Bulge forming is suitable for various types of blanks, such as deep-drawn cups, cut tubes, and rolled conical weldments.

Bulge forming methods can be categorized as follows:

1) Hard die bulge forming.

2) Soft die bulge forming, also known as rubber bulge forming.

When rubber elastomers are used as the medium, they can be further divided into with and without die cavities. With die cavities, there are closed-loop and open-loop cavities. Closed-loop cavities are made from a single piece of material shaped into a closed curve by turning or milling. Open-loop cavities consist of several petals that are closed by external force before forming.

3) Hydraulic bulge forming.

4) Low melting point alloy bulge forming.

This method uses a low melting point alloy as the medium, either by pouring the molten alloy directly into the tube or by inserting a core rod made of the alloy into the tube.

The process is essentially a radial extrusion of the whole blank. Its advantage is that it does not require sealing, but its disadvantages include inconvenient loading and cleaning, and low production efficiency. It is suitable for materials with high strength or parts that require large deformation forces despite having low strength.

5) Other medium bulge forming methods, such as semi-fluid media like paraffin, grease, and petroleum jelly, are characterized by good sealing properties and the ability to generate uniform internal bulge pressures. They are virtually incompressible, but their drawbacks include the alternating heating and cooling processes required for loading and cleaning.

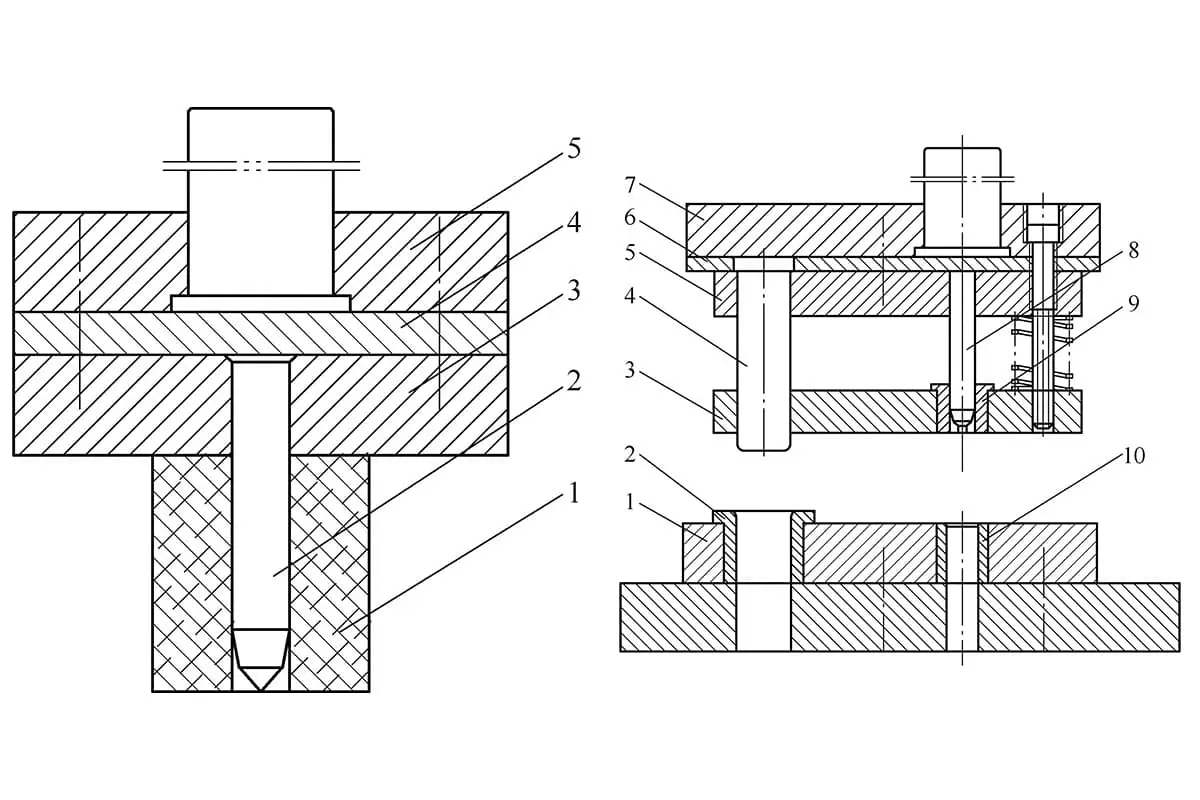

6) New processes like bulge forming with steel balls replacing soft molds or fluids, and explosive forming, as shown in Figure 6-2.

a) using a steel ball instead of a soft mold or fluid; b) explosive forming method consisting of 1 – male die, 2 – female die, 3 – steel ball, 4 – lower half of the female die, 5 – die ring, 6 – explosive, 7 – blank tube, 8 – water.

Bulge forming can also be divided into natural bulging and axial compression bulging based on the die structure.

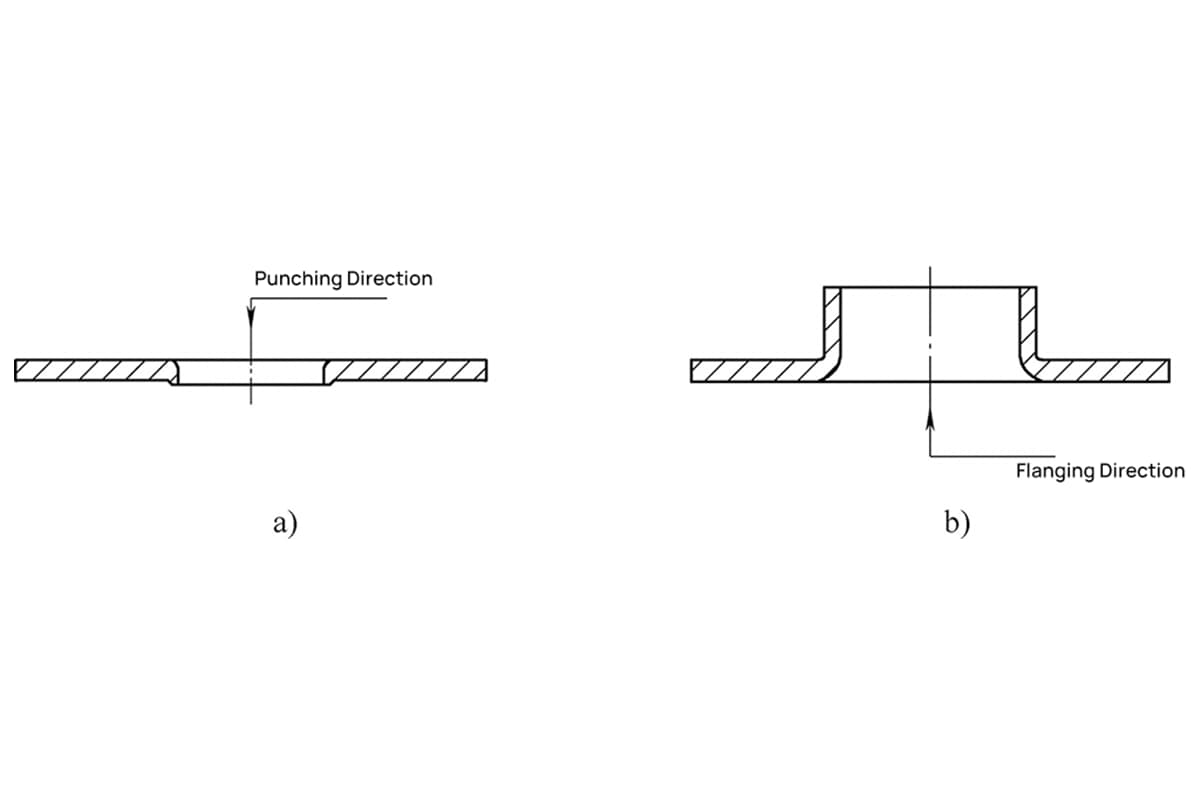

Natural bulging occurs when the part takes shape primarily through the thinning of the blank wall and the axial natural contraction (shortening). As shown in Figure 6-3, during natural bulging, the blank wall mainly bears biaxial tensile stresses in a plane stress state and deforms by thinning and elongating in two directions.

The deformation in natural bulging is quite complex, varying greatly with the shape of the bulged part and the location of the bulging due to the presence and magnitude of axial contraction during the process. The forming limit when shaping is solely reliant on the thinning of the blank wall is related to the material’s elongation rate and the wall thickness. This type of forming, which is entirely dependent on thinning, is actually a form of localized shaping.

a) Bulging process b) Component stress-strain state.

1. Pressure head 2. Composite die 3. Rubber elastomer rod 4. Die holder.

Axial compression bulging, also known as plastic extrusion bulging, is performed by applying compressive force along the axis of the tube while bulging. In practice, axial compression is often used to enhance the bulge factor and meet the material’s forming limit. The application of axial compression improves the stress and strain state in the bulging zone, facilitating plastic deformation.

For example, when the axial pressure is sufficiently high, the axial tensile stress in the deformation zone becomes compressive, resulting in a stress state of tension and compression, and the strain state may change from thinning in thickness and elongation in the radial and axial directions to axial compression and radial elongation, with little or no thinning in thickness, significantly increasing the limit of the bulge factor.

The axial compressive force applied to the workpiece and the bulging force exerted on the rubber die can be delivered by the same component, or separately by two or three components for bidirectional compression.

Depending on the magnitude of the axial compressive force on the workpiece relative to the bulging force on the rubber, as well as their ratio, the stress and strain experienced by the material in the bulging region can vary significantly.

Typically, the axial stress in the stress state should be compressive, but if the pressure on the workpiece is insufficient, or the ratio of the pressure on the workpiece to the bulging force on the rubber is too low, a tensile stress state may also develop.

This is essentially the same as natural bulging without axial compression. The strain state should typically be a plane strain state under tension and compression, or a volumetric strain state under tension in two directions and compression, which should be carefully distinguished in the mold design for specific components.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.