Choosing the right laser welding method can dramatically impact your manufacturing efficiency and product quality. Have you ever wondered whether continuous or pulse laser welding is better for your needs? This article breaks down the differences, comparing aspects like power, efficiency, and application suitability. By the end, you’ll understand which technique aligns best with your specific welding requirements, ensuring optimal performance and cost-effectiveness. Dive in to make an informed decision that could streamline your operations and enhance your output quality.

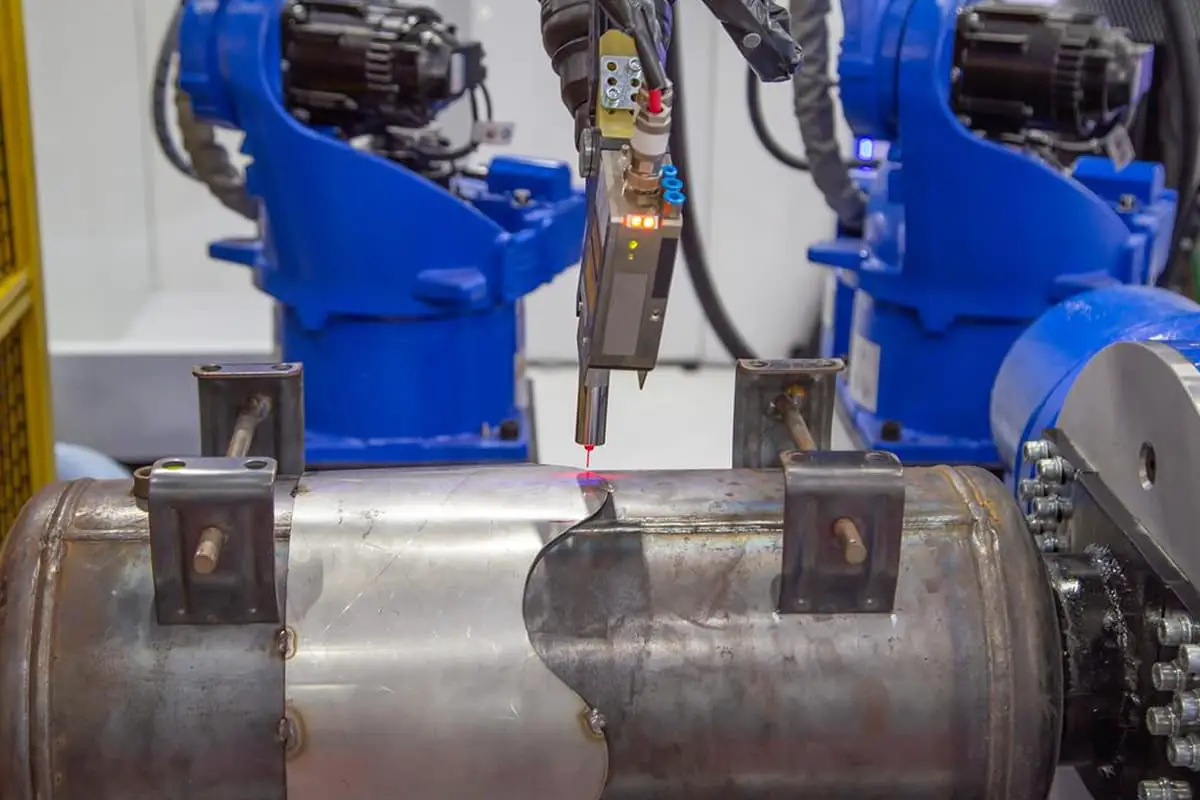

Continuous welding of the galvanized sheet by the semiconductor laser

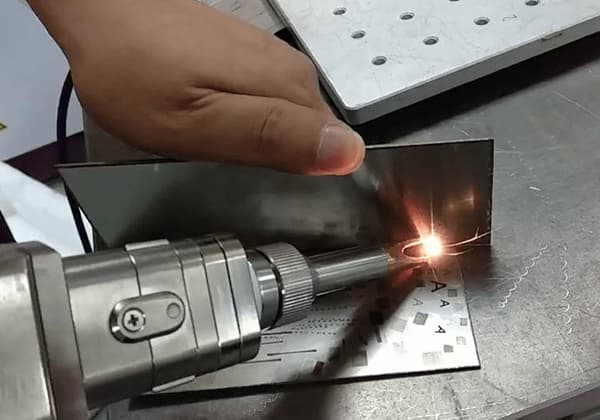

Pulsed welding of stainless steel plate with Nd 3 +: YAG laser

Lasers can be classified in various ways. One classification method is based on the wavelength, where lasers can be divided into infrared, visible, and ultraviolet.

Another classification is based on the working substance of the laser, including CO2 laser, fiber laser, Nd3+:YAG solid-state laser, Nd3+:YAG disc laser (unique to Trumpf), direct semiconductor laser, dye laser, among others. The mode of operation of the laser, whether continuous or pulse, also determines the type of laser.

In general, a laser beam outputs once as it oscillates in the resonant cavity, but multiple outputs can be formed through high-frequency oscillation. A laser is considered to have continuous light output when the output frequency reaches a critical value, and is considered a pulse laser if the output frequency is below that critical value.

However, there is no standard definition for the division between continuous and pulse laser in academia and industry. The common understanding is that when the repeated light frequency is below 102 Hz, it is considered a pulse laser, 102-103 Hz is considered quasi-continuous (QCW), 103-106 Hz is considered continuous (CW), and anything above 106-109 Hz is considered supercontinuum.

For instance, in the field of metal cutting, the typical frequency parameters of IPG and Raycus fiber lasers are 5000 Hz, while the typical frequency of early Nd3+:YAG solid-state laser cutting machines is 300 Hz. In terms of power parameters, CW lasers generally only provide power, while pulse lasers provide single pulse power, average power, pulse width, and frequency.

The specific cost-effective method is:

Average power = Single pulse power × Pulse width × Frequency

In the field of metal laser welding, Nd3+: YAG solid-state lasers are typically used in pulse welding, while fiber lasers are commonly used in continuous welding. However, with advancements in laser technology, the distinction between the two is becoming less clear, as industrial-grade direct semiconductor lasers are increasingly being used in continuous welding.

Pulse laser welding, which uses Nd3+: YAG lasers, is known for its low frequency, high-energy pulses. For instance, a 500W pulse laser can produce single pulse power of up to 12KW or more, resulting in greater welding penetration compared to fiber lasers of the same power.

On the other hand, continuous (fiber) lasers are characterized by high frequency and stable, low single pulse energy output.

A simple analogy to explain the difference between pulse and continuous welding is that pulse welding is like pile driving with a pile driver, where each impact is heavy but the speed is slow. On the other hand, continuous welding is like hammering nails with an electric hammer, where each impact is small but the hammering speed is fast.

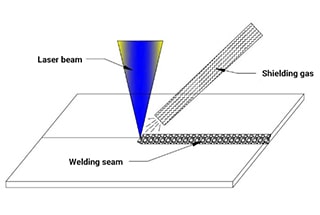

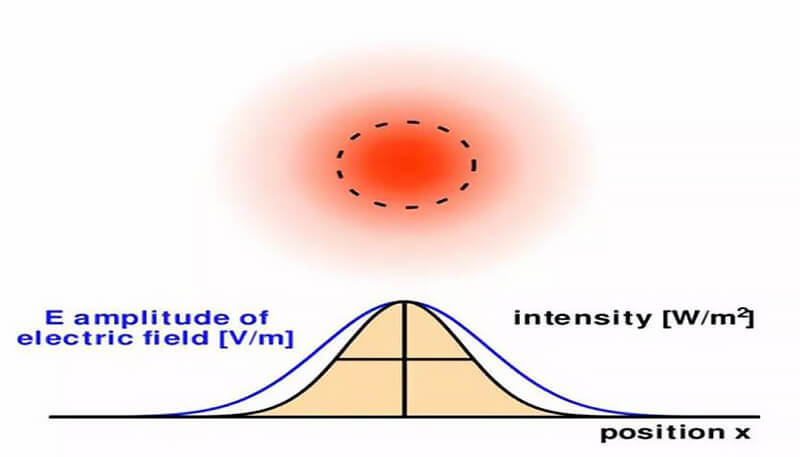

As is well known, the beam produced by a continuous wave (fiber) laser is a typical Gaussian beam. This means that the power density at the center of the beam is very high and decreases rapidly away from the center.

In contrast, the light intensity of a pulsed laser has a flat-top distribution, meaning that the energy is roughly evenly distributed across the surface perpendicular to the beam.

It’s worth noting that the beam distribution of a direct semiconductor laser is also similar to the flat-top distribution, but this will not be discussed further here.

Energy distribution of Gaussian beams

Energy distribution of flat-topped beam

The frequency of light output in continuous welding is extremely high.

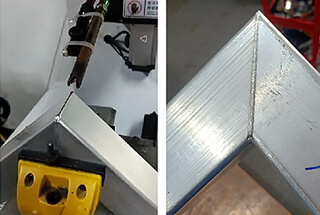

When proper welding protection and parameters are used, a uniform and smooth weld can be achieved that does not require grinding or polishing.

Pulse welding, on the other hand, has a lower light frequency and produces a clear, intermittent knocking sound during the welding process. The resulting weld has a flat fish scale appearance, similar to argon arc welding, or full single spot welding spots as needed.

Continuous welding only requires a few parameters to be selected, such as the appropriate welding track, running speed, and power, making it relatively simple. Pulse welding, however, requires a comprehensive consideration of multiple parameters, including pulse width, light output frequency, single pulse power, running speed, and pulse waveform, making it a more complex process.

Pulse welding spot (welding spot)

Continuous welding seam

Furthermore, the fiber laser beam has a high energy density at its optical center. With current technology, the laser beam can be efficiently transmitted through a fiber with a very small core diameter. This makes medium to high-power light lasers ideal for deep penetration welding, producing welds with a high depth-to-width ratio.

The flat-top distribution of pulsed laser beams offers significant benefits for heat conduction welding, particularly in thin-plate splicing welding.

The continuous (fiber) laser has gained a significant market share in the welding field, replacing CO2 and Nd3+: YAG solid-state lasers, due to its stability, low power consumption, efficiency, high beam quality, and energy density. This trend is expected to continue in the future.

The Nd3+: YAG solid-state laser, despite its long development history and large market, will have promising opportunities in specialized fields. Currently, continuous laser welding is mainly utilized for deep penetration welding. For instance, optical fiber (continuous) lasers are widely used in the auto parts industry. As technology advances, particularly in optical fiber laser and direct semiconductor laser technology, continuous laser welding is expected to be applied in a wider range of fields.

Furthermore, the high efficiency and stability of continuous laser welding aligns with the growing trend in the manufacturing industry towards intelligent and automated production methods.

While pulse welding has been shrinking in the market, it still holds a place in the future. Fiber lasers have developed quasi-continuous lasers that compete with pulse welding, but pulse welding still serves a purpose for special materials and welding requirements. Additionally, Nd3+: YAG solid-state laser has the advantages of low cost, ease of use, and simple maintenance, which will continue to keep pulse welding relevant in the long run.

Choosing between two welding methods requires a careful evaluation of various factors such as cost, operating expenses, process requirements, and production efficiency.

Pulse welding has a low overall efficiency, but it offers a high single pulse energy. However, it can be expensive to use. On the other hand, continuous welding is more efficient and has lower operating costs, but it comes with a higher upfront cost.

Both methods have their own advantages and disadvantages, and therefore, they have specific areas of application.