How does a simple screw transform into a precise control system used in robotics and aerospace? This article explores the fascinating mechanics behind ball screws, key components that convert rotational motion into linear motion with high efficiency and accuracy. Delve into their structure, operation, and critical role in various industries. By reading, you’ll understand how ball screws enhance performance in everything from medical devices to automated manufacturing lines.

Ball screw

The ball screw is made up of several components, including the screw, nut, steel balls, pre-compression piece, reverser, and dustproof device. Its main function is to convert rotary motion into linear motion by transforming sliding motion into rolling motion.

In 1898, the concept of using steel balls between the nut and screw to convert the sliding contact of a traditional screw into rolling contact was first introduced. This change in friction from sliding to rolling allowed for the rotary motion of the steel balls in the nut to be transformed into linear motion, resulting in an improved torque conversion and reduced positioning issues and damage compared to traditional screws.

The invention of the ball screw is credited to Rudolph G. Boehm from Texas, who was granted a US patent for it in 1929. When used as an active component, the nut is converted into linear motion with the rotation angle of the screw, guided by specific specifications. The passive workpiece can be connected to the nut through a nut holder.

The ball screw assembly is typically made of steel and consists of a female nut and a screw with a helical groove that matches the screw’s groove.

The groove inside the nut contains many small chrome steel balls. As these balls circulate within the nut, they provide smooth movement along the screw, while a deflector or return system retains the balls and enables their circulation through the nut.

When paired with a motor, the efficiency of a ball screw can reach up to 90%. They are highly accurate, with a precision of a few thousandths of an inch per foot.

Ball screws are utilized by various industries for precise control, including aerospace, computer, electronics, automotive, and medical industries.

Ball screws are frequently employed in manufacturing processes such as in robots, automated assembly lines, material handling equipment, conveyors, machine tools, wire control, and precision assembly equipment.

The ball screw assembly consists of a screw and a nut, each with a complementary spiral groove. The balls roll within these grooves, serving as the sole point of contact between the nut and the screw.

When the screw or nut rotates, the balls are directed by the deflector to the ball return system within the nut. They move continuously through the return system to the opposite end of the ball nut, and then exit to the threaded raceway of the ball screw and nut for repeated circulation in a closed loop.

The ball nut plays a crucial role in determining the load and lifespan of the ball screw assembly. The ratio of the number of threads in the ball nut circuit to the number of threads on the ball screw determines which component will experience fatigue failure (wear) first.

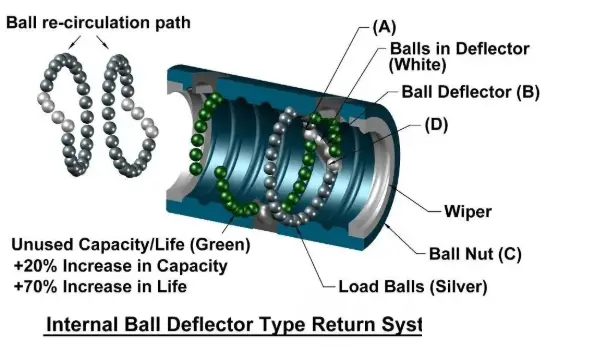

There are two types of ball return methods used in ball nuts: outer circulation and internal circulation.

In outer circulation, the balls return to the opposite end of the loop via a return pipe, which extends beyond the external diameter of the ball nut.

ball nut with external circulation

Inner circulation involves the balls passing through or returning along the interior wall of the nut, which is smaller in diameter than the outer diameter of the ball nut.

ball nut with internal circulation

In the case of internal circulation, the ball follows a rotating circuit and is forced to traverse the top of the screw’s thread through the return system. This is referred to as a cross deflector type internal return system.

In a ball nut with a cross deflector type, the balls only rotate the shaft once and the circuit is closed by a ball deflector (B) within the nut (C), enabling the balls to cross between adjacent grooves at points (A) and (D).

ball nut with internal circulation

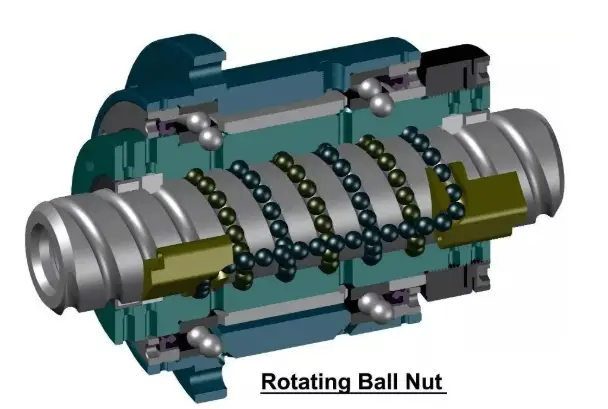

When a long ball screw rotates at high speed, if its slenderness ratio reaches the natural harmonic of its shaft size, it may start to vibrate. This is known as critical speed and can significantly reduce the lifespan of the ball screw. It is recommended to not operate the screw at a speed exceeding 80% of its critical speed for safety.

Rotation ball nut component

In some applications, longer shaft lengths and higher speeds are necessary, and in these cases, the use of a rotating ball nut assembly is required.