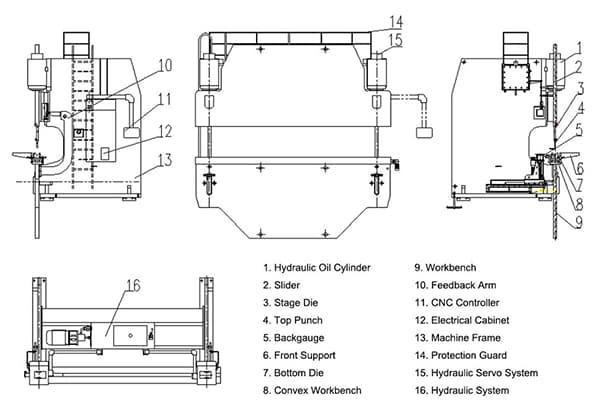

Have you ever wondered how to safely and efficiently operate a press brake machine? This article dives into the essential operating procedures every press brake operator should follow. From pre-operation inspections to the correct selection of bending dies and ensuring safety protocols, you’ll learn the key steps to prevent accidents and maintain machine performance. Understanding these guidelines will help you enhance workplace safety and improve operational efficiency.