Have you ever pondered the importance of bend radius in mechanical design? In this article, we’ll explore this crucial concept and its impact on material integrity. Drawing from the expertise of seasoned engineers, we’ll provide valuable insights and guidelines to help you optimize your designs. Get ready to discover the secrets of successful bending and take your projects to the next level!

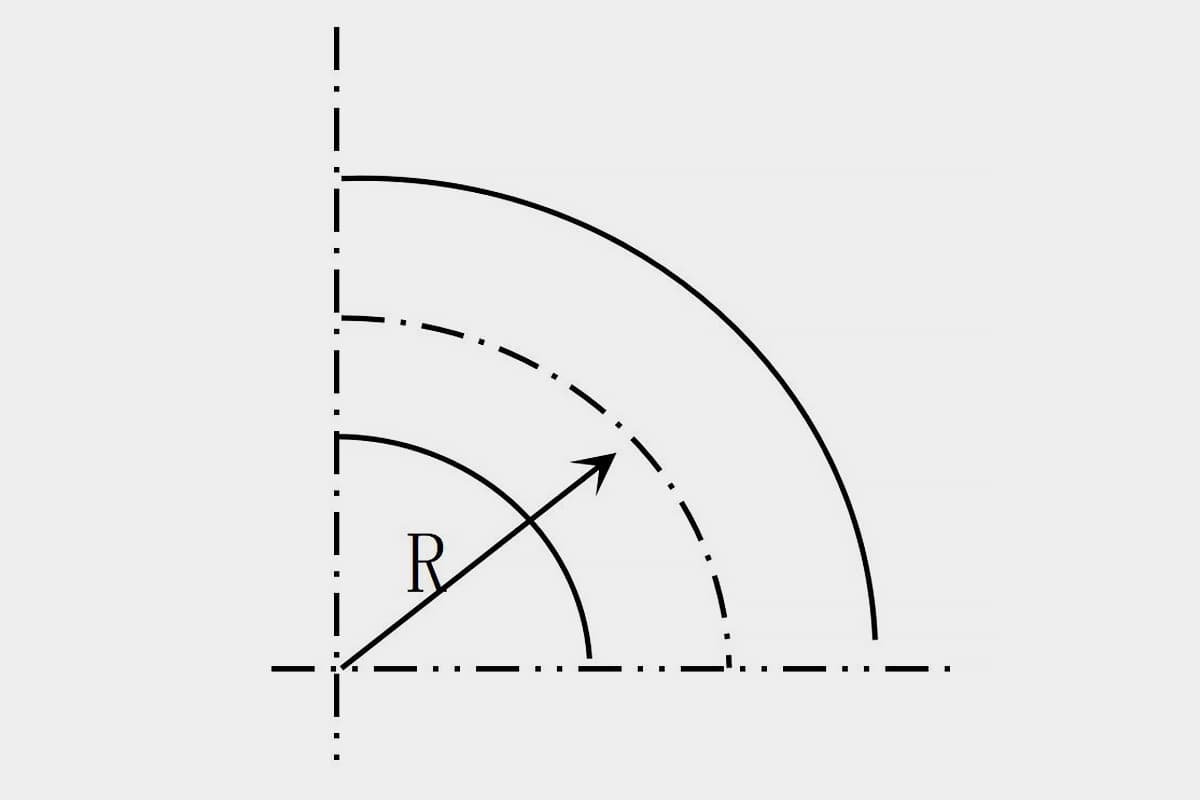

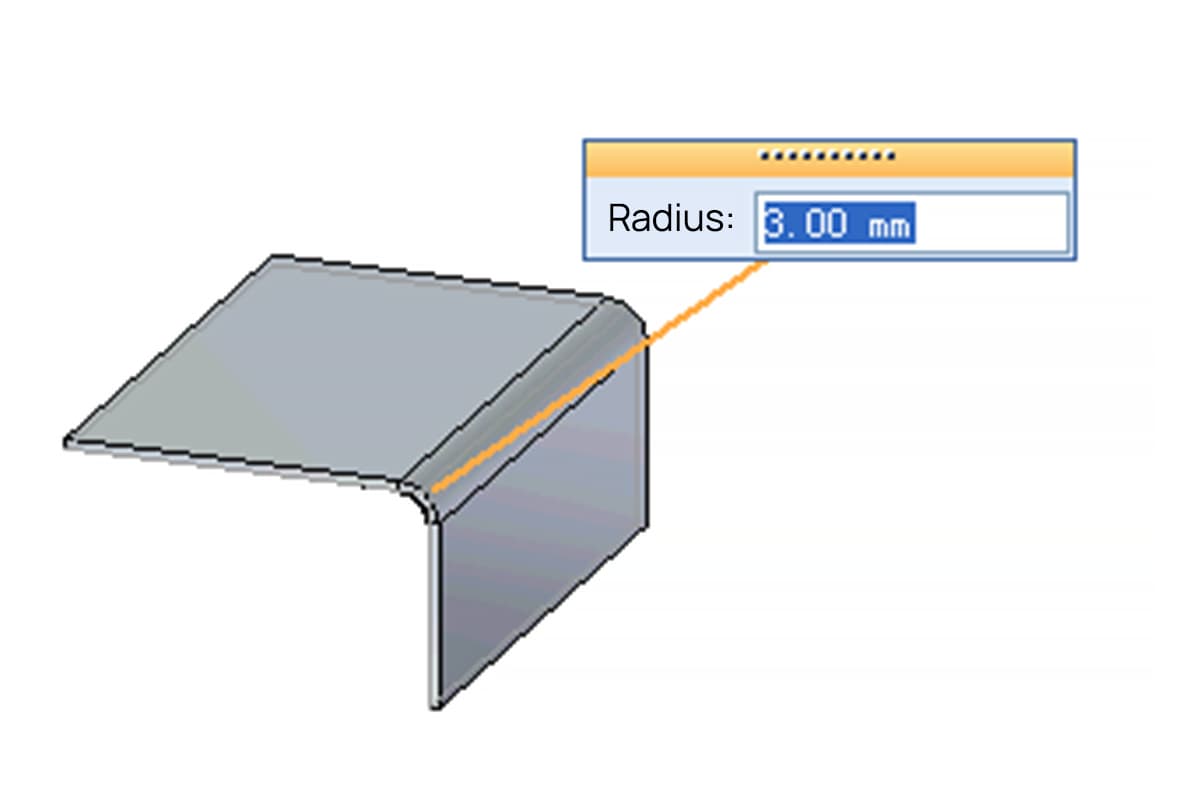

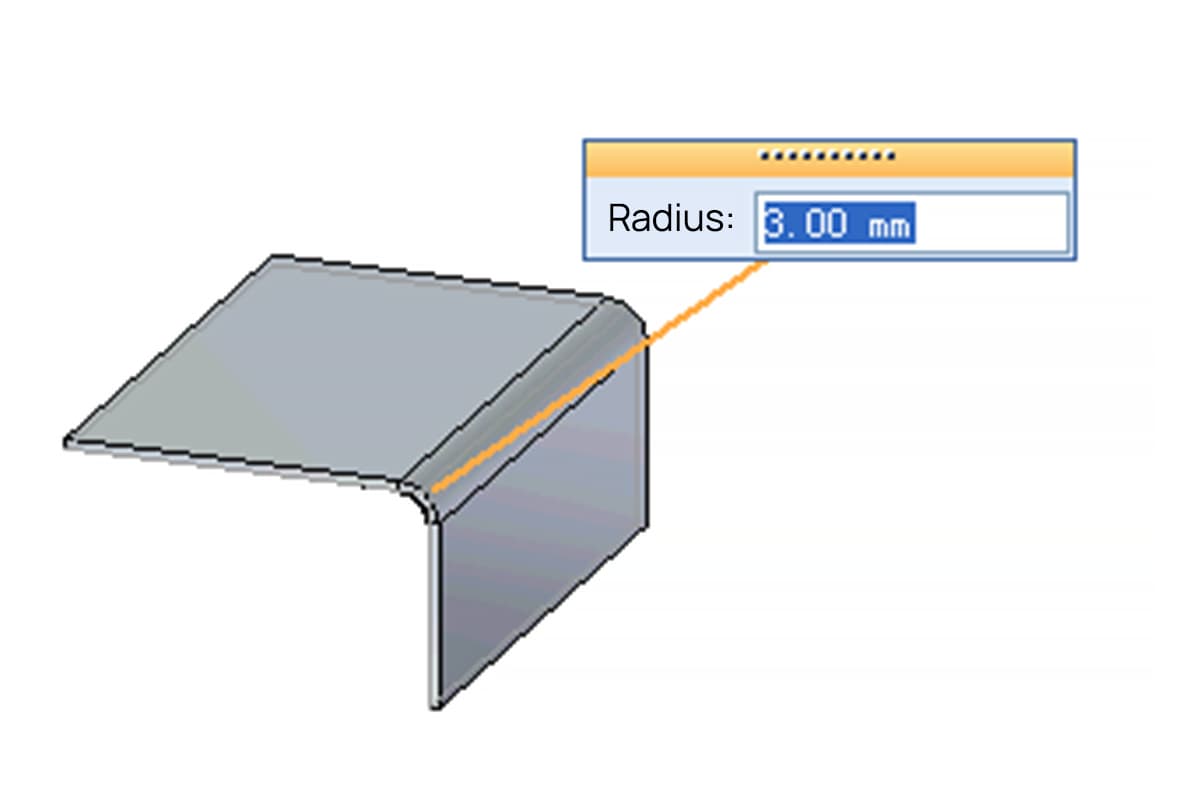

The bending radius refers to the inner radius of the bent part, where t represents the thickness of the material.

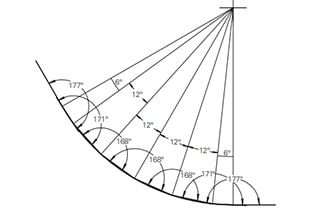

When the material bends, its rounded corner is stretched on the outside layer, while the inside layer is compressed. If the material thickness is fixed, the smaller the inner r, the more severe the material stretching and compression.

If the stretching stress of the outer rounded corner exceeds the material’s ultimate strength, cracks and breaks will occur. Therefore, the structural design of bent parts should avoid overly small bending corner radii.

| Item | Material | Thickness | Inside R | Die | Punch | ||

| Radius | V Width | Radius | Angle | ||||

| 1 | SPCC/SECC/SGCC | 0.8 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 2 | SPCC/SECC/SGCC | 0.9 | 1.3 | 0.5 | 6 | 0.2 | 88° |

| 3 | SPCC/SECC/SGCC | 1.0 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 4 | SPCC/SECC/SGCC | 1.2 | 1.0 | 0.4 | 6 | 0.2 | 88° |

| 5 | SPCC/SECC/SGCC | 1.2 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 6 | SPCC/SECC/SGCC | 1.5 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 7 | SPCC/SECC/SGCC | 1.6 | 1.3 | 0.5 | 8 | 0.6 | 88° |

| 8 | SPCC/SECC/SGCC | 1.8 | 2.0 | 0.8 | 12 | 0.6 | 88° |

| 9 | SPCC/SECC/SGCC | 2.0 | 2.0 | 0.8 | 12 | 0.6 | 88° |

| 10 | SPCC/SECC/SGCC | 2.3 | 2.0 | 0.8 | 12 | 0.6 | 88° |

| 11 | SPCC/SECC/SGCC | 2.5 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 12 | SPCC/SECC/SGCC | 3.0 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 13 | SPCC/SECC/SGCC | 4.0 | 4.0 | 0.8 | 25 | 0.6 | 88° |

| 14 | SPHC | 2.3 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 15 | SPHC | 3.2 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 16 | SPHC | 4.2 | 4.0 | 0.8 | 25 | 0.6 | 88° |

| 17 | SPHC | 4.8 | 4.0 | 0.8 | 25 | 0.6 | 88° |

| 18 | AL5052-H32 | 0.8 | 1.3 | 0.5 | 6 | 0.2 | 88° |

| 19 | AL5052-H32 | 1.0 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 20 | AL5052-H32 | 1.2 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 21 | AL5052-H32 | 1.5 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 22 | AL5052-H32 | 1.6 | 1.3 | 0.5 | 8 | 0.6 | 88° |

| 23 | AL5052-H32 | 1.6 | 1.3 | 0.6 | 10 | 0.6 | 88° |

| 24 | AL5052-H32 | 2.0 | 2.0 | 0.8 | 12 | 0.6 | 88° |

| 25 | AL5052-H32 | 2.3 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 26 | AL5052-H32 | 2.5 | 2.6 | 0.5 | 16 | 0.6 | 88° |

| 27 | AL5052-H32 | 3.0 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 28 | AL5052-H32 | 3.2 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 29 | AL5052-H32 | 3.5 | 4.0 | 0.8 | 25 | 1.5 | 88° |

| 30 | AL5052-H32 | 4.0 | 4.0 | 0.8 | 25 | 1.5 | 88° |

| 31 | AL5052-H32 | 5.0 | 4.0 | 0.8 | 25 | 3.2 | 88° |

| 32 | Copper | 0.8 | 1.3 | 0.5 | 6 | 0.2 | 88° |

| 33 | Copper | 1.0 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 34 | Copper | 1.2 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 35 | Copper | 1.5 | 1.3 | 0.5 | 8 | 0.2 | 88° |

| 36 | Copper | 2.0 | 2.0 | 0.8 | 12 | 0.6 | 88° |

| 37 | Copper | 2.5 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 38 | Copper | 3.0 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 39 | Copper | 3.2 | 2.6 | 0.8 | 16 | 0.6 | 88° |

| 40 | Copper | 3.5 | 4.0 | 0.8 | 25 | 1.5 | 88° |

| 41 | Copper | 4.0 | 4.0 | 0.8 | 25 | 1.5 | 88° |