Have you ever wondered how everyday objects stay together? From the plastic toys we play with to the sturdy metal bridges we cross, joining techniques are at work. In this blog, we’ll explore various fascinating methods of welding and bonding materials, revealing the secrets behind their strength and durability. Get ready to uncover the magic of material joining!

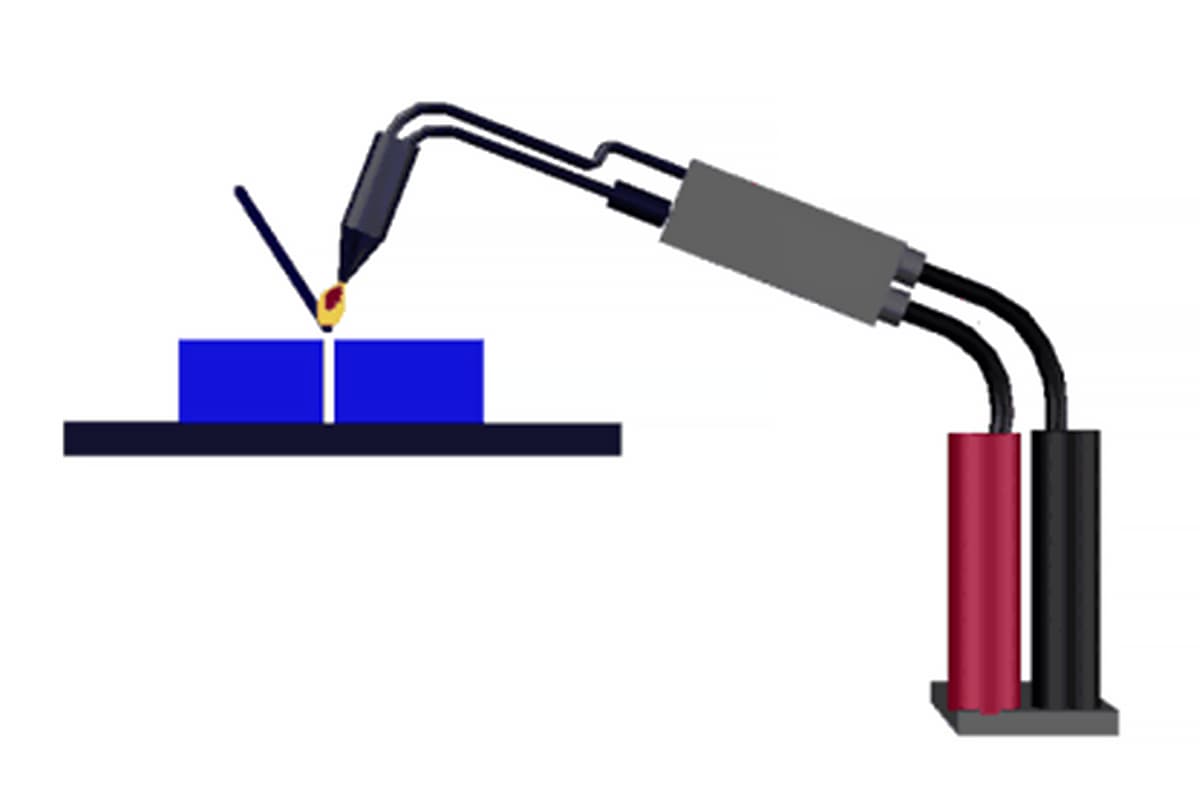

Also known as Hot Gas Welding.

Compressed air or inert gas (usually nitrogen) is heated to the desired temperature through a heater in the welding gun, sprayed onto the plastic surface and the welding rod, allowing them to melt and bond under minimal pressure.

Plastics sensitive to oxygen (like Polyamide) should use inert gas as the heating medium, while other plastics can generally use filtered air. This method is commonly used for welding plastics such as Polyvinyl Chloride, Polyethylene, Polypropylene, Polyoxymethylene, Polystyrene, and Acetate Carbonate.

Hot press welding employs heat and pressure to fuse a metal wire with the metal in the welding zone. The principle involves inducing plastic deformation in the metal of the welding area through heat and pressure, which disrupts the oxide layer on the welding interface. This allows the wire to come into the atomic attraction range with the contact surface of the weld metal, leading to interatomic attraction and accomplishing the bonding objective.

Hot plate welding adopts a drawer-like structure where heat from the hot plate machine is transferred to the fusion surface of the upper and lower plastic heating components through electrical heating. This melts their surfaces, after which the hot plate machine is quickly withdrawn, allowing the molten surfaces of the two heated components to fuse, solidify, and become unified.

The entire machine is of a frame format, composed of an upper template, a lower template, and a hot template, and is equipped with hot molds and upper and lower plastic cooling molds, operating through pneumatic control.

Ultrasonic metal welding utilizes high-frequency vibration waves transmitted to the surfaces of two metals that need to be welded. Under pressure, the two metal surfaces rub against each other, resulting in a fusion between the molecular layers. Its advantages include speed, energy efficiency, high fusion strength, good conductivity, absence of sparks, and its near-cold processing nature.

However, it does have its drawbacks: the metal pieces being welded cannot be too thick (generally less than or equal to 5mm), the weld points cannot be too large, and pressure is required.

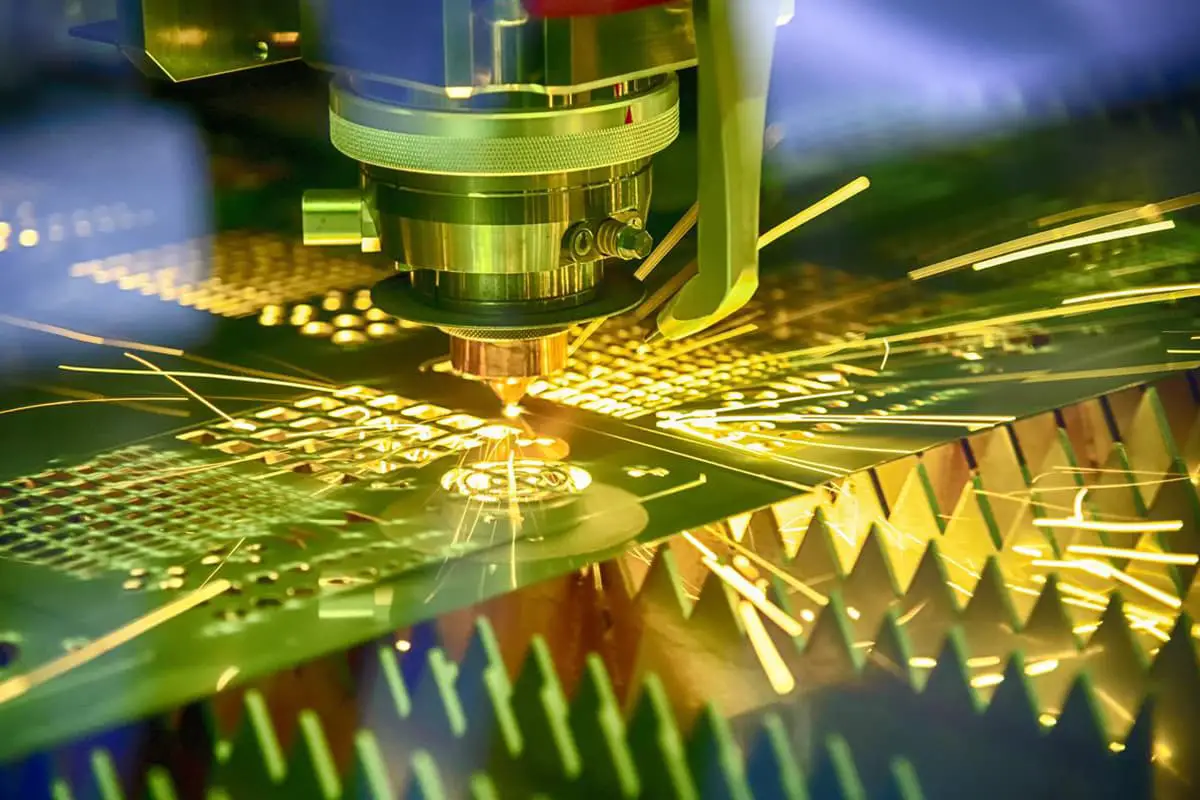

Laser welding is an efficient and precise welding method that utilizes a high-energy-density laser beam as a heat source. It represents a significant aspect of laser material processing technology. Typically, the connection of materials is achieved using a continuous laser beam. The metallurgical physics process is extremely similar to electron beam welding, where the energy conversion mechanism is completed through a “keyhole” structure.

The balanced temperature within the cavity reaches around 2500 °C, and heat is transferred from the high-temperature cavity wall, melting the metal surrounding the cavity. The keyhole is filled with high-temperature steam produced by continuous evaporation of the wall material under beam irradiation.

As the beam continuously enters the keyhole and the material outside flows, the keyhole remains in a stable state with the movement of the beam. Molten metal fills the void left after the keyhole moves and subsequently solidifies, thus forming a weld seam.

Brazing is a welding technique that heats a filler material, which has a lower melting point than the pieces to be joined, until it becomes sufficiently fluid. This fluid then fills the gap between the two pieces through capillary action (known as wetting) and, upon solidification, joins them together.

Traditionally in the United States, this method is referred to as brazing if the temperature exceeds 800°F (427°C), otherwise it’s called soft soldering.

Manual welding is a welding method that involves the operation of a handheld welding torch, welding gun, or welding clamp.

Resistance welding is a manufacturing process and technique that joins metals or other thermoplastic materials like plastics through heating. This method welds the assembled workpieces by applying pressure through electrodes and utilizing the resistive heat generated when an electric current passes through the contact surface and adjacent areas of the joint.

Friction welding is a solid-state welding process that uses mechanical energy as its power source. It works by generating heat through the friction of the workpiece’s end faces, bringing them to a plastic state, after which it completes the welding process through forge welding.

Electroslag welding is a process that utilizes the resistive heat generated by electric current passing through molten slag as the heat source, melting the filler metal and base material. This results in a solid connection between the metal atoms upon solidification. At the start of the welding process, the welding wire is short-circuited with the groove to create an arc. A minimal amount of solid flux is continuously added, and the heat from the electric arc melts it, forming liquid slag.

As the slag reaches a certain depth, the feed rate of the welding wire is increased, and the voltage is reduced, allowing the wire to be inserted into the slag pool. The arc is extinguished, transitioning into the electroslag welding process. The primary types of electroslag welding include consumable guide electroslag welding, non-consumable guide electroslag welding, wire electrode electroslag welding, and plate electrode electroslag welding.

Drawbacks of this method include high input heat, prolonged high-temperature exposure of the joint, overheating near the weld seam, and coarse crystalline cast structures in the weld metal, which results in low impact toughness. Typically, post-weld heat treatment such as normalizing and tempering is required for the welded parts.

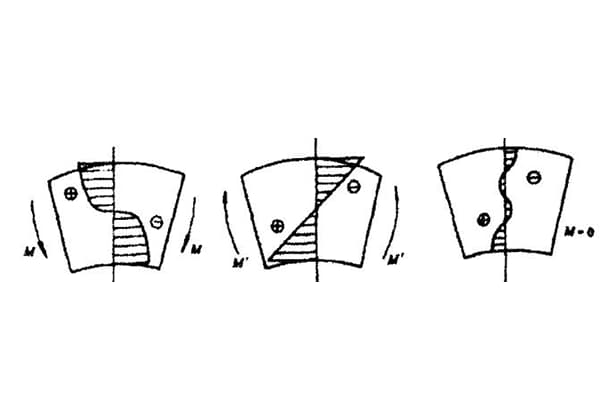

High-frequency welding is a process that utilizes solid-state resistance heat as an energy source. During welding, high-frequency electrical currents generate resistive heat within the workpiece, heating the surface area of the welding zone to a molten or near-plastic state. Subsequently, forging pressure is applied (or not applied), facilitating the union of metals.

Riveting refers to the method of connecting two relatively thin plates. This is accomplished by drilling holes in the appropriate locations, inserting rivets, and then using a rivet gun to secure the rivets, thus linking the two plates or objects together.

Hot fusion is a method of connection after heating to the melting point, transitioning to a liquid state.