Why do CNC machine tools sometimes fail to deliver precise results? From tool wear to improper machine calibration, various factors can impact accuracy. This article dives into nine common issues affecting CNC precision and offers practical solutions to enhance performance. Whether you’re troubleshooting a specific problem or aiming to improve overall efficiency, you’ll find valuable insights to ensure your CNC operations run smoothly and accurately.

Causes of Failure:

Solutions:

Causes of Failure:

Solutions:

Cause of Failure:

Solution:

Cause of Failure:

Solution:

Cause of Failure:

Solutions:

Cause of Failure:

Solution:

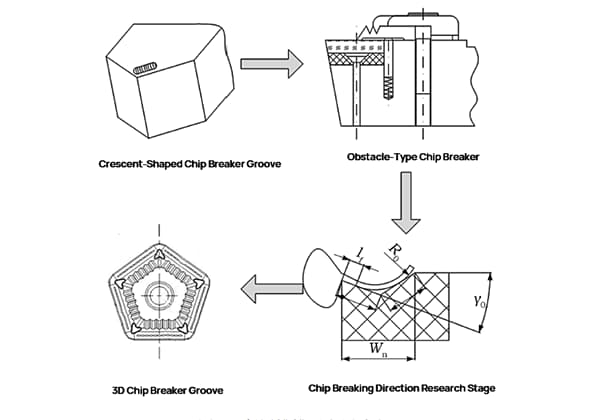

Cause of Failure:

The reason for the failure could be due to several factors, such as the reasonability of the program parameters, whether they are within the predetermined range, and if the programming format meets the requirements specified in the manual.

Solution:

In case of disordered teeth and incorrect pitch in the thread program section, it is likely to be related to the peripheral configuration (encoder) of the processing thread and the objective factors affecting its performance.

Cause of failure:

Solution:

Cause of Failure:

Solution: