Why does welding aluminum require alternating current (AC) instead of direct current (DC)? Aluminum’s oxide layer, with a high melting point, complicates the welding process. This article explains how AC current alternates polarity to break through the oxide layer and generate the heat needed for effective welding. Dive into the specifics of waveform choices and the role of tungsten electrodes to master this essential welding technique. Gain insights that will enhance your aluminum welding skills.

Aluminum welding is conducted using Tungsten Inert Gas (TIG) welding, with alternating current (AC) as the power source. This is because aluminum is covered with a layer of aluminum oxide, making welding difficult. The melting point of the surface oxide layer is close to 2015℃, while the melting point of pure aluminum is only 650℃. This results in the melting of both the oxide layer and the pure aluminum below it, making subsequent welding impossible when the oxide layer is penetrated during welding.

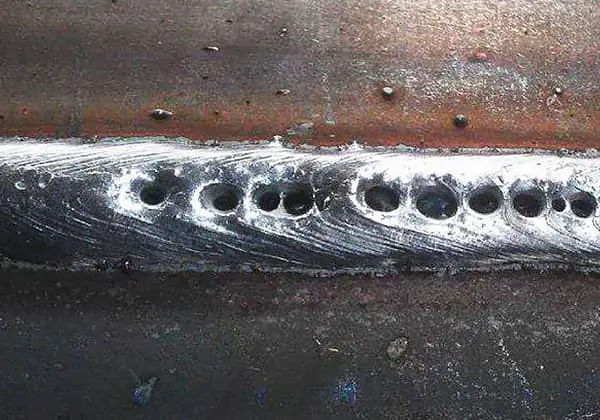

Effective welding can only be achieved when the surface oxide layer is damaged or exposed. During AC TIG welding, the tungsten electrode continuously alternates between positive and negative polarity. When the electrode is positive, negative electrons move from the workpiece to the electrode, causing the oxide layer to break. As the electrode becomes negative, electrons move from the electrode to the workpiece, generating heat and allowing the weld to penetrate.

Related reading: Aluminum Alloy Welding: Method and Material Selection

The welding power source that is designed for direct current is equipped with an inverter that produces alternating current.

Many welding machines have various settings that allow for adjusting the AC conductance during the conversion of positive and negative current.

Users can choose from various half-wave options.

Example: The current can flow in a positive range and then switch to a negative range with equal intensity, forming a constant rectangular waveform.

With these settings applied, the oscillogram will be stable, but the intense noise generated during the welding process can be bothersome for the welder, requiring the use of ear muffs.

A smooth sinusoidal waveform is also an option. However, this will reduce the noise level but result in an unstable arc.

For most aluminum welding applications, the optimal choice is a combination of both waveforms. The negative current half wave is represented by a rectangular waveform with rounded corners, while the positive current half wave is sinusoidal.

The Vonnex welding system also offers a triangle waveform, which can be combined with other waveforms for a stable high-voltage arc. The welder can choose the most suitable setting for each specific application.

When purchasing tungsten electrodes, the top of the electrode rod should be flat.

When using direct current, the tungsten electrode tip is typically cut into a sharp shape.

However, to maintain a stable arc, the top of the tungsten electrode tip must be shaped into a semicircular arc when working with alternating current, as this allows for better control of the arc.

This semicircular electrode tip is commonly referred to as a “cap.”