Are you puzzled about choosing between fiber lasers and solid-state lasers for your next project? This article explores the key differences in their applications, precision, and performance. By understanding these distinctions, you’ll gain insight into which laser type best suits your specific needs, whether it’s for micromachining, macro processing, or advanced manufacturing. Dive in to discover how these laser technologies can enhance your work and make informed decisions for optimal results.

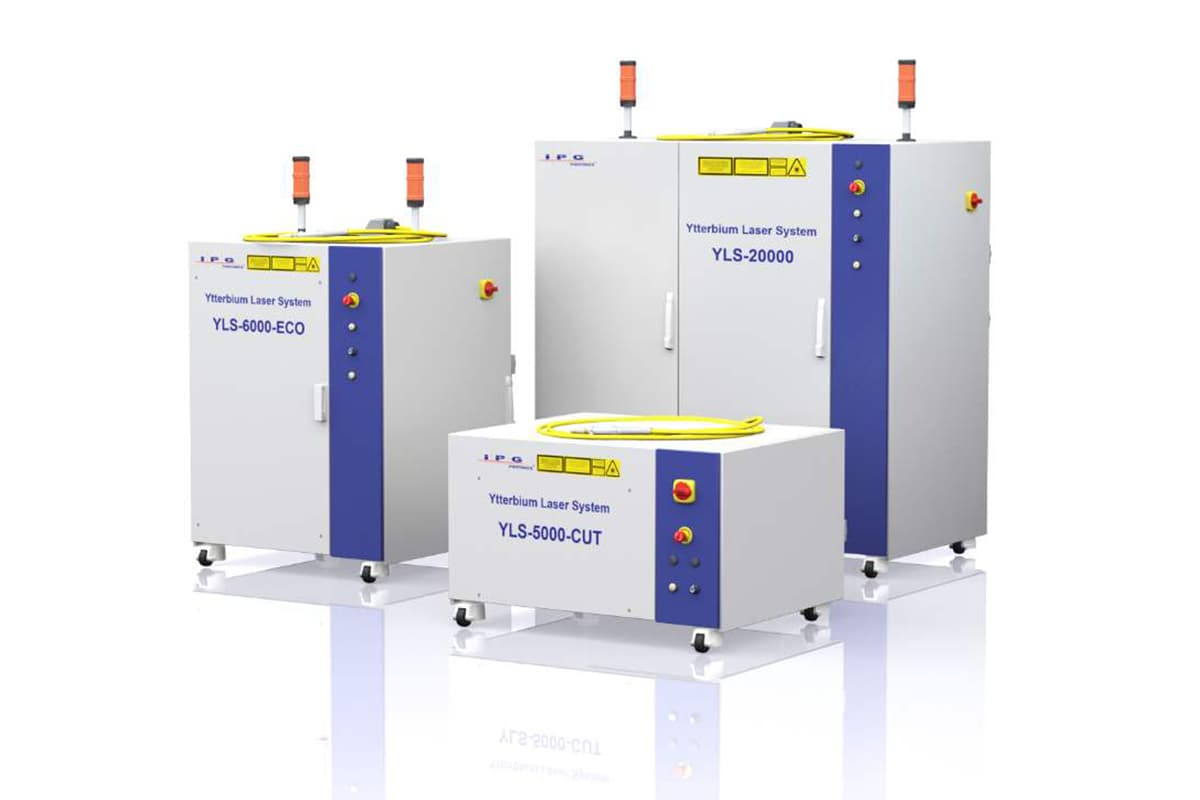

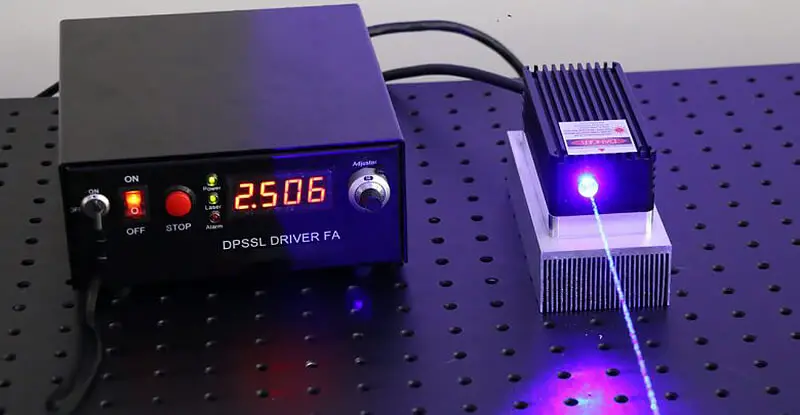

For the domestic market, the technology and development of fiber lasers have reached a relatively high level of maturity.

If you are considering using a fiber laser, it is advisable to opt for a domestic option as they tend to have better delivery times and are more cost-effective.

If you prefer solid-state lasers, high-end products are generally imported as domestic solid-state lasers have a relatively late start and are technologically limited. There are few large-scale solid-state laser manufacturers in China, making it challenging to find suitable products.

What distinguishes solid-state lasers from fiber lasers?

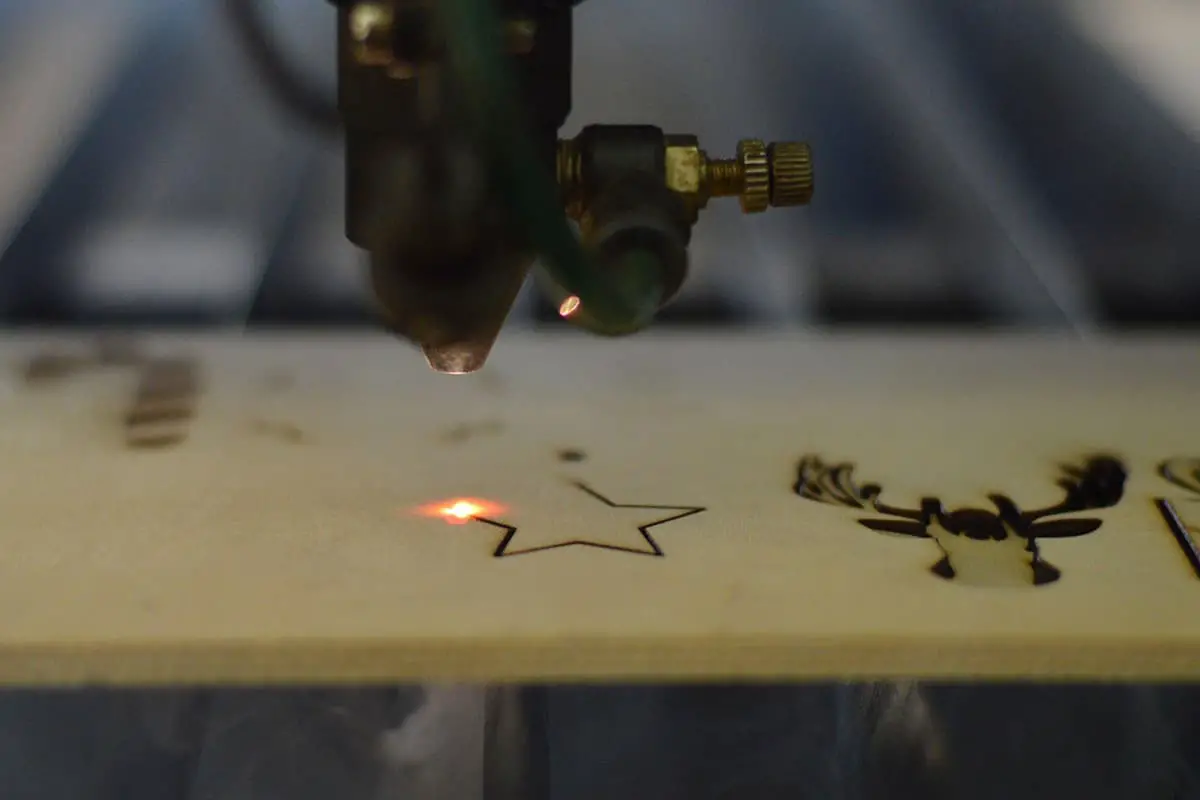

Both solid-state lasers and fiber lasers are commonly used in major laser processing fields such as marking, cutting, drilling, welding, and additive manufacturing. However, due to their distinct characteristics, there are differences in their specific application scenarios within each subdivision field.

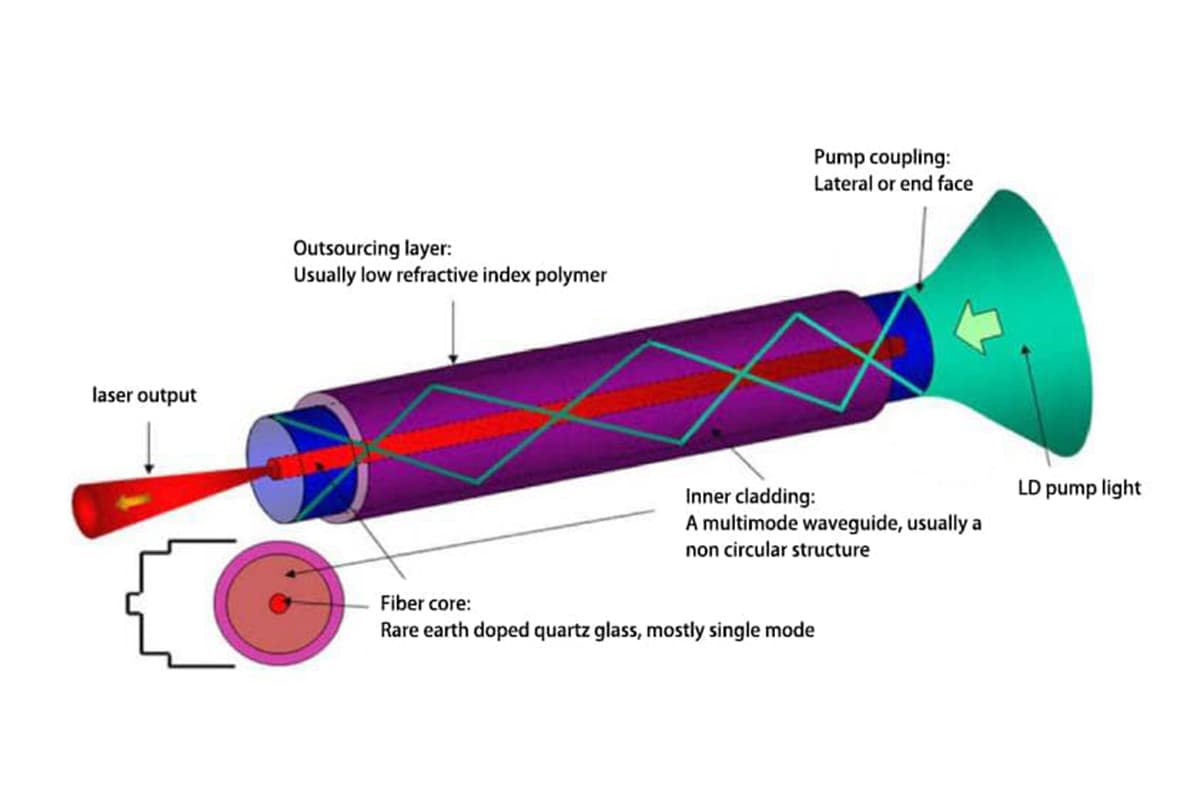

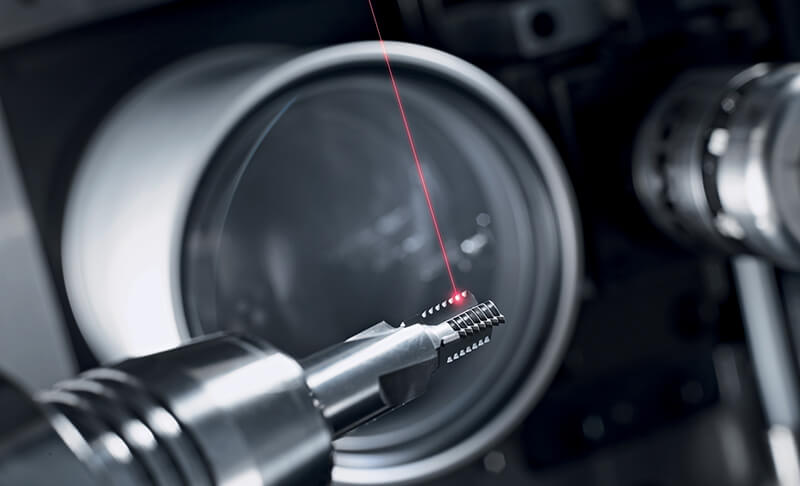

In the field of laser processing, solid-state lasers are predominantly used while pulsed fiber lasers may be used in certain cases. Solid-state lasers have the ability to convert infrared light into short wavelength lasers such as green light, ultraviolet light, and deep ultraviolet light through the use of frequency doubling crystals in the resonant cavity, which are then outputted to the outside.

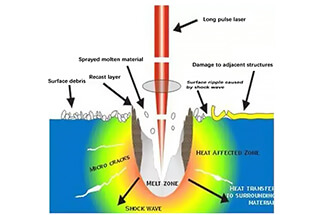

The trend in micromachining lasers is towards shorter wavelengths, which have low thermal effects and high energy utilization efficiency, thus improving machining accuracy and enabling ultra-fine and ultra-precision machining.

Solid-state lasers, with their short wavelength (UV, deep UV), short pulse width (picosecond, femtosecond), and high peak power, are mainly used in the field of precision micromachining of non-metallic materials, thin, brittle metals, and other materials. They are also widely used in cutting-edge scientific research in fields such as the environment, medicine, and military.

In the field of laser processing, fiber lasers are primarily used while solid-state lasers are generally not. Continuous wave (CW) fiber lasers have high average power and are widely used in macro processing such as cutting and welding thick metal materials. This type of laser has gained significant penetration in the field of macro processing, gradually replacing traditional processing methods.

In summary:

① Pulsed fiber lasers may be used in micromachining but their application is limited due to their output of only long wavelength infrared light with low single pulse energy and significant thermal effect, which results in lower machining accuracy and limitations in materials that cannot absorb infrared light. It is generally only used in micromachining scenes with machining accuracy greater than 20 microns.

② Solid-state lasers have a wide range of applications in micromachining, as they can convert infrared light into green light, ultraviolet light, and other wavelengths through frequency doubling in nonlinear crystals. They have good beam quality, large single pulse energy, and low thermal effect, allowing for “cold machining.” They are capable of high-precision micromachining with accuracy less than 20 microns (up to nanometer level), making them highly advantageous in the field of micromachining.

③ Continuous wave fiber lasers are the main type of fiber laser and are widely used in macro processing fields with processing accuracy above the millimeter level, such as cutting and welding industrial metals. The market capacity for macro processing is greater than that of micro processing, as it has a large demand for laser equipment.

In general, solid-state lasers are large in size and easily disturbed by external factors such as vibration and temperature changes, leading to stability issues and higher maintenance costs. However, they have high output peak power, good beam quality, and high signal-to-noise ratio.

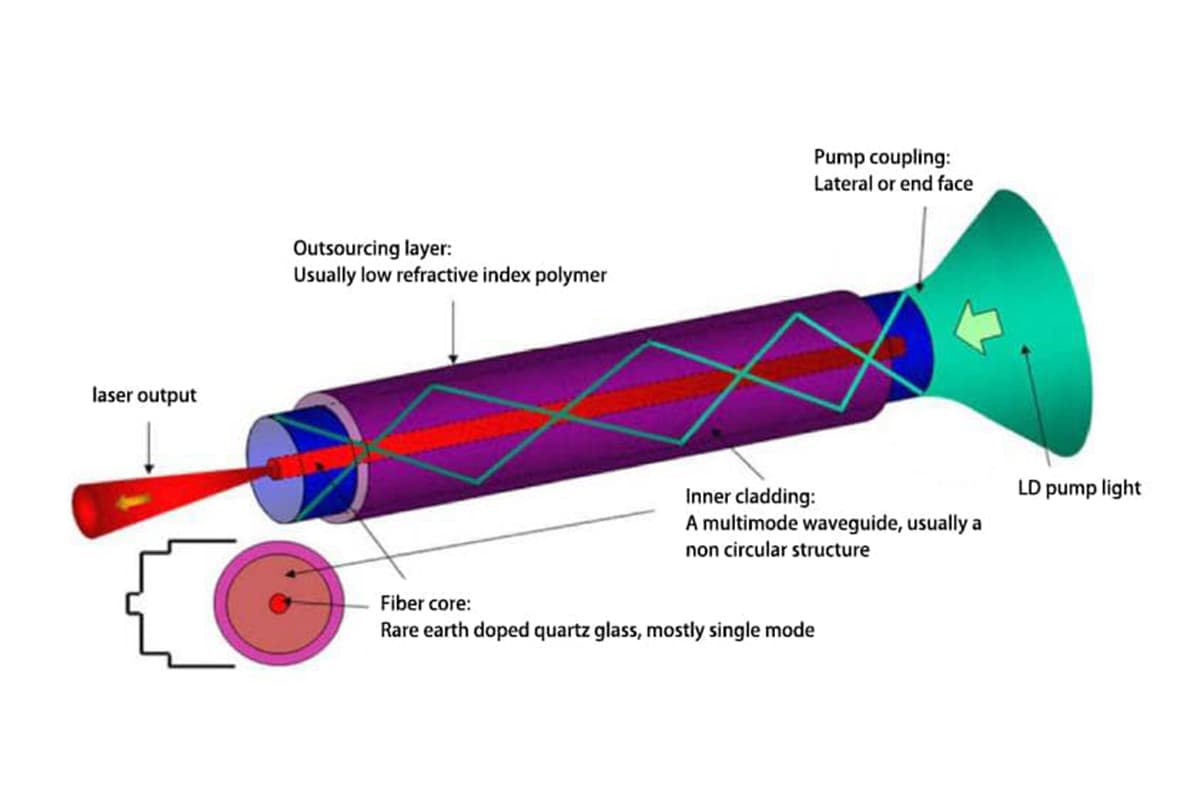

Fiber lasers have a compact structure, stable performance, and are not easily disturbed by external factors, making them easy to operate and maintain. However, they have poor beam quality, poor signal-to-noise ratio, and limited ability to achieve high peak power.

Due to its high output power, fiber laser is mainly used in macro processing, which refers to the processing of objects with size and shape that have a laser beam influence range of millimeters. On the other hand, micromachining refers to processing with a precision of microns or even nanoscale.

Solid-state lasers have the advantages of short wavelength, narrow pulse width, and high peak power, making them widely used in the field of micromachining. This results in different user groups for solid-state lasers and fiber lasers.

Both solid-state lasers and fiber lasers have their own specific application fields and there is little direct competition between the two in most cases.

In the field of metal material processing, fiber lasers are generally used when the metal reaches a certain thickness due to cost considerations, while solid-state lasers are used in scenes requiring high precision and where cost sensitivity is low.

Solid-state lasers are mainly used for processing non-metallic materials such as glass, ceramics, plastics, polymers, packaging, and other brittle materials. In the field of metal materials, they are used in scenes requiring high precision and with low sensitivity to cost.

China is undergoing a transformation and upgrading of its manufacturing industry from low to high-end production. Medium and low-end manufacturing still accounts for a large proportion. The macro processing market encompasses both medium and low-end manufacturing and some high-end manufacturing, making it a large market with high demand.

As a result, the market capacity for fiber lasers is substantial. Domestic low-power fiber lasers have a high degree of localization, with many large-scale manufacturers in China. According to reports on the development of China’s laser industry, low-power fiber lasers have been fully replaced by domestic counterparts.

For medium power continuous wave (CW) fiber lasers, domestic products have no significant disadvantages in quality and have a clear price advantage, leading to equal market share. In terms of high-power CW fiber lasers, some domestic brands have been successful in sales.

However, solid-state lasers in China have a late development and there are currently no listed companies with this product as their main business. These products are typically imported from foreign brands.

The precision requirements for electronic components in the consumer electronics industry are constantly improving. Laser processing technology has become a primary means of production in the industry due to its high precision, speed, and non-damaging characteristics.

For example, solid-state lasers have a wide range of applications in the production processes of printed circuit boards (PCB/FPC) such as cutting, drilling, and marking. Low to medium power nanosecond solid-state lasers can be used for PCB marking, while medium to high power nanosecond solid-state lasers, picosecond, and femtosecond lasers can be used for cutting, drilling, and PI film cutting of PCB/FPC boards.

Aside from printed circuit boards, laser micromachining technology is also utilized in cutting, marking, drilling, micro welding, and other fields involving brittle materials and metal materials.

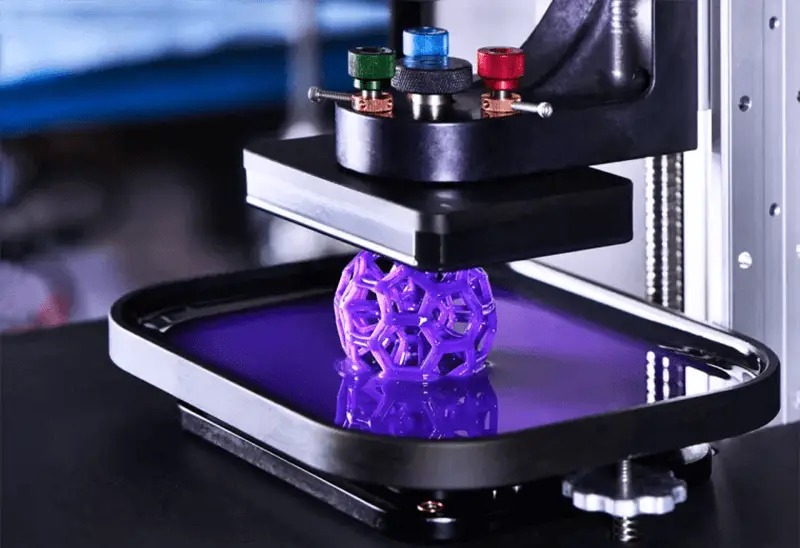

3D printing is a type of rapid prototyping technology that constructs objects layer by layer using bindable materials such as metal powder, plastic, and liquid photosensitive resin, based on a digital model file.

In the field of liquid photosensitive resin curing, solid-state lasers are the preferred choice in the industry. The issuer’s low-power nanosecond ultraviolet (UV) laser has been widely used in this field.

Solid-state lasers are extensively used in key processes such as cutting and precise scribing of solar cells and silicon wafers, marking, cutting, and welding of lithium battery materials.

For example, the issuer’s products can be used in the photovoltaic solar energy field where high-power nanosecond solid-state lasers and picosecond lasers can be used for cutting and precise scribing of solar cells and silicon wafers, and low-power nanosecond UV lasers can be used for grooving of these materials.

In the new energy vehicle field, low-power nanosecond solid-state lasers and picosecond lasers can be used for marking the shell of lithium batteries, while medium to high-power nanosecond solid-state lasers, picosecond, and femtosecond lasers can be used for precise cutting and welding of battery materials.

2019 is considered the “first year” of 5G technology commercialization. The gradual commercialization of 5G technology will offer a wide range of opportunities for the micro-processing laser industry.

5G networks have high speed and low latency, which requires high-performance compound semiconductors. The materials and manufacturing processes of mobile phones will need to change to adapt to 5G technology, and laser processing technology will play a crucial role in many aspects of mobile phone production.

Laser marking, welding, cutting, drilling, etching, and direct molding are widely used in various production stages of mobile phone manufacturing. Micro-processing laser technology will be significant in the field of 5G mobile phone manufacturing.

According to Canalys, the global shipment of 5G mobile phones is expected to reach about 1.9 billion in the next five years, and the laser micro-processing industry, represented by solid-state laser technology, will greatly benefit.

Furthermore, as the construction of 5G base stations enters a period of intensive construction, the demand for printed circuit boards (PCB/FPC) with higher processing accuracy will experience rapid growth as the main electronic materials.

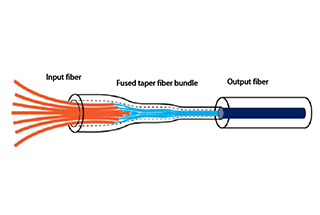

Fiber-coupled lasers can better achieve multi-dimensional, arbitrary space processing and production through fiber integration. The fiber-coupled laser simplifies the mechanical design principle, making the production process more streamlined and organized, ensuring standardized production.

With continuous upgrades and improvements, fiber-coupled lasers have low power consumption and can achieve strong operational results by adjusting product and accessory combinations. Fiber-coupled lasers meet the requirements of high-intensity processing and improve production processes to increase operational efficiency.

In addition, fiber-coupled lasers have fast heat dissipation and strong durability, ensuring that the equipment operates smoothly without generating heat or other problems during long-term use, even in harsh environments.