Imagine buying a press brake and realizing it doesn’t meet your needs—an expensive mistake! This guide explains the critical principles and factors to consider when purchasing a press brake. From understanding machine quality and enterprise reputation to assessing specific requirements like bending capacity and material type, it offers practical insights to help you make an informed decision. By reading further, you’ll gain the knowledge needed to choose the right press brake, ensuring efficiency and reliability in your production process.

If you’re considering purchasing a press brake machine to increase the processing capacity of parts and enhance production efficiency, please take a moment to carefully read the following information.

You are aware that many individuals face financial ruin due to purchasing the incorrect machine.

I am not creating panic. This type of situation occurs frequently. With nearly 10 years in this industry, I have seen it happen firsthand.

However, if you take the time to thoroughly research, you will gain a clear understanding of the type of press brake machine you require, the important factors to consider, and how to make the best decision possible.

For businesses looking to buy a press brake, manufacturers offer a range of pricing options with various controllers.

However, it can be challenging to consider all factors. So, which type of press brake should you choose?

The best approach is to assess your own needs and make them the center of the selection process.

Where should you start? The following press brake buying guide may assist you.

Let’s dive into it now.

Maybe you already know the definition of a press brake machine, but I still want to emphasize what it is.

See also:

Many people who are buying a press brake for the first time or purchasing the machine for someone else may not be very knowledgeable.

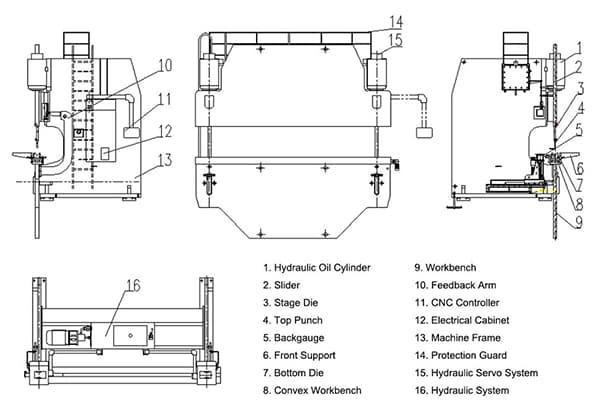

Press brake is a machine used to bend sheet metal and is made up of a workbench, ram, backgauge, oil cylinder, etc. By using a set of simple punches and dies, the metal sheet can be shaped into a specific geometry. To bend plates with varying thicknesses, V-shaped grooves with different openings should be chosen for the lower die.

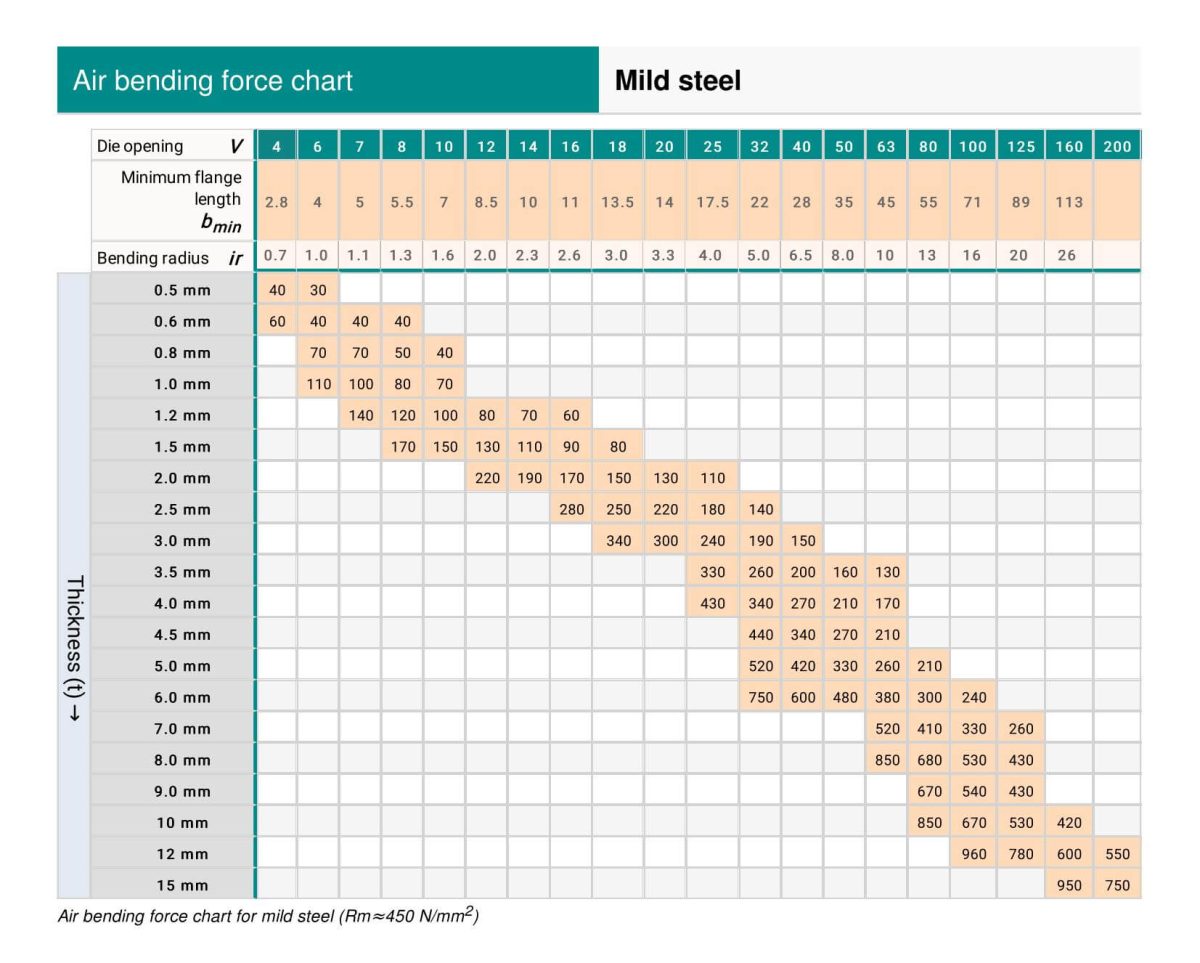

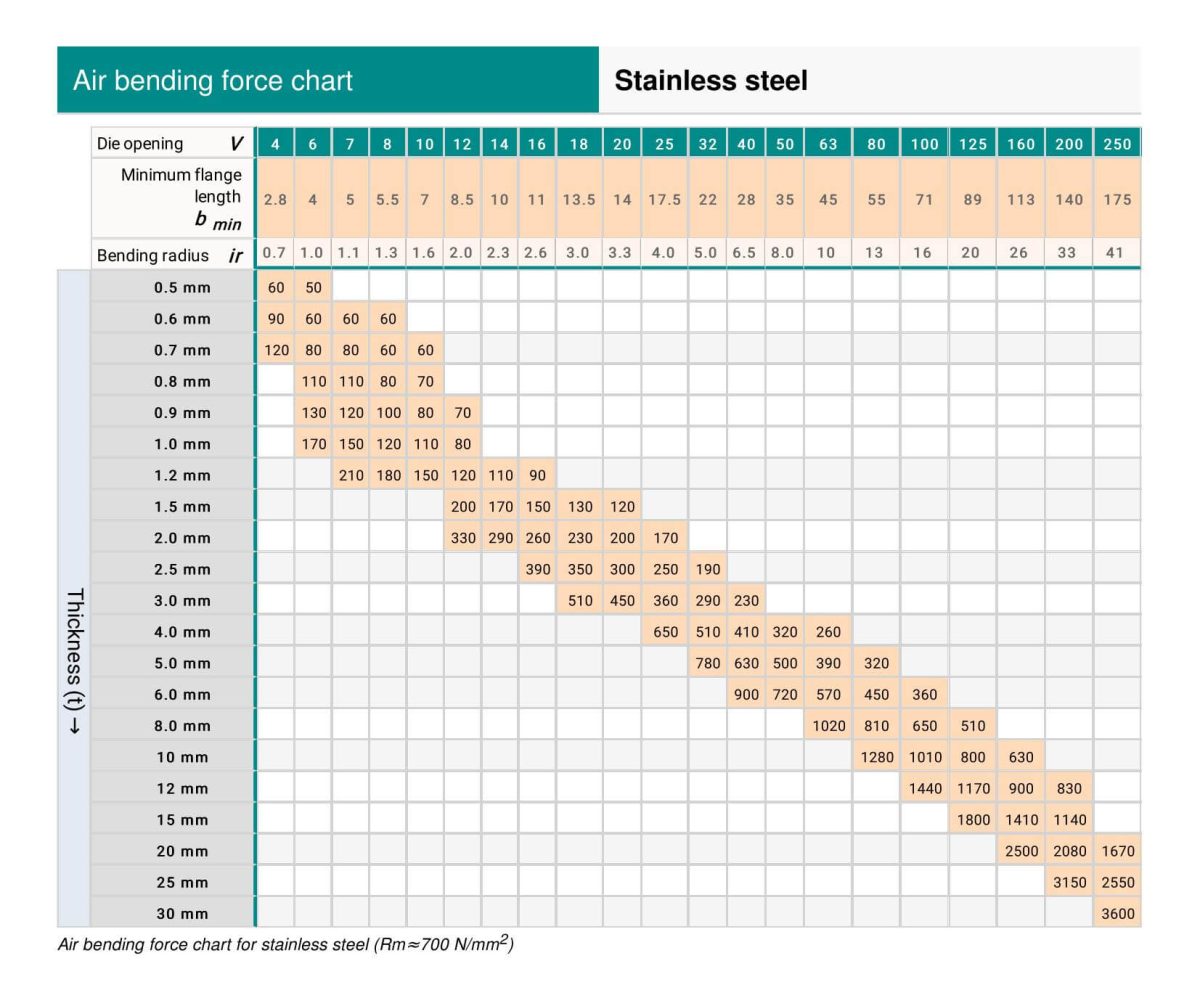

The required bending force can be calculated by the bending force chart.

See also:

Press brake machines are versatile equipment used to complete sheet metal bending by using a set of simple general punch and die. They can bend workpieces into various shapes and perform other processes such as stamping, punching, crimping, and shallow stretching. These machines are widely used across various industries, including electrical appliances, electronics, containers, metal structures, instrumentation, daily hardware, building materials, and others.

For more information on press brake machines, including their composition, toolings, and bending force, you can refer to the following articles:

In the Internet era, when searching for a product, you may come across many manufacturers promoting their offerings, making exaggerated claims and denigrating their competitors.

However, the most reliable indicator of a product’s quality is often its market share. In your industry, you can generally determine which machine is widely used, user-friendly, and which is considered a poor choice based on the experiences of users.

User feedback and reputation are critical as they provide first-hand insights and direct contact with the product. Ignoring their opinions is not advisable.

When considering purchasing a product, it’s important to take into account the reputation of the manufacturer and the quality of their after-sales service. In the internet age, it can be difficult to separate fact from marketing claims, but the market share of a product in your industry can give you a good idea of its popularity and reliability.

It’s also important to look for a regular and healthy enterprise with a clear division of labor, as this often indicates that they are trustworthy and able to provide reliable after-sales service. To assess the size and quality of an enterprise, it’s advisable to visit their factory in person to see their level of formality and production activity.

The two previously mentioned points are general terms that are not specifically tied to the machine. Now, I want to discuss the machine’s quality.

It can be difficult to compare machines if you are not familiar with press brake machines.

One factor to consider is the machine’s volume and weight. Machines that are larger and heavier are typically stronger and of higher quality than lighter machines, as the main component used in the machine is steel.

Another factor is accuracy. Ideally, you would bring your own machined parts to the factory to test the machine’s accuracy, but this is not always possible. The accuracy of a machine is impacted by the backgauge, side column strength, and mold.

If the rear stopper is still powered by a chain, it is not considered to be accurate. Aluminum beams may look attractive, but they can deform after repeated impacts.

A third factor is the screw and guide rail. Progressive enterprises now use ball screws and linear guide rails.

Finally, the strength of the side column is related to the thickness of the plate used.

If we compare machines to soldiers, then molds are like their weapons. If these weapons are not of good quality, it will be difficult to defeat others.

So, how can we determine the quality of a mold?

One important factor is the material. Currently, 42CrMo is considered a top-quality material for press brake tooling, and other materials like Cr6W2Si are also considered good.

Ordinary users may not be able to differentiate the materials until after using them for a certain period of time.

Furthermore, most molds are subjected to high-frequency quenching, which involves heat treating the knife edge. However, high-quality factories utilize whole body heat treatment.

A mold that has undergone whole body heat treatment is distinguished by a hole in the mold, which is a clear indication of this process.

It is worth noting that the production cost of whole body heat treatment is significantly higher compared to knife edge heat treatment.

See also:

When choosing a press brake, the following four principles should be taken into consideration:

Precision in the mechanical system operation.

It is understood that some physical error in the radius is unavoidable, but the question is how much deviation can be tolerated by the user.

For simpler parts, a slight lack of accuracy may be acceptable, but for most parts, high precision is often necessary, especially when it comes to continued fabrication after bending.

The required flexibility of the machinery.

The more diverse the parts and their varieties, the greater the need for flexibility in the press brake machine.

In other words, for economic reasons, the press brake must be easy to operate both in hardware and software.

This way, even when orders change frequently and are rarely repeated, the adjustment time can be minimized.

Determining the production capacity and size of the press brake machine.

The dimensions of the part, pressure, bending length, stroke, and structural height must be taken into account.

The prospective buyer should carefully consider the end-use of the machine, the potential deflection of the known machine, and the bending radius of the part, among other factors.

Press brake and other CNC equipment differ in terms of their processing field and technology. As a manufacturer, you need to take all relevant factors into consideration, such as the application, deflection, bending radius of parts, etc., before making a decision to purchase a press brake.

As the decision-maker, you have the responsibility of understanding the performance, processing range, functions, and precision of a press brake.

This is not a trivial matter as a wrong decision can result in increased production costs and make cost recovery impossible.

Therefore, before making a purchase decision, it is important to carefully consider the following 7 factors that can help you make the right choice.

The objective is to purchase a press brake that can effectively handle your processing tasks, not necessarily the one with the shortest worktable and the minimum tonnage.

It’s important to consider the type of steel sheets, as well as their maximum thickness and length.

If you are working with low-carbon sheet metal with a maximum thickness of 3mm and a length of 2500mm, then an air bending force of 80 tons is sufficient.

For more information on how to calculate the press brake bending force, you can refer to this article.

However, if you need to process a hollow block at the bottom, you should consider purchasing a press brake with a force of about 150-ton.

If the sheet metal is low-carbon steel with a thickness of 6mm and a length of 2500mm, then a 100-ton press brake is appropriate.

If you need to bend sheet metal with a hollow block at the bottom (bottoming), you will require a large CNC press brake.

For sheet metal with a length of 1250mm or shorter, a smaller CNC press brake may be more suitable, even if it is half the size of a larger press brake.

This can significantly reduce your purchase cost.

It’s important to remember that the length of the sheet metal is one of the key factors in choosing the right press brake.

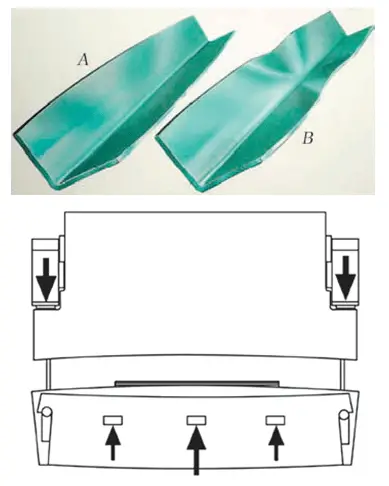

During the bending process, especially when bending long workpieces, deflection is inevitable for the CNC press brake.

The longer the workpiece, the greater the deflection of the press brake.

Under the same load, the deflection of a press brake processing a 2500mm sheet metal is four times greater than that of a press brake processing a 1250mm sheet.

In other words, a shorter press brake with less gasket adjustment can produce higher quality products.

Reducing gasket adjustment also shortens preparation time.

Fortunately, most CNC hydraulic press brakes have already added a hydraulic deflection compensation function during the manufacturing process, which reduces the need for operator adjustments and improves bending accuracy and production efficiency.

This function is controlled by the CNC system.

Hydraulic oil is directed into a compensation oil cylinder through a magnetic servo valve, which pushes the worktable upward.

At the same time, the deflection compensation force increases along with the bending force of the press brake, effectively compensating for deflection.

Mechanical deflection compensation is also a viable option.

When compared to low-carbon steel, the bending force required for stainless steel needs to be increased by about 50%.

However, for soft aluminum sheet metal, the required bending force will decrease by 50%.

You can obtain standard bending pressure parameters from press brake manufacturers.

The following data sheet shows the bending force required for 1000mm sheet metal of various thicknesses and materials.

There is one quick way to calculate the bending force which is required by your press brake.

You can use our online press brake bending force calculator to calculate the required press brake tonnage.

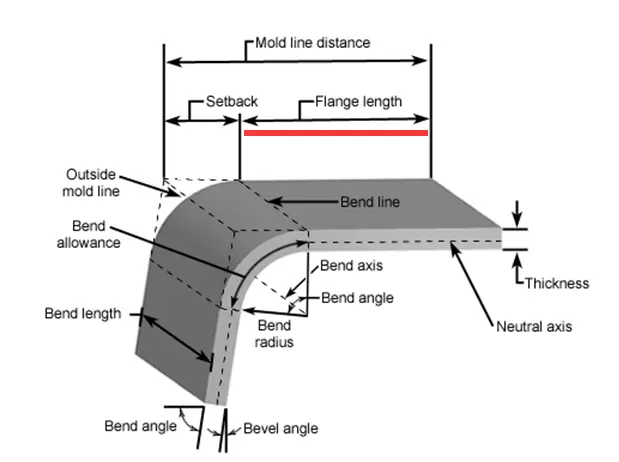

When bending workpieces, it’s important to consider the bending angle radius as well.

The bending radius is 0.156 times the V groove opening dimension.

During the air bending process, the V groove opening dimension should be 8 times larger than the thickness of the metal sheet.

For example, if a press brake with a 12mm V groove opening is used to bend a 1.5mm low-carbon sheet metal, the bending radius should be 1.9mm.

If the bending radius is close to or less than the thickness of the metal sheet, a bottoming die should be used.

However, the required bending force in this case will be four times greater than air bending.

When air bending, it’s important to pay attention to the clearance between the punch and die at the bottom of the stroke, as well as the resilience when bending sheet metal at 90°.

Typically, air bending molds will result in a resilience angle of less than 2 degrees on a new press brake.

The bending radius is equal to 0.156 times the down mold opening distance.

Thus, for common up and down bending processing, the top punch angle should be 86°-90°.

At the bottom of the stroke, there should be a clearance slightly larger than the thickness of the sheet metal.

The reason for the improved angle of the punch is the use of larger bottoming dies with a bending tonnage that is four times greater than air bending dies.

This helps reduce the resilience force within the specified bending radius.

Coining is similar to air bending, with the only difference being the front end of the punch being turned to the required bending radius.

The resilience force is also reduced as the clearance between the punch and die at the bottom of the stroke is less than the thickness of the sheet metal, and there is sufficient bending force (10 times greater than air bending). The front end of the punch contacts the sheet metal.

To choose a press brake with the lowest tonnage, it’s best to choose one with a bending radius larger than the thickness of the sheet metal and opt for air bending. This will not affect the quality of the finished product and ensure a long service life for the press brake.

The choice between a CNC press brake and a common NC press brake depends on the accuracy requirements.

If accuracy of ±0.5 degrees is required and cannot be altered, then a CNC press brake should be considered. The ram’s repositioning accuracy can be controlled to ±0.01mm.

For highly precise finished products, a press brake with high accuracy and good performance is necessary.

However, the ram’s repositioning accuracy of an NC press brake is around ±0.5mm, and under proper conditions, it can still result in ±2 to 3 degrees of deviation.

Additionally, CNC press brakes are typically equipped with a CNC controller for quick punch installation and clamping. If you need to process many small parts, this should be a top consideration.

Press brake toolings are been used for forming sheet metal and have a direct influence on the accuracy of the bending process.

Therefore, it’s important to carefully inspect the punch and die.

There are various shapes of tools, and different punches and dies are used for different parts.

To achieve the desired shape of the parts, the physical properties of the materials are mainly altered through molding.

The press brake mold is a tool that transforms blanks into parts with a specific shape and size under the influence of the press brake bending force.

Press brake standard molds can be divided into punches and dies for sheet metal stamping and separation.

The forming mold has a cavity, and the separation mold has a blade.

Press brake dies typically use T8 or T10 steel, and some better toolings use 42CrMo material, which requires high strength, high toughness, and good wear resistance.

Cold work dies steel Cr12MoV is also a good material.

42CrMo is a high-strength alloy quenched and tempered steel that has high strength, good toughness, and can work at temperatures below 500 degrees.

It’s important to check the wear of each mold by measuring the length of the punch from the front to the shoulder and the length between the die shoulders.

For conventional molds, the deviation per foot should be around ±0.001 inches, and the total length deviation should not exceed ±0.005 inches.

For fine grinding toolings, the accuracy per foot should be ±0.0004 inches, and the total accuracy should not be more than ±0.002 inches.

It’s best to use fine grinding toolings for CNC press brakes, and conventional toolings for manual and NC press brakes.

Based on varying needs and development phases, there are various types of press brake machines including manual press brakes, pneumatic press brakes, mechanical press brakes, hydraulic press brakes, hybrid press brakes, servo electric press brakes, and full electric press brakes, among others.

There are many types of press brake dies, including standard top punches for right-angle bending, acute punches, flattening punches and dies, radius punches, gooseneck punches, 1V lower dies, 2V lower dies, 3V lower dies, 4V lower dies, polyurethane lower dies, hard rubber lower dies, lower die guides, lower die bases, offset dies, forming dies, hemming dies, bending die sets, mark-free bending dies, among others.

Additionally, various non-standard punches and dies can be designed to suit different situations.

For bending between 90° and 180°.

Advantages: Universal for thick and thin plates, durable and widely used.

Used for bending between 20° and 180°.

Advantages: Can bend small angles and sizes, and the radius after bending is small, attractive, and angular.

For bending between 30° and 180°.

Advantages: Used for “U” shaped products that cannot be completed with standard dies and acute punches, with a wide range of applications.

Used to hem the edge and is suitable for use with the acute punch.

First, bend the workpiece into an angle less than 45° using the acute punch, then press it into the hemming edge with the flattening die, primarily used for reinforcing the frame.

Mainly used for one-time bending of small “Z” shaped workpieces and is available in both fixed and adjustable types.

Including Radius Punch and Die, door frame forming die, U-shaped forming die, light pole die, etc.

Typically used for bending complex products with a variety of bending angles and styles, so the one-time bending forming die is designed to improve bending accuracy and efficiency.

Refers to the lower die used to support the CNC press brake machine and is composed of a die holder and segmented lower die.

The same core means that when using any notch, you only need to change to the specified notch without re-centering the punch and die positions, making die changes convenient and ensuring high bending accuracy.

When using hydraulic crowning, the compensation pressure is separate from the pressure of the entire system. This means that when the compensation valve operates, the pressure of the entire system will partially decrease. Additionally, hydraulic oil control can lead to oil leakage and pollution if the oil pipe breaks, the sealing ring of the compensation cylinder ages, or the joint is loose.

Mechanical crowning, on the other hand, utilizes the numerical control system to automatically calculate the compensation amount based on the thickness and length of the material being bent, and the selected mold. The system module then controls the positive and negative rotation of the compensation motor to adjust the compensation deformation, which is fed back through a potentiometer.

The advantage of mechanical crowning is that the compensation deformation will not change with changes in the pressure holding time of the ram, and it does not require power every time the ram enters the slow-down position. This helps to conserve energy in the entire system and eliminates the risk of oil leakage and pollution. Additionally, the use of an integral workbench reduces the manufacturing cost.

The following articles will let you know more:

Closed loop

Closed-loop control is also known as a feedback control system. This system compares the actual output of the system with the desired value, generating a deviation signal, which is then used to control and adjust the output so that it approaches the desired value.

Closed-loop control is highly accurate and fast in its response, as it takes into account the operation of each part of the machine tool. However, compared to open-loop systems, closed-loop systems have a more complex structure and are more expensive due to the involvement of multiple elements.

Open loop

Compared to closed-loop control, open-loop control does not provide feedback on the current control results of the system. As a result, the accuracy of the bending process in an open-loop press brake machine depends solely on the accuracy of each individual component of the machine.

The system is unable to control and compensate for changes in parameters during the bending process, leading to low accuracy. External disturbances can also cause changes to the internal parameters of the machine, but the open-loop design is simpler and more stable, making installation and maintenance easier.

Wrap it up

Therefore, whether you should choose open-loop or closed-loop depends on your specific budget and requirements for bending your workpieces. However, it’s important to keep in mind that if you choose the closed-loop method, you should select a company with strong research and development capabilities.

Only such companies can make the press brake machine truly utilize the closed-loop function and remain unaffected over time. Usually, small enterprises do not have the capability to effectively utilize the closed-loop system on a press brake machine.

The following article explains in detail the difference between CNC press brake machine and ordinary press brake machine.

In short, the main difference between them is the presence of computer control and automatic feedback. This results in differences in processing speed, accuracy, and efficiency.

The factors that affect the price of CNC press brake machine mainly include the tonnage of the press brake machine, body width, component brand, mold type, product quality, service, etc.

The top ten press brake brands in the world are the best choice. You can choose according to your geographical location and the local reputation of the brand.

You can learn about the top ten press brake brands through the following links:

Electro-Hydraulic Servo Press Brake

The main cylinders on both sides are controlled synchronously by hydraulic control systems, such as proportional electro-hydraulic servo valves and grating rulers, which are independently controlled by the CNC. Accurate data is fed back to ensure the accuracy of ram operation.

Torque Synchronous Press Brake

A torsion shaft is used to connect the left and right swing rods, forming a torsion shaft forced synchronization mechanism that keeps the up and down movement of the oil cylinders on both sides synchronized.

When choosing the CNC system for a press brake machine, there are several popular brands to consider, such as Delem, Cyblec, and ESA. Many press brake manufacturers also use their own in-house CNC system. To learn more about how to choose the right CNC system for your press brake machine, you can refer to relevant articles.

If you carefully read the above content, you should now have a clear understanding of the factors to consider when purchasing a good press brake machine. The next step is to communicate with the manufacturer directly, thoroughly understand the manufacturer and their products, and make a final decision based on your budget.

After many years of working in this field, I understand the importance of purchasing a high-quality press brake machine for the end-user. “Good” not only refers to quality, but also includes a reasonable price and excellent after-sale services.

I have seen many instances where people purchase press brake machines from small factories without adequate services, only to be left without support when problems arise. I have also witnessed agents losing a significant amount of money due to their choice of the wrong supplier.

To avoid these issues, I strongly recommend taking the time to thoroughly research your options before making a final decision. Trust me, the time invested will be well worth it.