Have you ever considered what keeps your car engine from leaking oil or your airplane’s turbines running smoothly? Dynamic seals are crucial yet often overlooked components in many machines. This article explores seven types of dynamic seals—packing seals, mechanical seals, dry gas seals, labyrinth seals, oil seals, power seals, and spiral seals. By understanding their functions and applications, you’ll gain insight into how these seals maintain efficiency and reliability in various industries. Dive in to discover how these small components play a significant role in modern engineering.

GUIDE

This article provides an overview of the 7 commonly used dynamic seal forms in mechanical design, including packing seal, mechanical seal, dry gas seal, labyrinth seal, oil seal, power seal, and spiral seal.

The issue of sealing in moving equipment is a constant problem during the equipment’s operation. Today, we have specifically organized the various types of sealing forms commonly used in mobile equipment, including their range of use and characteristics, to deepen everyone’s understanding of sealing issues.

According to its structural characteristics, packing seal can be divided into:

Type: packing

The sealing problem of moving equipment is always present during its operation. To help people understand the sealing problem better, we have organized different types of seals commonly used in mobile equipment, as well as their scope of use and characteristics.

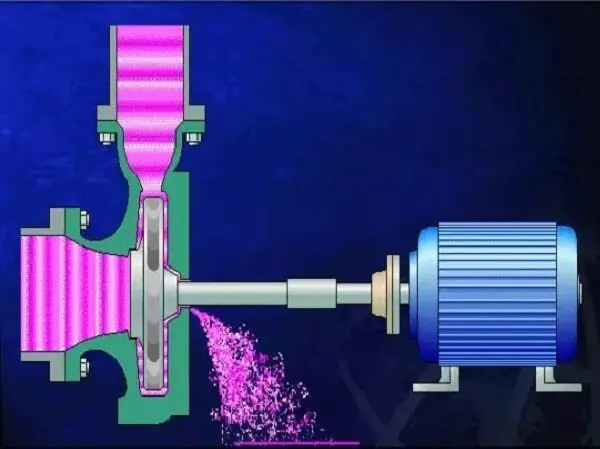

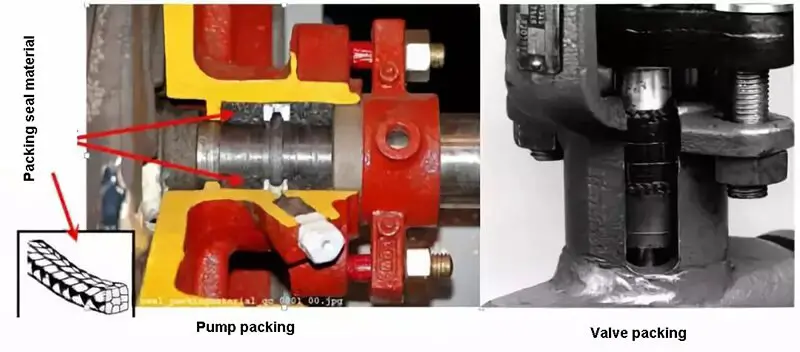

Packing is typically made from soft threads woven together and then filled into a sealed cavity through a strip with a square cross-section. The pressure is created by the gland, which compresses the packing and forces it to be pressed against the sealing surface (the outer surface of the shaft and the seal cavity), resulting in a radial force with a sealing effect.

The choice of material for packing affects its sealing effectiveness. Generally, the materials used for packing are limited by the temperature, pressure, and pH of the working medium, as well as by the surface roughness, eccentricity, and linear velocity of the mechanical equipment the packing works on. These factors will also affect the material selection of the packing.

Graphite packing is a highly effective solution for high temperature and high pressure sealing. It is known for its resistance to corrosion, excellent sealing performance, and stable and reliable operation.

| PH range of applicable medium | 0-14 usually used for dynamic sealing parts |

|---|---|

| Graphite packing temperature | -100 ℃ -850 ℃ |

| Graphite packing pressure | 0-30.0MPa |

Aramid packing is a kind of high-strength organic fiber. Then the braided packing is impregnated with PTFE latex and lubricant.

| PH range of applicable medium | 2-13 Suitable for dynamic sealing parts containing solid particles |

|---|---|

| Graphite packing temperature | 260 ℃ |

| Graphite packing pressure | 10.0MPa |

PTFE packing is made from pure PTFE dispersion resin as the raw material. The raw material film is first produced, then twisted, braided, and woven into packing material. It is widely used in valves and pumps in industries with high cleanliness requirements, such as food, pharmaceuticals, paper-making, and chemical fibers, and can handle strong corrosive media effectively.

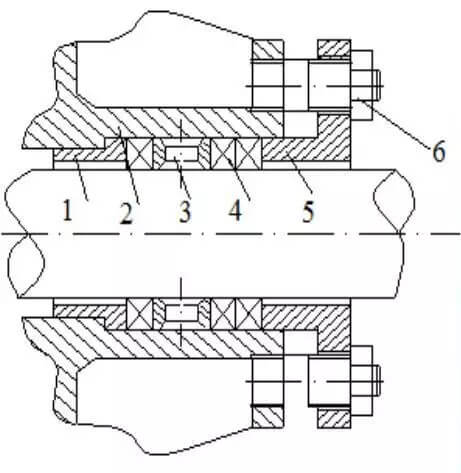

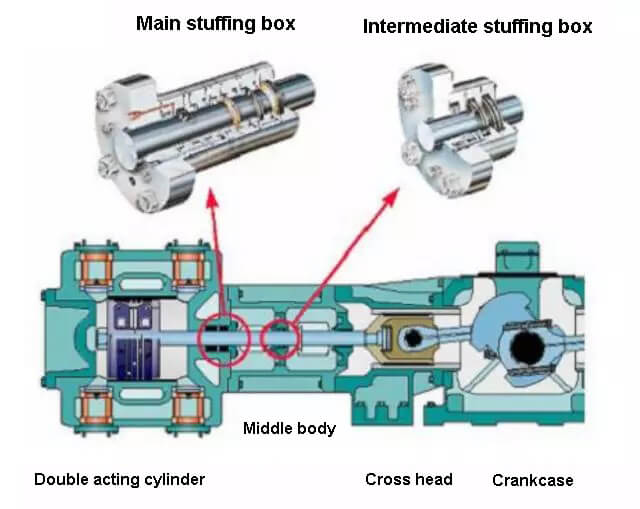

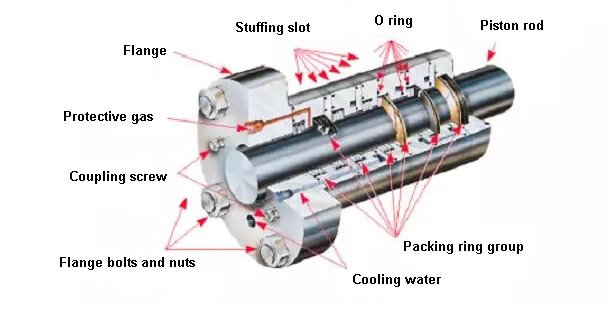

There are two types of hard packing seals: opening loop and split loop.

The opening loop ring is a metal self-tensioning seal ring used in piston machines as piston rings and in rotary machines as expansion rings. The split ring is a cylindrical surface contact dynamic seal that can be used as a rotary dynamic seal for steam turbines and aero engines, as well as a reciprocating seal for steam engines, internal combustion engines, and piston compressors (sealing between the piston rod and cylinder).

Main stuffing box structure

Classification of packing rings

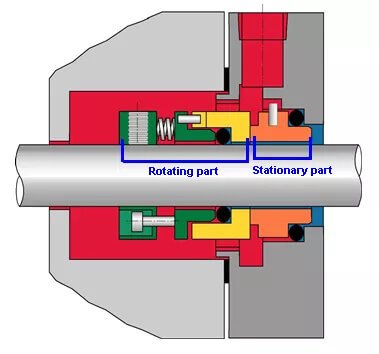

The mechanical seal typically comprises two components: the rotating component (yellow part) and the stationary component (orange part).

The components move in relation to one another, with the stationary ring surface serving as the primary sealing surface of the seal.

Mechanical seals are also referred to as face seals.

According to relevant national standards, they are defined as devices that consist of at least one pair of end faces perpendicular to the rotation axis. These end faces are kept in contact and move relative to each other with the cooperation of fluid pressure, the elastic or magnetic force of the compensation mechanism, and an auxiliary seal, thus preventing fluid leakage.

The basic components that make up a mechanical seal are:

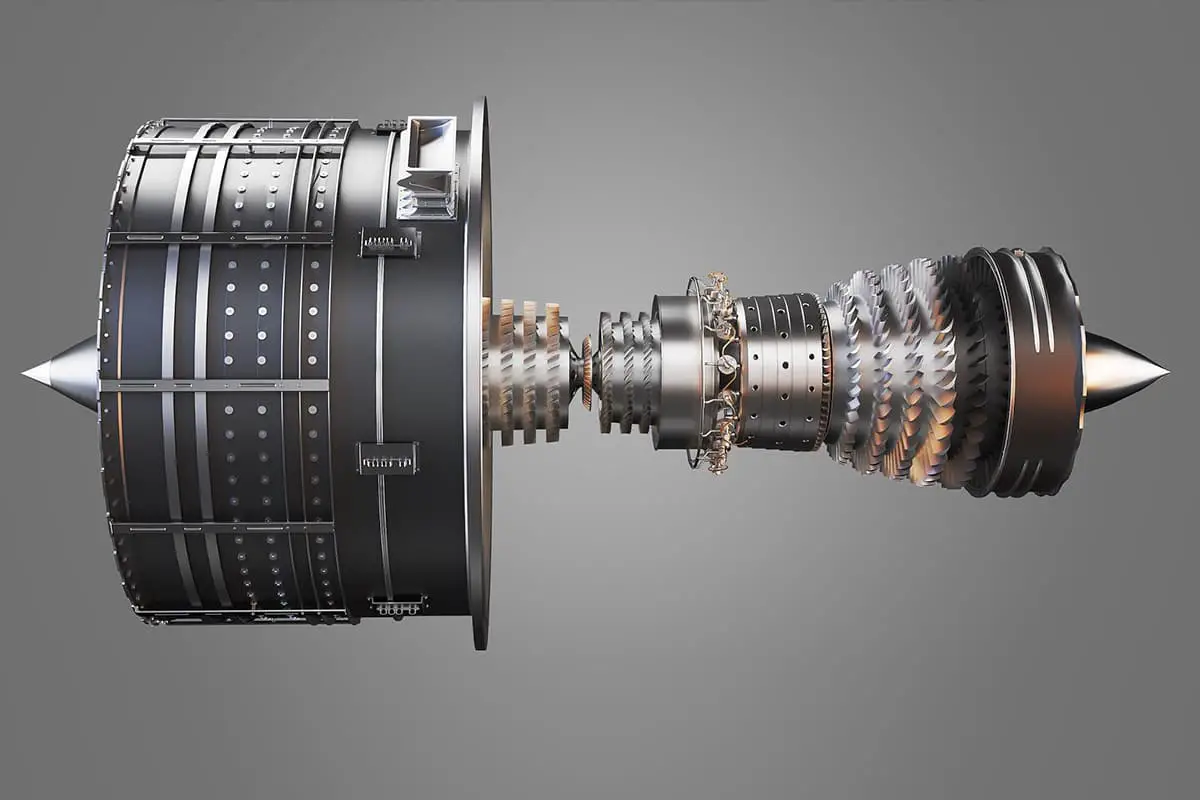

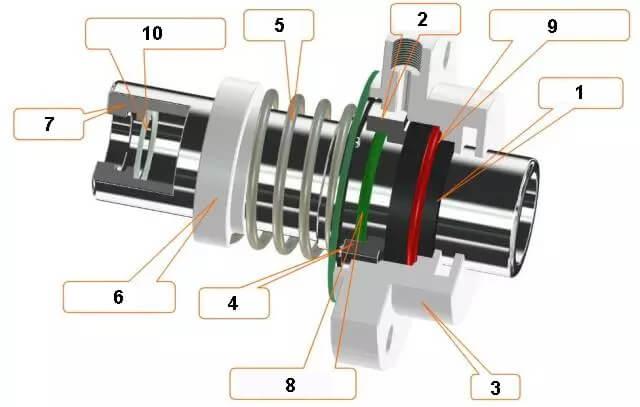

The Dry Gas Seal is a new type of shaft end seal that utilizes slotted seal technology for gas sealing and falls under the category of non-contact seals.

Key features include:

As a maintenance-free sealing system that does not require cooling or lubricating oil for the sealing end surfaces, the Dry Gas Seal is rapidly replacing the floating ring seal and labyrinth seal as the primary shaft seal for high-speed centrifugal compressors in the petrochemical industry.

Applications:

The Dry Gas Seal is ideal for use in centrifugal compressors and other high-speed fluid machinery where a small amount of process gas leakage into the atmosphere is acceptable, such as air compressors and nitrogen compressors.

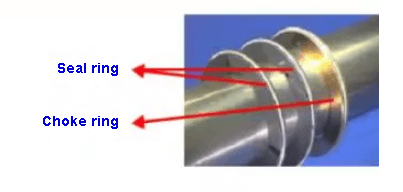

The Labyrinth Seal is a series of annular sealing teeth arranged in sequence along the rotating shaft. These teeth create a series of interception gaps and expansion cavities between them.

The Labyrinth Seal features a series of annular sealing teeth arranged in a circular pattern along the rotating shaft. These teeth create a series of gaps and cavities that function as seals.

Labyrinth seals are the simplest form of sealing between stages and shaft ends of centrifugal compressors.

Based on its structural characteristics, Labyrinth seals can be classified into four types: smooth, zigzag, step, and honeycomb.

The Smooth Labyrinth Seal comes in two structures: integral and panel. It has a simple design and is easy to manufacture, but its sealing performance is limited.

The Zigzag Labyrinth Seal also has two structures: integral and panel.

This type of labyrinth seal is characterized by its alternating arrangement of high and low sealing teeth, with a different height of protrusion. The matching shaft surface is a special concave-convex groove.

The arrangement of the high and low teeth with the concave and convex grooves transforms the smooth sealing gap into a zigzag shape, resulting in increased flow resistance and improved sealing efficiency.

However, it can only be used in cylinders or partitions with a horizontal split surface and must be constructed as a horizontal split type.

The Step Labyrinth Seal has a similar structure to the Smooth Labyrinth Seal, but its sealing performance is similar to the Zigzag Labyrinth Seal. It is commonly used at the impeller cover and balance plate.

The Honeycomb Labyrinth Seal teeth are welded together to form a complex honeycomb-shaped expansion chamber.

This type of labyrinth seal offers superior sealing performance compared to other forms of sealing and is ideal for applications with significant pressure differences, such as the balance plate seal of a centrifugal compressor.

The Honeycomb Labyrinth Seal has a complex manufacturing process but boasts a high strength sealing sheet and excellent sealing capabilities.

The Oil Seal is a self-tightening lip seal that features a simple design, small size, low cost, easy maintenance, and low resistance torque.

This type of seal is used to prevent the leakage of a medium and the intrusion of external dust or other harmful substances. It also has limited compensation for wear, but is not suitable for high-pressure applications.

As a result, it is commonly used in low-pressure applications in chemical pumps.

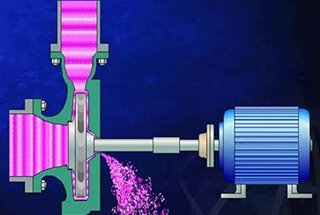

When operating, the pressure generated by the auxiliary impeller of the chemical pump balances the high-pressure liquid at the outlet of the main impeller, achieving a seal. However, when the pump stops, the auxiliary impeller no longer operates, so it must be equipped with a parking seal to address the potential leakage that may occur during downtime.

The auxiliary impeller has a straightforward sealing structure, providing reliable sealing and a long service life. With its ability to prevent fluid leakage, it is often used in chemical pumps that transport media containing impurities.

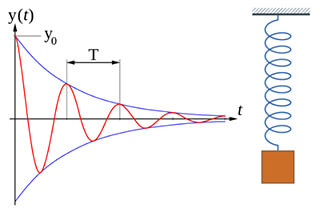

Spiral seals are a type of dynamic seals.

A spiral groove is machined on either a rotating shaft or on a shaft containing sleeve, and a sealing medium is filled between the shaft and sleeve.

The rotation of the shaft causes the spiral groove to have a pump-like effect, thereby preventing the leakage of the sealing fluid.

Its sealing performance is dependent on the spiral angle, pitch, tooth width, tooth height, tooth length, and the gap between the shaft and sleeve.

Since there is no friction between the seals, it has a long lifespan. However, due to the limitations of structural space, the spiral length is usually short, thus limiting its sealing ability.

When the pump is operated at reduced speeds, its sealing effectiveness is greatly diminished.