Have you ever noticed the persistent smoke and dust clouding your laser cutting workspace? This article dives into practical solutions to enhance dust collection efficiency in laser cutting machines. By exploring methods like improving sealing performance, optimizing air suction pathways, and addressing design flaws, you’ll discover how to create a cleaner, safer, and more efficient working environment. Read on to transform your laser cutting operations and meet stringent environmental standards with ease.

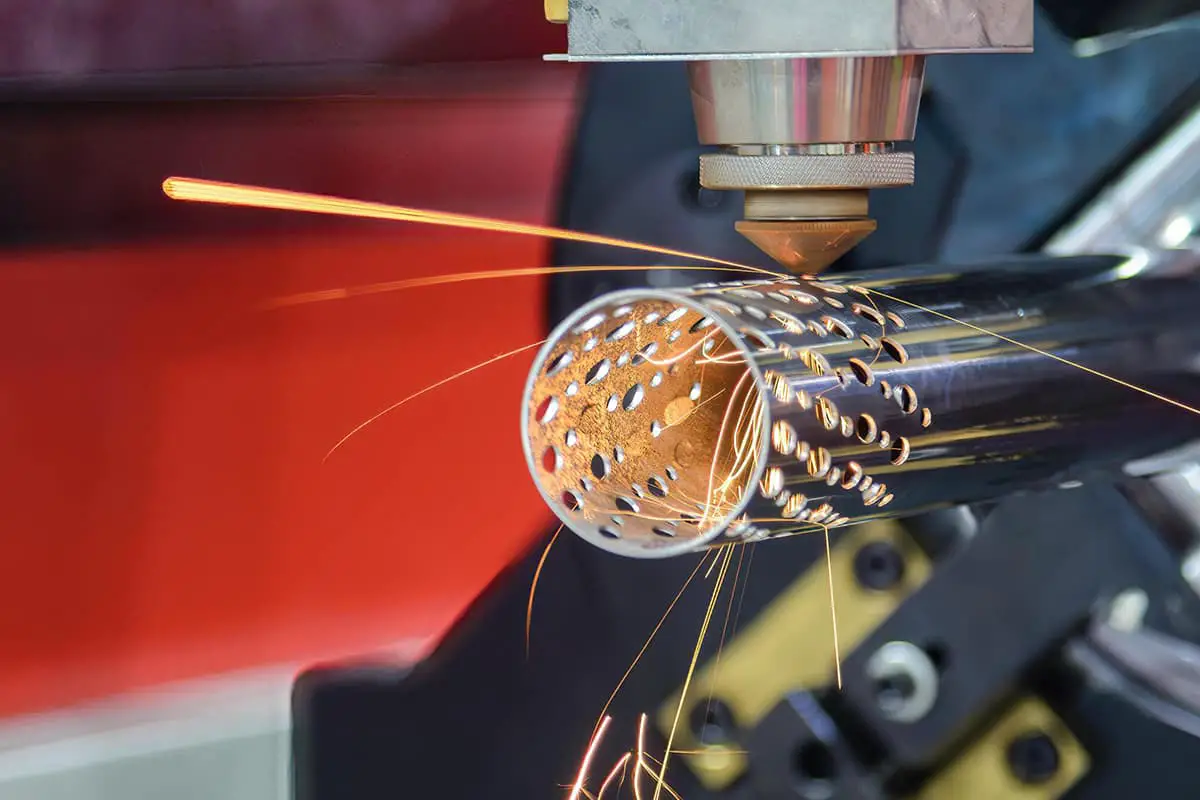

With the advent of fiber laser technology, laser cutting machines have gained a significant position in the sheet metal processing industry.

During the workpiece processing of laser cutting machines, high-temperature ablation leads to an increase in smoke and dust production, which can contaminate delicate parts of the equipment. Moreover, the smoke and dust also pose a threat to the health of operators.

Untreated cutting dust can significantly degrade the service life and cutting performance of laser cutting machines. Hence, the dust removal system is a crucial aspect of laser cutting machines.

The dust removal system of most laser cutting machines is designed as a comprehensive exhaust structure with a spacious cavity. To align with environmental protection requirements, the use of a high-powered dust collector is necessary, which demands a large coverage area and complex pipeline installation.

The design of the dust removal system of laser cutting machines can easily lead to unsealing and air leakage, resulting in ineffective exhaust. During operation, the smoke and dust generated by the cutting process are not properly exhausted, affecting the working environment for operators.

One solution is to install a partition at the bottom of the worktable of the laser cutting machine, dividing it into several longitudinal chambers of equal geometric dimensions with the main air suction duct located at the front. The main air suction duct is connected to the dust collector and valves are placed between each chamber and the main air suction duct. The machine control valve regulates the air flow through the air inlet and air outlet pipes. A hopper is placed in a small room with end plates sealed at both ends and ventilation holes on the lower sides. The ventilation process is controlled by the opening and closing of the valves, saving space and improving the dust removal effect.

Another solution includes the main body, main box, and control cabinet. The dust removal cover absorbs all the smoke and dust generated during laser cutting machine operation, ensuring a clear line of sight and improved working efficiency. It also prevents residue from splashing, protects the safety of operators, and enhances the device’s popularity and applicability.

While the dust removal system may not be the most crucial factor in selecting a laser cutting machine, an efficient dust removal system is crucial for normal production. In the current era of strict environmental protection regulations, devices with good environmental performance have a significant advantage.

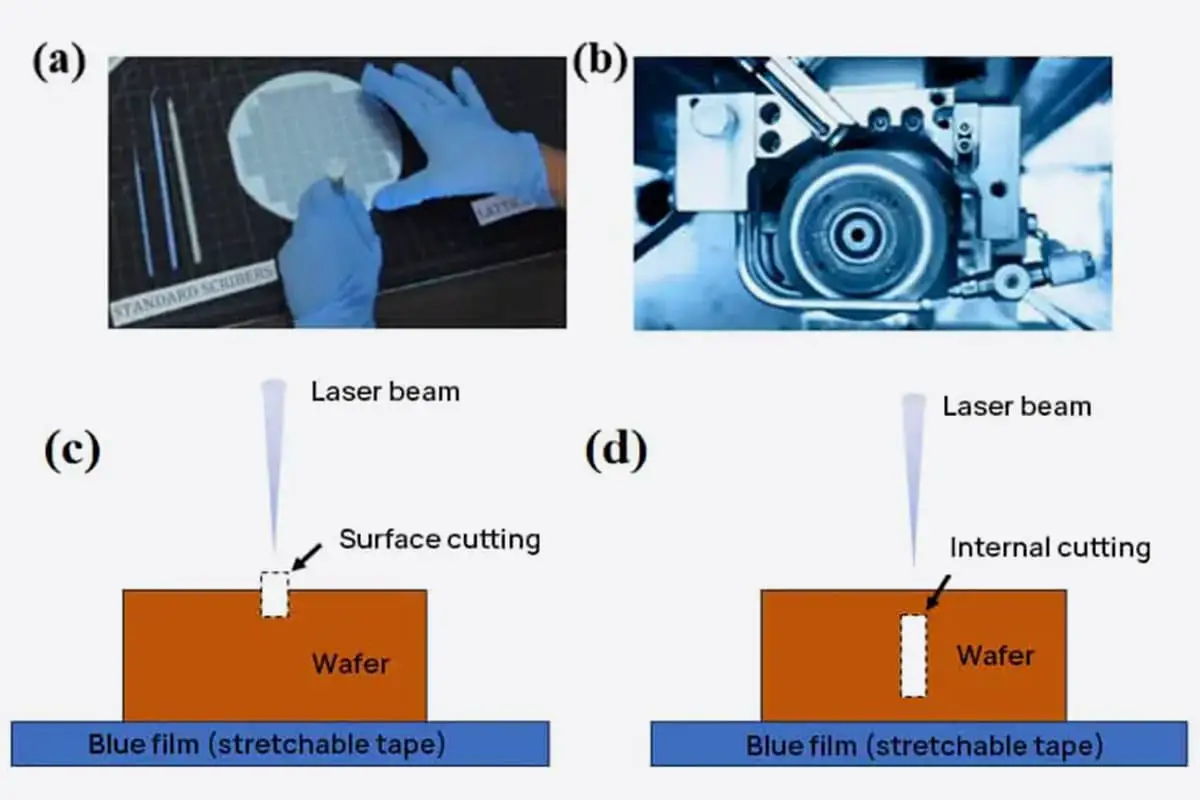

Fiber laser cutting machines do not produce the large amounts of smoke and dust associated with traditional plasma cutting methods. The optical fiber laser cutting machine has a dedicated dust removal system that directly transports collected smoke and dust to a filtration and purification unit before discharging it to meet environmental standards. The smoke and dust generated during the cutting process are mainly produced below the workpiece notch. To save on equipment investment and improve exhaust efficiency, only the cutting area is collected, with an air outlet on the side of the optical fiber laser cutting machine. This structure is simple and effective, and widely used.

After conducting extensive experiments, we have developed a dust collection system that effectively reduces smoke and dust during the laser processing process.

The system consists of an air purification dust collector that can effectively adsorb fine particles in the air flow. It is connected to the laser cutting machine via a 250mm diameter dust collection pipe.

The dust collector extracts air from the laser cutting machine through the pipe, filters, and purifies it before discharging clean air.

Despite the widespread availability of laser cutting machines with dust removal systems designed according to the above steps, on-site use has revealed that these systems are not effective in removing smoke and dust generated during cutting.

The visible smoke and dust from cutting scatter within the equipment, affecting the precision transmission device and reducing the machining accuracy of the machine tool. The smoke can even spread to the entire workshop, posing a threat to the health of users and polluting the environment.

The root cause of this issue is that although the dust collector extracts a significant amount of air from the machine tool, it is unable to effectively remove the desired cutting smoke and dust.

Thus, despite the effort put into designing the dust suction pipe in the machine tool, the dust removal system’s performance is inadequate due to design and processing/assembly issues. The result is a dust removal system that requires excessive effort for subpar results.

Given the above facts, we have conducted numerous tests and have identified the following methods that can effectively improve the dust removal efficiency of the system:

Improve the sealing performance of dust removal system.

The dust collector provides a fixed suction air volume, so improving the sealing performance of the dust removal system is sure to increase the suction air volume of the specific suction outlet, thereby improving the system’s dust removal efficiency.

The dust collection system consists of the following components: an air purifying dust collector, a dust collection pipe, the dust collection pipe within the machine tool, and air suction outlets with controllable opening and closing in each partition of the machine tool.

The main unsealed links that affect dust collection efficiency are the sealing of the dust collection pipeline and the sealing of each suction outlet.

Currently, most air ducts on both sides of the machine body are integrated as part of the machine body through welding. However, this method poses a challenge in ensuring full welding between pipes to prevent air leakage.

The sealing performance of the air suction outlet requires dividing the processing area into several zones based on the position of the laser head. For the zones not processed by the laser head, the dust suction port must be sealed.

Reduce the right angle transition at the pipe connection in the machine tool.

Taking a 3m x 1.5m processing format as an example, most manufacturers currently design their systems with pipes located under the side worktables on the left and right fuselages. This approach divides the air suction outlet into left and right sections along the Y direction, which theoretically improves dust suction efficiency, but also results in right-angled connected pipes in the fuselage.

These right-angled connected pipes impede air flow and weaken the wind force at the air suction outlet. Furthermore, when designing the fuselage, it is important to increase the cross-sectional area of the pipeline from the dust collector to the suction outlet inside the fuselage as much as possible.

A larger pipeline cross-section reduces the resistance experienced by the air flow and minimizes the loss of wind generated by the dust collector when it reaches the suction outlet.

Improve the sealing performance of the machine tool itself.

In theory, the final air extracted by the dust collector should come from inside the machine tool, but its dust collection efficiency is reduced due to the poor sealing performance of the machine tool itself.

In practical application, the smoke and dust produced during laser head processing originates from the workbench plate. Under the influence of the high-energy laser beam, metal vapor produced during processing condenses into small metal dust particles when it encounters the surrounding cold air. These metal dust particles are primarily concentrated near the workbench.

The goal is for the suction negative pressure generated by the suction outlet to remove these metal dust particles. However, the poor sealing performance of the machine tool itself leads to large gaps between the discharge truck and the machine body at the bottom of the machine tool and between the machine body and the ground. Additionally, the suction port is close to the ground and the discharge truck, which results in most of the suction air entering the machine tool through the gap between the machine body and the ground and being carried to the air purification dust collector by the suction system.

This results in the suction system performing unnecessary work.

Do a good job of the shield and top cover of the machine tool.

The top cover of the machine tool is an important component of the dust collection system. Laser head processing requires cutting gas.

A portion of the cutting gas will mix with metal dust and spread to the upper space above the workbench, which is typically not easily removed by the dust collection system.

In this case, the top cover of the machine tool will trap the dust within the machine tool, and then, under the influence of gravity, this portion of the dust will eventually be removed from the machine tool by the dust suction system.

The implementation of these design ideas can significantly enhance the dust collection efficiency of laser cutting machine tools.

Our machine tools not only provide value for customers, but also align with the principles of green and sustainable development.