Have you ever wondered about the origins of the term “press brake”? In this captivating blog post, we’ll embark on a fascinating journey through history to uncover the reasons behind this curious name. As a mechanical engineering expert with years of experience, I’ll shed light on the evolution of this essential metalworking machine and its vital role in shaping the world around us. Get ready to discover the secrets behind the press brake!

If this is your first time encountering the term “press brake”, it’s possible that you are unfamiliar with its meaning and may not immediately associate it with a machine used for bending sheet metal.

So, let’s start by defining what a press brake is.

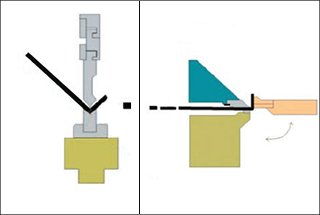

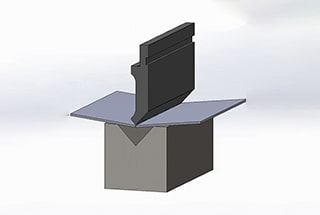

A Press Brake is a metalworking machine designed to bend sheet and plate material, primarily steel, by clamping the workpiece between a matching punch and die, forming predetermined bends. This tool is instrumental in metalworking industries, often used for producing components for vehicles, aircraft, and construction equipment.

In the metalworking industry, a press brake refers to a specialized machine tool designed to bend sheet and plate materials, with sheet metal being the most commonly utilized material.

This machine tool employs a clamping technique whereby the workpiece is secured between a punch and die that correspond to one another, allowing for the creation of accurate and precise bends.

Related reading: What Is Press Braking?

Currently, there are five widely used types of press brakes in the market, each with its own advantages, disadvantages, and usage scenarios.

Of course, hydraulic press brake is still the most popular at present. The following are the five main types of press brakes:

Mechanical Press Brakes operate using a flywheel and crank mechanism to generate the force required to bend the metal. They are renowned for their speed and accuracy.

Hydraulic Press Brakes utilize hydraulic cylinders to generate the force required to bend the metal. They are known for their power and versatility.

Pneumatic Press Brakes employ compressed air to generate the force required to bend the metal. They are known for their speed and ease of use.

Electric Press Brakes use an electric motor to generate the force required to bend the metal. They are known for their precision and energy efficiency.

Manual Press Brakes require the operator to manually apply the force required to bend the metal. They are known for their simplicity and affordability.

A press brake is a vital machine in the metalworking industry, employed to bend and shape sheet metal or plate materials. This machine utilizes a hydraulic or mechanical press to apply force to the top punch and bottom die, which in turn alters the metal to a desired angle or shape.

Press brakes can be operated manually or by using a computerized numerical control (CNC) or numerical control (NC) controller, enabling more precise and intricate bending operations. These controllers allow the operator to enter specific bending parameters, such as bend angle and depth, resulting in highly accurate and repeatable results.

To better comprehend the functioning of a press brake, we recommend watching the following video.

After viewing the aforementioned video, I am confident that you now possess a more comprehensive understanding of the purpose and functionality of a press brake.

As we delve into the topic of press brakes, a common question that arises is why they are called “press brakes” instead of simply being referred to as bending machines.

In modern times, the term “press brake” is used to describe a hydraulic bending machine that is specifically designed for sheet metal bending.

However, the origins of the term may not be immediately clear to everyone.

Like many, I too was once perplexed by the use of the term “press brake.” It made me question whether the term was an accurate description of the hydraulic bending machine.

After conducting extensive research on the topic, I have finally discovered the answer.

It’s worth noting that the term “press break” is incorrect as nothing is being broken or shattered.

So why is it called a press brake? Let’s explore this question in more depth.

It is commonly understood that the word “brake” in modern usage means to slow or stop. However, in the 15th century, the definition of “brake” was quite different. It was used to describe an instrument for crushing or pounding.

As time passed, the term “brake” became associated with the machine used for crushing grain. Therefore, when referring to a machine used for pressing, the term “press brake” emerged as the simplest term to use.

Over time, the two terms became synonymous and began to hold the same meaning.

The Old English verb “brecan” and its Middle English form “breken” were the predecessors of the modern English verb “break”. They meant to divide solid objects into parts violently or to destroy.

The term “brake” is closely related to “break” and has its origins in the 15th century, where it was used to describe an instrument for crushing or pounding. Eventually, it became associated with the machine used for crushing grain, and then later, the term “press brake” was coined to describe the machine used for pressing and bending sheet metal.

Interestingly, in modern sheet metal bending, the Middle English verb “breken” or “break” is used to refer to bending, changing direction, or deflecting. Even a light beam can be “broken” by using a mirror.

Therefore, it can be said that the verb “brake” in the context of a press brake refers to a machine that bends sheet metal.

You might be curious about why the term “press brake” includes the word “press.”

In the 13th century, “presse” was used as a noun meaning “to crush or crowd.” Later, in the 14th century, “press” was used to refer to a device for pressing clothes or squeezing juice from grapes and olives.

As time passed, “press” evolved to mean “a machine that applies force by squeezing.” For sheet metal fabricators, the punches and dies that exert force on the sheet metal to make it bend were referred to as “presses.”

This is where the term “press brake” originated.

Different types of sheet metal bending machines are named based on the power source that actuates the machine, the tools used to bend the metal, and the type of bend produced. For instance, a leaf brake uses an upward-swinging leaf to bend the metal.

A box brake, which is also commonly known as a pan brake or finger brake, is a machine tool that is primarily used for forming boxes or pans from sheet metal. This is achieved by bending the metal around segmented fingers that are attached to the upper jaw of the machine.

A press brake performs bending using punches and dies.

See also:

Advancements in technology have led to the creation of different types of press brakes, which include manual press brakes, mechanical press brakes, hydromechanical press brakes, hydraulic press brakes, and electro press brakes. Despite the various names, the term “press brake” still refers to the machine used for bending, as illustrated in the video below.

The terms “Brake Press” and “Press Brake” are often used interchangeably to refer to the same machine. A press brake is a machine used for bending sheet metal and metal plate, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching top tool and bottom die. There are several types of press brakes including nut-stop hydraulic, synchro hydraulic, electric and hybrid.

Press brakes use a similar mechanism as stamping presses to manipulate the shape of a workpiece, but press brakes are designed exclusively for metal workpieces. In recent years, hydraulic and CNC press brakes have gained momentum among manufacturing companies.

So, whether you call it a “Brake Press” or a “Press Brake”, they refer to the same machine that is used for bending and deforming metal workpieces.

Now that we have gained a better understanding of what a press brake is and why it is called as such, those who are seeking more comprehensive information about press brakes can refer to the ultimate guide to press brakes. This guide covers in-depth details on the different types of press brakes, their working principles, tooling, applications, training, programming, and also provides valuable tips.