Ever thought bending sheet metal could be so intricate? Closed bending, a critical technique in sheet metal processing, uses specialized methods to achieve precise, durable bends without needing a professional die. This article explores three practical approaches to mastering this technique. From leveraging long round holes to implementing reverse bending and grooving methods, you’ll gain valuable insights into achieving flawless closed bends in sheet metal fabrication. Ready to elevate your metalworking skills? Dive in and learn these advanced techniques to enhance your projects.

When I first started working in sheet metal processing, I believed that it was impossible to achieve close bending without using a professional die, as it appeared to be a challenging task.

However, later on, I had the chance to examine some sheet metal parts with closed bending designs that were processed using a press brake machine.

Upon analysis with my colleagues, I realized that sheet metal closed bending was possible after all.

So, I am writing this down for everyone to learn from.

I would like to share three feasible options that I have come up with.

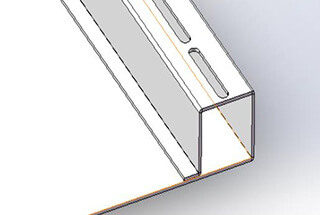

It’s important to note that not all closed bends are alike. Based on my recollection, I have created a diagram of a closed bend, as shown below:

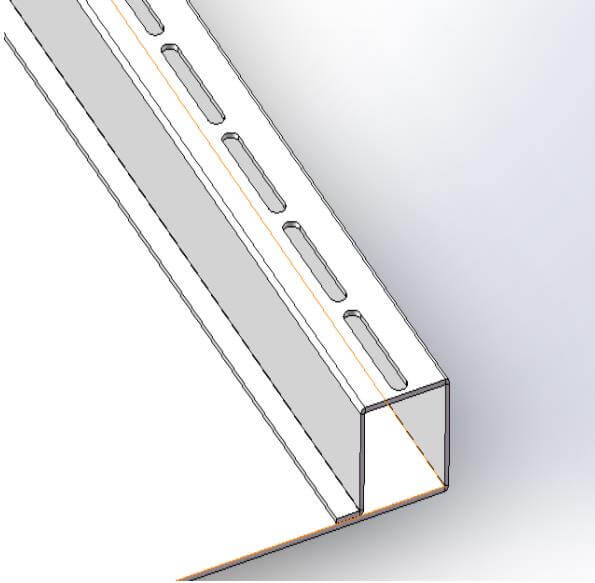

The picture above shows the sheet metal part that I encountered during that time. It is a door panel on a chassis cabinet.

This design serves a reinforcing purpose, which is similar to adding a square tube.

The critical aspect of this closed bending is the row of long circular holes in the figure. This is because of these long round holes, regular bending punches and dies can be used to complete the bending process, without the need for specialized dies.

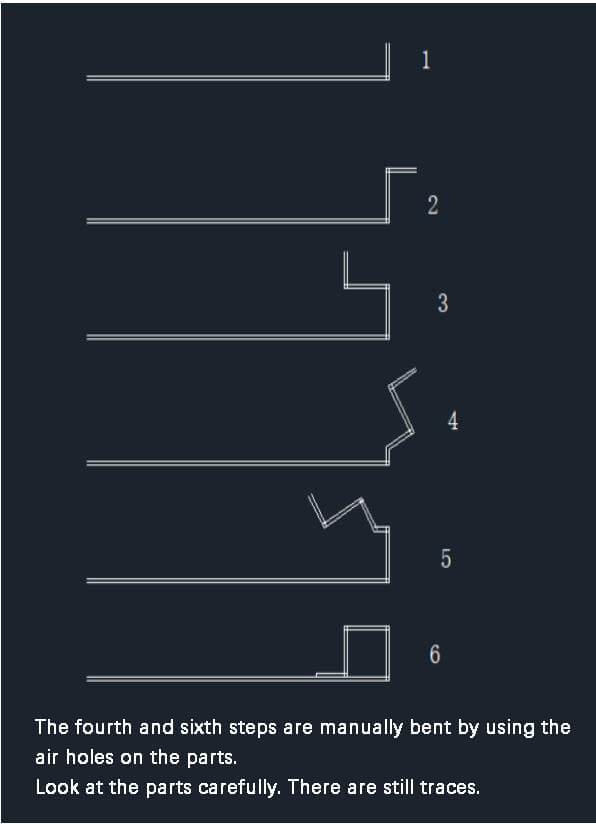

The specific steps are demonstrated in the figure below.

Steps for closed bending

The first to third steps involve normal bending, which a skilled bending master with experience can accomplish.

In the fourth step, the sheet metal part’s long round hole is used as it is the weakest point in terms of strength. The long round hole can be bent manually or pressed at a 45-degree angle using a bending machine.

The fifth step is completed using a bending machine, with care taken to avoid bending interference.

Once the fifth bend is completed, the bending deformation from step four can be flattened manually by tapping it with a hammer or using a flattening die.

According to a skilled bending master, uneven bending can occur if the bottom is closed and excessive deformation may result in cracks.

It’s true that after repair, there may be gaps. However, when the two sides are welded together, they will not separate. By following all the steps outlined above, the desired outcome can generally be achieved.

If not performed correctly, the bending results will be unsatisfactory, with deformation and depression at the long round hole.

For plastic sprayed parts, this is not a major concern as they can be repaired before being sprayed with plastic.

However, for stainless steel parts or sheet metal parts without surface treatment, there is another method that can be used, known as reverse bending without pre-opening the long round hole. This method is shown in the following figure:

In the third step, instead of bending to 90 degrees, the bend is made in place using a gooseneck punch in the fourth step. In the fifth step, the angle that was not folded in place in step three is pressed using a bending punch.

Finally, use a flattening die to achieve a desirable appearance.

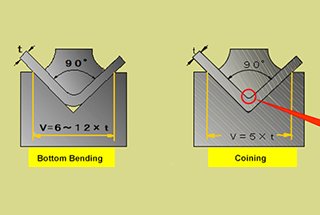

There is another method, that is, grooving before bending.

Some sheet metal factories may not have implemented grooving in their processes, and it may be added later in the work process.

In simple terms, a groove is processed at the bending line position using the grooving method. It is important to maintain some thickness and not groove completely. Usually, leaving 0.4 times the plate thickness is sufficient.

Grooving makes bending at this line much easier.

As shown in the above figure, the third step can bend to 90 degrees in one go, eliminating the need for the following steps. Because the last bend has been grooved, it can be bent manually or shaped and bent using a rubber hammer.

While the bending steps are relatively straightforward, grooving must be done first.

Additionally, after grooving, the rounded corners of the last bend will be smaller than those of the previous three bends, resulting in a different appearance.

A variety of methods for closed bending of sheet metal have been introduced, each with its own limitations.

This information is intended to provide inspiration and encourage further exploration.

Additionally, there are various forms of closed bending and different sizes, so the methods mentioned above may not be suitable in all cases. Detailed analysis is necessary to address any problems that may arise.