Ever wondered why the same CNC machine can have wildly different production efficiencies? The secret lies in the fixtures! In this article, we’ll explore how choosing the right CNC fixtures can revolutionize small batch production, saving time and boosting efficiency. Get ready to learn practical tips that can transform your machining process!

Currently, machining can be categorized into two groups based on production batch:

Among these two categories, the first one accounts for about 70-80% of the total output value of machining and is the primary sector of machining.

Why does the production efficiency of the same CNC machine tool vary greatly?

The answer lies in the selection of an inappropriate fixture for the CNC machine tool, significantly reducing its production efficiency.

Today, we will provide a comprehensive overview of the reasonable selection and use of CNC fixtures.

The requirements for fixtures in CNC machining are twofold:

In addition, the following four points should be considered:

Technical analysis shows that the use of fixtures has a significant impact.

Statistics show that over 50% of domestic enterprises choose inappropriate fixtures for their CNC machine tools.

The cycle time for small batch production is comprised of the “production (preparation/waiting) time” and “workpiece processing time.” Since the “workpiece processing time” in small batch production is brief, the length of the “production (preparation/waiting) time” has a crucial impact on the overall processing cycle.

To improve production efficiency, it is necessary to find ways to shorten the “production (preparation/waiting) time.” The following three types of CNC machine tools and fixtures are recommended for priority use in small batch production:

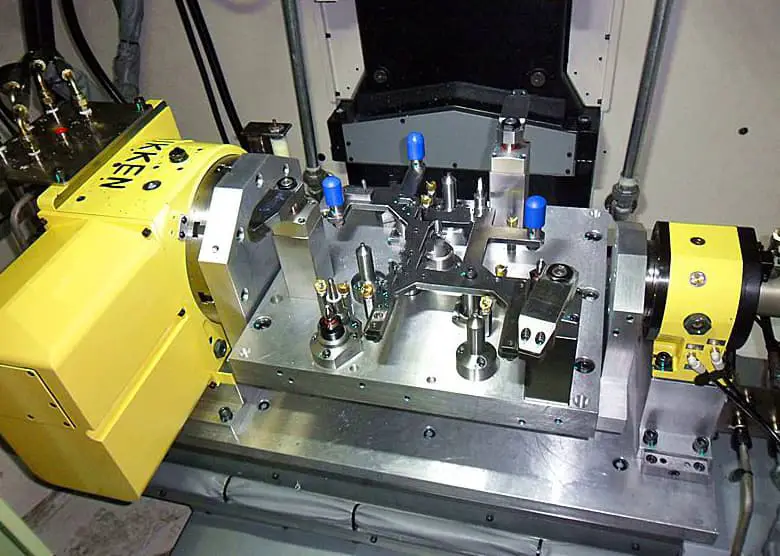

Modular fixtures, also known as “building block fixtures,” are comprised of a series of standardized machine tool fixture elements with different functions and sizes.

Customers can quickly assemble various types of machine tool fixtures as needed, similar to building blocks.

Since the modular fixture saves time in designing and manufacturing special fixtures, it significantly reduces production preparation time, thereby shortening the small batch production cycle and improving production efficiency.

Moreover, the combined fixture also has advantages such as high positioning accuracy, large clamping flexibility, recyclability, energy and material savings in manufacturing, and low cost of use.

Therefore, for small batch processing, especially for complex product shapes, the use of combined fixtures should be given priority.

Precision combination flat pliers are a type of component within the category of combined fixtures.

Compared to other components in combined fixtures, precision combination flat pliers are more versatile, standardized, user-friendly, and reliable in clamping.

As a result, they are widely used globally.

Precision combination flat pliers offer quick installation and clamping, which reduces production preparation time and improves efficiency in small batch production.

Currently, the commonly used clamping range for precision combination flat pliers globally is within 1000mm, and the clamping force is generally limited to 5000Kgf.

It’s important to note that precision combination flat pliers are not the same as traditional machine vises.

Traditional machine vises have limited functions, low manufacturing accuracy, cannot be used in groups, and have a short service life, making them unsuitable for use on CNC machine tools and machining centers.

In contrast, precision combination flat pliers are a new type of flat pliers originating from developed industrial countries like Europe and America, designed specifically for the requirements of CNC machine tools and machining centers.

These products have the benefits of large clamping flexibility, high positioning accuracy, fast clamping and the ability to be used in groups, making them ideal for use on CNC machine tools and machining centers.

The electric permanent magnet clamp is a new type of clamp that uses neodymium iron boron and other advanced permanent magnet materials as the source of magnetic force and is designed based on modern magnetic circuit principles. In practice, the use of electric permanent magnet clamps has been shown to significantly improve the overall efficiency of CNC machine tools and machining centers.

The clamping and release process of the permanent magnet clamp only takes about 1 second, greatly reducing clamping time. Additionally, the electric permanent magnet clamp does not have the positioning and clamping elements that take up space like traditional machine tool clamps, making the clamping range larger and allowing for better utilization of the CNC machine tool’s working table and processing stroke.

The suction force of the permanent magnet clamp is typically around 15 to 18 kgf/cm2, so it’s important to ensure that the suction force is sufficient to withstand the cutting force. The adsorption area should not be less than 30 cm2, meaning the clamping force should not be less than 450 kgf.

Machine tool fixtures can be broadly categorized into eight types:

Flat tongs are highly versatile and cost-effective, making them ideal for clamping square-shaped workpieces of a small size. The V-shaped groove or V-shaped block on the jaw also allows for clamping of cylindrical surfaces.

Features:

Flat tongs offer convenient clamping, quick and dependable operation, and precise positioning, making them suitable for a range of square parts, but not ideal for clamping thin plate parts. In CNC milling machines, flat tongs are often secured using mechanical screw, pneumatic, or hydraulic clamping methods, as shown in the figure. The commonly used types include:

(a) Screw-clamped Universal Flat Tongs;

(b) Hydraulic Sine Gauge Flat Tongs;

(c) Pneumatic Precision Flat Tongs;

(d) Hydraulic Precision Flat Tongs.

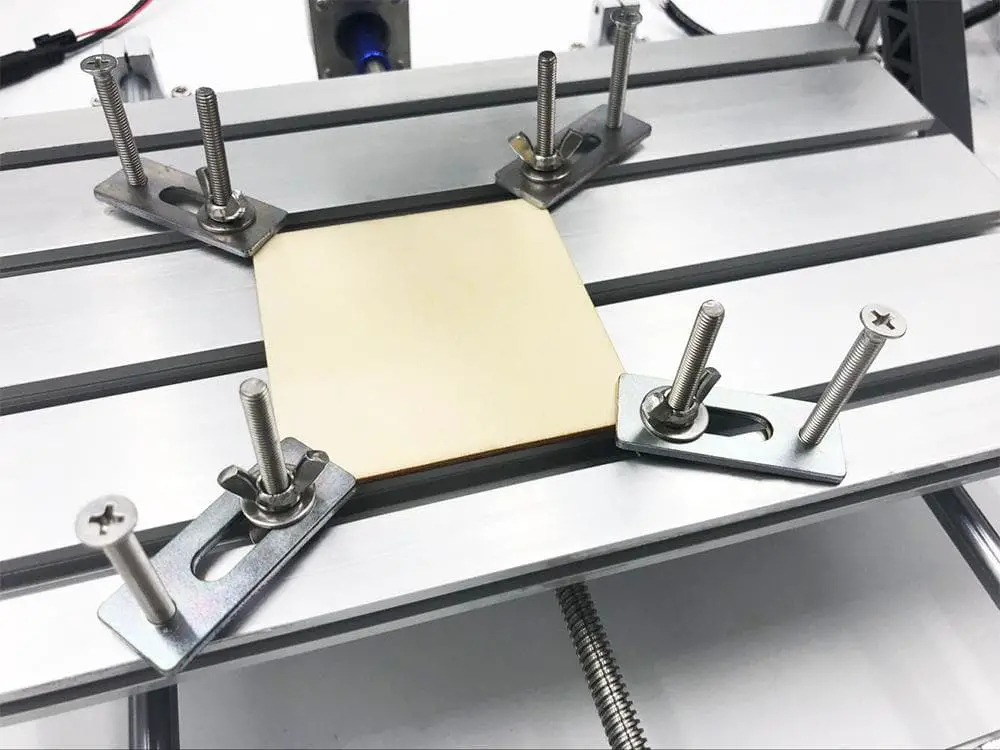

For larger or irregularly shaped workpieces that cannot be clamped using flat tongs or other clamps, pressing plates can be used for direct clamping, or the workpieces can be secured through process holes using bolts.

(a) Screw-clamped Universal Flat Tongs;

(b) Hydraulic Sine Gauge Flat Tongs;

(c) Pneumatic Precision Flat Tongs;

(d) Hydraulic Precision Flat Tongs.

Characteristic:

Clamping and aligning using pressing plates takes a significant amount of time, and the position and height of the pressing plate must be carefully considered in the machining programming to prevent interference with the cutting tool.

The bolt penetration method through process holes is space-saving and easy to implement, but the hole position must align with the position of the T-groove on the machine tool. If not, fabricating a backing plate for bolt penetration becomes a cumbersome task.

This method is most appropriate for specialized-shaped parts, large-sized parts, and workpieces that cannot be clamped by flat tongs.

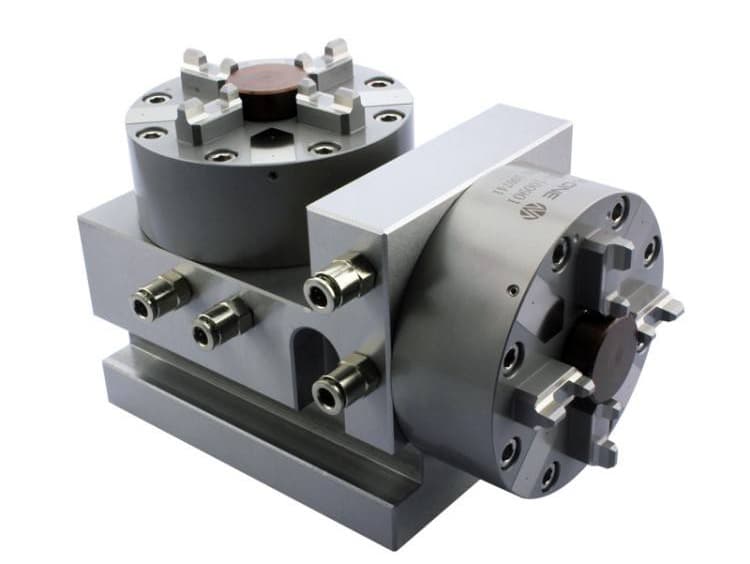

Chucks can be categorized into two-jaw chucks, three-jaw self-centering chucks, four-jaw chucks, and six-jaw chucks based on the number of jaws they possess.

Three-jaw self-centering single-action chucks and four-jaw chucks are widely used on CNC milling machines and machining centers. The three-jaw self-centering chuck is highly sought after due to its automatic centering and convenient clamping capabilities. As a result, when processing small to medium-sized cylindrical workpieces on a CNC milling machine or machining center, the three-jaw self-centering single-action chuck is frequently employed for clamping purposes.

Chucks can be secured using a variety of methods, including mechanical screw, pneumatic, hydraulic, and others.

The features of a chuck include convenient and dependable clamping, automatic centering, and suitability for cylindrical parts.

Characteristic:

The clamping of the chuck is both convenient and reliable, with a high degree of repeatable positioning accuracy. It is particularly suitable for the manufacture of die electrodes.

Features: easy and reliable clamping, wide application range, but the parts must be made of magnetic absorbing materials.

It is suitable for workpieces with large positioning plane or large sealable area.

Some CNC milling machines, such as wall plate milling machines, are equipped with a general vacuum platform for easy installation of workpieces. For workpieces with a regular shape, such as rectangular ones, special rubber strips can be inserted directly into the sealing groove of the fixture. These rubber strips come in either hollow or solid circular sections and must meet certain size requirements. Once the workpieces are placed on the surface, the vacuum pump can be started to securely clamp them in place.

However, for workpieces with an irregular shape, using rubber strips is not suitable. In this case, rubber putty, commonly known as putty, must be applied around the workpieces for sealing. This process is not only time-consuming and inefficient, but also tedious.

To overcome this challenge, a special transition vacuum platform can be used, which can be placed on top of the general vacuum platform.

When processing mechanical parts such as splines, clutches, gears, and others on a machining center, the dividing plate method is often used to divide each tooth slot equally and produce high-quality parts. This method ensures that each part is processed accurately and consistently.

For small to medium batches of workpieces, combined fixtures can be used for clamping during processing on a machining center. However, when processing large quantities of workpieces, special or group fixtures are commonly used for clamping.

It is worth noting that the machining center is more suitable for processing single or small batches of workpieces, and thus the use of special or group fixtures is less common in CNC machine tools.

Figure 10-8 illustrates a fixture used for drilling on a sleeve. Despite the variety in their purposes, types, and structures, machine tool fixtures are composed of the following fundamental elements.

a) Back Cover Part Diagram

b) Drill Jig for Hole Drilling

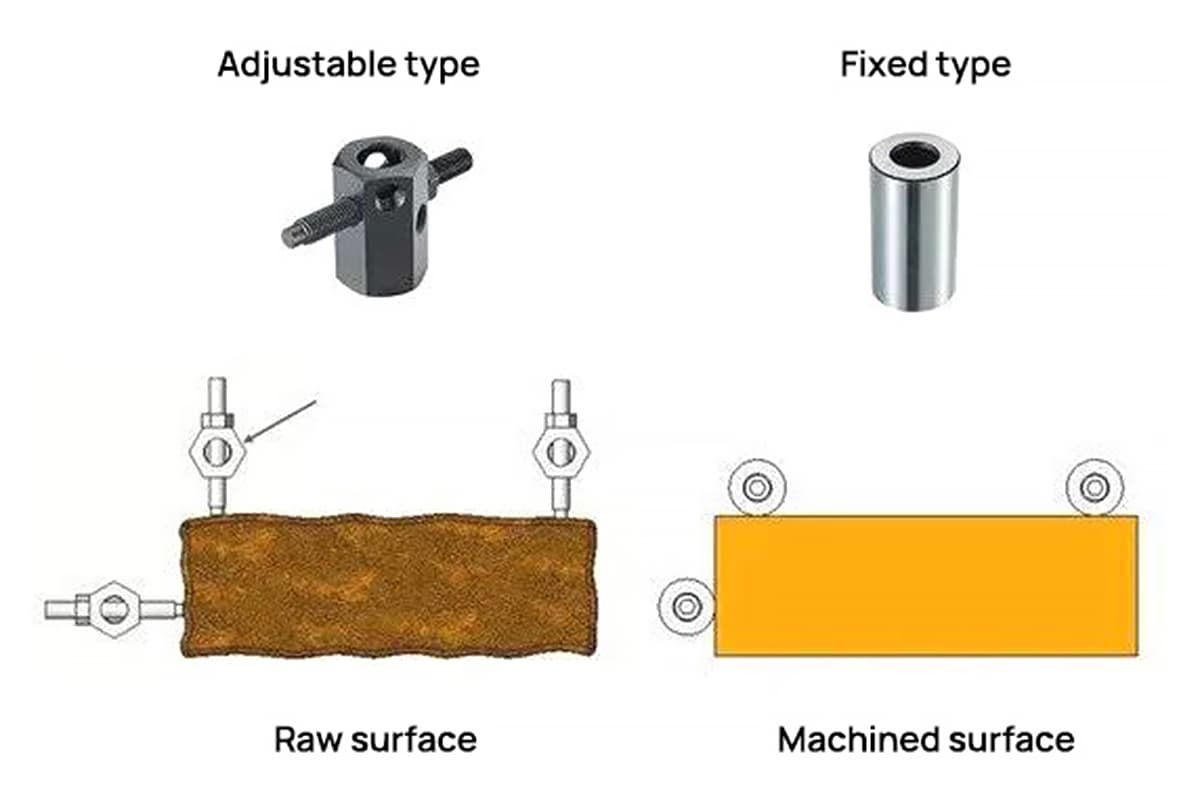

These are various components used to establish the correct position of the workpiece within the fixture. When the workpiece is positioned by a plane, support pins or plates serve as the locating elements (Figure 10-9).

a) Support Pin

b) Support Plate

There are three forms of support pins: flat-headed ones for positioning machined surfaces, ball-headed ones for positioning rough blank surfaces, and threaded ones to increase friction but are not suitable for chip removal, primarily used for side positioning. When the workpiece is positioned by an external cylindrical surface, V-blocks and locating sleeves serve as the locating elements (Figure 10-10).

a) V-block

b) Locating Sleeve

When the workpiece is positioned by a hole, locating spindles and pins serve as the locating elements (Figure 10-11). In Figure 10-8, the cylindrical pin, diamond pin, and support plate in the fixture for drilling a 10mm radial hole in the back cover are all locating elements, which ensure the workpiece occupies the correct position in the fixture.

a) Locating Center Pin

b) Locating Pin

Clamping devices are used to maintain the correct position of the workpiece in the fixture, ensuring that the position is not compromised when the workpiece is subjected to external forces (such as cutting force, gravity, inertia) during the machining process. As shown in Figure 10-8, the open washer in the drill fixture is a clamping element, which together with the screw and nut, forms the clamping device.

These are used to determine the correct position of the tool relative to the fixture and guide the tool during machining. Among them, tool setting elements are parts in the fixture that set the tool, such as the tool setting block and feeler gauge on the milling machine fixture. Guiding elements are parts in the fixture that set the tool and guide the tool. The drill bushing in the drill fixture shown in Figure 10-8 is a guiding element.

This is the base of the machine tool fixture, used to connect various elements or devices on the fixture into a whole, and through which the fixture is installed on the machine tool. In Figure 10-8, the fixture body of the drill fixture connects all elements of the fixture into a whole.

These are components that determine the correct position of the fixture on the machine tool, such as positioning keys, pins, and fastening bolts.

Depending on the requirements of the workpiece, indexing mechanisms, loading and unloading devices, workpiece ejecting devices (or tool clearing devices) may sometimes be equipped on the fixture.

The batch processing cycle is composed of three parts: processing waiting time, workpiece processing time, and production preparation time. The processing waiting time primarily includes the time for clamping the workpiece and changing tools.

In traditional manual machine tools, the workpiece clamping time can take up to 10-30% of the mass processing cycle. As a result, workpiece clamping has become a crucial factor in determining production efficiency, and is therefore a key target for improving the performance of the machine tool fixture.

To improve production efficiency during mass processing, special fixtures designed for quick positioning and rapid clamping (and loosening) should be used. The following three types of machine tool fixtures are recommended:

The hydraulic/pneumatic clamp is a specialized clamp that uses either oil pressure or air pressure as its power source. This type of fixture uses hydraulic or pneumatic elements to achieve precise positioning, support, and pressure on the workpiece.

One of the advantages of the hydraulic/pneumatic fixture is its ability to quickly and accurately determine the position of the workpiece, machine tool, and tool relative to each other.

The use of a hydraulic/pneumatic fixture ensures the accurate positioning of the workpiece, leading to high machining accuracy. Additionally, the rapid positioning and clamping process significantly reduces the time required for clamping and releasing the workpiece.

These fixtures also have the advantage of a compact design, multi-station clamping capabilities, high-speed heavy cutting, and automatic control. These attributes make hydraulic/pneumatic fixtures particularly suitable for use in CNC machine tools, machining centers, and flexible production lines, especially for mass processing.

The electric permanent magnet fixture offers a number of benefits, including fast clamping, ease of multi-station clamping, the ability to perform multi-faceted processing with one clamping, stable and reliable clamping, energy efficiency and environmental friendliness, and automatic control.

Compared to traditional machine tool fixtures, the electric permanent magnet fixture significantly reduces clamping time, reduces the number of clamping operations, and enhances clamping efficiency.

These advantages make the electric permanent magnet fixture suitable for both small and large batch production, making it a versatile option for various manufacturing needs.

Smooth fixture base is not commonly used in China, but it is widely utilized in industrialized countries like Europe and America. This type of fixture is made from a fine blank of the fixture base that has undergone finishing processing.

The positioning connecting portion between the components, machine tool, and the positioning surface of the parts on the fixture have already been completed and finished. This results in a smooth and polished fixture base that is ready for use.

Users have the ability to manufacture custom fixtures to meet their specific needs. The smooth surface of the fixture base enables a shorter cycle for manufacturing these special fixtures and reduces the production preparation time. This, in turn, shortens the overall cycle of mass production and increases production efficiency.

Moreover, the cost of producing a professional fixture can be reduced with the use of a smooth fixture base.

Therefore, this type of fixture base is particularly suitable for large-scale production with tight schedules and deadlines.

Experience has shown that to improve the efficiency of CNC machine tools, it is not enough to simply choose the right CNC machine tools and fixtures, but it is also important to effectively utilize them. Here are three common methods to achieve this:

The multi-station method is based on the idea of reducing the unit clamping time and increasing the effective cutting time of the tool by clamping multiple workpieces at once.

A multi-station fixture is a fixture with multiple positioning and clamping positions. With the advancement of CNC machine tools and the demand for increased production efficiency, the use of multi-station fixtures has become more widespread.

In the design of hydraulic/pneumatic clamps, combination clamps, electro-permanent magnet clamps, and precision combination flat clamps, the inclusion of a multi-station design is becoming more common. This design allows for greater efficiency and productivity in mass production processes.

One method to achieve multi-station clamping is to place multiple clamps on a single workbench. The fixtures used in this approach should be designed with standardization and precision in mind to ensure they meet the requirements for processing on a CNC machine.

This group clamping method maximizes the travel range of the CNC machine tool, resulting in balanced wear of its transmission components. Additionally, the fixtures can be used separately to clamp multiple parts or together to clamp larger workpieces, providing versatility and increasing production efficiency to meet the diverse needs of various production processes.

The local quick change method involves rapidly altering the function or mode of the fixture by quickly replacing parts of the fixture, such as the positioning element, clamping element, tool setting element, and guide element, on the CNC machine tool.

For instance, quick change combined flat jaw pliers can quickly change their clamping function by replacing the jaws, for example, from clamping square materials to clamping bar materials. Similarly, the clamping mode can be changed quickly by replacing the clamping element, for example, from manual to hydraulic clamping.

The local quick change method significantly reduces the time needed for fixture replacement and adjustment and is especially beneficial for small batch production.

Fixtures are an essential component of a CNC machining center. Every CNC machining center requires the use of fixtures, which vary depending on the product being processed. However, despite the differences in fixtures used, the requirements for fixtures in CNC machining centers are similar, with some variations for fixtures used for special workpieces.

What are the requirements of a CNC machining center for fixtures?

It is widely known that CNC machining centers possess exceptional accuracy and are commonly used for processing parts or molds that require high precision.

As a result, CNC machining centers have stringent requirements for the precision of fixture positioning devices and for the accuracy of indexing and positioning.

To fulfill the needs of high-speed machining fixtures in CNC machining centers, hydraulic and pneumatic quick locking forces are often selected, particularly for locking workpieces during extended processing times.

Typically, the hydraulic clamping system is equipped with a reservoir, which compensates for internal leakage and prevents the workpieces from becoming loose on the fixture.

The CNC machining center processes the workpiece through tool-to-workpiece contact, and the workpiece must be securely clamped by the fixture to provide ample operating space for the fast-moving tool and quick tool changes.

For workpieces with complex machining and multiple tool changes, the fixture’s structure should be simple, easy to use, and open to facilitate tool entry and exit and prevent collisions between the tool and workpiece during machining movements.

It is well known that the CNC machining center experiences mobility and multi-deformation during machining, thus it is essential that the fixture be highly adaptable to different workpieces and clamping requirements.