How can you ensure the welding rods you’re using are of high quality? This article introduces straightforward methods for checking welding rod quality, including visual inspection, testing coating strength, and identifying electrode deterioration. By understanding these simple techniques, you can avoid common welding issues like excessive spatter and unstable arcs. Discover practical tips to ensure your welding rods meet necessary standards, ensuring better welding performance and reliability.

Welding rods are a commonly used welding material, but sometimes they can be difficult to use. Problems such as excessive spatter, unstable arcs, and poor weld formation can be caused by low-quality welding rods.

Fortunately, there are simple methods to inspect welding rods even if you don’t have access to professional testing equipment. Allow me to briefly introduce a few of these methods.

Related reading: How to Choose the Right Welding Rod?

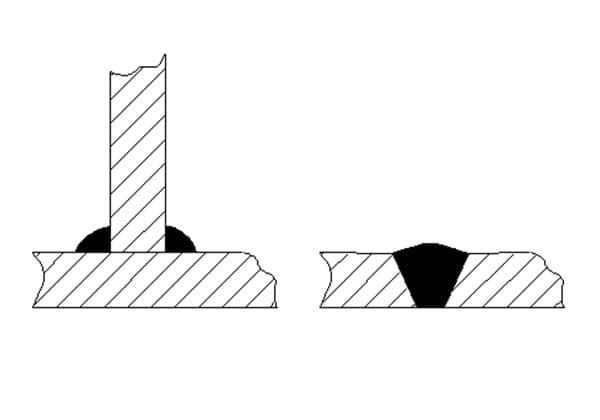

The quality of a welding rod can be inspected by examining the resulting welding joint. A high-quality welding rod will produce a stable arc during welding, with even melting of both the welding core and coating. There will be minimal splatter, and the resulting weld joint will be well-formed with easily removable slag.

One way to test the quality of a welding rod’s coating strength is to lift the electrode to a height of one meter and let it fall freely onto a smooth, thick steel plate. If the coating does not come off, it indicates that the coating strength meets the required quality standards.

The surface of a welding rod’s coating should be smooth and even, without any pores or mechanical damage. The coating should also be free from any eccentricities, and the welding core should not have any corrosion.

To ensure the quality of the welding rod, it is necessary to recheck the chemical composition and mechanical properties of the deposited metal in accordance with the requirements of the engineering design.

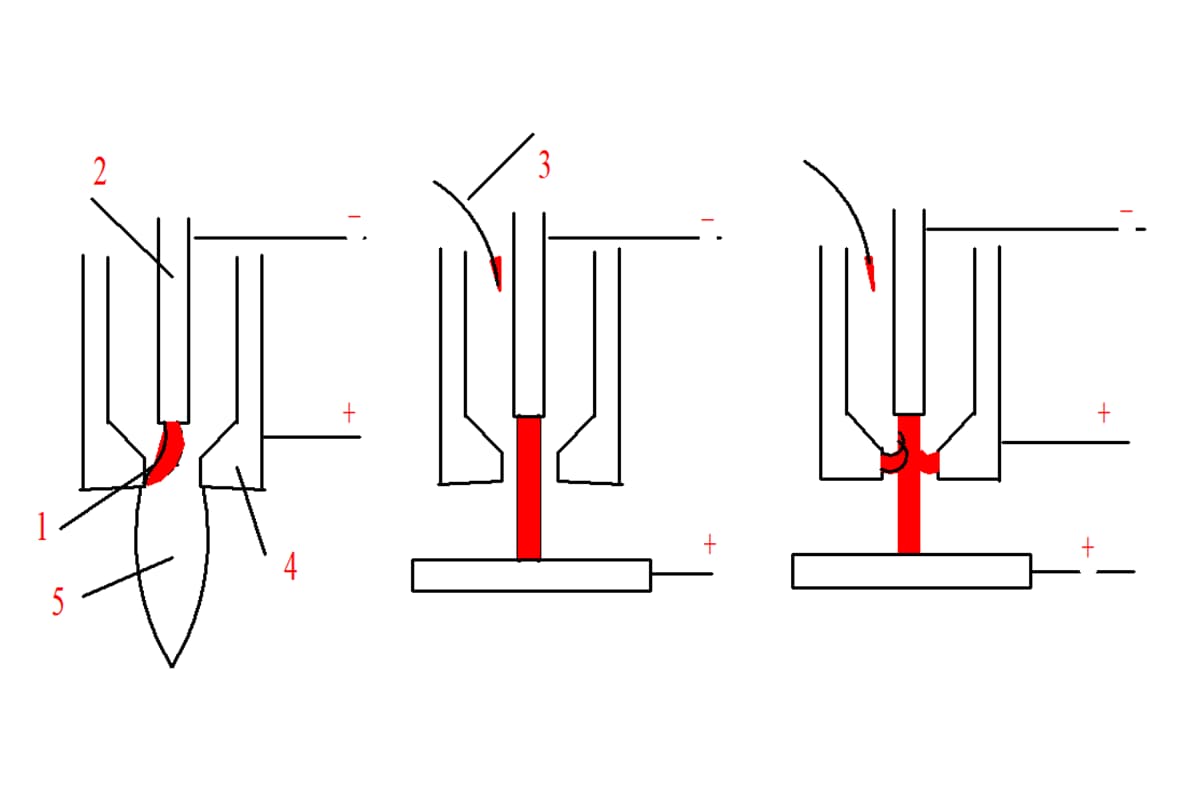

(1) To determine if a welding rod is dry or damp, place several welding rods in the palm of your hand and roll them against each other. If you hear a clear metallic sound, it is a dry welding rod. If you hear a low rustling sound, it is a damp welding rod.

(2) To check if an electrode is damp, short circuit it in the welding circuit for several seconds. If granular spots appear on the coating surface, it is a damp electrode.

(3) Damp electrodes often have rust marks on the welding core.

(4) For electrodes with thick coatings, slowly bend them to 120°. If a large amount of coating falls off or there are no cracks on the coating surface, it is a damp electrode. Dry electrodes will produce a small, brittle cracking sound when lightly bent, and when bent to 120°, a small crack will appear on the side of the coating under tension.

(5) If the coating falls off in large chunks or a significant amount of water vapor is generated during welding, it is an indication of a damp electrode. In such cases, the damp electrode must be discarded.

While damp electrodes can be reused after drying, it is important to note that low hydrogen welding rods for important projects cannot be used if rust is present on the welding core.