Discover the secret language that brings machines to life! In this captivating blog post, we’ll dive into the fascinating world of G-code and M-code, the essential programming commands that power CNC machining. Whether you’re a seasoned engineer or a curious learner, join us as we unravel the mysteries behind these codes and explore how they enable machines to perform complex tasks with unparalleled precision. Get ready to be amazed by the incredible potential of CNC programming!

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools.

G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool. These codes instruct the machine on how to move, such as rapid motion (G00), linear interpolation (G01), and circular interpolation (G02 and G03), among others.

On the other hand, M-code, also known as “miscellaneous code,” controls various functions of the machine tool, such as spindle rotation, coolant flow adjustment, and tool change. Each G and M code is usually followed by a number representing a specific function or command.

The existence of G-codes and M-codes enables CNC machine tools to perform complex machining tasks. By precise programming instructions, they control the actions of the machine tool, resulting in high precision and high-quality machining effects.

Different combinations of G and M codes can complete various machining operations, including but not limited to drilling, milling, and turning. However, it’s important to note that different manufacturers’ CNC systems may have variations in the specific meanings and applications of these codes. Therefore, reference to the specific machine tool’s operating manual or consultation with the manufacturer is necessary to ensure correct application.

In summary, G-codes and M-codes are indispensable parts of CNC machining. Together, they form the programming language of CNC machine tools, making the mechanical machining process more flexible and efficient. Mastery of these codes’ meanings and applications is crucial for CNC programmers.

G-code (also known as RS-274) is the most widely used numerical control (NC) programming language in computer-aided manufacturing (CAM). It serves as a standardized set of instructions for controlling automated machine tools, including CNC mills, lathes, 3D printers, and other computer-controlled manufacturing equipment.

Developed in the 1950s by the Electronic Industries Alliance (EIA), G-code has evolved through various versions and implementations. Despite its name, G-code encompasses not only “G” commands (preparatory functions) but also “M” codes (miscellaneous functions), coordinate values, and other parameters that collectively form a comprehensive machine control language.

Key features and applications of G-code include:

G-code instructions typically follow a structured format, with each line representing a single command or set of parameters. For example:

G01 X100 Y50 F500

This instruction directs the machine to move linearly (G01) to the X-coordinate of 100mm and Y-coordinate of 50mm at a feed rate of 500mm/minute.

While G-code remains the industry standard, modern CAM software often generates G-code automatically from 3D models and toolpath strategies, simplifying the programming process for complex parts. However, understanding G-code fundamentals remains crucial for optimizing machining processes, troubleshooting, and fine-tuning automated manufacturing operations.

M-code, short for Miscellaneous code, is a crucial component of CNC (Computer Numerical Control) programming, specifically defined as an auxiliary function code in FANUC and other control systems. These codes play a vital role in controlling various non-axis movement functions of the machine tool, complementing G-codes which primarily handle motion and cutting operations.

M-codes are used to command auxiliary operations that are essential for the overall machining process but do not directly involve the movement of cutting tools or workpiece positioning. These functions can include:

The implementation and specific functions of M-codes can vary slightly between different machine manufacturers and control systems, although many standard codes are widely recognized across platforms. Proper use of M-codes is essential for efficient and safe operation of CNC machines, allowing for precise control over various machine functions throughout the manufacturing process.

| G-code | Explain |

| G00 | Positioning (fast moving) |

| G01 | Linear cutting |

| G02 | Clockwise arc cutting (CW, clockwise) |

| G03 | Counterclockwise tangential positioning (fast moving) arc (CCW, counter clock) |

| G04 | Pause (dwel1) |

| G09 | Stop at the exact position |

| G20 | Imperial input |

| G21 | Metric input |

| G22 | Internal travel effective limit |

| G23 | Invalid internal travel limit |

| G27 | Check reference point return |

| G28 | Reference point return |

| G29 | Return from reference point |

| G30 | Return to the second reference point |

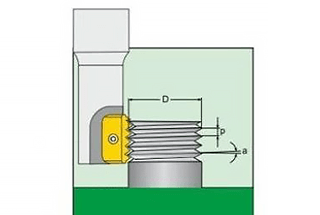

| G32 | Thread cutting |

| G40 | Cancel tool tip radius offset |

| G41 | Nose radius offset (left) |

| G42 | Nose radius offset (right) |

| G50 | Modify workpiece coordinates; Sets the maximum rpm of the spindle |

| G52 | Set local coordinate system |

| G53 | Select machine coordinate system |

| G70 | Finishing cycle |

| G71 | Internal and external diameter rough cutting cycle |

| G72 | Step rough cutting cycle |

| G73 | Forming repeat cycle |

| G74 | Z-step drilling |

| G75 | X-direction grooving |

| G76 | Thread cutting cycle |

| G80 | Cancel fixed cycle |

| G83 | Drilling cycle |

| G84 | Tapping cycle |

| G85 | Front boring cycle |

| G87 | Side drilling cycle |

| G88 | Side tapping cycle |

| G89 | Side boring cycle |

| G90 | (inside and outside diameter) cutting cycle |

| G92 | Thread cutting cycle |

| G94 | (step) cutting cycle |

| G96 | Constant linear speed control |

| G97 | Constant linear speed control cancelled |

| G98 | Feed rate per minute |

| G99 | Feed rate per revolution |

| G code | Explain |

| G00 | Top position (rapid movement) positioning (rapid movement) |

| G01 | Linear cutting |

| G02 | Clockwise circular arc |

| G03 | Counterclockwise tangent arc |

| G04 | Suspend |

| G15/G16 | Polar command |

| G17 | XY face assignment |

| G18 | XZ face assignment |

| G19 | YZ face assignment |

| G28 | Machine return to origin |

| G30 | The machine returns to the 2nd and 3rd origin |

| *G40 | Cancel tool diameter offset |

| G41 | Tool diameter left offset |

| G42 | Tool diameter right offset |

| *G43 | Tool length + direction offset |

| *G44 | Tool length offset in one direction |

| G49 | Cancel tool length offset |

| *G53 | Machine coordinate system selection |

| G54 | Workpiece coordinate system 1 Selection |

| G55 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection |

| G57 | Workpiece coordinate system 4 selection |

| G58 | Workpiece coordinate system 5 Selection |

| G59 | Workpiece coordinate system 6 selection |

| G73 | High speed deep hole drilling cycle |

| G74 | Left spiral cutting cycle |

| G76 | Fine boring cycle |

| *G80 | Cancel fixed cycle |

| G81 | Center drilling cycle reverse boring cycle |

| G82 | Reverse boring cycle |

| G83 | Deep hole drilling cycle |

| G84 | Right spiral cutting cycle |

| G85 | Boring cycle |

| G86 | Boring cycle |

| G87 | Reverse boring cycle |

| G88 | Boring cycle |

| G89 | Boring cycle |

| *G90 | Use absolute value command |

| G91 | Use incremental value command |

| G92 | Set workpiece coordinate system |

| *G98 | Fixed cycle return to starting point |

| M-code | Explain |

| M00 | Program stop |

| M01 | Select Stop |

| M02 | Program end (reset) |

| M03 | Spindle forward rotation (CW) |

| M04 | Spindle reversal (CCW) |

| M05 | Spindle stop |

| M06 | Change knife |

| M08 | Cutting fluid on |

| M09 | Cutting fluid off |

| M30 | Return to the beginning of the program (reset) and end |

| M48 | Cancel spindle overload does not work |

| M49 | Spindle overload cancellation function |

| M94 | Image cancellation |

| M95 | X-coordinate mirror image |

| M96 | Y-coordinate mirror image |

| M98 | Subroutine call |

| M99 | End of subroutine |

| Address | Explain |

| D | Tool complement number |

| F | Feed rate (dwell time can be programmed with G4) |

| G | G function (prepare function word) |

| GO | Fast move |

| G1 | Linear interpolation |

| G2 | Clockwise circular interpolation |

| G3 | Counterclockwise circular interpolation |

| CIP | Middle point arc interpolation |

| G33 | Thread cutting with constant pitch |

| G331 | Cutting internal thread without compensation fixture |

| G332 | Cutting internal thread without compensation fixture. Retract knife |

| CT | Transition arc interpolation with tangent |

| G4 | Fast move |

| G63 | Fast move |

| G74 | Back to the reference point |

| G75 | Fixed point |

| G25 | Lower limit of spindle speed |

| G26 | Upper limit of spindle speed |

| G110 | Pole size, relative to the last programmed set position |

| G110 | Pole size, relative to the zero point of the current workpiece coordinate system |

| G120 | Pole size, relative to the last valid pole |

| G17* | X / Y plane |

| G18 | Z / X plane |

| G19 | Y / Z plane |

| G40 | Cancellation of tool tip radius compensation |

| G41 | The tool tip radius compensation is called, and the tool moves on the left side of the contour |

| G42 | The tool tip radius compensation is called, and the tool moves on the right side of the contour |

| G500 | Cancel settable zero offset |

| G54 | First settable zero offset |

| G55 | Second, the zero offset can be set |

| G56 | Third, the zero offset can be set |

| G57 | Fourth, the zero offset can be set |

| G58 | Fifth, the zero offset can be set |

| G59 | Sixth, the zero offset can be set |

| G53 | Cancel by program segment to set zero offset |

| G60* | Accurate positioning |

| G70 | Inch size |

| G71* | Metric size |

| G700 | Inch size, also used for feed rate F |

| G710 | Metric size, also used for feed rate F |

| G90* | Absolute size |

| G91 | Incremental size |

| G94* | Feed rate F in mm / min |

| G95 | Spindle feed rate F, in mm / revolution |

| G901 | Feed compensation “on” in arc segment |

| G900 | Feed compensation “off” |

| G450 | Arc transition |

| G451 | Intersection of equidistant lines |

| I | Interpolation parameters |

| J | Interpolation parameters |

| K | Interpolation parameters |

| I1 | Middle point of circular interpolation |

| J1 | Middle point of circular interpolation |

| K1 | Middle point of circular interpolation |

| L | Subroutine name and subroutine call |

| M | Auxiliary function |

| MO | Program stop |

| M1 | The program stops conditionally |

| M2 | Program end |

| M3 | The spindle rotates clockwise |

| M4 | The spindle rotates counterclockwise |

| M5 | Spindle stop |

| M6 | Tool change |

| N | Subroutine segment |

| : | Main program segment |

| P | Number of subroutine calls |

| RET | End of subroutine |

| S | Spindle speed, which indicates pause time in G4 |

| T | Tool number |

| X | Coordinate axis |

| Y | Coordinate axis |

| Z | Coordinate axis |

| CALL | Loop call |

| CHF | Chamfer, general use |

| CHR | Chamfer contour line |

| CR | Circular interpolation radius |

| GOTOB | Backward jump instruction |

| GOTOF | Forward jump command |

| RND | Fillet |

| Circulate | Explain |

| LCYC82 | Drilling and counterbore processing |

| LCYC83 | Deep hole drilling |

| LCYC840 | Thread cutting with compensation fixture |

| LCYC84 | Thread cutting without compensation fixture |

| LCYC85 | Boring |

| LCYC60 | Linear hole arrangement |

| LCYC61 | Circular hole arrangement |

| LCYC75 | Rectangular groove, keyway, circular groove milling |

| Circulate | Explain |

| CYCLE82 | Central drilling |

| CYCLE83 | Deep hole drilling |

| CYCLE84 | Sexual tapping |

| CYCLE85 | Reaming |

| CYCLE86 | Boring |

| CYCLE88 | Boring with stop |

| CYCLE71 | End milling |

| LONG HOLE | A rectangular hole in an arc |

| POCKE T4 | Annular groove milling |

| POCKE T3 | Rectangular groove milling |

| SLOT1 | Keyway on an arc |

| SLOT2 | Circular groove |

| Address | Explain |

| D | Tool complement number |

| F | |

| F | Feed rate (dwell time can be programmed with G4) |

| G | G function (prepare function word) |

| GO | Fast move |

| G1 | Linear interpolation |

| G2 | Clockwise circular interpolation |

| G3 | Counterclockwise circular interpolation |

| G33 | Thread cutting with constant pitch |

| G4 | Fast move |

| G63 | Fast move |

| G74 | Back to the reference point |

| G75 | Fixed point |

| G17 | (required when machining center hole) |

| G18* | Z / X plane |

| G40 | Cancellation of tool tip radius compensation |

| G41 | The tool tip radius compensation is called, and the tool moves on the left side of the contour |

| G42 | The tool tip radius compensation is called, and the tool moves on the right side of the contour |

| G500 | Cancel settable zero offset |

| G54 | First settable zero offset |

| G55 | Second, the zero offset can be set |

| G56 | Third, the zero offset can be set |

| G57 | Fourth, the zero offset can be set |

| G58 | Fifth, the zero offset can be set |

| G59 | Sixth, the zero offset can be set |

| G53 | Cancel by program segment to set zero offset |

| G70 | Inch size |

| G71* | metric size |

| G90* | Absolute size |

| G91 | Incremental size |

| G94* | Feed rate f in mm / min |

| G95 | Spindle feed rate F, in mm / revolution |

| I | Interpolation parameters |

| I1 | Middle point of circular interpolation |

| K1 | Middle point of circular interpolation |

| L | Subroutine name and subroutine call |

| M | Auxiliary function |

| MO | Program stop |

| M1 | The program stops conditionally |

| M2 | Program end |

| M30 | |

| M17 | |

| M3 | The spindle rotates clockwise |

| M4 | The spindle rotates counterclockwise |

| M5 | Spindle stop |

| M6 | Tool change |

| N | Subroutine segment |

| : | Main program segment |

| P | Number of subroutine calls |

| RET | End of subroutine |

| S | Spindle speed, which indicates pause time in G4 |

| T | Tool number |

| X | Coordinate axis |

| Y | Coordinate axis |

| Z | Coordinate axis |

| AR | Circular interpolation angle |

| CALL | Loop call |

| CHF | Chamfer, general use |

| CHR | Chamfer contour line |

| CR | Circular interpolation radius |

| GOTOB | Backward jump instruction |

| GOTOF | Forward jump command |

| RND | Fillet |

| Circulate | Explain |

| LCYC82 | Drilling and counterbore processing |

| LCYC83 | Deep hole drilling |

| LCYC840 | Thread cutting with compensation fixture |

| LCYC84 | Thread cutting without compensation fixture |

| LCYC85 | Boring |

| LCYC93 | Grooving cycle |

| LCYC95 | Blank cutting cycle |

| LCYC97 | Thread cutting |

| Circulate | Explain |

| CYCLE71 | Plane milling |

| CYCLE82 | Central drilling |

| YCLE83 | Deep hole drilling |

| CYCLE84 | Rigid tapping |

| CYCLE85 | Reaming |

| CYCLE86 | Boring |

| CYCLE88 | Boring with stop |

| CYCLE93 | Grooving |

| CYCLE94 | Undercut shape E.F |

| CYCLE95 | Blank cutting |

| CYCLE97 | Thread cutting |

| G-code | Explain |

| G00 | Positioning (fast moving) |

| G01 | Linear cutting |

| G02 | Clockwise arc cutting (CW, clockwise) |

| G03 | Counter clockwise arc cutting (CCW, counter clock) |

| G04 | Pause (dwel1) |

| G09 | Stop at the exact position |

| G20 | Imperial input |

| G21 | Metric input |

| G22 | The internal travel limit is valid |

| G23 | Invalid internal travel limit |

| G27 | Check reference point return |

| G28 | Reference point return |

| G29 | Return from reference point |

| G30 | Return to the second reference point |

| G32 | Thread cutting |

| G36 | Diameter programming |

| G37 | Radius programming |

| G40 | Cancel tool tip radius offset |

| G41> | Nose radius offset (left) |

| G42 | Nose radius offset (right) |

| G53 | Direct machine coordinate system programming |

| G54-G59 | Coordinate system selection |

| G71 | Internal and external diameter rough cutting cycle |

| G72 | Step rough cutting cycle |

| G73 | Closed loop turning compound cycle |

| G76 | Thread cutting cycle |

| G80 | Internal and external diameter cutting cycle |

| G81 | Fixed cycle of face turning |

| G82 | Thread cutting fixed cycle |

| G90 | Absolute value programming |

| G91 | Incremental value programming |

| G92 | Workpiece coordinate system setting |

| G96 | Constant linear speed control |

| G97 | Constant linear speed control cancelled |

| G94 | Feed rate per minute |

| G95 | Feed rate per revolution |

| G Code | Explain |

| G00 | Positioning (fast moving) |

| G01 | Linear cutting |

| G02 | Clockwise arc cutting (CW, clockwise) |

| G03 | Counter clockwise arc cutting (CCW, counter clock) |

| G04 | Pause (dwell) |

| G09 | Stop at the exact position |

| G20 | Imperial input |

| G21 | Metric input |

| G22 | The internal travel limit is valid |

| G23 | Invalid internal travel limit |

| G27 | Check reference point return |

| G28 | Reference point return |

| G29 | Return from reference point |

| G30 | Return to the second reference point |

| G32 | Thread cutting |

| G36 | Diameter programming |

| G37 | Radius programming |

| G40 | Cancel tool tip radius offset |

| G41> | Nose radius offset (left) |

| G42 | Nose radius offset (right) |

| G53 | Direct machine coordinate system programming |

| G54—G59 | Coordinate system selection |

| G71 | Internal and external diameter rough cutting cycle |

| G72 | Step rough cutting cycle |

| G73 | Closed loop turning compound cycle |

| G76 | Thread cutting cycle |

| G80 | Internal and external diameter cutting cycle |

| G81 | Fixed cycle of face turning |

| G82 | Thread cutting fixed cycle |

| G90 | Absolute value programming |

| G91 | Incremental value programming |

| G92 | Workpiece coordinate system setting |

| G96 | Constant linear speed control |

| G97 | Constant linear speed control cancelled |

| G94 | Feed rate per minute |

| G95 | Feed rate per revolution |

| G-code | Explain |

| G00 | Positioning (fast moving) |

| G01 | Linear cutting |

| G02 | Clockwise circular arc |

| G03 | Counterclockwise tangent arc |

| G04 | suspend |

| G07 | Virtual axis assignment |

| G09 | Quasi stop verification |

| *G17 | XY face assignment |

| G18 | XZ face assignment |

| G19 | YZ face assignment |

| G20 | Inch input |

| *G21 | Mm input |

| G22 | Pulse equivalent |

| G24 | Mirror on |

| *G25 | Mirror off |

| G28 | Return to reference point |

| G29 | Return from reference point |

| *G40 | Cancel tool diameter offset |

| G41 | Tool diameter left offset |

| G42 | Tool length + direction offset |

| G43 | Tool length + direction offset |

| G44 | Tool length offset in one direction |

| *G49 | Cancel tool length offset |

| *G50 | Zoom off |

| G51 | Retract and release |

| G52 | Local coordinate system setting |

| G53 | Direct machine coordinate system programming |

| *G54 | Workpiece coordinate system 1 Selection |

| G55 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection |

| G57 | Workpiece coordinate system 4 selection |

| G58 | Workpiece coordinate system 5 Selection |

| G59 | Workpiece coordinate system 6 selection |

| G60 | Unidirectional positioning |

| *G61 | Precise stop verification method |

| G64 | Continuous mode |

| G68 | Rotation transformation |

| *G69 | Rotation cancel |

| G73 | High speed deep hole drilling cycle |

| G74 | Left spiral cutting cycle |

| G76 | Fine boring cycle |

| *G80 | Cancel fixed cycle |

| G81 | Central drilling cycle |

| G82 | Reverse boring cycle |

| G83 | Deep hole drilling cycle |

| G84 | Right spiral cutting cycle |

| G85 | Boring cycle |

| G86 | Boring cycle |

| G87 | Reverse boring cycle |

| G88 | Boring cycle |

| G89 | Boring cycle |

| *G90 | Use absolute value command |

| G91 | Using the increment command |

| G92 | Set workpiece coordinate system |

| *G94 | Feed per minute |

| G95 | Feed per revolution |

| *G98 | Fixed cycle return to starting point |

| G99 | Return to fixed cycle R point |

| M-code | Explain |

| M00 | Program stop |

| M01 | Select Stop |

| M02 | Program end (reset) |

| M03 | Spindle forward rotation (CW) |

| M04 | Spindle reversal (CCW) |

| M05 | Spindle stop |

| M06 | Change knife |

| M07 | Cutting fluid on |

| M09 | Cutting fluid off |

| M98 | Subroutine call |

| M99 | End of subroutine |

| G-code | Group | Explain |

| G00 | 1 | Positioning (fast moving) |

| G01 | Linear cutting | |

| G02 | Clockwise circular arc | |

| G03 | Counterclockwise tangent arc | |

| G04 | 0 | Suspend |

| G17 | 2 | XY face assignment |

| G18 | XZ face assignment | |

| G19 | YZ face assignment | |

| G28 | 0 | Machine return to origin |

| G29 | Return from reference point | |

| *G40 | 7 | Cancel tool diameter offset |

| G41 | Tool diameter left offset | |

| G42 | Tool diameter right offset | |

| *G43 | 8 | Tool length + direction offset |

| *G44 | Tool length offset in one direction cancels the tool length offset | |

| G49 | Cancel tool length offset | |

| *G53 | 14 | machine tool coordinate system selection |

| G54 | workpiece coordinate system 1 Selection | |

| G55 | workpiece coordinate system 2 selection | |

| G56 | workpiece coordinate system 3 selection | |

| G57 | workpiece coordinate system 4 selection | |

| G58 | workpiece coordinate system 5 Selection | |

| G59 | workpiece coordinate system 6 selection | |

| G73 | 9 | high speed deep hole drilling cycle |

| G74 | left spiral cutting cycle | |

| G76 | fine boring cycle | |

| *G80 | cancel fixed cycle | |

| G81 | drilling cycle (spot drilling) | |

| G82 | drilling cycle (boring stepped holes) | |

| G83 | deep hole drilling cycle | |

| G84 | tapping cycle | |

| G85 | boring cycle | |

| G86 | borehole circulation | |

| G87 | reverse boring cycle | |

| G88 | boring cycle | |

| G89 | boring cycle | |

| *G90 | 3 | use absolute value command |

| G91 | use incremental value command | |

| G92 | 0 | set workpiece coordinate system |

| *G98 | 10 | fixed cycle return to starting point |

| *G99 | return to fixed cycle r point |

| G-code | Group | Explain |

| G00 | 1 | Positioning (fast moving) |

| G01 | Linear cutting | |

| G02 | Clockwise arc cutting (CW, clockwise) | |

| G03 | Counter clockwise arc cutting (CCW, counter clock) | |

| G04 | 0 | Pause (dwe11) |

| G10 | Offset value setting | |

| G20 | 6 | Imperial input |

| G21 | Metric input | |

| G27 | 0 | Check reference point return |

| G28 | Reference point return | |

| G29 | Return from reference point | |

| G31 | Jumping function | |

| G32 | 1 | Thread cutting |

| G36 | X-axis automatic tool deviation setting | |

| G37 | Z-axis automatic tool deviation setting | |

| G40 | 7 | Cancel tool tip radius offset |

| G41 | Nose radius offset (left) | |

| G42 | Nose radius offset (right) | |

| G50 | 0 | Coordinate system setting |

| G54 | Workpiece coordinate system | |

| G55—G59 | Workpiece coordinate system | |

| G70 | 0 | Finishing cycle |

| G71 | Internal and external diameter rough cutting cycle | |

| G72 | Step rough cutting cycle | |

| G73 | Forming repeat cycle | |

| G74 | End face deep hole machining cycle | |

| G75 | Outer circle and inner circle cutting cycle | |

| G76 | Thread cutting cycle | |

| G90 | 1 | (inside and outside diameter) cutting cycle |

| G92 | Thread cutting cycle | |

| G94 | (step) cutting cycle | |

| G96 | 12 | Constant linear speed control |

| G97 | Constant linear speed control cancelled | |

| G98 | 5 | Feed rate per minute |

| G99 | Feed rate per revolution |

| M-code | Instruction |

| M00 | Program stop |

| M01 | Select Stop |

| M02 | Program end (reset) |

| M03 | Spindle forward rotation (CW) |

| M04 | Spindle reversal (CCW) |

| M05 | Spindle stop |

| M06 | Change knife |

| M08 | Cutting fluid on |

| M09 | Cutting fluid off |

| M10 | Clamping |

| M11 | Release |

| M32 | Lubrication on |

| M33 | Lubrication off |

| M99 | End of subroutine |

| G-code | Group | Function |

| G00 | 1 | Positioning (fast moving) |

| *G01 | Linear interpolation (cutting feed) | |

| G02 | Arc interpolation CW (clockwise) | |

| G03 | Circular interpolation CCW (counterclockwise) | |

| G04 | 0 | Pause, quasi stop |

| G28 | Return to reference point | |

| G32 | 1 | Thread cutting |

| G50 | 0 | Coordinate system setting |

| G65 | Macro program command | |

| G70 | 0 | Finishing cycle |

| G71 | Outer circle rough turning cycle | |

| G72 | End rough turning cycle | |

| G73 | Closed cutting cycle | |

| G74 | End face deep hole machining cycle | |

| G75 | Outer circle, inner circle, grooving cycle | |

| 1 | Outer circle, inner circle, turning cycle | |

| G92 | Thread cutting cycle | |

| End cutting cycle | ||

| G96 | 2 | Constant linear speed on |

| G97 | Constant linear speed off | |

| *G98 | 3 | Feed per minute |

| G99 | Feed per revolution |

| M-code | Instruction |

| M03 | Spindle forward rotation |

| M04 | Spindle reversal |

| M05 | Spindle stop |

| M08 | Coolant on |

| M09 | Coolant off (no output signal) |

| M32 | Lubrication on |

| M33 | Lubrication off (no output signal) |

| M10 | Spare |

| M11 | Spare tip (no signal output) |

| M00 | The program is suspended. Press the ‘cycle start’ program to continue |

| M30 | The program ends and returns to the beginning |

| G-code | Function |

| G00 | Positioning (fast moving) |

| *G01 | Linear interpolation (cutting feed) |

| G02 | Arc interpolation CW (clockwise) |

| G03 | Circular interpolation CCW (counterclockwise) |

| G32 | Tapping circulation |

| G33 | Thread cutting |

| G71 | Outer circle rough turning cycle |

| G72 | End rough turning cycle |

| G74 | End face deep hole machining cycle |

| G75 | Outer circle, inner circle, grooving cycle |

| G90 | Outer circle, inner circle, turning cycle |

| G92 | Thread cutting cycle |

| G94 | Outer circle inner conical surface circulation |

| G22 | Local cycle start |

| G80 | End of local cycle |

| *G98 | Feed per minute |

| G99 | Feed per revolution |

| G50 | Set workpiece absolute coordinate system |

| G26 | 10. Z-axis back reference |

| G27 | X-axis back to reference point |

| G29 | Z axis back to reference point |

| M-code | Instruction |

| M03 | Spindle forward rotation |

| M04 | Spindle reversal |

| M05 | Spindle stop |

| M08 | Coolant on |

| M09 | Coolant off (no output signal) |

| M32 | Lubrication on |

| M33 | Lubrication off (no output signal) |

| M10 | Spare |

| M11 | Spare tip (no signal output) |

| MOO | Program pause, press’ cycle start ‘program to continue |

| M30 | The program ends and returns to the beginning |

| G-code | Group | Explain |

| G00 | 1 | Positioning (fast moving) |

| G01 | Linear cutting | |

| G02 | Clockwise circular arc | |

| G03 | Counterclockwise tangent arc | |

| G04 | 0 | suspend |

| G17 | 2 | XY face assignment |

| G18 | XZ face assignment | |

| G19 | YZ face assignment | |

| G28 | 0 | Machine return to origin |

| G29 | Return from reference point | |

| *G40 | 7 | Cancel tool diameter offset |

| G41 | Tool diameter left offset | |

| G42 | Tool diameter right offset | |

| *G43 | 8 | Tool length + direction offset |

| *G44 | Tool length minus direction offset | |

| G49 | Cancel tool length offset | |

| *G53 | 14 | machine tool coordinate system selection |

| G54 | workpiece coordinate system 1 Selection | |

| G55 | workpiece coordinate system 2 selection | |

| G56 | workpiece coordinate system 3 selection | |

| G57 | workpiece coordinate system 4 selection | |

| G58 | workpiece coordinate system 5 Selection | |

| G59 | workpiece coordinate system 6 selection | |

| G73 | 9 | high speed deep hole drilling cycle |

| G74 | left spiral cutting cycle | |

| G76 | fine boring cycle | |

| *G80 | cancel fixed cycle | |

| G81 | drilling cycle (spot drilling) | |

| G82 | drilling cycle (boring stepped holes) | |

| G83 | deep hole drilling cycle | |

| G84 | tapping cycle | |

| G85 | boring cycle | |

| G86 | borehole circulation | |

| G87 | reverse boring cycle | |

| G88 | boring cycle | |

| G89 | boring cycle | |

| *G90 | 3 | use absolute value command |

| G91 | use incremental value command | |

| G92 | 0 | set workpiece coordinate system |

| *G98 | 10 | fixed cycle return to starting point |

| *G99 | return to fixed cycle r point |

| M-code | Instruction |

| M00 | Program stop |

| M01 | Select Stop |

| M02 | Program end (reset) |

| M03 | Spindle forward rotation (CW) |

| M04 | Spindle reversal (CCW) |

| M05 | Spindle stop |

| M06 | Change knife |

| M08 | Cutting fluid on |

| M09 | Cutting fluid off |

| M10 | Clamping |

| M11 | Release |

| M32 | Lubrication on |

| M33 | Lubrication off |

| M98 | Subroutine call |

| M99 | End of subroutine |

| G-code | Explain |

| G00 | Positioning (fast moving) |

| G1 | Linear cutting |

| G02 | Clockwise circular arc |

| G03 | Counterclockwise tangent arc |

| G04 | Delay waiting |

| G17 | XY face assignment |

| G18 | XZ face assignment |

| G19 | YZ face assignment |

| G28 | Machine return to origin |

| G29 | Return from reference point |

| *G40 | Cancel tool diameter offset |

| G41 | Tool diameter left offset |

| G42 | Tool diameter right offset |

| *G43 | Tool length + direction offset |

| *G44 | Tool length offset in one direction |

| G49 | Cancel tool length offset |

| *G53 | Machine coordinate system selection |

| G54 | Workpiece coordinate system 1 Selection |

| G55 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection |

| G57 | Workpiece coordinate system 4 selection |

| G58 | Workpiece coordinate system 5 Selection |

| G59 | Workpiece coordinate system 6 selection |

| G73 | High speed deep hole drilling cycle |

| G74 | Left spiral cutting cycle |

| G80 | Cancel fixed cycle |

| G81 | Drilling cycle (spot drilling) |

| G82 | Drilling cycle (boring stepped holes) |

| G83 | Deep hole drilling cycle |

| G84 | Right tapping circulation |

| G85 | Boring cycle |

| G86 | Drilling cycle |

| G89 | Boring cycle |

| *G90 | Use absolute value command |

| G91 | Use incremental value command |

| G92 | Set floating coordinate system |

| *G98 | Fixed cycle return to starting point |

| *G99 | Return to fixed cycle r point |

| G10 G11 | Rough milling in circular groove |

| G12 G13 | Full circle internal finish milling |

| G14 G15 | Cylindrical finish milling |

| G22 | System parameter operation (mode) |

| G23 | Parameter value jump |

| G27 | Mechanical zero point detection |

| G28 | Quickly locate the program through the middle point |

| G31 | Quick return to R datum |

| G34 G35 | Finish milling in rectangular groove |

| G38 G39 | Rectangular external finish milling |

| M2 | The program ends and stops. Stop the spindle, turn off the coolant, eliminate the G93 coordinate offset and tool offset, and return to the starting program section (not running). After executing M2, the system will switch to the reference workpiece coordinate system. |

| M3 | Spindle forward rotation |

| M4 | Spindle reversal |

| M5 | Stop spindle |

| M8 | Turn on the cooling pump |

| M9 | Turn off the cooling pump |

| M12 | Pause: wait for the “run” key to continue running (press the emergency stop key to stop) |

| M30 | At the end of the program, eliminate the tool offset and return to the starting program segment (not running). After executing M30, the system will switch to the reference workpiece coordinate system. |

| M32 | Lubrication on; |

| M33 | Lubrication off; |

| M98 | Call subroutine |

| M99 | Subroutine end return |

| G-code | Group | Explain |

| ※G00 | 1 | Position positioning (rapid feed) |

| *G01 | Straight line repair | |

| G02 | Clockwise arc cutting (CW) | |

| G03 | Counterclockwise arc cutting (CCW) | |

| G04 | 0 | suspend |

| G05 | High speed machining mode | |

| G09 | Stop the check correctly | |

| G10 | Program parameter input / correction input | |

| G11 | Program parameter input cancel | |

| G12 | Circular cutting CW | |

| G13 | Circular cutting CCW | |

| *G17 | 2 | Plane selection X-Y |

| ※G18 | Plane selection z-x | |

| G19 | Plane selection Y-Z | |

| ※G20 | 6 | Imperial directive |

| G21 | Metric instruction | |

| G27 | 0 | Reference origin check |

| G28 | Reference origin reset | |

| G29 | Start point reset | |

| G30 | The 2nd ~ 4th reference origin reset | |

| G31 | Jumping function | |

| G33 | 1 | Thread cutting |

| G37 | 0 | Automatic tool length measurement |

| G38 | Tool diameter correction vector assignment | |

| G39 | Angle arc correction tool | |

| *G40 | 7 | Tool diameter correction cancellation |

| G41 | Tool diameter correction left | |

| G42 | Tool diameter correction right | |

| G43 | 8 | Tool length correction (+) |

| G44 | Tool length correction (I) | |

| *G49 | Tool length correction quantity cancellation | |

| G52 | 0 | Local coordinate system setting |

| G53 | Selection of mechanical coordinate system | |

| *G54 | 12 | Workpiece coordinate system 1 Selection |

| G55 | 12 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection | |

| G57 | Workpiece coordinate system 4 selection | |

| G58 | Workpiece coordinate system 5 Selection | |

| G59 | Workpiece coordinate system 6 selection | |

| G60 | 0 | Unidirectional position positioning |

| G61 | 13 | Make sure to stop the inspection mode |

| G62 | Automatic angle feed rate adjustment | |

| G63 | Tapping mode | |

| *G64 | Cutting mode | |

| G73 | 9 | Fixed cycle (step cycle) |

| G74 | Fixed circulation (reverse tapping) | |

| G76 | Fixed cycle (fine boring) | |

| *G80 | Fixed cycle cancellation | |

| G81 | Fixed circulation (drilling / lead hole) | |

| G82 | Fixed cycle (drilling / counter boring) | |

| G83 | Fixed circulation (deep drilling) | |

| G84 | Fixed circulation (tapping) | |

| G85 | Fixed cycle (boring) | |

| G86 | Fixed cycle (boring) | |

| G87 | Fixed cycle (reverse boring) | |

| G88 | Fixed cycle (boring) | |

| G89 | Fixed cycle (boring) | |

| *G90 | 3 | Absolute value instruction |

| *G91 | Incremental value instruction | |

| G92 | 0 | Mechanical coordinate system setting |

| G93 | 5 | Counterclockwise feed |

| *G94 | Asynchronous cutting (feed per minute) | |

| *G95 | Simultaneous cutting (feed for each drilling) | |

| *G96 | 17 | The cycle speed must be controlled effectively |

| *G97 | The cycle speed control must be invalid | |

| *G98 | 10 | Fixed cycle starting point reset |

| G99 | Fixed cycle r-point reset |

| G-code | Group | Explain |

| ※G00 | 1 | Position positioning (rapid feed) |

| *G01 | Straight line repair | |

| G02 | Clockwise arc cutting (CW) | |

| G03 | Counterclockwise arc cutting (CCW) | |

| G04 | 0 | suspend |

| G05 | High speed machining mode | |

| G09 | Stop the check correctly | |

| G10 | Program parameter input / correction input | |

| G11 | Program parameter input cancel | |

| G12 | Circular cutting CW | |

| G13 | Circular cutting CCW | |

| *G17 | 2 | Plane selection X-Y |

| ※G18 | Plane selection z-x | |

| G19 | Plane selection Y-Z | |

| ※G20 | 6 | Imperial directive |

| G21 | Metric instruction | |

| G27 | 0 | Reference origin check |

| G28 | Reference origin reset | |

| G29 | Start point reset | |

| G30 | The 2nd ~ 4th reference origin reset | |

| G31 | Jumping function | |

| G33 | 1 | Thread cutting |

| G37 | 0 | Automatic tool length measurement |

| G38 | Tool diameter correction vector assignment | |

| G39 | Angle arc correction tool | |

| *G40 | 7 | Tool diameter correction cancellation |

| G41 | Tool diameter correction left | |

| G42 | Tool diameter correction right | |

| G43 | 8 | Tool length correction (+) |

| G44 | Tool length correction (I) | |

| *G49 | Tool length correction quantity cancellation | |

| G52 | 0 | Local coordinate system setting |

| G53 | Selection of mechanical coordinate system | |

| *G54 | 12 | Workpiece coordinate system 1 Selection |

| G55 | 12 | Workpiece coordinate system 2 selection |

| G56 | Workpiece coordinate system 3 selection | |

| G57 | Workpiece coordinate system 4 selection | |

| G58 | Workpiece coordinate system 5 Selection | |

| G59 | Workpiece coordinate system 6 selection | |

| G60 | 0 | Unidirectional position positioning |

| G61 | 13 | Make sure to stop the inspection mode |

| G62 | Automatic angle feed rate adjustment | |

| G63 | Tapping mode | |

| *G64 | Cutting mode | |

| G73 | 9 | Fixed cycle (step cycle) |

| G74 | Fixed circulation (reverse tapping) | |

| G76 | Fixed cycle (fine boring) | |

| *G80 | Fixed cycle cancellation | |

| G81 | Fixed circulation (drilling / lead hole) | |

| G82 | Fixed cycle (drilling / counter boring) | |

| G83 | Fixed circulation (deep drilling) | |

| G84 | Fixed circulation (tapping) | |

| G85 | Fixed cycle (boring) | |

| G86 | Fixed cycle (boring) | |

| G87 | Fixed cycle (reverse boring) | |

| G88 | Fixed cycle (boring) | |

| G89 | Fixed cycle (boring) | |

| *G90 | 3 | Absolute value instruction |

| *G91 | Incremental value instruction | |

| G92 | 0 | Mechanical coordinate system setting |

| G93 | 5 | Counterclockwise feed |

| *G94 | Asynchronous cutting (feed per minute) | |

| *G95 | Simultaneous cutting (feed for each drilling) | |

| *G96 | 17 | The cycle speed must be controlled effectively |

| *G97 | The cycle speed control must be invalid | |

| *G98 | 10 | Fixed cycle starting point reset |

| G99 | Fixed cycle r-point reset |

| G-code | Group | Explain |

| ※G00 | 1 | Fast mobile positioning |

| ※G01 | Straight line repair | |

| G02 | Arc gap (CW, Clockwise Clock) | |

| G03 | Arc gap repair (CCW, counter clock) | |

| G04 | 0 | suspend |

| G09 | Correct stop | |

| G10 | Program parameters / correction input | |

| G11 | Program parameter / correction input mode cancelled | |

| ※G17 | 2 | X-Y plane selection |

| ※G18 | Z-x plane selection | |

| ※G19 | Y-Z plane selection | |

| ※G20 | 6 | Imperial input |

| ※G21 | Metric input | |

| G27 | 0 | Reference point reset check |

| G28 | Automatic reference point reset | |

| G29 | Reset from reference point | |

| G30 | Reset of reference points 2, 3 and 4 | |

| G31 | Jumping function | |

| G33 | 1 | Thread cutting |

| G34 | Variable thread cutting | |

| G37 | 0 | Automatic tool correction |

| *G40 | 7 | Tool diameter correction cancellation |

| G41 | Tool diameter correction (left side) | |

| G42 | Tool diameter correction (right side) | |

| G46 | Tool diameter correction (automatic direction selection) | |

| G52 | 0 | Local coordinate system setting |

| G53 | Selection of mechanical coordinate system | |

| ※G54 | 12 | Workpiece coordinate system selection 1 |

| G55 | Workpiece coordinate system selection 2 | |

| G56 | Workpiece coordinate system selection 3 | |

| G57 | Workpiece coordinate system selection 4 | |

| G58 | Workpiece coordinate system selection 5 | |

| G59 | Workpiece coordinate system selection 6 | |

| G61 | 13 | Correct stop check mode |

| G62 | Automatic angle speed control | |

| G63 | Tapping mode | |

| *G64 | Cutting mode | |

| G70 | 9 | Finish cutting cycle |

| G71 | Straight turning rough cutting cycle | |

| G72 | End face rough cutting cycle | |

| G73 | Spindle table movement in rough machining cycle | |

| G74 | End cutting cycle | |

| G75 | Straight turning cycle | |

| G76 | Thread cutting cycle | |

| G77 | From cutting cycle | |

| G78 | Tooth fixation cycle | |

| G79 | End cutting fixed cycle | |

| G80 | Machining hole cycle command cancel | |

| G83 | Deep drilling cycle (Z-axis) | |

| G84 | Tapping cycle (Z axis) | |

| G85 | Boring cycle (Z axis) | |

| G87 | Deep hole drilling cycle (x-axis) | |

| G88 | Tapping cycle (x-axis) | |

| G89 | Boring cycle (x-axis) | |

| ※G90 | 3 | Absolute value command |

| ※G91 | Incremental value command | |

| G92 | 0 | Coordinate system setting / spindle speed setting |

| ※G94 | 5 | Asynchronous feed (feed per minute) |

| ※G95 | Synchronous feed (feed per revolution) | |

| ※G96 | 17 | Cycle speed control on |

| ※G97 | Cycle speed must be controlled off | |

| *G98 | 10 | Fixed cycle |

| Initial value reversion | ||

| G99 | Fixed cycle | |

| R-point reset |

| G-code | Explain |

| G00 | Fast positioning |

| G01 | Linear interpolation |

| G02 | Clockwise circular interpolation |

| G03 | Counterclockwise circular interpolation |

| G04 | delayed |

| G09 | Feed quasi stop |

| G20 | Independent subroutine call |

| G22 | Independent subroutine definition |

| G24 | When the independent subroutine definition is finished, return to the calling program |

| G25 | Jump processing |

| G26 | Block call subroutine call in machining program |

| G27 | Infinite loop |

| G30 | Magnification cancellation |

| G31 | Magnification definition |

| G47 | Short linear speed automatic transition |

| G48 | cancel |

| G54~G59 | Workpiece coordinate system selection |

| G71 | Internal and external circular cutting |

| G72 | Face cutting compound cycle |

| G73 | Closed contour compound cycle |

| G74 | Return to machine reference point (mechanical origin) |

| G75 | Return to tool setting point |

| G76 | Return to machining start point |

| G77 | Restore the current coordinate system |

| G81 | Cylindrical machining cycle |

| G82 | End face machining cycle |

| G85 | Inch rigid tapping cycle |

| G86 | Metric thread machining cycle |

| G87 | Inch thread machining cycle |

| G90 | Absolute value mode programming |

| G91 | Incremental value programming |

| G92 | Set program zero |

| G96 | Constant linear speed cutting is effective |

| G97 | Cancel constant linear speed cutting |

| G98 | Cancel feed per revolution |

| G99 | Set feed per revolution |

| P = parameter assignment |

| M instruction | Explain |

| M01 | Conditional stop |

| M02 | Program end and shutdown |

| M03 | Spindle forward rotation |

| M04 | Spindle reversal |

| M05 | Spindle stop |

| M06 | Cooling on |

| M07 | Cooling off |

| M08 | Workpiece clamping |

| M09 | Workpiece loosening |

| M10 | Turn on the specified relay |

| M11 | Turn off the specified relay |

| M20 | Set tool complement number |

| M21 | The program ends and returns to the beginning of the program |

| M71~M85 | Relay pulse output |

| G-code | Explain |

| G01 | linear interpolation |

| G02 | Clockwise arc interpolation or spiral interpolation |

| G03 | Counterclockwise arc interpolation or spiral interpolation |

| G04 | delayed |

| G09 | Servo quasi stop in place |

| G11 | The block is mirrored along the Y axis |

| G12 | The block is mirrored along the X axis |

| G13 | The program block is processed by mirror image at the origin |

| G17 | Select the xoy plane |

| G18 | Select the x0z plane |

| G19 | Select the y0z plane |

| G20 | Subroutine call |

| G22 | subprogram declaration |

| G24 | The subroutine definition ends and returns to the calling program |

| G25 | Jump processing |

| G26 | Transfer processing |

| G27 | Infinite loop |

| G30 | Zoom in / out magnification cancel |

| G31 | Definition of magnification / reduction ratio |

| G40 | Cancel tool radius compensation |

| G41 | Left tool radius compensation |

| G42 | Right tool radius compensation |

| G43 | Establish tool length compensation |

| G44 | Undo tool length compensation |

| G47 | Short linear speed automatic transition |

| G48 | Cancel the automatic transition of short linear speed |

| G54~G59 | Workpiece coordinate system selection |

| G73 | High speed deep hole machining cycle |

| G74 | Return to machine reference point (mechanical origin) |

| G75 | Return to tool setting point |

| G76 | Return to program zero from current position |

| G78 | Fine boring cycle |

| G81 | Central hole drilling cycle |

| G82 | Central drilling cycle with pause |

| G83 | Deep hole machining cycle |

| G84 | Metric rigid tapping cycle |

| G85 | Inch rigid tapping cycle |

| G86 | Boring cycle (automatic return) |

| G87 | Reverse boring cycle |

| G88 | Boring cycle (manual return) |

| G89 | Boring cycle with pause |

| G90 | Absolute value mode programming |

| G91 | Incremental value programming |

| G92 | Set workpiece coordinate system |

| P = parameter assignment |

| G-code | Explain |

| M00 | Program pause |

| M01 | L ×× (K ××) |

| M02 | Program end and shutdown |

| M03 | Spindle forward rotation |

| M04 | Spindle reversal |

| M05 | Spindle stop |

| M08 | Cooling on |

| M09 | Cooling off |

| M10 | Workpiece clamping |

| M11 | Workpiece loosening |

| M20 | K ×× Relay No |

| M21 | K ×× shut ×× Relay No |

| M30 | The program ends and returns to the beginning of the program |

| M71~M85 | Relay pulse output |

| G code | Explain |

| G00 | quick point positioning instructions |

| G01 | Linear interpolation instruction |

| G02、G03 | Circular interpolation instruction |

| G04 | Program delay instruction |

| G26、G27 | Return to starting point instruction |

| G28、G29 | |

| G22、G80 | Program loop instruction |

| G23 | Rectangular loop instruction |

| G37、G38G39、G36 | Return hard reference point command |

| G82、G83 | Thread cycle command |

| G46、G47G48、G49 | Return soft reference point command |

| G96、G97 | Constant linear speed cutting function |

| M instruction | Explain |

| M00 | Program pause instruction |

| M02 | Program end instruction |

| M30 | Spindle stop, program end command |

| M20 | Automatic cycle command |

| M03 | Spindle forward rotation command |

| M04 | Spindle reverse command |

| M05 | Spindle stop command |

| M06 | Wait for instructions after sending a letter |

| M26 | Sending instructions |

| M21 | Wait for instructions after sending a letter |

| M97 | Program jump instruction |

| M98 | Subroutine call instruction |

| M99 | Subroutine return instruction |

| G-code | Group | Type | Function |

| G00 | 01 | 1 | Positioning (fast moving) |

| G01 | Linear interpolation (feed) | ||

| G02 | Arc interpolation (clockwise) | ||

| G03 | Arc interpolation (counterclockwise) | ||

| G02+Z | Right helix interpolation | ||

| G03+Z | Left spiral interpolation | ||

| G04 | 02 | 2 | suspend |

| G17 | 04 | 1 | XY plane selection |

| G18 | 1 | ZX plane selection | |

| G19 | YZ plane selection | ||

| G40 | 07 | 1 | Tool compensation erase |

| G41 | Tool compensation left | ||

| G42 | Tool compensation right | ||

| G43 | 08 | Tool length forward compensation | |

| G44 | Tool length negative compensation | ||

| G49 | Tool length compensation erasure | ||

| G50 | 11 | Zoom, mirror off | |

| G51 | 11 | Zoom, mirror on | |

| G54 | 14 | Workpiece coordinate system 1 Selection | |

| G55 | Workpiece coordinate system 2 selection | ||

| G56 | Workpiece coordinate system 3 selection | ||

| G57 | Workpiece coordinate system 4 selection | ||

| G58 | Workpiece coordinate system 5 Selection | ||

| G59 | Workpiece coordinate system 6 selection | ||

| G68 | 03 | Coordinate rotation | |

| G69 | 03 | Coordinate rotation erasure | |

| G73 | 15 | Step cycle | |

| G74 | Counter attack tooth circulation (machining center) | ||

| G76 | Fine boring cycle (machining center) | ||

| G80 | Fixed cycle erasure | ||

| G81 | Drilling and spot facing cycle | ||

| G82 | Drilling and reverse boring cycle | ||

| G83 | Deep hole drilling cycle | ||

| G84 | Tapping circulation | ||

| G85/G86 | Boring cycle | ||

| G87 | Reverse boring cycle | ||

| G88/G89 | Boring cycle | ||

| G90 | 00 | Absolute value programming | |

| G91 | Incremental value programming | ||

| G92 | 05 | Coordinate system setting | |

| G98 | 16 | Return to initial plane | |

| G99 | Return to r-point plane |

| Group | M-code | Function |

| A | M00,M01,M02 | The program stops, the program chooses to stop, and the program ends |

| B | M03,M04,M05 | Spindle forward rotation, spindle reverse rotation, spindle stop |

| C | M06 | Automatic tool change |

| D | M08,M09 | Coolant on, coolant off |

| E | M98,M99 | Call the subroutine and the subroutine returns |

To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential. Here’s an optimized explanation:

System-Specific Knowledge:

Thoroughly understand the characteristics and capabilities of the specific CNC system you’re working with (e.g., Fanuc, Siemens, Heidenhain). Each system may have unique implementations of G and M codes, custom cycles, or proprietary functions. Consult the manufacturer’s programming manuals and keep updated on the latest firmware versions and supported features.

Code Functionality and Hierarchy:

Master the fundamental functions of G and M codes:

Process-Driven Selection:

Choose codes based on the specific machining operations and part requirements:

Optimization for Efficiency:

Select codes that optimize machining efficiency:

Coordinate Systems and Workpiece Setup:

Properly select and utilize coordinate system codes:

Safety and Compliance:

Incorporate safety-related codes and best practices:

Machine-Specific Optimizations:

Leverage machine-specific features:

Testing and Validation:

Rigorously test your code selections:

Documentation and Standardization:

Develop and maintain a standardized code library for common operations within your organization. This promotes consistency, reduces programming errors, and facilitates knowledge transfer among team members.

By following this comprehensive approach, you can select the most appropriate G and M codes for your specific CNC system, ensuring efficient, safe, and optimized machining processes. Remember to continuously update your knowledge as CNC technology and programming techniques evolve.

In practical CNC machining, effectively combining G-codes and M-codes is crucial for enhancing machining efficiency and precision. This integration requires a deep understanding of both code types and their strategic application within the machining process.

G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 (canned cycles for drilling, boring, and tapping). M-codes, on the other hand, manage auxiliary functions such as coolant control (M08/M09), spindle control (M03/M04/M05), and tool changes (M06).

To optimize machining efficiency and precision:

By strategically combining these G-codes and M-codes, CNC programmers can significantly enhance both machining efficiency and precision. This approach requires a thorough understanding of the machine’s capabilities, the workpiece material properties, and the specific requirements of each machining operation. Continuous optimization and refinement of these code combinations, based on real-world performance data and emerging technologies, will further push the boundaries of CNC machining capabilities.