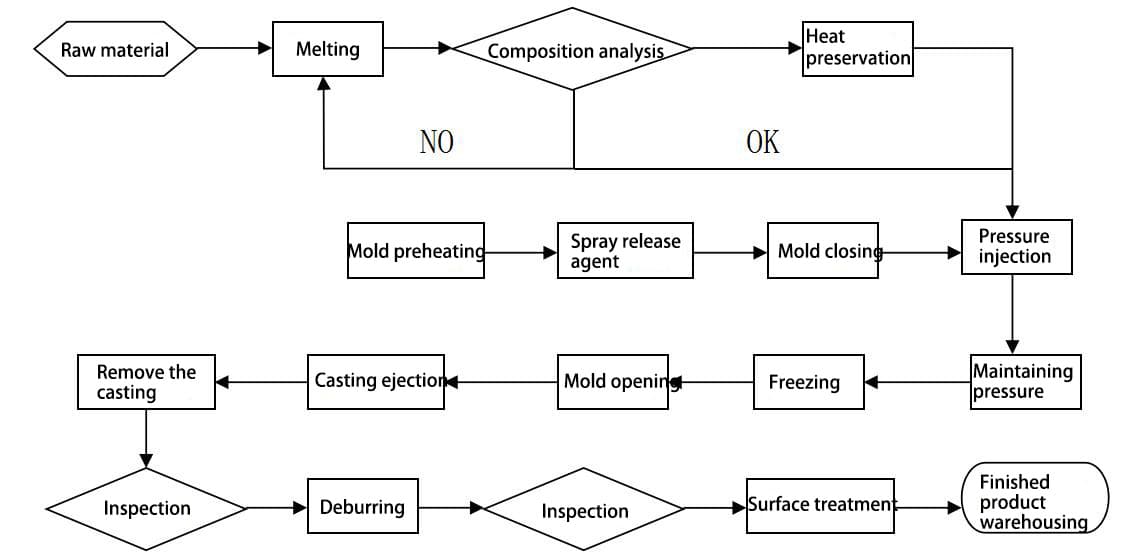

1. Objective To standardize the production operational procedures for all zinc alloy die-casting products within the company. 2. Scope This is applicable as an operational guide for both the company’s internal production and for supporting manufacturers producing zinc alloy die-casting products. 3. Process Flowchart 4. Production Operation Procedure 4.1 Initially, the alloy smelting temperature is […]

To standardize the production operational procedures for all zinc alloy die-casting products within the company.

This is applicable as an operational guide for both the company’s internal production and for supporting manufacturers producing zinc alloy die-casting products.

4.1 Initially, the alloy smelting temperature is set between 435°C and 440°C. After the complete melting of the alloy, the temperature is adjusted to a maintenance range of 420°C to 430°C.

4.2 After the alloy is fully melted, slag is removed, and a compositional assay is conducted.

4.3 The alloy composition is controlled as follows:

| Element | Al | Cu | Mg | Fe | Pb | Cr | Sn | Zn |

| Content | 3.8-4.3 | 0.7-1.1 | 0.035-0.06 | <0.02 | <0.003 | <0.003 | <0.001 | Remaining |

4.4 Adjust the injection pressure to: 45-50 Kg/cm2; the injection speed is: 2.5m/s; the mold filling time is 0.01s; the pressure increasing time is: 1.5s; the cooling time is: 6s.

4.5 Preheat the mold to 150-200°C.

4.6 Apply mold release and punch oil evenly, the ratio of original mold release to water is approximately 1:200.

4.7 Retract the ejection rod, and perform mold closing action.

4.8 After loading, perform the injection action to fill the alloy melt into the mold cavity.

4.9 After the casting cools down, eject the casting and remove it from the mold.

4.10 Inspect the casting for defects such as cold shut, porosity, short shot, blistering, patterns, etc.

4.11 Remove sprue, slag mouth, flash, etc. from the qualified castings.

4.12 Perform sand blasting on the casting surface, and inspect before warehousing.

5.1 Ensure that the alloy casting ingots are stored in a clean, dry area.

5.2 The ratio of new material to recycled material should not exceed 50%.

5.3 Strictly adhere to the safety operating procedures.

5.4 Clearly mark qualified and unqualified products, strictly differentiate.

5.5 Wear labor protection gear during the production operation process to ensure safe production.

5.6 At the end of production, perform protection and cleaning work on the machine and equipment.