Ever wondered how the right cutting fluid can transform your machining process? This article dives into the essentials of selecting cutting fluids for CNC machining, highlighting their impact on tool life, surface quality, and efficiency. Discover practical tips and insights to enhance your machining operations and achieve superior results.

In mechanical cutting, there are several methods used when using CNC machine tools, including turning, milling, drilling, and boring. The amount of material removed is divided into three categories: rough machining, semi-finishing, and finishing.

The cutting tool materials used can be classified into five types: high-speed steel, hard alloy, ceramics, diamond, and cubic boron nitride.

The machine tools used can be divided into four categories: those that require oil-based cutting fluids, those that do not, single-piece small batch production tools, and batch or automatic production lines (flexible manufacturing systems).

It’s important to note that different cutting methods have different cutting characteristics for the same metal and can result in varying levels of processing difficulty.

For instance, when using Q235 carbon steel as the material, it can be challenging to machine threads while ensuring the desired surface roughness quality index. The process of finishing is more challenging than roughing.

Difficult cutting processes often require higher-quality cutting fluids. Proper usage of cutting fluid can guarantee the processing quality, extend the lifespan of the tool, and improve processing efficiency.

When separating roughing and finishing in a CNC machine tool or when the workpiece is not finished on a single machine, you can choose the cutting fluid based on the characteristics of roughing and finishing.

During rough machining, a large cutting depth and feed result in significant cutting resistance and heat. This causes the workpiece to deform and the tool to wear due to the increased heat transfer.

A water-based cutting fluid that primarily cools and has some lubricating, cleaning, and rust prevention effects should be used, with a high flow rate.

In milling or machining irregular shapes, uneven margins, and intermittent machining, the cutting speed is lower, and the impact of shock and vibration on the tool and workpiece is greater than the cutting heat. The cutting fluid should have a balanced lubrication and cooling effect.

When conditions permit, you can use internal liquid supply holes in the inner hole bar, boring knife, and grooving knife for hole processing, or use pressure and spray supply for rough machining of difficult-to-machine materials for better results.

Generally, the machining allowances for rough machining workpieces are large, and the accuracy requirements for surface roughness are not high when processing difficult-to-machine materials and non-ferrous metals.

Therefore, water-based extreme-pressure emulsions can be used without high chemical components in the cutting fluid. When rough-casting cast iron and brittle non-ferrous metals, a common characteristic is chip chipping during cutting.

Related reading: Ferrous vs Non-ferrous Metals

The fine chips become fluid when impacted by the cutting fluid, and most of them will settle when the cutting fluid circulates through the cutting fluid tank.

However, some chips flow with the cutting fluid and collect in small parts of the cutting fluid conveying pipe, which can block the cooling nozzle and cause the chips to adhere to the machine tool’s moving parts, such as the guide rail pair.

Additionally, the cutting fluid chemically reacts with certain components in the cast iron, leading to the deterioration of the cutting fluid’s performance.

Due to the challenges associated with cutting fluids, they are generally avoided. If conditions permit, a dust extraction device can be used to remove dust, fine chips, and some heat to reduce their impact.

If cutting fluid is necessary, water-based cutting fluid is recommended, and it is important to filter and purify the cutting fluid properly to prevent its deterioration and a decrease in concentration.

During rough machining, the cutting fluid’s concentration is typically lower than during finishing.

Finishing can be classified into high-speed finishing and low-speed finishing based on the cutting speed.

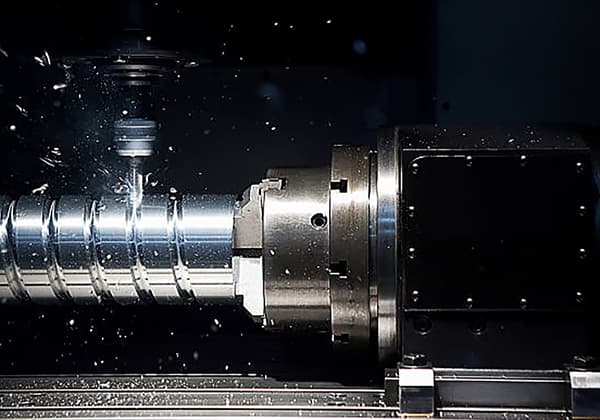

During high-speed finishing, using oil-based cutting fluid can improve the surface quality of the workpiece and extend the tool’s service life. However, the mineral oil contained in it has low viscosity and flash point, and it often produces oil fumes, oil mist, and oil vapor that can release toxic components, affecting the production environment and harming the operator’s physical and mental health.

Therefore, when high-speed finishing, it is best to use a water-based cutting fluid with an emulsion or micro-emulsion that contains extreme pressure additives, and the concentration should be higher than during rough machining.

In low-speed finishing, the cutting temperature is low, and these issues are less likely to occur.

To maintain the accuracy of the workpiece, oil-based cutting fluid should be used.

Compared to roughing, the cutting speed during finishing is higher. The cutting heat generated by chip deformation is lower than the cutting heat generated by friction on the tool’s flank, and the cutting force is smaller.

Even during high-speed cutting, the thermal deformation of the workpiece from cutting heat is not as pronounced as it is during rough machining.

The main reason for using cutting fluids in cutting tools is to reduce tool flank wear.

During finishing, the relative cutting speed is high and the temperature at the moment when the chip is removed from the workpiece is very high.

Even with the use of cutting fluid, if the fluid has poor permeability or insufficient pressure, it won’t penetrate the cutting area enough, which will cause the tool to be highly susceptible to flank wear.

Even if the tool can still be used, the surface roughness quality of the workpiece will not meet the requirements and the tool will still need to be replaced.

Therefore, during finishing, it is important to use cutting fluid with good lubrication and permeability to extend the tool’s service life and ensure the workpiece’s machining accuracy and surface roughness quality requirements.

For low-speed finishing of ferrous materials, active extreme pressure cutting oil can be used. For low-speed finishing of non-ferrous metals, non-reactive extreme pressure cutting oil should be used.

For high-speed finishing of non-ferrous metals, an emulsion with inactive extreme pressure additives can be used.

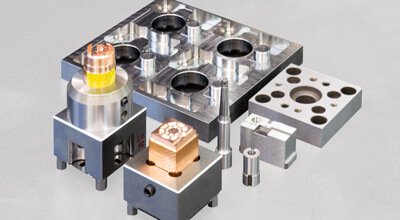

In CNC machining, hole machining mainly involves drilling, reaming, turning inner holes on a lathe, and boring on a boring machine.

Due to the challenges of chip removal and heat dissipation, the tool (rod) has poor rigidity, and the cutting speed for hole machining is lower and more difficult than for outer contour machining.

Drilling usually uses a general twist drill, which is considered rough machining.

Chip removal is difficult during drilling, and it is challenging to dissipate cutting heat, which often causes the blade to soften and affects the drill’s service life and processing efficiency.

Using a cutting fluid with good performance can significantly extend the drill’s life and significantly increase productivity.

Typically, extreme pressure emulsion or extreme pressure synthetic cutting fluid is used. The latter has low surface tension, good permeability, and can cool the drill bit promptly, making it very effective in extending tool life and improving processing efficiency.

For hard-to-cut materials such as stainless steel and heat-resistant alloys, low-viscosity extreme pressure cutting oils can be used.

When drilling, whether it’s normal drilling or deep hole drilling, poor heat dissipation conditions generate a lot of cutting heat. The direction of chip discharge is opposite to the drill’s feed direction, and the cutting fluid needs to penetrate the drill bit to lubricate, cool, and aid in chip removal.

The cutting fluid must have good permeability and the fluid supply method, flow rate, and pressure must also meet the requirements.

When it comes to improving drill life indicators, oil-based cutting fluids are generally better than water-based cutting fluids, and extreme pressure micro-emulsions in water-based cutting fluids are the best.

Of all cutting fluids, low-viscosity active sulfurized oil in oil-based cutting fluids has the best overall performance.

Reaming is a medium-to-low speed finishing operation, so when reaming a hole, two quality indicators, dimensional accuracy and surface roughness accuracy of the reamed hole, as well as the reamer’s service life and holding accuracy should be considered.

In terms of controlling the pore diameter index, oil-based cutting fluids all increase the pore diameter, with mineral oil making the pore diameter larger, extreme pressure cutting oil making it smaller, and active sulfurized and chlorinated oil making it the smallest.

Water-based cutting fluids reduce the pore size, with sulfur-containing extreme pressure micro-emulsions and micro-emulsions minimizing the pore size, the emulsion being centered, and synthetic cutting fluid being the smallest.

Therefore, to control the size of the reamed hole, when using a new reamer, water-based cutting fluid should be used to make the hole difficult to expand. When the reamer is worn to a certain extent, oil-based cutting fluid can be used to slightly expand the aperture.

In terms of reducing the surface roughness of the reamed hole, water-based cutting fluid is better than oil-based cutting fluid.

Among oil-based cutting fluids, active sulfurized chlorinated oil has the best effect, followed by chlorine-containing extreme pressure oil, mixed mineral oil, and pure mineral oil being the worst.

Among water-based cutting fluids, emulsions, micro-emulsions, and extreme pressure micro-emulsions containing sulfur have basically the same effect, and synthetic cutting fluid has the worst effect.

In terms of controlling the reamer’s service life, inactive extreme pressure cutting oil and anti-friction cutting oil in oil-based cutting fluid have the best performance.

Among water-based cutting fluids, synthetic cutting fluid has the worst effect.

Turning inner bores and boring, except for floating boring tools, are both single-edged cutting operations.

Heat dissipation conditions are worse than for outer circles.

When using cutting fluid, as with drilling and reaming, the flow and pressure must be appropriately increased.

Thread processing is a type of forming process.

When performing the tapping and thread setting operations, it falls under the category of multi-edge, low-speed cutting.

Due to the cutting material surrounding the cutting edge, the cutting torque is significant, and chip removal is challenging.

The lack of proper chip removal results in the accumulation of heat, which can cause the chips to become congested and vibrate, leading to tool wear.

Tapping conditions are particularly demanding, as the chip removal space is narrow, making it difficult for chips to break and flow out. This results in a high cutting force and friction force, which increases the risk of tap breakage.

To mitigate these issues, it’s essential to use a cutting fluid with both a low coefficient of friction and good permeability. This will reduce the frictional resistance on the tool and prolong its service life.

When cutting ferrous metal materials, it is generally recommended to use oil-based cutting fluids that contain high levels of sulfur and chlorine additives, with low viscosity and good permeability.

When using high-speed steel for low-speed turning of threads, the criteria for selecting a cutting fluid are the same as those for tapping and sleeve threading.

When turning threads with carbide tools, the cutting speed is high, the impact force is substantial, the cutting temperature is elevated, and the cutting edge area is small. This results in a high cutting force, and the thread profile must be accurate to avoid issues affecting the surface quality of the thread, such as chip accumulation and scale thorns.

To maintain the high service life of the tool, it’s crucial to have a cutting fluid that provides adequate cooling, lubrication, and penetration.

In this case, it’s appropriate to use a water-based cutting fluid that contains extreme pressure additives.

In order to prevent damage from uneven heating of the tool, dry cutting is often used when cutting with carbide tools.

However, for maximum efficiency, comprehensive cost savings, and optimal machining quality, it’s best to use cutting fluid when working on CNC machine tools.

When using carbide tools for machining, water-based cutting fluids are usually employed when the cutting speed is relatively high. It’s important to maintain a high flow rate and carefully monitor the alignment of the nozzle with the cutting position.

For low-speed cutting with high-speed steel tools, oil-based cutting fluids that provide lubrication are typically used.

The use of ceramic, cermet, diamond, and cubic boron nitride tools is mainly suitable for high-speed cutting, dry cutting, and hard cutting methods, and cutting fluid is not always necessary.

However, to prevent excessive cutting temperatures, cutting fluids are often used in most cases when using these tools.

Due to their high cutting speed, water-based cutting fluids are recommended when using these tools.

The selection of cutting fluid must take into account multiple factors such as the machine tool, cutting tool, and machining process. The type of cutting fluid, be it oil-based or water-based, is determined according to safety and waste fluid treatment limitations.

If fire prevention and safety are prioritized, water-based cutting fluids should be considered. When choosing water-based fluids, waste emission issues should be taken into account, and companies should have waste treatment facilities. For some operations, like grinding, water-based cutting fluids are usually the only choice. For machining processes using carbide tools, oil-based cutting fluids are typically preferred.

For high-speed machine tools that mandate the use of oil-based cutting fluids, it’s not advisable to switch to water-based ones as it might affect the machine’s performance. After considering these factors, the appropriate type of cutting fluid can be decided. Once the primary cutting fluid type is determined, a secondary selection can be made based on the machining method, required precision, surface roughness, and other factors. If the chosen cutting fluid does not meet expectations, it should be reassessed, the cause of the problem identified and corrected, and a final decision made.

With a wide variety of cutting fluids available, improper selection can lead to adverse outcomes. Water-based cutting fluids should be chosen in the following situations:

Oil-based cutting fluids should be considered under the following situations:

The proper use of cutting fluids plays a crucial role in improving machining efficiency, enhancing machining quality, extending tool life, and reducing overall costs during NC cutting.

However, cutting fluids can pose health hazards to the operator and contribute to environmental pollution through waste fluid disposal and discharge.

In support of green manufacturing, it’s important for operators to explore alternative methods that minimize or eliminate the use of cutting fluids.

Industry and research organizations should continue to develop cutting fluids with improved performance, green credentials, versatility, and affordability to meet the needs of users.

Machine tool managers, process technicians, and operators should stay informed and actively promote the use of new, environmentally friendly cutting fluids and cooling and lubrication technologies in production. This will ensure that the most appropriate cutting fluids and technologies are used in practice.