Are your press brake tools wearing out too quickly? This article dives into essential repair techniques to extend the lifespan of your tooling, ensuring optimal performance in your sheet metal processing. From identifying wear patterns to precise grinding methods, learn how to maintain your press brake dies effectively. By following these tips, you’ll enhance product quality and machine efficiency, saving time and costs in the long run.

The repair and regrinding of press brake tooling is an essential process for sheet metal processing plants to fix worn molds in the later stages.

No manufacturer will continue to use a set of press brake tooling without repairing and regrinding it for several years, which is detrimental to both the bending machine and the molds.

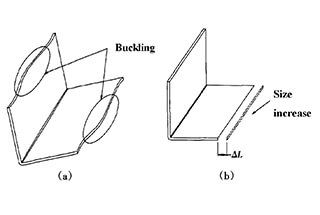

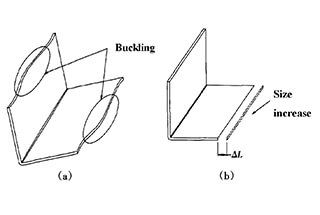

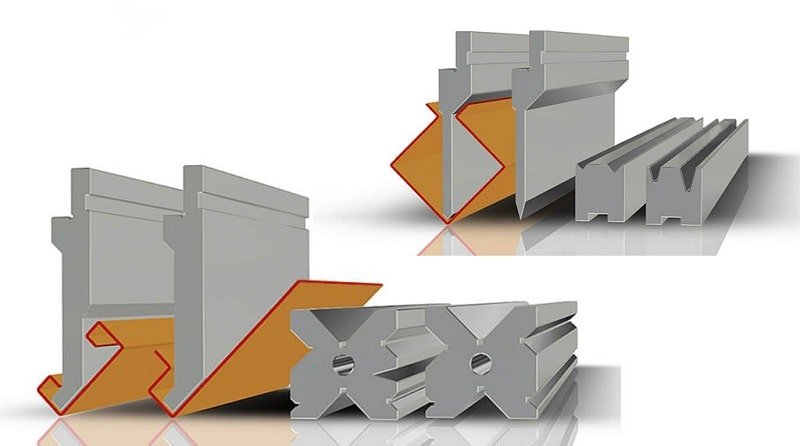

The main cause of wear on the bending machine die is due to the sheet metal processing process. Local bending leads to the die being worn down at the fixed point from the bending pressure over a long period of time. Excessive pressure can also scratch the lower die, which will further increase the degree of wear on both the upper and lower dies.

The best solution to address the wear caused by local bending is to process multiple workpieces at the same time, which can distribute the pressure on the bending machine and prevent damage to the die caused by pressure concentration.

When the angle deviation of the bent workpiece is significant or the surface roughness is large, it is important to repair the mold promptly to change its surface and extend its lifespan.

Before starting the processing, the sheet metal operator should inspect the upper and lower dies of the bending machine. If there are noticeable wear and tear marks on the surface, it is necessary to repair the die.

Minimizing the number of times the die is ground and the number of cycles it goes through will help extend its lifespan, improve the quality of the workpiece, reduce the load on the machine tool, and increase the rate of product qualification.

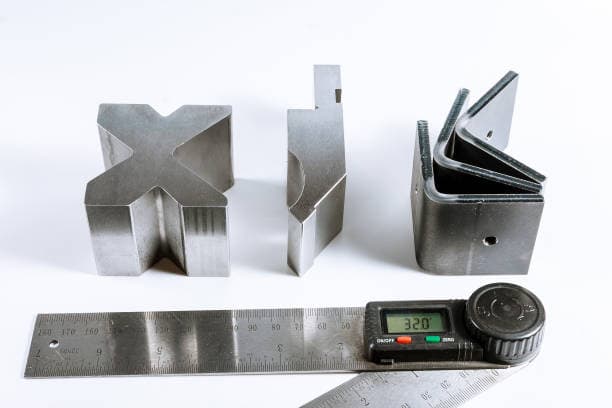

There are various methods for mold grinding, with the most common method being to place the mold on a special fixture and then use a precision grinder for processing. This is particularly true for arc molds (R molds) and forming molds, which require the use of high-precision grinding wheels and mold repair tools.

During each grinding session, it is important to maintain a tool clearance of 0.03mm to 0.05mm.

Repeated grinding not only fails to completely process the mold, but also causes significant damage to it, and is generally not recommended.

It is best to make appropriate corrections to most of the grindable areas and then conduct a final fine grinding, which helps improve the accuracy of the NC bending machine die and facilitates installation and commissioning.

In conclusion, proper regrinding of press brake machine dies is an important process for sheet metal fabrication enterprises. Improving the accuracy and lifespan of the dies is another way to boost the benefits of the enterprise.