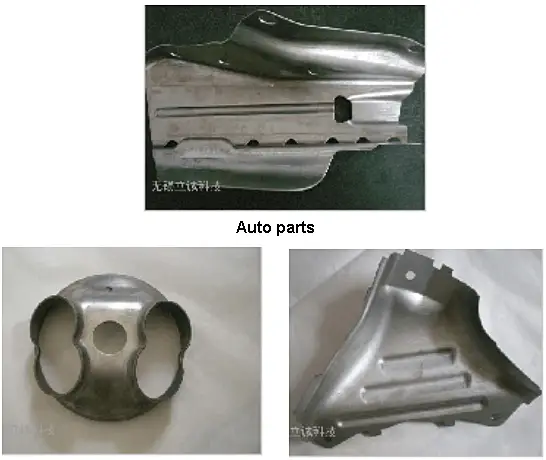

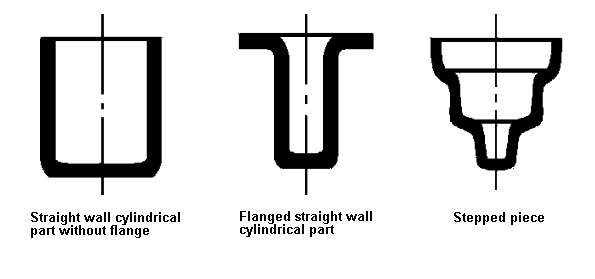

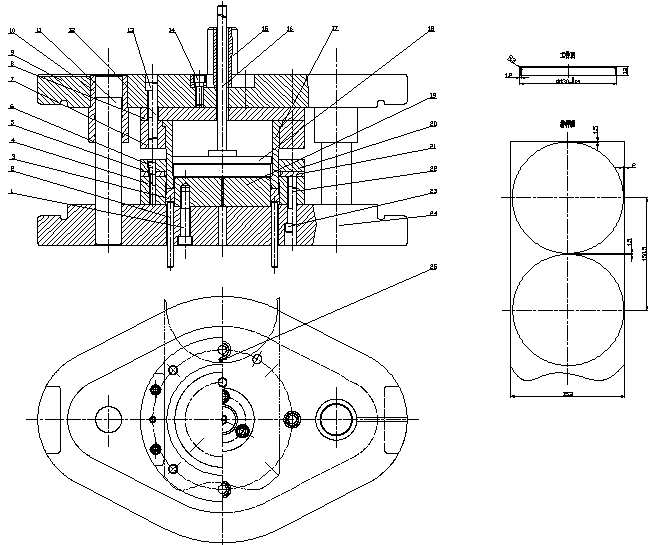

Types of deep drawing parts

Deep drawing parts with more complicated shape

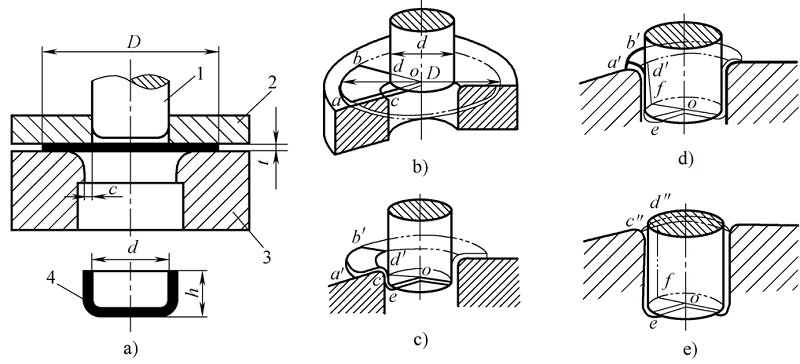

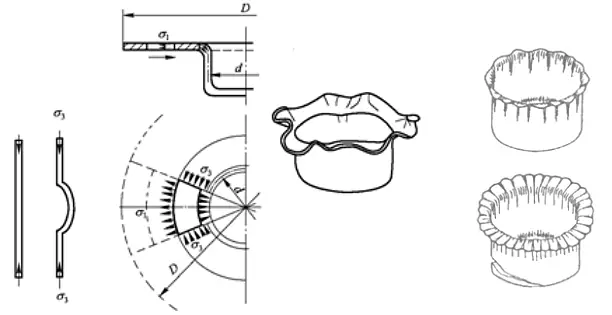

Deep drawing is the process of plastic flow of materials

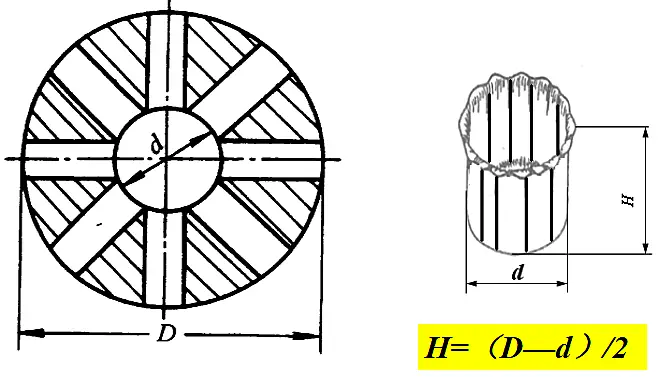

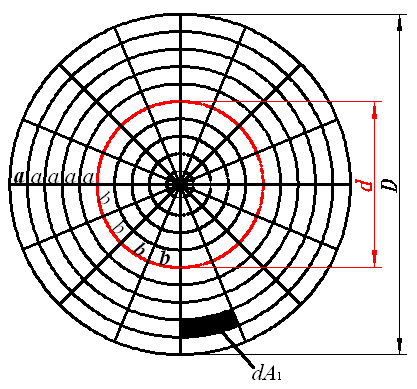

How to process a round flat blank into an open hollow part without a mold?

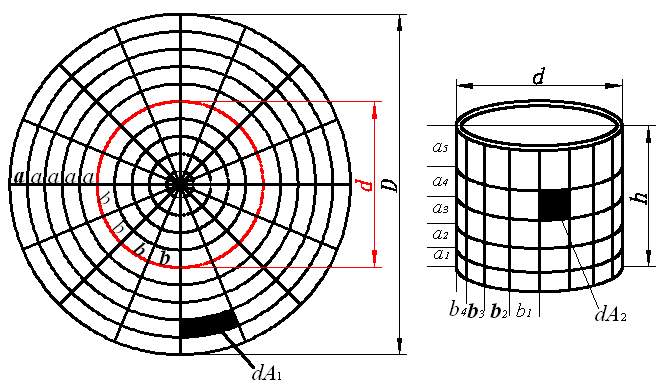

Before deep drawing:

a=a=……=a

b=b=……=b

Material thickness t

After deep drawing:

a<a1<a2<a3<a4<a5

b1=b2=… …=b

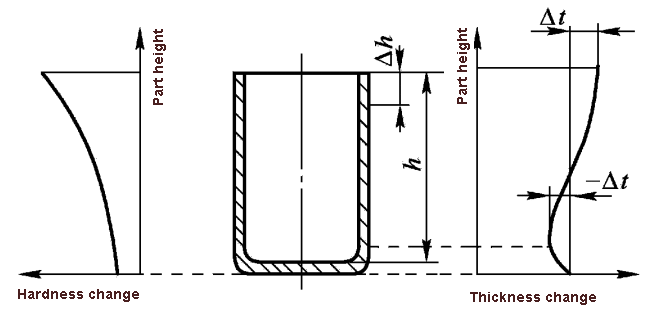

The thickness of the material varies along the height, and the mouth thickens.

h>(D—d)/2

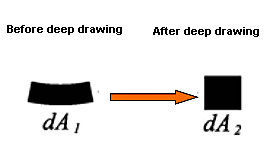

Changes before and after grid deep drawing.

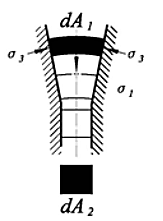

Forces on the grid during deep drawing

Change of sheet thickness in height direction

Deep deformation characteristics:

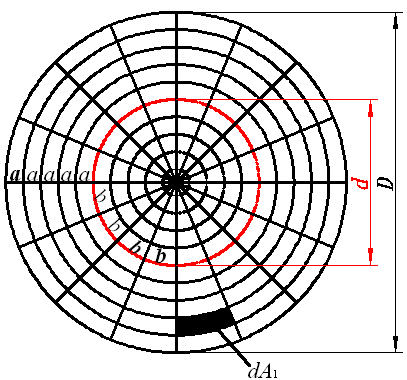

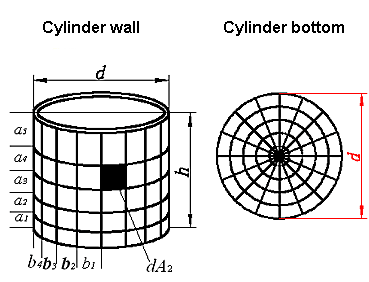

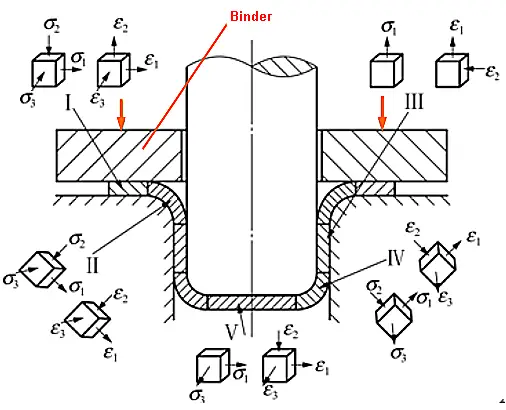

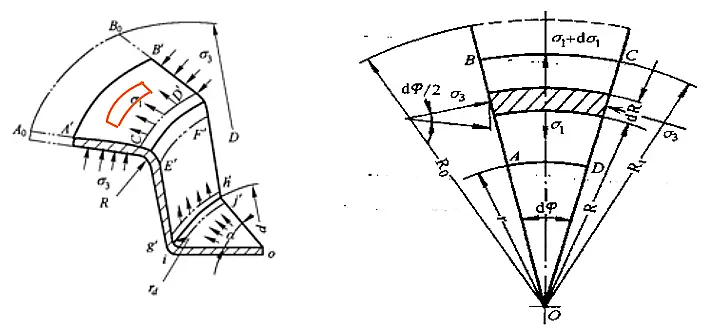

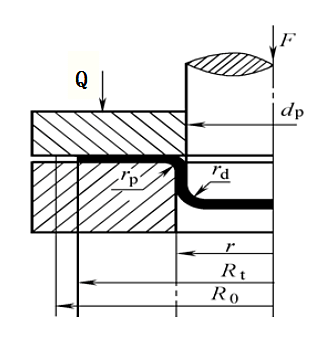

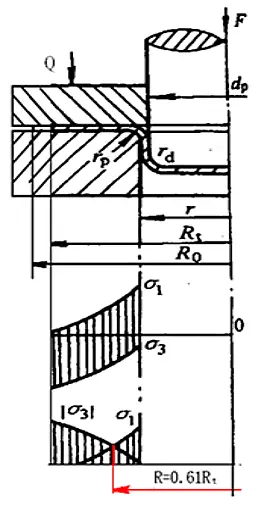

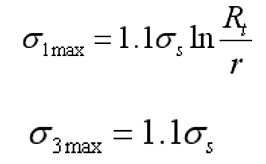

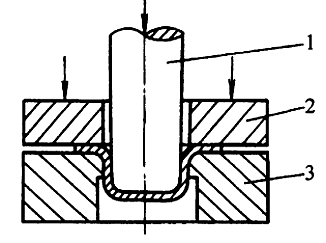

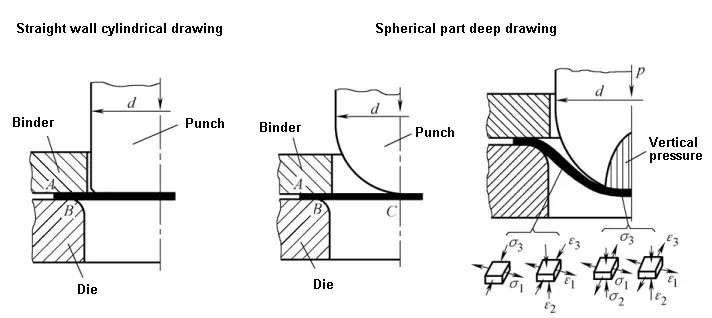

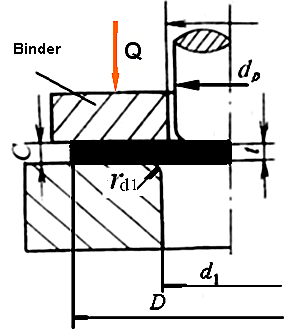

Take the first deep drawing of a straight-walled cylindrical part with a blank holder as an example.

Subscripts 1, 2, and 3 represent the radial, thick, and tangential stresses and strains of the billet, respectively.

1) Ignore the stress in the thickness direction and do not consider work hardening

2) Solve two unknowns from the two equations of plastic deformation condition and force equilibrium condition

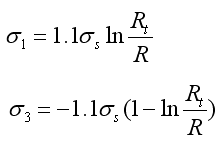

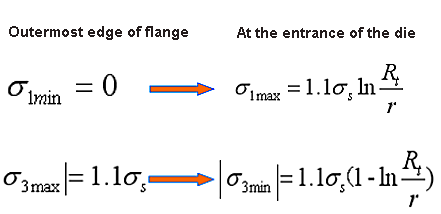

Stress in deformation zone

The value range of R: [r ~ Rt], σ1 and σ3 are changing every moment in the drawing process

Stress σ1 and σ3 distribution in deformation zone

When Rt = 0.61R0, |σ1|=|σ3|

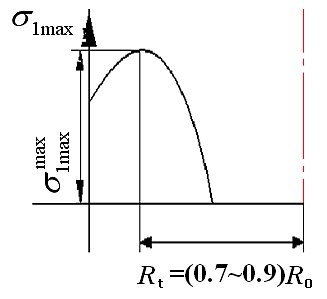

Variation of σ1max and σ3max during deep drawing

σ1max reaches the maximum value during drawing when Rt = (0.7 ~ 0.9) R0

The main quality issues in the drawing process:

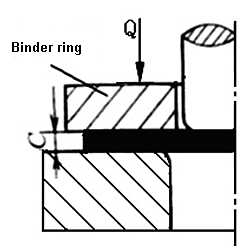

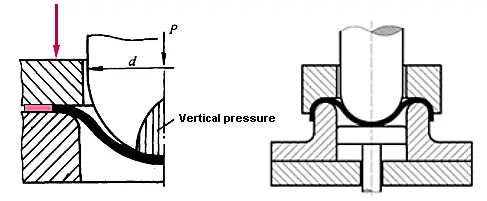

Wrinkling refers to the phenomenon that uneven wrinkles are formed in the deformation area of the flange along the tangential direction during deep drawing deformation.

In general: the larger the flange width, the thinner the thickness, the smaller the elastic modulus and the hardening modulus of the material, the weaker the resistance to instability, and the easier it is to wrinkle.

The most effective measure to prevent deep wrinkling in actual production is to use a blank holder ring and apply a suitable blank holder force Q

A few important conclusions about wrinkling:

(1) Wrinkling law: It has been proved in practice that wrinkles are most likely to occur during the first drawing of a straight-walled cylindrical part: the initial stage of deep drawing

(2) Anti-wrinkle measures: use blank holder ring to apply appropriate blank holder force

(3) Wrinkling position: the main deformation area of deep drawing (flange deformation area)

When the tensile stress of the cylinder wall exceeds the tensile strength of the material of the cylinder wall, the drawn part will rupture at the tangent of the bottom corner and the cylinder wall-the “dangerous section”.

Mainly depends on:

(1) sheet mechanical properties

(2) drawing coefficient m

(3) the corner radius of the die

(4) friction

(5) blank holder force

Practice proves:

In the first deep drawing of the straight-walled cylindrical part, the most likely time for the crack to occur is in the initial stage of deep drawing.

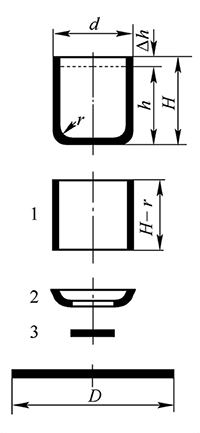

(1) Determination of the shape and size of the blank

The basis for determining the shape and size of the blank:

Shape similarity principle: The shape of the blank before drawing of the rotating body part is similar to the shape of the cross-section of the workpiece after drawing.

According to this, the shape of the blank used for the cylindrical part is circular

Principle of equal surface area: If the thickness of the material before and after drawing is unchanged, the surface area of the blank before drawing and after drawing are approximately equal.

Calculation steps of blank size:

1) Determine the margin for trimming.

2) Calculate the surface area of the drawn part.

3) According to the principle of equal surface area, find the diameter of the blank.

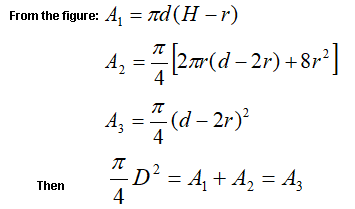

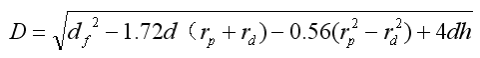

Calculation formula of blank size

1) Check the table 5-2 to get the trim margin △h

Table: Trim allowance for non-flanged parts

| Deep drawing height H | Deep drawing height H/d | |||

| >0.5~0.8 | >0.8~1.6 | >16~2.5 | >2.5~4 | |

| ≤10 | 1 | 1.2 | 1.5 | 2 |

| >10~20 | 1.2 | 1.6 | 2 | 2.5 |

| >20~50 | 2 | 2.5 | 3.3 | 4 |

| >50~100 | 3 | 3.8 | 5 | 6 |

| >100~150 | 4 | 5 | 6.5 | 8 |

| >150~200 | 5 | 6.3 | 8 | 10 |

| >200~250 | 6 | 7.5 | 9 | 11 |

| >250 | 72 | 8.5 | 10 | 12 |

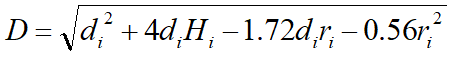

2) Calculate surface area

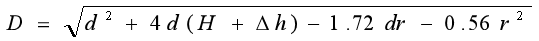

The simplified blank diameter is:

Note: When the sheet thickness t<1mm, all dimensions are substituted with the marked dimensions, otherwise the midline dimensions are substituted.

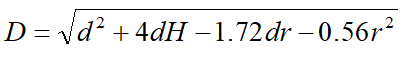

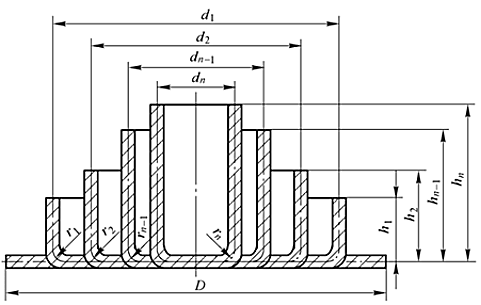

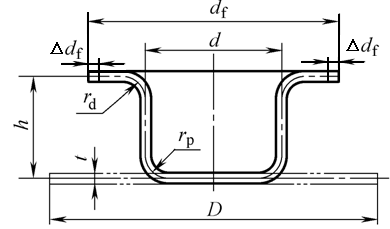

(2) Determination of drawing coefficient

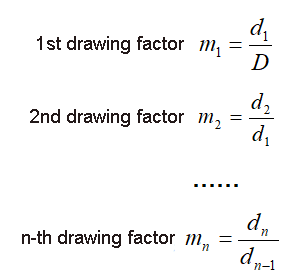

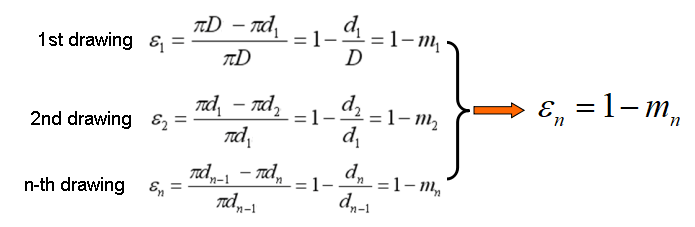

1) The concept of drawing coefficient

Relationship between drawing coefficient and drawing deformation

That is, the size of m can indirectly reflect the amount of tangential deformation.

The important conclusion of the deep drawing coefficient:

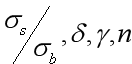

2) Factors affecting the limit drawing coefficient

① Material

② The relative thickness of the sheet is large, and [m] can be reduced.

③ In terms of mold (small ultimate drawing coefficient)

④ Deepening working conditions

The overall influence law: Any factor that can increase the strength of the dangerous section of the tube wall force transmission zone and reduce the tensile stress in the tube wall force transmission zone will reduce the limit drawing coefficient, and vice versa.

3) Determination of the limit drawing coefficient

Table 5-3 and Table 5-4 are the limit drawing coefficients for each drawing of flangeless cylindrical parts.

Table: The limit stretching ratio of the cylindrical part with flanging (08, 10, 15Mn, and H62).

| Deep drawing coefficient | Relative thickness t/D*100 | |||||

| 2~1.5 | 1.5~1 | 1~0.6 | 0.6~0.3 | 0.3~0.15 | 0.15~0.08 | |

| m1 | 0.48~0.50 | 0.5~0.53 | 0.53~0.55 | 0.55~0.58 | 0.58~0.60 | 0.60~0.63 |

| m2 | 0.73~0.75 | 0.75~0.76 | 0.76~0.78 | 0.78~0.79 | 0.79~0.80 | 0.80~0.82 |

| m3 | 0.76~0.78 | 0.78~0.79 | 0.79~0.80 | 0.80~0.81 | 0.81~0.82 | 0.82~0.84 |

| m4 | 0.78~0.80 | 0.80~0.81 | 0.81~0.82 | 0.82~0.83 | 0.83~0.85 | 0.85~0.86 |

| m5 | 0.80~0.82 | 0.82~0.84 | 0.84~0.85 | 0.85~0.86 | 0.86~0.87 | 0.87~0.88 |

Table: The ultimate drawing coefficient of cylindrical parts without blank holder (08, 10 & 15Mn)

| Relative thickness t/D*100 | Deep drawing coefficient for each time | |||||

| m1 | m2 | m3 | m4 | m5 | m6 | |

| 1.5 | 0.65 | 0.80 | 0.84 | 0.87 | 0.90 | – |

| 2.0 | 0.60 | 0.75 | 0.80 | 0.84 | 0.87 | 0.90 |

| 2.5 | 0.55 | 0.75 | 0.80 | 0.84 | 0.87 | 0.90 |

| 3.0 | 0.53 | 0.75 | 0.80 | 0.84 | 0.87 | 0.90 |

| >3 | 0.50 | 0.70 | 0.75 | 0.78 | 0.82 | 0.85 |

In order to improve process stability and part quality, deep drawing coefficients slightly larger than the limit drawing coefficient [mn] should be used in actual production for deep drawing.

(3) Determination of drawing times

When [mtotal]> [m1], the drawing part can be drawn at one time, otherwise multiple drawing times are required.

There are several ways to determine the number of deep drawing:

Steps to calculate the number of deep drawing methods:

1) Check the limit drawing coefficient [mn] of each time from Table 5-3 or Table 5-4.

2) Calculate the ultimate diameter of each drawing in turn, that is,

d1=[m1 ]D;

d2=[m2 ]d1;

…;

dn=[mn]dn-1;

3) When dn≤d, the number of calculations n is the number of deep drawing.

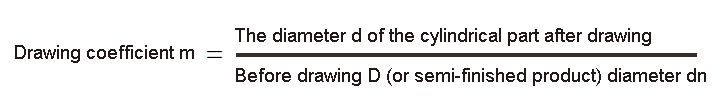

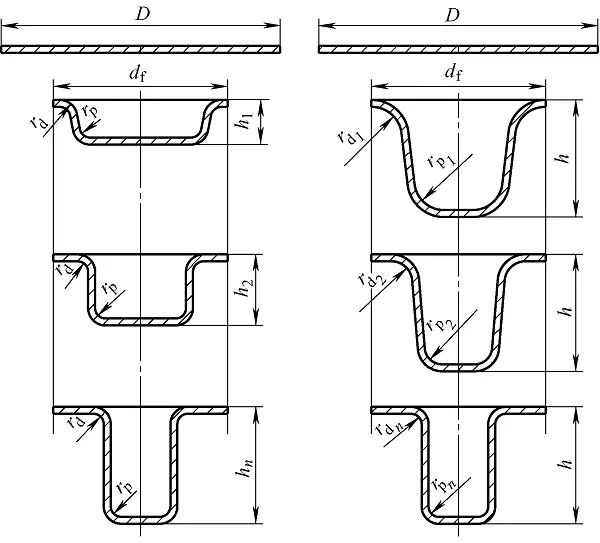

4) Determination of the size of the drawing process

1) Diameter of semi-finished product

From Tables 5-3 and 5-4, the limit drawing coefficient [mn] of each drawing is found, and it is appropriately enlarged and adjusted to obtain the actual drawing coefficient mn.

The principles of adjustment are:

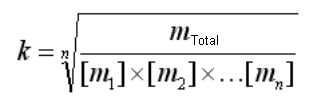

1)Ensure that mtotal=m1m2…mn=

2)Make m1<m2<…mn<1

Finally, calculate the diameter of each process according to the adjusted drawing coefficient:

d1=m1D;d2=m2d1;…;dn=mndn-1=d

Amplification factor k

When calculating the diameter of the semi-finished product according to the above method, it is necessary to repeatedly try to take the values of m1, m2, m3, …, mn, which is cumbersome. In fact, the limit drawing coefficient can be enlarged by an appropriate multiple k.

In the formula, n is the number of deep drawing.

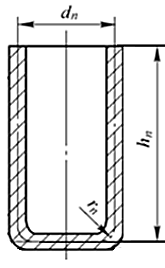

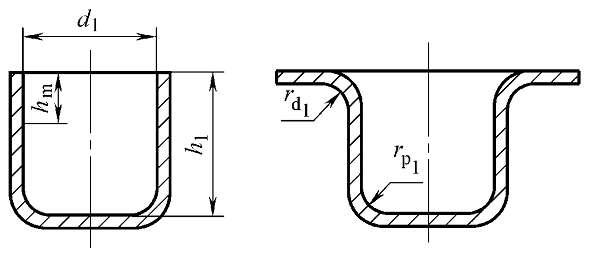

2) Round bottom corner radius rn

The fillet radius rn at the bottom of the cylinder is the fillet radius rp of the deep drawing die of this process.

The determination method is as follows:

In general, except for the deep drawing process, rpi = rdi is preferable.

For the last drawing process:

When the fillet radius of the workpiece r≥t , then rpn = r;

When the fillet radius of the workpiece is r <t, then rpn> t is taken. After the drawing is finished, r is obtained through the shaping process.

3) Calculation of process part height Hi

According to the principle that the surface area of the process parts after drawing is equal to the surface area of the billet, the following formula for calculating the height of the process parts can be obtained.

Before the calculation, the bottom corner radius of each work piece should be determined.

Hi is solved by the calculation formula of the blank diameter:

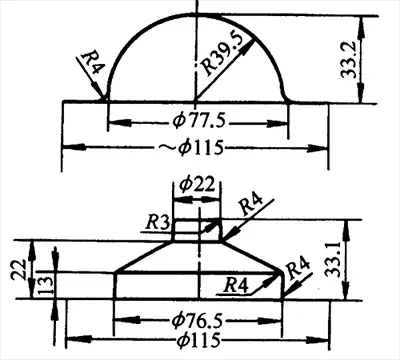

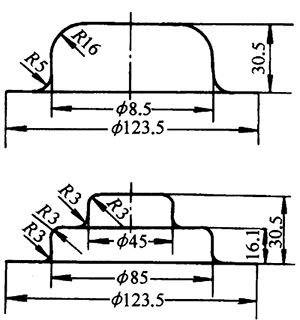

Deep drawing process calculation example

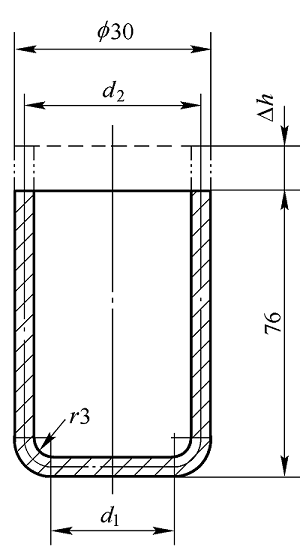

Example 4.1 Find the blank size of the cylindrical part shown in the figure and the dimensions of each drawing process. The material is 10 steel, and the sheet thickness is t = 2mm.

Solution:

Because t> 1mm, it is calculated according to the thickness and diameter of the plate.

(1) Calculate the diameter of the billet

According to the size of the part, its relative height is

Check the table 5-2 to get the cutting margin

Billet diameter is

Substitute the known conditions into the above formula to obtain D = 98.2mm, here D = 98mm

(2) Determine the number of deep drawing

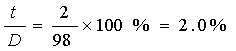

The relative thickness of the blank is:

According to Table 5-1, the blank holder ring can be used or not, but for insurance, the blank holder ring is still used for the first drawing.

Table: Using a binder ring (flat die cavity)

| Stretching Method | First stretch | Subsequent stretches | ||

| (t/D)×100 | m1 | (t/D)×100 | mn | |

| Using a Flanging Ring | <1.5 | <0.60 | <1 | <0.80 |

| Optional use of a flanging ring | 1.5~2.0 | 0.6 | 1~1.5 | 0.8 |

| Without a flanging ring | >2.0 | >0.60 | >1.5 | >0.80 |

According to t/D=2.0%, check the table 5-3 to get the ultimate drawing coefficient for each drawing process:[m1 ]=0.50,[m2 ]=0.75,[m3 ]=0.78,[m4 ]=0.80,…

Table: Limit drawing coefficient of blank holder for cylindrical parts (08, 10, 15Mn and H62)

| Corner radius | Relative thickness of sheet t/D*100 | |||||

| 2~15 | 1.5~1 | 1~0.6 | 0.6~0.3 | 0.3~0.15 | 0.15~0.08 | |

| m1 | 0.48~0.50 | 0.5~0.53 | 0.53~0.55 | 0.55~0.58 | 0.58~0.60 | 0.60~0.63 |

| m2 | 0.73~0.75 | 0.75~0.76 | 0.76~0.78 | 0.78~0.79 | 0.79~0.80 | 0.80~0.82 |

| m3 | 0.76~0.78 | 0.78~0.79 | 0.79~0.80 | 0.80~0.81 | 0.81~0.82 | 0.82~0.84 |

| m4 | 0.78~0.80 | 0.80~0.81 | 0.81~0.82 | 0.82~0.83 | 0.83~0.85 | 0.85~0.86 |

| m5 | 0.80~0.82 | 0.82~0.84 | 0.84~0.85 | 0.85~0.86 | 0.86~0.87 | 0.87~0.88 |

Therefore,

d1=[m1 ]D=0.50×98mm=49.0mm

d2= [m2 ]d1=0.75×49.0mm=36.8mm

d3= [m3 ]d2=0.78×36.8mm=28.7mm

d4= [m4 ]d3=0.8×28.7mm=23mm

At this time,

d4=23mm<28mm, so it should be drawn 4 times.

Table: The coefficient K1 value for the first draw of cylindrical parts (steel grades 08 to 15)

| Relative thickness(t/D0)×100 | First-time deep drawing coefficient (m1) | |||||||||

| 0.45 | 0.48 | 0.50 | 0.52 | 0.55 | 0.60 | 0.65 | 0.70 | 0.75 | 0.80 | |

| 5.0 | 0.95 | 0.85 | 0.75 | 0.65 | 0.60 | 0.50 | 0.43 | 0.35 | 0.28 | 0.20 |

| 2.0 | 1.10 | 1.00 | 0.90 | 0.80 | 0.75 | 0.60 | 0.50 | 0.42 | 0.35 | 0.25 |

| 1.2 | 1.10 | 1.00 | 0.90 | 0.80 | 0.68 | 0.56 | 0.47 | 0.37 | 0.30 | |

| 0.8 | 1.10 | 1.00 | 0.90 | 0.75 | 0.60 | 0.50 | 0.40 | 0.33 | ||

| 0.5 | 1.10 | 1.00 | 0.82 | 0.67 | 0.55 | 0.45 | 0.36 | |||

| 0.2 | 1.10 | 0.90 | 0.75 | 0.60 | 0.50 | 0.40 | ||||

| 0.1 | 1.10 | 0.90 | 0.75 | 0.60 | 0.50 | |||||

Table: The coefficient K1 value for the first draw of cylindrical parts (steel grades 08 to 15)

| Relative thickness(t/D0)×100 | Second-time deep drawing coefficient (m2) | |||||||||

| 0.7 | 0.72 | 0.75 | 0.78 | 0.80 | 0.82 | 0.85 | 0.88 | 0.90 | 0.92 | |

| 5.0 | 0.85 | 0.70 | 0.60 | 0.50 | 0.42 | 0.32 | 0.28 | 0.20 | 0.15 | 0.12 |

| 2.0 | 1.10 | 0.90 | 0.75 | 0.60 | 0.52 | 0.42 | 0.32 | 0.25 | 0.20 | 0.14 |

| 1.2 | 1.10 | 0.90 | 0.75 | 0.62 | 0.52 | 0.42 | 0.30 | 0.25 | 0.16 | |

| 0.8 | 1.00 | 0.82 | 0.70 | 0.57 | 0.46 | 0.35 | 0.27 | 0.18 | ||

| 0.5 | 1.10 | 0.90 | 0.76 | 0.63 | 0.50 | 0.40 | 0.30 | 0.20 | ||

| 0.2 | 1.00 | 0.85 | 0.70 | 0.56 | 0.44 | 0.33 | 0.23 | |||

| 0.1 | 1.10 | 1.00 | 0.82 | 0.68 | 0.55 | 0.40 | 0.30 | |||

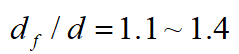

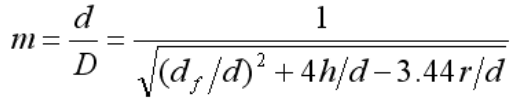

(3) Determination of the size of each drawing process

The diameter of each process part is

d1=k[m1 ]D=1.051185×0.50×98mm=51.51mm

d2=k[m2 ]d1=1.051185×0.75×51.51mm=40.61mm

d3=k[m3 ]d2=1.051185×0.78×40.61mm=33.30mm

d4=k[m4 ]d3=1.051185×0.80×33.30mm≈28mm

The radius of the fillet at the bottom of each process part takes the following values:

r1=8mm,r2=5mm,r3=4mm,r4=4mm

The height of each process part is ……

(4) Process part sketch

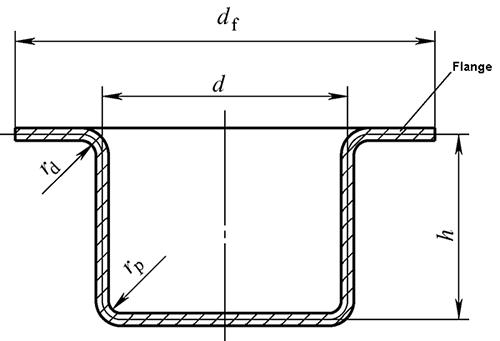

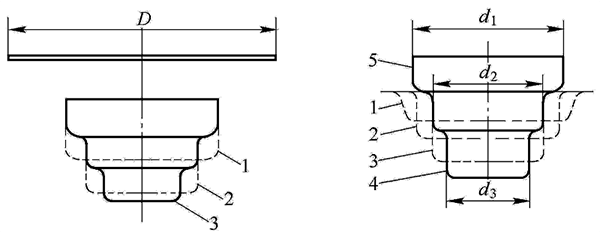

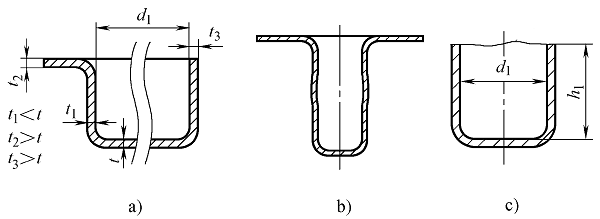

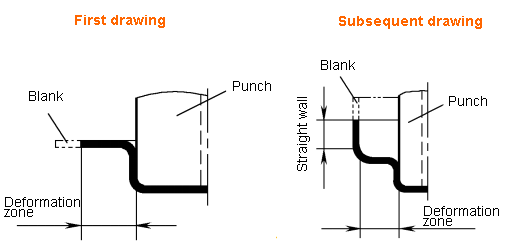

The flanged cylindrical part can be regarded as a semi-finished product when the flangeless cylindrical part is drawn to a certain point in the middle and stopped.

Same drawing as flangeless tube:

(1) Classification and deformation characteristics of flanged cylindrical parts

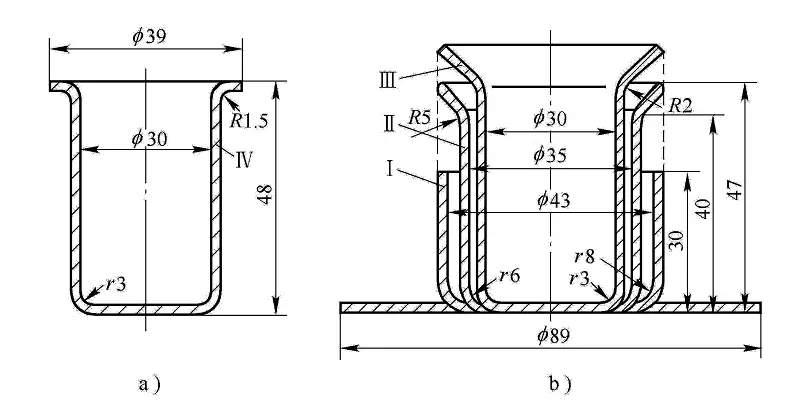

1) Narrow flange cylindrical parts

Narrow flange cylinder:

Drawing method and process calculation method are the same as those of flangeless cylindrical parts

2) Wide flange cylindrical parts

df/d>1.4

Drawing method and process calculation are different from flangeless cylindrical parts

(2) Deep drawing method of wide flange cylindrical part

df/d>1.4

Special reminder:

Regardless of the drawing method, the flange size must be obtained during the first drawing. The height of the punch entering the cavity must be strictly controlled.

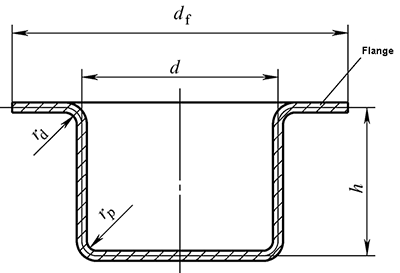

(3) Process calculation of wide flange cylindrical parts

1) Determination of the blank size of the wide flange

Blank unfolding: calculated according to the blank calculation method for flangeless cylindrical parts, that is, the blank surface area is calculated according to the principle of equal surface area.

When rp=rd=r,

df contains trim margin △df

2) Deformation of wide flanged cylindrical parts

The degree of deformation of wide flanged cylindrical parts cannot be measured only by the drawing coefficient

The number of drawing times is determined according to the drawing coefficient and the relative height of the parts.

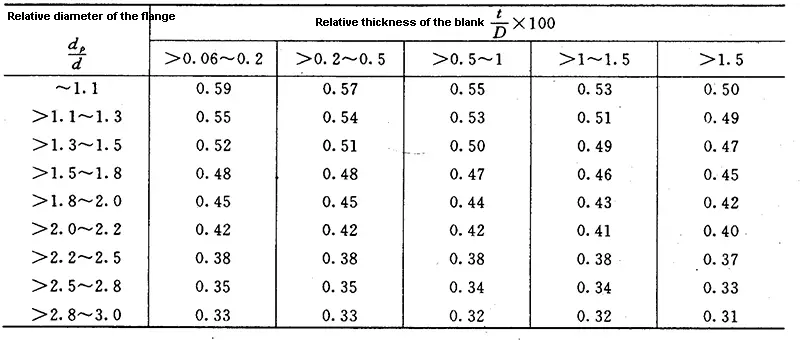

Table 5-7 First limit drawing coefficient of wide flange

(3) Judge whether it can be pulled at once

Judging from the drawing coefficient and relative height, find the total drawing coefficient m and the total relative height h/d, find out the limit drawing coefficient [m1] and relative height [h1/d1] that are allowed for the first time, and compare: mtotal> [m1], h/d≤[h1/d1], it can be pulled out at one time, otherwise multiple deep drawing is required.

(4) Determining the number of deep drawing: it can still be calculated by using the extrapolation algorithm.

(5) Determination of the size of the semi-finished product

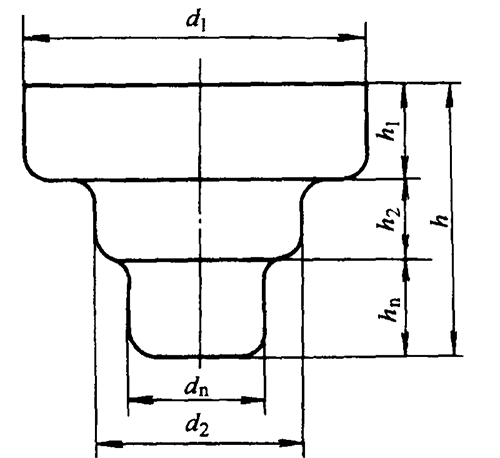

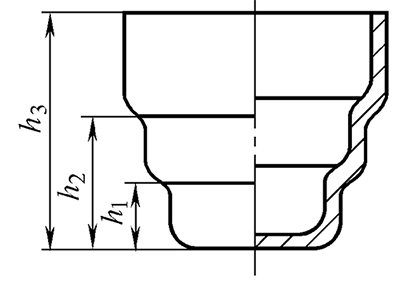

3.Deep drawing of stepped cylindrical parts

Deformation characteristics:

The deep drawing of the stepped part is basically the same as that of the cylindrical part, and each step is equivalent to the drawing of the corresponding cylindrical part.

(1) Judge whether it can be deep-drawn at one time

Judging by the ratio of the part height h to the minimum diameter dn.

If h/dn≤[h1/d1], it can be pulled out once, otherwise it can be drawn multiple times. [h1/d1] can be found in Table 5-5

Table: Maximum relative height h1/d1 of wide flange cylindrical parts for first stretching (08, 10 steel)

Unit:mm

| Relative diameter dconvex/d | Relative thickness of sheet t/D×100 | ||||

| <2~1.5 | <1.5~1.0 | <1.0~0.5 | <0.5~0.2 | <0.2~0.06 | |

| ≤1.1e | 0.75~0.90 | 0.65~0.82 | 0.50~0.70 | 0.50~0.62 | 0.45~0.52 |

| >1.1~1.3 | 0.65~0.80 | 0.56~0.72 | 0.45~0.60 | 0.45~0.52 | 0.40~0.47 |

| >1.3~1.5 | 0.58~0.70 | 0.50~0.63 | 0.42~0.54 | 0.40~0.48 | 0.35~0.42 |

| >1.5~1.8 | 0.48~0.58 | 0.42~0.53 | 0.37~0.44 | 0.34~0.39 | 0.29~0.35 |

| >1.8~2.0 | 0.42~0.51 | 0.36~0.46 | 0.32~0.38 | 0.29~0.34 | 0.25~0.30 |

| >2.0~2.2 | 0.35~0.45 | 0.31~0.40 | 0.27~0.33 | 0.25~0.29 | 0.22~0.26 |

| >2.2~2.5 | 0.28~0.35 | 0.25~0.32 | 0.22~0.27 | 0.20~0.25 | 0.17~0.21 |

| >2.5~2.8 | 0.22~0.27 | 0.19~0.24 | 0.17~0.21 | 0.15~0.18 | 0.13~0.16 |

| >2.8~3.0 | 0.18~0.22 | 0.16~0.20 | 0.14~0.17 | 0.12~0.15 | 0.10~0.13 |

Table: The maximum relative height (h/d) for flangeless cylindrical deep-drawn parts.

| Deep drawing time (n) | Relative thickness of the blank t/D×100 | |||||

| 2~1.5 | <1.5~1 | <1~0.6 | <0.6~0.3 | <0.3~0.15 | <0.15~0.08 | |

| 1 | 0.94~0.77 | 0.84~0.65 | 0.70~0.57 | 0.62~0.5 | 0.52~0.45 | 0.46~0.38 |

| 2 | 1.88~1.54 | 1.60~1.32 | 1.36~1.1 | 1.13~0.94 | 0.96~0.83 | 0.9~0.7 |

| 3 | 3.5~2.7 | 2.8~2.2 | 2.3~1.8 | 1.9~1.5 | 1.6~1.3 | 1.3~1.1 |

| 4 | 5.6~4.3 | 4.3~3.5 | 3.6~2.9 | 2.9~2.4 | 2.4~2.0 | 2.0~1.5 |

| 5 | 8.9~6.6 | 6.6~5.1 | 5.2~4.1 | 4.1~3.3 | 3.3~2.7 | 2.7~2.0 |

Note:

(2) Determination of deep drawing method for stepped pieces

1) When the ratio of the diameter of any two adjacent steps (dn/dn-1) is greater than the limit drawing coefficient of the corresponding cylindrical part, each step forms a step, from the large step to the small step the number of deep times is the number of steps.

2) If the ratio of the diameters of two adjacent steps (dn/dn-1) is less than the limit drawing coefficient of the corresponding cylindrical part, the drawing method is based on the wide flange part, which is drawn from the small step to the large step.

Drawing method of shallow stepped piece

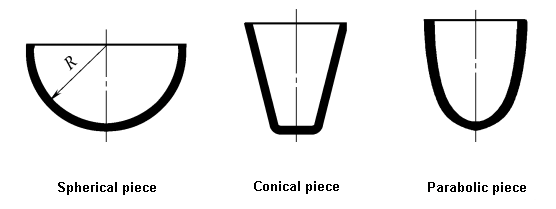

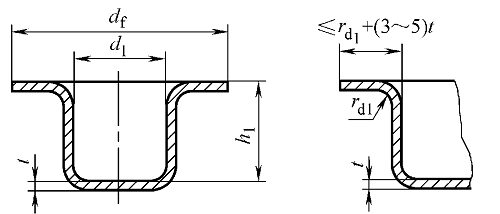

Deep drawing characteristics of non-straight wall rotating body parts:

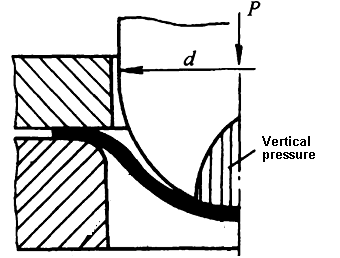

(1) When the non-straight wall rotating body part is deepened, the flange portion below the blank holder ring and the suspended portion in the die opening are deformation regions.

(2) The drawing process of non-straight wall rotating body parts is a combination of drawing deformation and bulging deformation.

(3) Bulging deformation is mainly located in the vicinity of the bottom of the punch die

Wrinkling has become a major problem to be solved in the drawing of such parts. Especially the wrinkling of the suspended part-the inner wrinkle

Measures to neither wrinkle nor break

The drawing coefficient is constant and cannot be used as a basis for process design.

m=0.707

Drawing method for spherical parts

Deep drawing is more difficult than spherical parts

Common drawing methods are:

(1) Shallow paraboloid (h/d <0.5 ~ 0.6). Because its height-to-diameter ratio is nearly spherical, the drawing method is the same as that of spherical parts.

(2) Deep paraboloid (h/d> 0.5 ~ 0.6). Its deepening difficulty has increased. At this time, in order to make the middle part of the blank close to the mold without wrinkling, a mold with deep drawing ribs is usually used to increase the radial tensile stress.

Deep drawing of deep paraboloids

Deepening method depends on:h/d2,α

Deep drawing method of cone

(1) For shallow conical pieces (h / d2 <0.25 ~ 0.30, α = 50 ° ~ 80 °), it can be drawn at one time

(2) For medium conical pieces (h / d2 = 0.30 ~ 0.70, α = 15 ° ~ 45 °), the drawing method depends on the relative material thickness:

1) When t / D> 0.025, the blanking ring can be used for one-time drawing.

2) When t / D = 0.015 ~ 0.20, it can be drawn at one time, but measures such as blank holder ring, deep drawing ribs and adding process flanges are required.

3) When t / D <0.015, it is easy to wrinkle because the material is thin. It is necessary to use a blank holder mold and draw it twice.

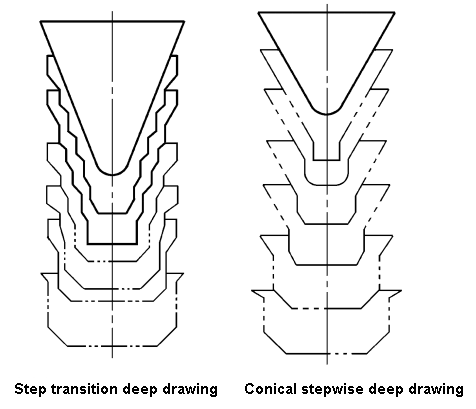

(3) For highly tapered parts (h / d2> 0.70 ~ 0.80, α≤10 ° ~ 30 °), adopt:

1) Step transition deep drawing method

2) Stepwise deep drawing of cone surface

Deep forming method of high-cone piece

The box-shaped part is a non-rotating body part. When deep drawing is deformed, the rounded part is equivalent to the deep drawing of cylindrical part, and the straight edge part is equivalent to bending deformation.

Before deformation:

Δl1=Δl2=Δl3

Δh1=Δh2=Δh3

After deformation:

Δh1<Δh1′<Δh2′<Δh3′

Δl1>Δl1′>Δl2′>Δl3′

Drawing features of box-shaped parts:

(1) The material in the flange deformation zone is subject to the combined effect of radial tensile stress and tangential compressive stress, resulting in radial deformation and tangential compression deep deformation. The distribution of stress and strain is uneven, with the rounded corners being the largest and the straight edges being the smallest.

(2) The amount of deformation of the straight edge and the fillet in the deformation area is different.

(3) The degree of mutual influence between the straight edge portion and the rounded corner portion varies with the shape of the box.

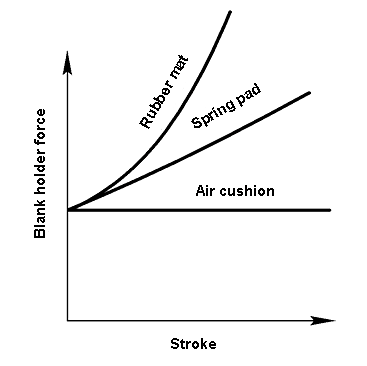

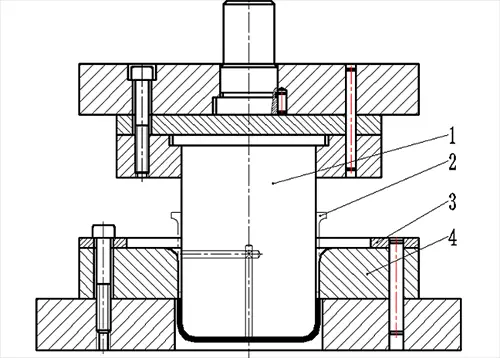

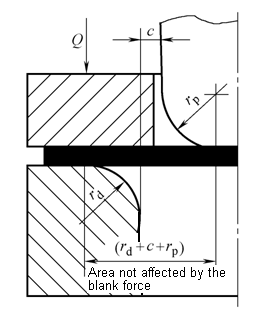

(1) Blank holding force

The blank holding force Q is provided by a blank holding device provided in a mold.

The blank holding force Q generated by the blank holder should be as small as possible on the premise of ensuring that the deformation area does not wrinkle.

The required blank holder force for deep drawing parts of any shape: Q = Aq

In the formula:

Blank holder force for straight wall cylindrical parts

Deep drawing of straight wall cylindrical parts for the first time:

Deep drawing of straight wall cylindrical parts in the subsequent process:

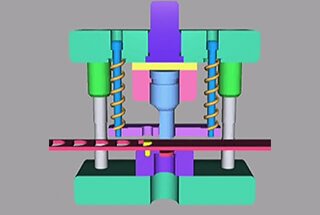

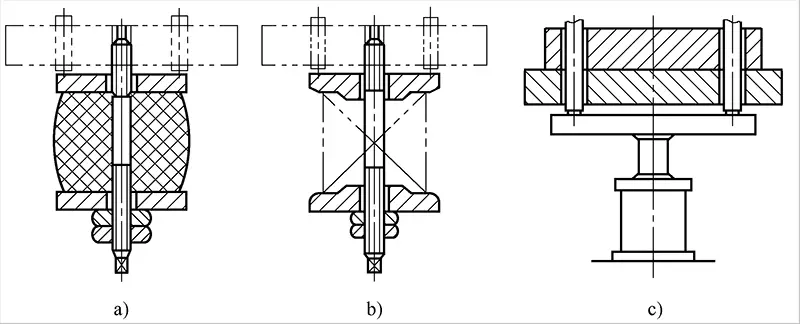

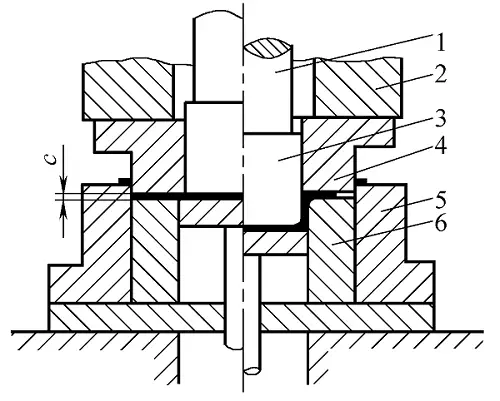

(2) Blank holder

The function of the blank holder is to prevent wrinkling in the deep deformation zone.

Depending on the source of the blank holder force, there are two types of blank holder devices:

Elastic blank holder

Application example of elastic blank holder

7–blank ring

Rigid blank holder on double action press

4–blank ring

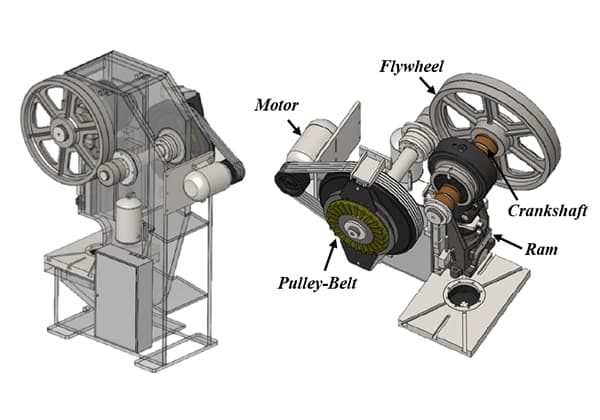

For cylindrical, elliptical, box-shaped parts, the drawing force is:

For single-acting presses, the nominal pressure of the equipment should meet:

FE > Fi + Q

For double-acting presses, the tonnage of the equipment should meet:

Finner > Fi

Fouter > Q

Pay attention:

When the drawing working stroke is large, especially when the blanking drawing is combined, the process force curve should be below the allowable pressure curve of the press slider.

In actual production, the nominal pressure Fpressure of the press can be determined by the following formula:

The processability of the drawn part refers to the adaptability of the drawn part to the drawing process.

The analysis of whether a deep-drawn part is suitable for deep drawing is mainly based on the structural shape, size, dimensioning, accuracy and material selection of the deep-drawn part, which is a requirement for product design from the perspective of product processing.

(1) The shape of the drawn part should be as simple and symmetrical as possible, and it should be drawn as soon as possible. Try to avoid sharp shape changes.

2) Shape error of the drawn part

The height dimension of the drawn parts should be reduced as much as possible, and drawn as far as possible.

Flange of flanged straight wall cylinder

The diameter should be controlled at:

d1 + 12t ≤ df ≤ d1+25t

Wide flange straight wall cylinder:

df ≤ 3d1, h1 ≤ 2d1

The flange width of the drawn part should be as consistent as possible and similar to the contour shape of the drawn part.

Rounded corners of bottoms and walls, flanges and walls of drawn parts

The radius should satisfy:

rp1 ≥ t, rd1 ≥ 2t, rc1 ≥ 3t

Otherwise, plastic surgery procedures should be added.

The hole in the drawing part is usually punched after the drawing is finished.

Ladder height dimensioning

Requires:

1) If it is a shallow drawn part that can be formed in one drawing, the blanking drawing composite process is used to complete it.

2) For high-drawing parts, single-step stamping can be used when the batch size is not large; when the batch size is large and the size of the deep-drawn parts is not large, progressive drawing with strip can be used.

3) If the size of the drawn part is large, usually only single-step stamping can be used.

4) When the drawing parts have higher accuracy requirements or need to draw a small fillet radius, it is necessary to add a shaping process after the drawing is finished.

5) The trimming and punching processes of deep-drawn parts can usually be completed in combination.

6) Except that the bottom hole of the drawing part may be compounded with blanking and drawing, the holes and grooves of the flange part and side wall part of the drawing part must be punched out after the drawing process is completed.

7) If other forming processes (such as bending, flipping, etc.) are required to complete the shape of the drawn part, other stamping processes must be performed after the drawing is finished.

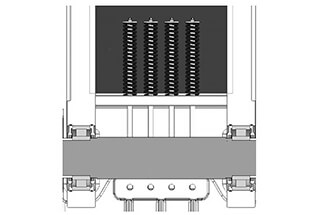

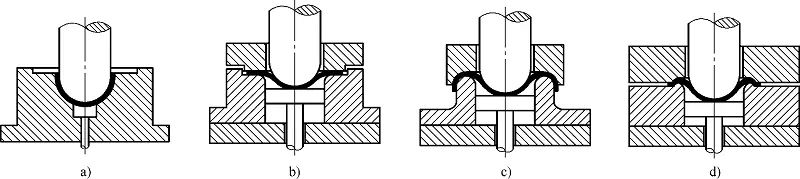

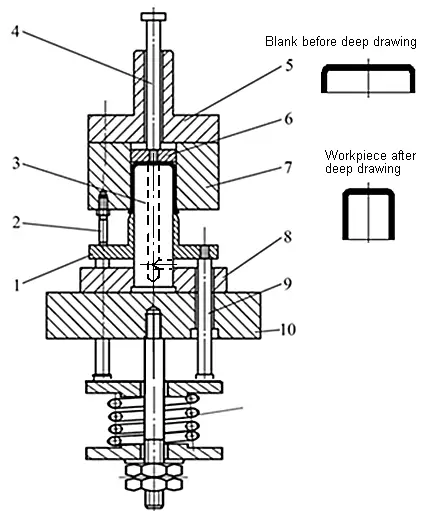

Features of subsequent deep drawing:

(1) Simple drawing die without blank holder

(2) Drawing die with blank holder

1) Formal drawing die

2) Inverted deep drawing die

(3) Blanking and drawing composite die

(4) Deep drawing die with rigid blank holder

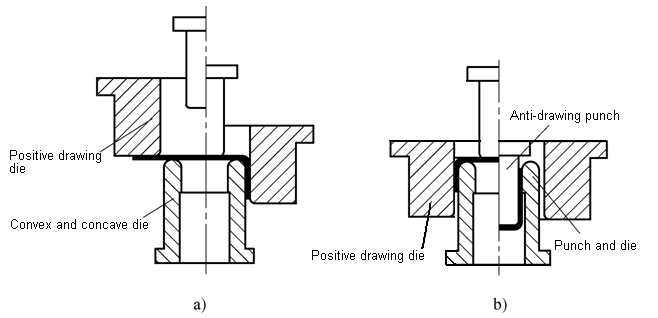

(1) Positive drawing die

1) No blank holder

2) With blank holder

(2) Reverse deep drawing die

1) No blank holder

2) The blank holder is on the upper die

3) The blank holder is in the lower die

Simple drawing die for the first time without blank holder

First formal drawing die with blank holder

First reverse deep drawing die with blank holder

Blanking and drawing composite die

First drawing die for double action press

(1) Positive drawing die

1) Each subsequent formal drawing die without blank holder

2) Subsequent inverted drawing die with blank holder

(2) Reverse deep drawing die

1) Reverse drawing die without blank holder

Double-action press forward and reverse drawing principle

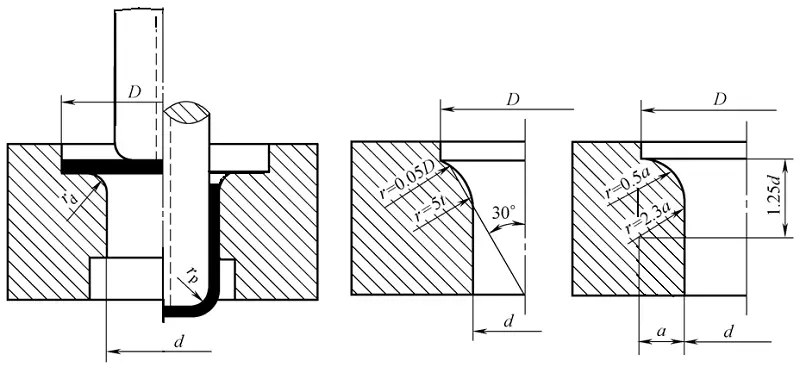

(1) One-time drawing of convex and concave die working structure without blank holder

Multi-drawing convex and concave die working part structure without blank holder

(2) Deep drawing convex and concave die working part structure with blank holder

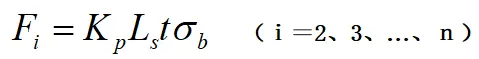

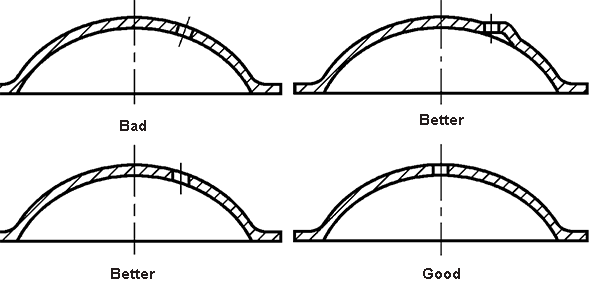

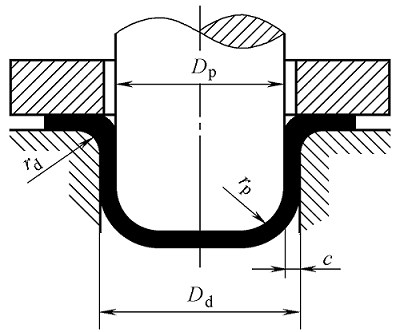

(1) Corner radius of convex and concave die

1) The influence of the fillet radius of the die:

Need to meet: rdi≥2t

2) Fillet radius rp

In the middle steps, take rpi equal rdi, that is: rpi = rdi

The last deep drawing:

Finally, the corner radius r of the workpiece is obtained.

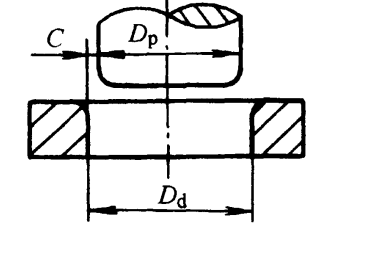

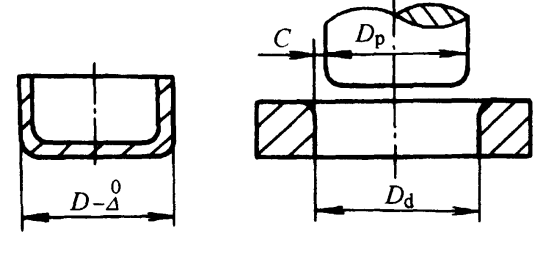

(2) Gap between convex and concave die c

Gap size affects:

C = tmax + Kct

(3) Lateral dimension of the working part of the convex and concave die

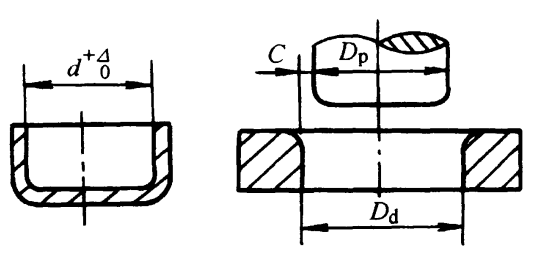

For the first and intermediate deep drawing in multiple deep drawing, it is preferable to:

For one deep drawing or the last deep drawing in multi deep drawing,