Have you ever wondered how everyday metal objects with complex shapes are created? Metal spinning is the fascinating process behind items like lampshades and aerospace components. This technique involves rotating a metal disc at high speed and shaping it with a tool against a mold. In this article, you’ll explore the step-by-step operations of metal spinning, learn about the materials used, and understand the design considerations crucial for producing high-quality parts. Dive in to uncover the secrets of this intricate and essential metalworking method!

Metal spinning is a symmetrical rotational forming process for sheet metal that is widely used in a variety of industries, including furniture, lamps, tableware, aerospace, and more.

Cost: The cost of molds is low, but the unit cost is medium.

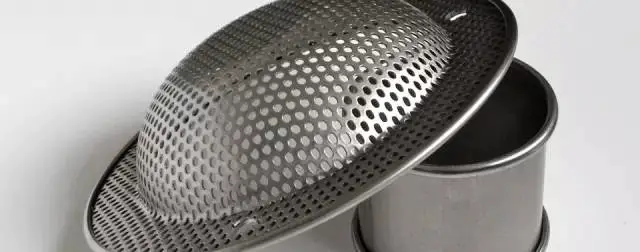

Typical Products: Metal spinning is commonly used to produce products such as furniture, lamps, aerospace components, transportation equipment, tableware, jewelry, and more.

Suitable Batch Size: Metal spinning is best suited for small to medium batches.

Quality: The surface quality of metal spinning products is largely dependent on the skill and production speed of the operator.

Speed: Metal spinning has a moderate production speed, which mainly depends on the size, complexity, and thickness of the sheet metal being processed.

Suitable for mild metal plates, such as stainless steel, brass, copper, aluminum, titanium, etc.

Limitations: Metal spinning is only suitable for producing rotationally symmetrical parts, with hemispherical thin shell metal parts being the most ideal shape.

Size Constraints: The internal diameter of parts formed through metal spinning should be kept within 2.5m.

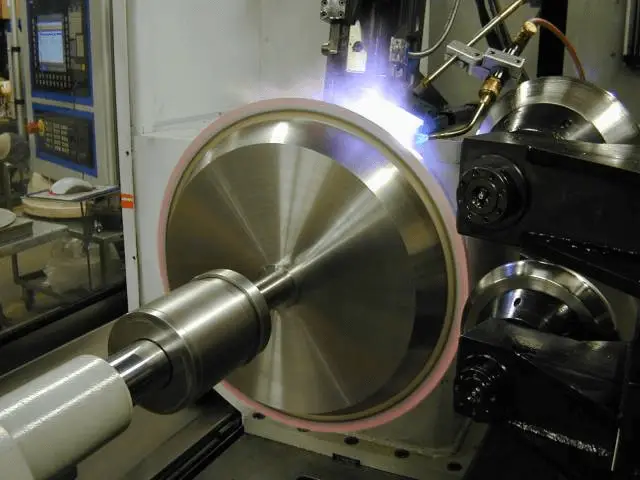

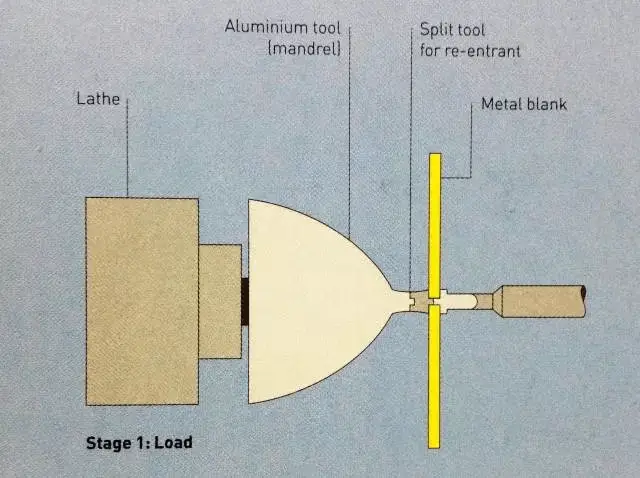

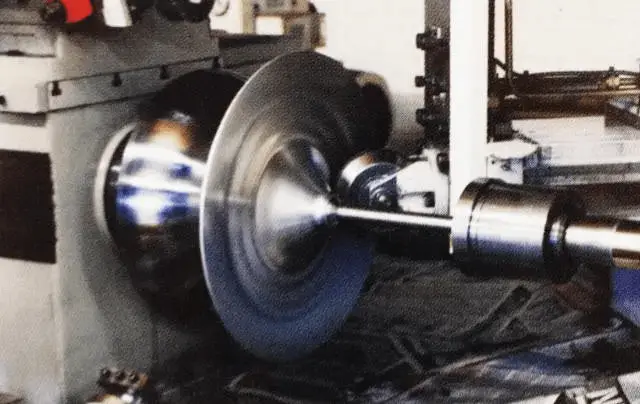

Step 1: Fix the cut circular metal plate on the machine mandrel

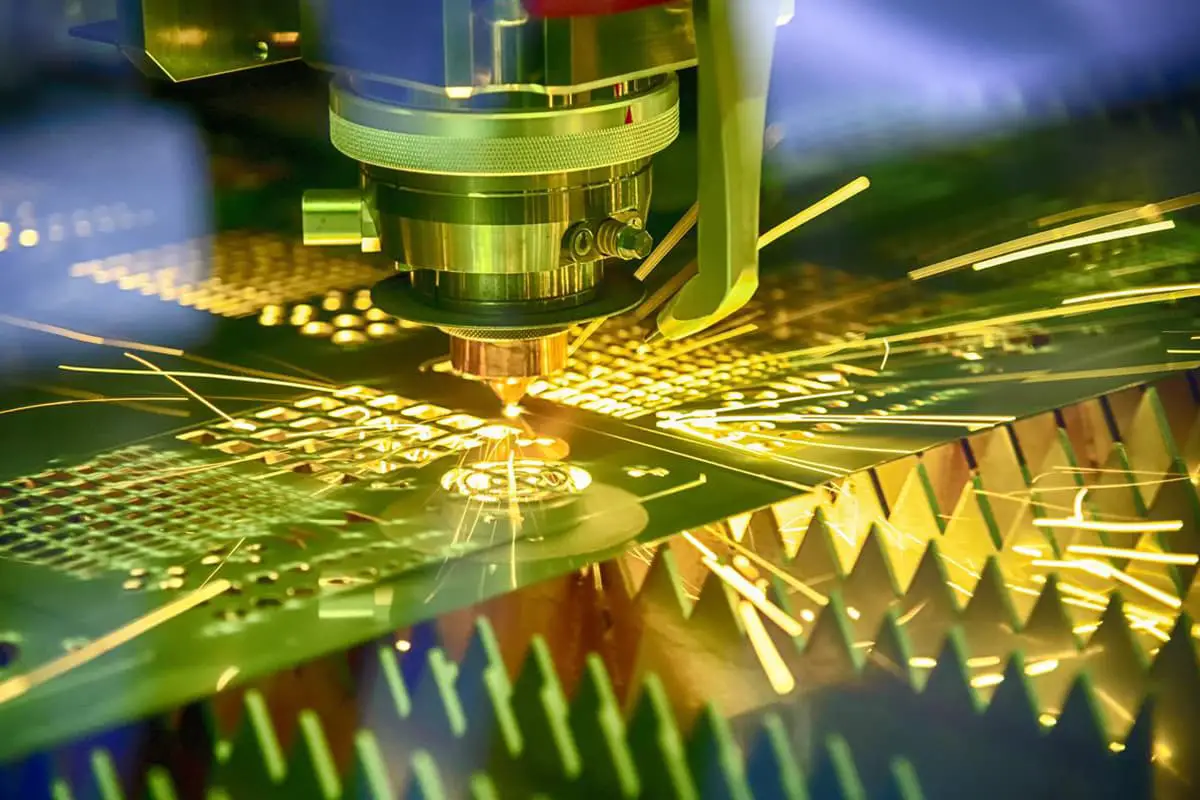

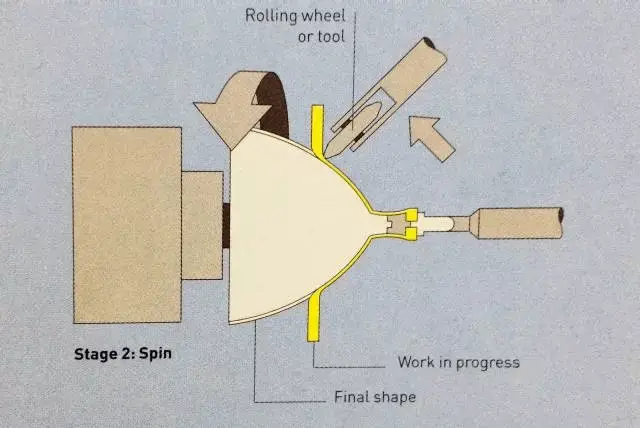

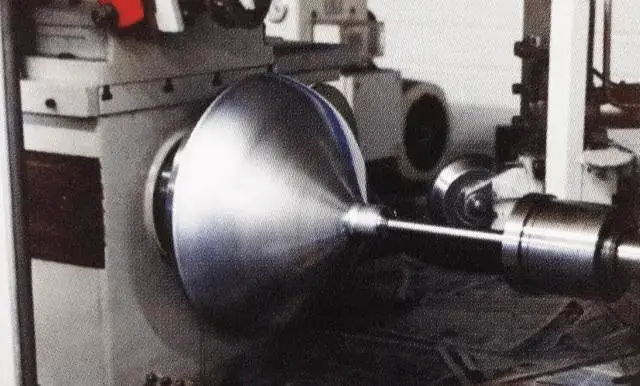

Step 2: The mandrel rotates the circular metal plate at high speed, while the tool with the wheel begins pressing against the metal surface until the metal plate conforms to the inner wall of the mold.

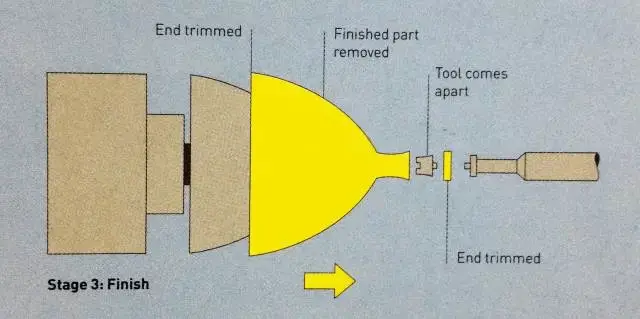

Step 3: Once the molding process is complete, the mandrel is removed and the top and bottom of the part are trimmed for demolding.

Example 1: Metal spinning of lampshade (picture)

Procedure:

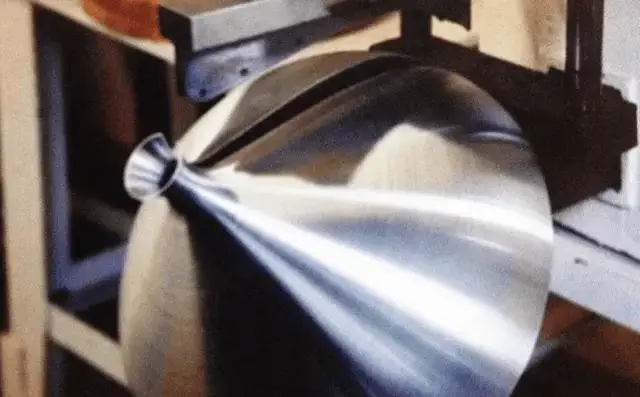

Example 2: Spinning process of other metal products