In the vast world of manufacturing, one machine stands tall: the press brake. With its ability to bend and shape metal with precision and power, it has become an indispensable tool across industries. But what exactly is a press brake, and who are the top manufacturers driving innovation in this field? Join us as we dive into the fascinating world of press brakes, guided by the insights of seasoned experts in the field.

A few days ago, I had a chat with the sales of a machine tool manufacturing factory, a seasoned professional with over 20 years of experience in the field. He expressed his views on machine tool brands, with which I wholeheartedly agreed. Therefore, I wanted to share his words. Hopefully, it can bring a new perspective to those who are blindly pursuing brands.

In his own words, he said,

“When it comes to machine tools, don’t focus on the brand, but rather on whether the seller is honest and conscientious. Some people, for the sake of money, will sell you refurbished machines or substitute inferior products as superior ones. For instance, if you buy a branded computer for $10,000 or assemble a computer for the same amount, which do you think would be better? Which one would be more practical? What brand could you attribute to the assembled one? I’ve been assembling machine tools since 2004, from after-sales to current sales, and I’ve seen a lot of equipment. They’re indeed good, from workmanship to configuration, precision – I won’t deny that. The price will also surprise you! Nowadays, domestically produced machine tools are very mature. You can buy equipment with the same performance as branded and imported ones at less than half the price. So why pursue the brand? I believe that practicality is the most realistic pursuit. This is just my personal opinion, so if you find it incorrect, please forgive me!“

A press brake, also known as a brake press, is a machine tool used for bending and forming sheet metal and plate material. It is an essential piece of equipment in metalworking, fabrication, and manufacturing industries.

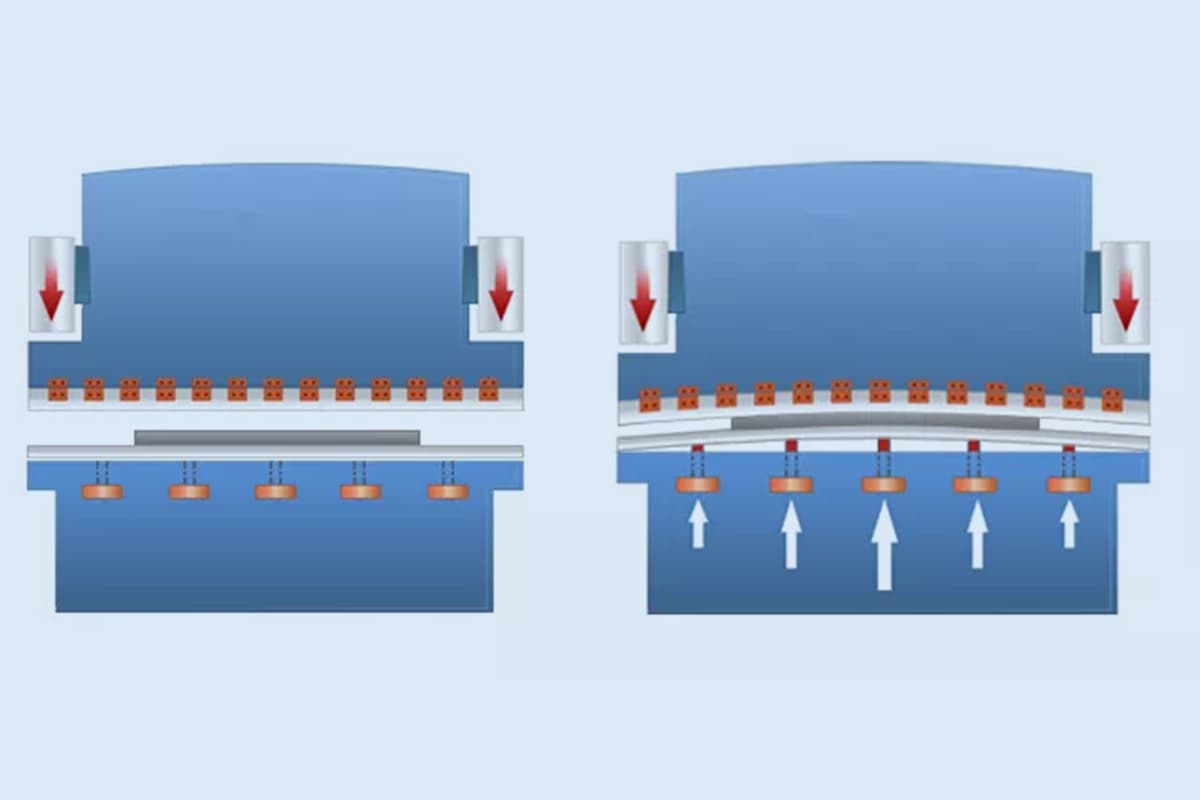

A typical press brake consists of a long bed with a stationary lower beam and a movable upper beam. The upper beam, called the ram, holds the punches while the lower beam has the corresponding dies secured in place. The workpiece, usually a sheet metal part, is placed between the punch and die.

During operation, hydraulic or mechanical force is applied to the ram, pushing the punch into the die. As the punch presses into the workpiece, it conforms to the shape of the die, creating the desired bend or form in the metal sheet. The angle and shape of the bend is determined by the design of the punch and die set being used.

Press brakes are highly versatile and can perform a variety of bending and forming operations, including:

Modern press brakes are often equipped with CNC (computer numerical control) systems for precise control of the bending process. The CNC controller allows operators to program the desired bend angles, bend sequences, and ram positions. This automation increases productivity, ensures consistency, and reduces setup times.

Press brakes come in a range of sizes and tonnages to accommodate different sheet metal thicknesses and part sizes. Typical press brake capacities range from 20 to 2,000 tons of bending force and bed lengths of 4 to over 20 feet.

In summary, a press brake is a critical machine tool for bending and shaping sheet metal components across metalworking industries. Its flexibility, precision, and power make it an indispensable asset for fabricating parts in sectors such as aerospace, automotive, construction, and general manufacturing.

Here are the main types of press brakes used in sheet metal fabrication:

Mechanical Press Brakes

Hydraulic Press Brakes

Pneumatic Press Brakes

Electric Servo Press Brakes

Hybrid Press Brakes

The choice of press brake type depends on factors like production volume, part complexity, material properties, speed and precision requirements, as well as budget considerations. Many modern press brakes incorporate CNC controls and can be highly automated for optimal performance in different bending applications.

The manufacturing of press brakes has seen significant advancements over the years with numerous companies establishing a strong presence in this specialized market. Press brakes are crucial in the metal fabrication industry, allowing for precise bending of sheet metal, and the selection of a press brake can significantly influence production quality and efficiency. Some manufacturers stand out for their long-standing tradition of innovation, quality, and service in this sector.

Top manufacturers in this field are characterized by their extensive experience, robust engineering practices, and commitment to technological development. For instance, Amada, originally established in 1946, has been a pioneer in fabricating sheet metal processing machinery, including press brakes. Another notable leader is Trumpf, with its inception dating back to 1923, recognized for its innovative high-tech solutions in machine tools, laser technology, and electronics. These companies have a proven track record and are esteemed for their contributions to advancements in manufacturing technology.

The industry benefits from a diversity of press brake manufacturers, each bringing forward unique strengths and specializations. The best manufacturers deliver a combination of reliability, advanced features, and responsive customer service, aligning with various business needs and operational demands. When evaluating the top players in the press brake domain, several other significant names are considered, underlined by continuous improvement and adaptability to the demands of the modern metalworking industry.

Please note that the list is arranged alphabetically and not by rank.

Amada, established in 1946, is a multinational company that specializes in the production of sheet metal processing machinery.

With a strong market presence, diverse product portfolio, high-performing products, and an effective management system, Amada has evolved into a publicly traded company that offers a comprehensive range of services, including product development, design, manufacturing, education and training, after-sales service, and marketing network.

AccurPress, founded in Canada in 1973, is a leading supplier of high-quality CNC machine tools in North America. They specialize in providing CNC bending and shearing machines and have six factories and one research and development center located in Canada, the United States, and China.

In 2003, AccurPress established a wholly-owned subsidiary in China to serve as a research and development, production, and service center for the Asia Pacific region. Since then, they have supplied over 6,000 high-quality machine tools to customers in the Asia Pacific region.

Bystronic, established in Switzerland in 1964, specializes in automating the entire material and data flow for cutting and bending processes.

Their offerings include laser cutting systems, press brakes, and related automation and software solutions, making them a complete solution provider for sheet metal processing.

Bystronic has sales and technical service subsidiaries in more than 30 locations globally.

Located on an 80-acre campus near Cincinnati, Ohio, they operate a modern 500,000-square-foot plant and technical center.

Their products, including laser cutting systems, automation, press brakes, shears, powder metal presses, and additive manufacturing, are engineered and built with the ruggedness required for the North American market.

As the leader in its sector in Turkey, Durma is a global manufacturer of metal sheet processing machinery with a team of 1,500 experts. They have a state-of-the-art production line spanning 150,000 square meters.

Durma exports to 120 countries through 80 distributors and partners, with 80% of their machinery being sold to industrialized countries such as the USA, EU, and Australia.

The remaining 20% is sold to companies in developing countries or to those partnering with foreign investors.

As a market leader in CNC bending/forming technology, LVD offers a comprehensive range of press brakes, ranging from economical manual and CNC options to multi-axis machines featuring LVD’s proprietary adaptive forming system and touchscreen control, as well as custom designs.

All of these press brakes are engineered to make programming easier, eliminate the need for trial bending, and deliver accurate and consistent results.

Prima Power is a division of the Prima Industrie Group, which is listed on the Milan Stock Exchange.

In 2017, the group celebrated 40 years of operating in the field of sheet metal working machinery.

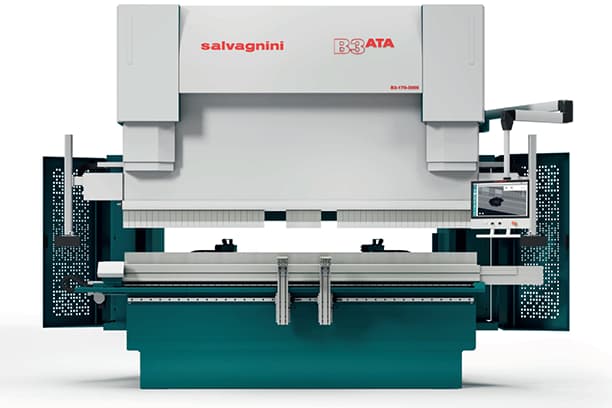

Flexible automation and process efficiency form the foundation of Salvagnini‘s product range.

These products offer intelligent, autonomous, and independent solutions that are easy to program and use.

They are automated and interconnected, communicating with each other and the surrounding environment to create a more streamlined production process for efficient and effective production of various pieces in sequence.

TruBend machines integrate a vast amount of expertise in press brake technology with pioneering innovations, allowing you to fabricate parts of any complexity with precision and cost-effectiveness.

They are particularly renowned for their versatility, exceptional finished part quality, and favorable cost-benefit ratio.

Ursviken provides power and productivity for heavy plate metal working, as well as ensuring efficiency, accuracy, flexibility, and high quality in working with lighter materials. All of their machines are designed to meet the demanding needs of their customers.

Here are some key considerations when selecting a press brake manufacturer to ensure you get a high-quality, reliable machine that meets your specific needs:

Experience and Reputation

Machine Quality and Capabilities

Technology and Innovation

Service and Support

Price and Value

By carefully evaluating press brake manufacturers on these key factors, you can select the right partner to provide a machine that will deliver high-quality bending output and reliable performance for years to come. Take the time to research and compare options to make an informed investment in your business.

Many people are curious about the world’s top CNC press brake manufacturers or the top 10 press brake manufacturers. However, few of them will choose the best press brake in the world because of its high cost. The high cost of a press brake does not necessarily indicate its quality. The high price is often due to factors such as high labor costs, steel prices, and component prices.

If you’re on a tight budget or looking for a cost-effective option, I recommend considering press brake manufacturers in China. Not only do they offer good quality, but they also offer competitive prices. This is due to China’s dominance in steel production, machine tool consumption, and machine tool manufacturing.

In fact, many well-known press brake brands are manufactured in China, either through their factories or OEM arrangements with Chinese manufacturers. Therefore, regardless of whether you purchase a press brake from Germany, Italy, or China, you will receive the same quality product.

However, purchasing from non-Chinese manufacturers or the so-called famous brand often comes with a higher price tag.

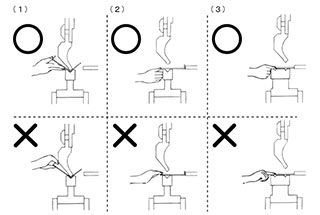

When choosing a press brake machine, there are several factors to consider, and this buying guide is meant to provide insight into making an informed decision.

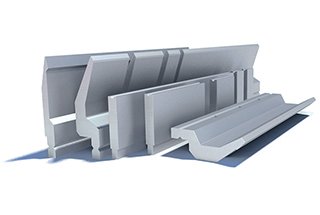

Additionally, the press brake dies guide can help you choose the right punches and dies for your sheet metal fabrication needs.