Imagine cutting intricate car parts with the precision of a laser beam. Laser cutting technology is transforming the automotive industry, allowing manufacturers to create high-quality components with unmatched accuracy and speed. This article delves into how laser cutting improves efficiency, reduces costs, and enhances material versatility in car production. Discover the benefits of this cutting-edge technology and learn how it shapes the future of automotive manufacturing.

Laser refers to a type of light that is intensified through stimulation to emit radiation. Its properties, such as good directionality, high brightness, and monochromatic nature, make it widely applicable in various fields, including laser cutting, welding, engraving, perforation, and marking, among others.

Laser applications are considered to be one of the most promising and growing fields. Among its various applications, laser cutting stands out as a key technical process. There are two main types of laser cutting: pulsed laser, which is suitable for cutting metallic materials, and continuous laser, which is ideal for non-metallic materials.

In the automotive industry, laser cutting technology has found a significant application. The following is an overview of the use of laser cutting technology in the automotive industry.

Laser cutting is a process that uses a high-density laser beam to heat the material to several thousand to ten thousand degrees Celsius in a short period of time. This causes the material to melt or vaporize, and a high-pressure gas then blows the molten or vaporized material away from the cut line, resulting in a clean cut.

In the production of automotive parts, laser cutting has several advantages:

(1) High precision: The positioning accuracy is approximately 0.05mm.

(2) Narrow cut: The laser beam is focused to a small spot, resulting in a high power density that heats the material to the point of vaporization. This forms small, continuous slits with a very narrow width.

(3) Smooth surface: The cut surface is smooth and free of burrs.

(4) Fast speed: The cutting speed is much faster than wire cutting.

(5) Good cutting quality: With no contact cutting and minimal thermal impact on the cutting edge, there is little to no thermal deformation of the workpiece, and the kerf generally does not require secondary processing.

(6) No damage to workpiece: The laser cutting head does not come into contact with the workpiece, preventing any scratches or damage.

(7) Material versatility: The hardness of the material does not affect the laser cutting process, allowing for the cutting of steel, stainless steel, aluminum alloys, cemented carbide, and other materials.

(8) Shape flexibility: The laser cutting process can be programmed to cut any graphic or shape, including tubes and other profiles.

(9) Reduced investment in dies: Laser cutting does not require dies, reducing the cost of investment and maintenance.

(10) Material savings: With computer programming, the entire board can be used to produce products of different shapes, improving material utilization.

(11) Shorter development cycle: New products can be developed more quickly without the need for manufacturing dies.

(12) Cutting of non-metallic materials: The laser cutting process can also be used to cut non-metallic materials.

There are various types of laser cutting equipment, including:

(1) Flat laser cutting machine: This type of machine is specifically designed to cut flat workpieces.

(2) Three-dimensional laser cutting machine: This machine is capable of cutting workpieces with three-dimensional shapes.

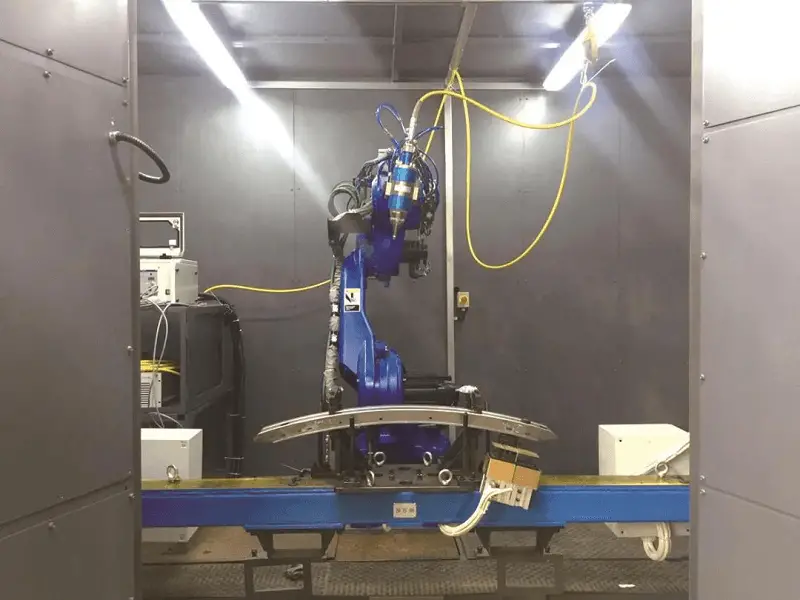

(3) Laser cutting robot (Figure 1): This type of laser cutting equipment is capable of cutting complex three-dimensional workpieces.

Fig.1 Laser cutting robot workstation

With the growth of the automotive industry, the use of laser cutting robots is becoming more widespread. This type of laser cutting equipment is capable of cutting both flat workpieces and simple 3D workpieces. The following outlines the components of a laser cutting robot workstation:

(1) High-precision trajectory robot: This component provides high precision, high speed, and three-dimensional processing while reducing costs.

(2) Laser generator: There are three types of laser generators: solid-state laser generator, gas laser generator, and fiber laser generator. The laser generator is the device that produces the laser source.

(3) Cooler: This component is used to cool the laser generator.

(4) Optical fiber cable: This component is used to transmit the laser beam.

(5) Cutting head: This component mainly includes parts such as a cavity, a focusing lens holder, a focusing mirror, a capacitive sensor, and an auxiliary gas nozzle.

(6) Worktable: This component is used to hold the workpiece to be cut and can be moved precisely according to the control program, driven by a servo motor.

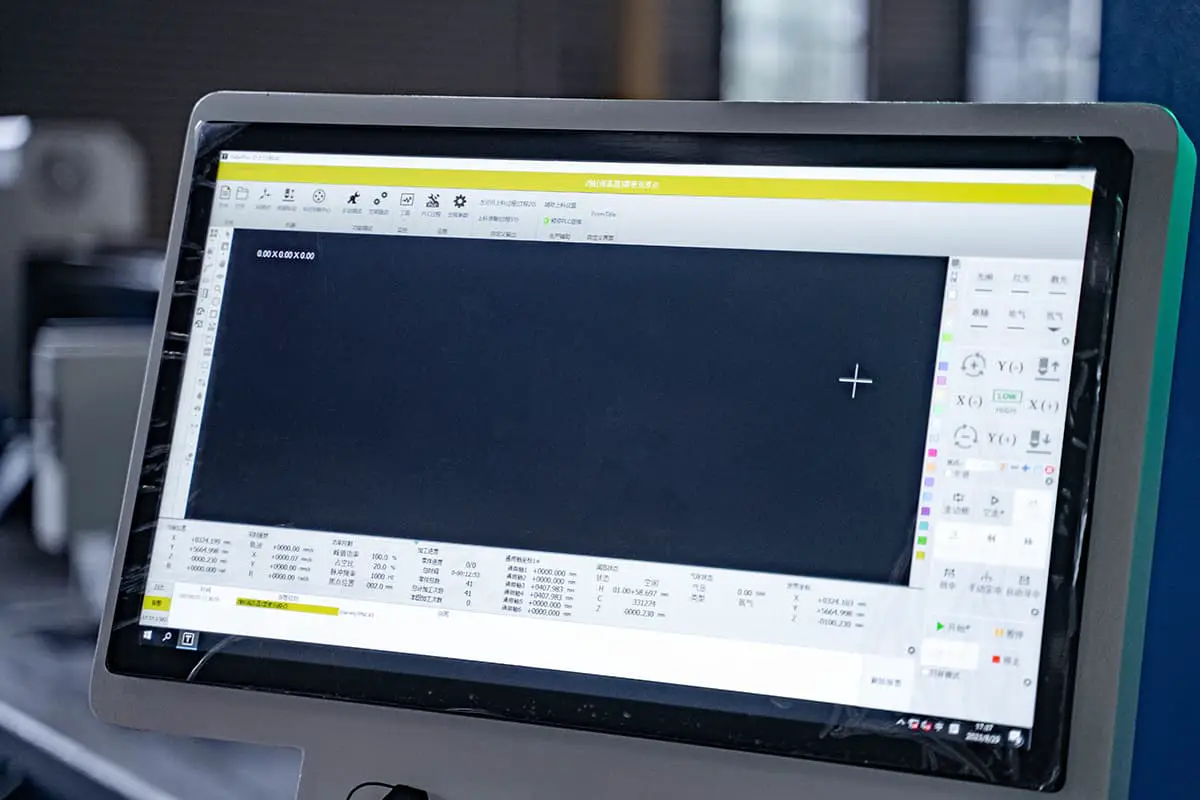

(7) CNC: This component controls the table’s X, Y, and Z-axis movements and also controls the output power of the laser.

(8) Manipulation platform: This component controls the entire cutting unit’s work process.

(9) Gas cylinders: These components include working medium cylinders and auxiliary cylinders for the laser cutting machine.

(10) Air compressor: This component is used to supply compressed air.

(11) Air cooling dryers and filters: These components are used to remove moisture and impurities from the compressed air.

(12) Auxiliary equipment: This includes components such as an extractor and dust collector.

The illustration below demonstrates the use of laser cutting robots in the production of automotive components.

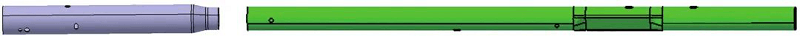

As depicted in Figure 2, the part is made through laser cutting of all the holes in the pipe, with 4 holes on the left part and 5 holes on the right part.

Due to the high number of holes and varying hole sizes, using a punch tool would require a complex tooling setup and a relatively large number of dies, leading to a substantial investment and frequent maintenance that takes up a lot of time and manpower. Furthermore, it may result in substandard products, requiring special quality inspection to prevent such occurrences.

Laser cutting technology, on the other hand, can significantly reduce the capital investment in dies and bring the following benefits:

Fig.2 Tube parts

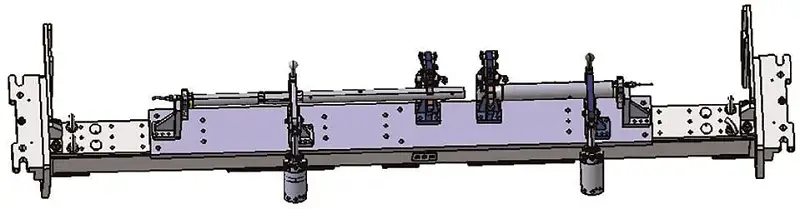

To ensure the accuracy of the part’s positioning, a positioning fixture must be used (as shown in Figure 3). The fixture structure is comprised of three parts:

In conclusion, the fixture structure is straightforward, easy to operate, and cost-effective, making it a practical solution.

Fig.3 Positioning fixture for making pipe parts

As shown in Figure 4, the part requires cutting two large holes and two ends, which would cause distortion if punched using a die. To avoid this, laser cutting is used to ensure the quality of the part.

Cutting the holes is relatively straightforward, but cutting and machining the end of the profile is challenging. The profile has a B-shaped cross-section that requires 360-degree cuts in each direction.

Therefore, it is necessary for the laser cutting head to have the ability to rotate 360 degrees and have enough room to do so. If there is limited space in the normal direction, a small angled cut can be used without affecting the part.

Setting the cutting trajectory of the cutting head requires continuous trial and error to ensure the quality of the part, while reducing manufacturing costs and improving production efficiency.

Fig. 4 Parts made of profiles

The laser cutting fixture for this part is depicted in Figure 5. It is similar in design to the fixture for the pipe and is comprised of three components:

The positioning mechanism employs a cylinder-driven positioning pin that can move forwards and backwards, facilitating the easy pick-and-place of the workpiece.

Fig. 5 Positioning fixture fixed on the table

These two examples of laser cutting fixtures are relatively straightforward in comparison to dies and are both composed of three parts: a fixed plate, a positioning device, and a clamping device.

It demonstrates that the implementation of laser cutting robots can address numerous challenges in the production of automobile components and bring numerous benefits.

In summary, laser cutting has become a prominent advantage in the field of automotive processing due to its ability to reduce costs and improve the quality of cars.

The use of laser processing robot workstations in the automotive industry is becoming increasingly common, covering not just laser cutting, but also laser welding, laser marking, laser engraving, and processing of non-metallic materials.