Attention all metalworking professionals! Are you tired of unexpected downtime due to perplexing error codes on your AMADA CNC Press Brake? Look no further! In this blog post, a seasoned mechanical engineering expert demystifies the most common alarm codes, providing clear explanations and practical troubleshooting solutions to keep your press brake running smoothly. Get ready to boost your productivity and minimize frustration with these invaluable insights!

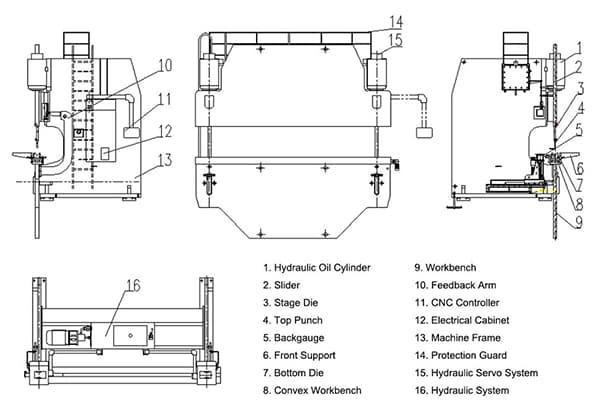

AMADA Press Brake Machine is a cost-effective equipment in the sheet metal processing plant due to its high bending precision, fast speed, and low number of faults.

However, when using the AMADA CNC Press Brake for the first time, the operator may not be familiar with the alarm code information. This is often due to incorrect operation, and some codes may indicate faults with the equipment.

This post provides a list of error codes and their handling methods for AMADA CNC Press Brake to help you troubleshoot any problems with your press brake.

Let’s dive right into it.

Battery failure

Press the reset key.

ROM check sum error

Turn off the power, replace the ROM and turn on the power.

D / A digital to analog converter error (host side)

Shut down, repair and turn on the power supply.

D / A digital to analog converter error (slave side)

Shut down, repair and turn on the power supply.

PC ROM fault

Turn off the power, replace the ROM and turn on the power.

D-axis ROM fault

Turn off the power, replace the ROM and turn on the power.

D-axis ROM fault

Turn off the power, replace the motherboard and turn on the power.

Y-axis ROM fault

Turn off the power, replace the ROM and turn on the power.

Y-axis ROM fault

Turn off the power, replace the motherboard and turn on the power.

Z-axis ROM fault

Turn off the power, replace the ROM and turn on the power.

Z-axis ROM fault

Turn off the power, replace the motherboard and turn on the power.

D-axis cannot be sequenced

Shut down, turn off the power, repair and turn on the power.

Y-axis cannot be sequenced

Shut down, turn off the power, repair and turn on the power.

Z-axis cannot be sequenced

Shut down, turn off the power, repair and turn on the power.

D-axis parameter failure

Shut down, turn off the power, repair and turn on the power.

Y-axis parameter failure

Shut down, turn off the power, repair and turn on the power.

Z-axis parameter fault

Shut down, turn off the power, repair and turn on the power.

Relay fault

Shut down, turn off the power, repair and turn on the power.

Temperature switch of hydraulic motor

Find out the possible causes and deal with them. Reset the temperature switch and turn on the power.

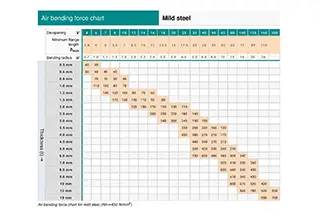

Tonnage error

Shut down, turn off the power, repair and turn on the power.

Main pressure too high

Find out the possible causes and handle them, and press the alarm reset key.

Air pressure drop

Find out the possible causes and handle them, and press the alarm reset key.

Uneven pressure

Find out the possible causes and handle them, and press the alarm reset key.

NC hardware emergency stop

Shut down, turn off the power, repair and turn on the power.

The protective cover is opened

Close the cover and press the alarm reset key.

Upper mold action failed

Shut down, turn off the power, repair and turn on the power.

Relay fault (1)

Turn off the power and then turn it on.

Relay fault (2)

Turn off the power and then turn it on.

Relay fault (3)

Turn off the power and then turn it on.

Relay fault (4)

Turn off the power and then turn it on.

Relay fault (5)

Turn off the power and then turn it on.

Relay fault (6)

Turn off the power and then turn it on.

Relay fault (7)

Turn off the power and then turn it on.

Relay fault (8)

Turn off the power and then turn it on.

Abnormal stop

Press the emergency open button to open the upper die and press the alarm reset key.

Message error (ladder detection)

Shut down, turn off the power, repair and turn on the power.

Message error (bndnc detection)

Message error (bndnc found)

Mmi-nc information error

Turn off the power and then turn it on.

CS1 – remote I / O information error

Shut down, turn off the power, repair and turn on the power.

NC temperature alarm

Turn off the power and cool.

Control panel temperature alarm

Turn off the power and cool.

EEPROM write overcurrent

Shut down, turn off the power, repair and turn on the power.

Parameter alarm & Shutdown

Turn off the power, repair and turn on the power.

System alarm

Shut down, turn off the power, repair and turn on the power.

WDT alarm

Shut down, turn off the power, repair and turn on the power.

Thermometer failure

Shut down, turn off the power, repair and turn on the power.

Pressure sensor failure

Shut down, turn off the power, repair and turn on the power.

Upper die lifting failed

Shut down, turn off the power, repair and turn on the power.

Upper module return failed

Turn off the power, find out the possible causes and deal with them, and press the alarm reset key.

M1AT (Main) fault

Turn off the power and then turn it on.

M1AT (Times) fault

Turn off the power and then turn it on.

Abnormal stop (M1 tilt abnormal stop)

Shut down, turn off the power, repair and turn on the power.

Abnormal stop (2) (MPC abnormal stop)

Shut down, turn off the power, repair and turn on the power.

Abnormal stop (3) (M1 deceleration abnormal stop)

Shut down, turn off the power, repair and turn on the power.

Abnormal stop (4) (abnormal close detection)

Shut down, turn off the power, repair and turn on the power.

Relay fault (10) (foot switch error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (11) (abnormal stop error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (12) (sending off signal error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (13) (M1 sends open signal error)

Shut down, turn off the power, repair and turn on the power.

Relay failure (14) (alternative safety device invalid error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (15) (close start MPC error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (16) (maximum closing limit on error)

Shut down, turn off the power, repair and turn on the power.

Relay failure (17) (causing abnormal fr bending (number of blows)

Shut down, turn off the power, repair and turn on the power.

Relay fault (18) (FS1a error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (19) (fs1b error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (20) (prevent reoperation error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (21) (operation error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (22) (closing start Ka error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (23) (maximum closing limit storage error)

Shut down, turn off the power, repair and turn on the power.

Relay fault (24) (full up mode error)

Shut down, turn off the power, repair, and turn on the power.

Relay fault (25) (closing M1 error)

Shut down, turn off the power, repair, and turn on the power.

Relay fault (26) (closing LSV error)

Shut down, turn off the power, repair, and turn on the power.

Relay fault (27) (normal action relay error)

Shut down, turn off the power, repair, and turn on the power.

Relay fault (28) (initialization detection error)

Shut down, turn off the power, repair, and turn on the power.

Safety valve error

Press alarm reset.

Pre injection pilot valve error

Press alarm reset.

Transmission valve error

Press alarm reset.

Internal logic error 1 (unable to count SD timer)

Reset the power supply.

Internal logic error 1 (SD position output when SD timer counts)

Press the alarm reset key.

Internal logic error 1 (start condition is different from valve condition)

Reset the power supply.

Raster error

Press the alarm reset key.

Float valve error

Move the upper die to its opening limit position, and then inject oil again.

The upper die and tension bar may have been twisted

Move the upper die to its opening limit position and reset the alarm. If the l-axis tilts, repair and restart the system.

Upper mold locking movement error

Repair and reset the power supply.

Replace the filter element

If blocked, replace the element.

Action gain change error

Leakage error

Shut down, turn off the power, repair and turn on the power.

Leakage error

Shut down, turn off the power, repair and turn on the power.

Filter blockage alarm

The signal line may be disconnected. Turn off the power, repair and turn on the power.

CS1 abnormal stop circuit fault (remote I / O)

Shut down, turn off the power, repair and turn on the power.

NC abnormal stop circuit fault 1

Shut down, turn off the power, repair and turn on the power.

Abnormal gain detection circuit fault 1

Shut down, turn off the power, repair and turn on the power.

CS1 abnormal stop circuit fault 1

Shut down, turn off the power, repair and turn on the power.

Tilt detection circuit fault 1

Shut down, turn off the power, repair and turn on the power.

CS1 abnormal stop circuit fault 2

Shut down, turn off the power, repair and turn on the power.

Restart to prevent circuit failure

Shut down, turn off the power, repair and turn on the power.

Abnormal gain detection circuit fault 2

Shut down, turn off the power, repair and turn on the power.

NC abnormal stop circuit fault 2

Shut down, turn off the power, repair and turn on the power.

Tilt detection circuit fault 2

Shut down, turn off the power, repair and turn on the power.

Fu1 (linear servo amplifier power fuse) is off

Replace fuse 1 and reset the power supply.

Fu2 (AC100V power fuse) is off

Replace fuse 2 and reset the power supply.

Fu2 (DC24V power fuse) is off

Find out the cause, replace fuse 2 and reset the power supply.

Fu3 (Z-axis brake fuse) is off

Replace fuse 3 and reset the power supply.

Fu3 (AC100V power fuse) is off

Find out the cause, replace fuse 3 and reset the power supply.

Fu5 (DC24V power fuse) is off

Replace fuse 5 and reset the power supply.

Fu5 (DC24V power fuse) is off

Find out the cause, replace fuse 5 and reset the power supply.

Fu (valve controller power fuse) is off

Replace fuse 6 and reset the power supply.

Fu4 (Z-axis brake fuse) is off

Find out the cause, replace fuse 4 and reset the power supply.

D1 – abnormal pressure on shaft rod

The hydraulic system may have broken. Turn off the power, repair and then power on.

D2 – abnormal pressure on shaft rod

The hydraulic system may have broken. Turn off the power, repair and then power on.

D1 – abnormal logic pressure on shaft rod

The hydraulic system may have broken. Turn off the power, repair and then power on.

D2 – abnormal logic pressure on shaft rod

The hydraulic system may have broken. Turn off the power, repair and then power on.

Ramlocklimit error.

Shut down, repair and turn on the power supply.

Axis d1abs encoder initialization error

Shut down, repair and turn on the power supply.

Axis d1abs encoder initialization error

Shut down, repair and turn on the power supply.

Parameter changes are prohibited before resetting the origin

Reset the power supply.

The beam is opened during ABS encoder loading

Reset the power supply.

ABS encoder error 1

Shut down, repair and turn on the power supply.

ABS encoder error 2

Shut down, repair and turn on the power supply.

Encoder data alarm (servo amplifier alarm a.84)

Shut down, repair and turn on the power supply.

Encoder battery alarm (servo amplifier alarm a.83)

Replace the battery (servo amplifier).

Encoder summation check alarm (servo amplifier alarm a.82)

Reset the power supply.

Encoder backup alarm (servo amplifier alarm a.81)

Reset absolute origin.

Valve action error

Turn off the power and then turn it on. (repair required).

High voltage signal error

The ball joint or pressure sensor may have been disconnected. Turn off the power, repair and turn on the power.

CC shaft overtravel (-)

Move the CC axis in the (+) direction and press the alarm reset key.

D-axis overtravel (+)

Move the d-axis in the (-) direction and press the alarm reset key.

D-axis tilt

Fix and press the alarm reset key.

L1 – shaft overtravel (+)

Move L1 axis in (-) direction and press alarm reset key.

L2 – shaft overtravel (+)

Move the L2 axis in the (-) direction and press the alarm reset key.

L-axis tilt

Turn off the power, straighten the reverse travel limiter to balance it with the base, and turn on the power again.

Handwheel encoder error.

Turn off the power and then turn it on.

Yr axis super program (+)

Move the yr axis in the (-) direction and press the alarm reset key.

YL axis program (-)

Move the YL axis in the (+) direction and press the alarm reset key.

ZL axis program (-)

Move the ZL axis in the (+) direction and press the alarm reset key.

Zr axis program (-)

Move the Zr axis in the (+) direction and press the alarm reset key.

CC axis servo failure

Turn off the power, find out the possible causes, deal with them and turn on the power.

L1 axis servo failure

Turn off the power, find out the possible causes, deal with them and turn on the power.

L2 axis servo failure

Turn off the power, find out the possible causes, deal with them and turn on the power.

Y-axis servo failure

Turn off the power, find out the possible causes, deal with them and turn on the power.

Z-axis servo failure

Turn off the power, find out the possible causes, deal with them and turn on the power.

D-axis encoder circuit fault

Turn off the power, replace the motherboard and turn on the power.

Y-axis encoder circuit fault

Turn off the power, replace the motherboard and turn on the power.

Z-axis encoder circuit fault

Turn off the power, replace the motherboard and turn on the power.

D1 axis high frequency alarm

Restart the system after inspection.

D2 axis high frequency alarm

Restart the system after inspection.

Y-axis automatic zero balance fault

Shut down, turn off the power, repair and turn on the power.

Z-axis automatic zero balance fault

Shut down, turn off the power, repair and turn on the power.

D1-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

D2-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

L1-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

L2 axis encoder fault

Shut down, turn off the power, repair and turn on the power.

CC-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

YL-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

YR-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

ZL-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

ZR-axis encoder fault

Shut down, turn off the power, repair and turn on the power.

Timeout while positioning D1 axis

Press the alarm reset key. (repair required).

Timeout while positioning D2 axis

Press the alarm reset key. (repair required).

L1-axis position setting timeout

Press the alarm reset key. (maintenance required)

L2-axis position setting timeout

Press the alarm reset key. (maintenance required)

Timeout while positioning YL axis

Press the alarm reset key. (repair required).

Timeout when positioning yr axis

Press the alarm reset key. (repair required).

Timeout while positioning ZL axis

Press the alarm reset key. (repair required).

Timeout while positioning Zr axis

Press the alarm reset key. (repair required).

Too many L1 axis errors

Adjust the servo mechanism.

Too many errors in L2 axis

Adjust the servo mechanism.

Too many errors on CC axis

Adjust the servo mechanism.

Too many errors on d-axis

Shut down, turn off the power, repair and turn on the power.

D1 – shaft overtravel (+)

Move the D-axis in the (-) direction and press the alarm reset key.

D2 – shaft overtravel (+)

Move the d-axis in the (-) direction and press the alarm reset key.

ZL axis overtravel (+)

Move the Z-axis in the (-) direction and press the alarm reset key.

ZR axis overtravel (+)

Move the Z-axis in the (-) direction and press the alarm reset key.

No zero phase limit signal (D1 axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (D2 axis)

Turn off the power and then turn it on. (repair required).

No grid point (L1 axis)

Turn off the power and then turn it on. (repair required).

No grid point (L2 axis)

Turn off the power and then turn it on. (repair required).

No grid point (CC axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (YL axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (YR axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (ZL axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (ZR axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (PT axis)

Turn off the power and then turn it on. (repair required).

No zero phase limit signal (PW axis)

Turn off the power and then turn it on. (repair required).

Clearance along D-axis

Press the alarm reset key.

Clearance along l-axis

Press the alarm reset key.

Clearance along YZ axis

Press the alarm reset key.

The origin height has changed

Press the alarm reset key and reset the origin

The difference between left and right is too big

Turn off the power and then turn it on. (repair required).

Passedgoal exceeded the target

Turn off the power and then turn it on. (repair required).

D-axis command sequence failure

Turn off the power and then turn it on. (repair required).

D-axis super program (-)

Turn off the power and then turn it on.

D1 – shaft overtravel (-)

Turn off the power and then turn it on.

D2 – shaft overtravel (-)

Turn off the power and then turn it on.

Too many errors on D1-axis

Adjust the servo mechanism.

Too many errors on D2 axis

Adjust the servo mechanism.

Z1-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

Z2-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

D1-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

D2-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

Y1-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

Y2-axis servo failure

Turn off the power, check the servo amplifier and turn on the power.

Main coil fault

Turn off the power and then turn it on. (repair required).

YR-axis sequence fault

Press the alarm reset key.

ZL-axis sequence fault

Press the alarm reset key.

ZR- axis sequence fault

Press the alarm reset key.

PT-axis sequence fault

Press the alarm reset key.

PW-axis sequence fault

Press the alarm reset key.

L-axis movement timing fault

Press the alarm reset key.

YZ-axis movement timing fault

Press the alarm reset key.

D1 – too many errors on the axis (when stopped)

Adjust the servo mechanism.

Too many errors on D2-axis (at stop)

Adjust the servo mechanism.

D1 – too many errors on the axis (in motion)

Adjust the servo mechanism.

Too many errors on D2-axis (in motion)

Adjust the servo mechanism.

D1 – too many errors on the axis (combined)

Adjust the servo mechanism.

Too many errors on D2-axis (combined)

Adjust the servo mechanism.

Too many errors on Y1-axis

Adjust the servo mechanism.

Too many errors on Y2-axis

Adjust the servo mechanism.

Too many errors on Z1 -axis

Adjust the servo mechanism.

Too many errors on Z2- axis

Adjust the servo mechanism.

L1 -axis communication determined

Turn off the power and then turn it on.

L2- axis communication determined

Turn off the power and then turn it on.

Y1- axis communication determined

Turn off the power and then turn it on.

Y2- axis communication determined

Turn off the power and then turn it on.

Z1- axis communication determined

Turn off the power and then turn it on.

Z2-axis communication determined

Turn off the power and then turn it on.

7-axis communication determined

Turn off the power and then turn it on.

8-axis communication determined

Turn off the power and then turn it on.

9-axis communication determined

Turn off the power and then turn it on.

10 -axis communication determined

Turn off the power and then turn it on.

11- axis communication determined

Turn off the power and then turn it on.

Communication fault alarm

Turn off the power and then turn it on. (repair required).

External posture

Turn off the power and then turn it on. (repair required).

Overpressure

Turn off the power and then turn it on. (repair required).

Control power error

Turn off the power and then turn it on. (repair required).

The main power supply voltage decreases

Turn off the power and then turn it on.

Main power loss

Turn off the power and then turn it on.

Read write error

Turn off the power and then turn it on.

L1- axis power supply error

Turn off the power and then turn it on.

L2- axis power supply error

Turn off the power and then turn it on.

Y1- axis power supply error

Turn off the power and then turn it on.

Y2 -axis power supply error

Turn off the power and then turn it on.

Z1- axis power supply error

Turn off the power and then turn it on.

Z2- axis power supply error

Turn off the power and then turn it on.

7-axis power supply error

Turn off the power and then turn it on.

8-axis power supply error

Turn off the power and then turn it on.

9-axis power supply error

Turn off the power and then turn it on.

10- axis power supply error

Turn off the power and then turn it on.

11- axis power supply error

Turn off the power and then turn it on.

12- axis power supply error

Turn off the power and then turn it on.

L1 – shaft overload

Turn off the power and then turn it on.

L2- axis overload

Turn off the power and then turn it on.

Y1- axis overload

Turn off the power and then turn it on.

Y2- axis overload

Turn off the power and then turn it on.

Z1 – shaft overload

Turn off the power and then turn it on.

Z2 -axis overload

Turn off the power and then turn it on.

7-shaft overload (optional)

Turn off the power and then turn it on.

8-axis overload (optional)

Turn off the power and then turn it on.

9-axis overload (optional)

Turn off the power and then turn it on.

10 – shaft overload (optional)

Turn off the power and then turn it on.

11 – shaft overload (optional)

Turn off the power and then turn it on.

12 – shaft overload (optional)

Turn off the power and then turn it on.

L1-axis acceleration

Turn off the power and then turn it on.

L2 -axis acceleration

Turn off the power and then turn it on.

Y1 -axis acceleration

Turn off the power and then turn it on.

Y2- axis acceleration

Turn off the power and then turn it on.

Z1- axis acceleration

Turn off the power and then turn it on.

Z2 -axis acceleration

Turn off the power and then turn it on.

7-axis acceleration (optional)

Turn off the power and then turn it on.

8-axis acceleration (optional)

Turn off the power and then turn it on.

9-axis acceleration (optional)

Turn off the power and then turn it on.

10 – shaft acceleration (optional)

Turn off the power and then turn it on.

11 – shaft acceleration (optional)

Turn off the power and then turn it on.

12 – shaft acceleration (optional)

Turn off the power and then turn it on.

L1 -axis speed control abnormal

Turn off the power and then turn it on.

L2 -axis speed control abnormal

Turn off the power and then turn it on.

Y1- axis speed control abnormal

Turn off the power and then turn it on.

Y2 -axis speed control abnormal

Turn off the power and then turn it on.

Z1- axis speed control abnormal

Turn off the power and then turn it on.

Z2 -axis speed control abnormal

Turn off the power and then turn it on.

7-axis speed control abnormal (optional)

Turn off the power and then turn it on.

8-axis speed control abnormal (optional)

Turn off the power and then turn it on.

9-axis speed control abnormal (optional)

Turn off the power and then turn it on.

10 – abnormal shaft speed control (optional)

Turn off the power and then turn it on.