Why do some grinding tools fail faster than others? In this blog post, we delve into six common problems in tool grinding, from material issues to equipment limitations, and provide practical solutions. Whether you’re dealing with carbide or high-speed steel, understanding these pitfalls can save time and improve precision. Dive in to learn how to enhance your tool’s performance and longevity.

In order to ensure optimal performance of the tool application, it is essential for the professional grinding center to adjust the grinding strategy in a timely manner based on the failure mode of the tool being polished and to monitor the usage of the tools.

To further improve its efficiency and expertise, the professional tool grinding center must regularly analyze its experiences and apply the knowledge gained to its grinding processes.

This article will highlight six critical factors that must be taken into consideration during tool grinding, including the hardware components such as tool materials, grinding equipment, and testing equipment, as well as other factors like grinding standards, grinding technicians, and more.

In tool grinding, common materials include high speed steel, powder metallurgy high speed steel, cemented carbide, and some super-hard materials such as polycrystalline diamond (PCD), cubic boron nitride (CBN), and cermet.

High speed steel tools are known for their sharpness and durability, while cemented carbide tools have a high hardness but low toughness.

It’s worth noting that the density of cemented carbide tools is much greater than that of high speed steel tools.

These two materials are primarily used for the production of drills, reamers, milling cutters, and taps.

The performance of high-speed steel produced through powder metallurgy falls between two commonly used materials for manufacturing rough milling cutters and taps.

High-speed steel tools are known for their good material toughness, making them less susceptible to breakage in the event of collisions.

On the other hand, carbide tools have a high hardness but are brittle and prone to breakage if subjected to collisions. Hence, great care must be taken during the grinding process to prevent any collisions between tools or accidental dropping of tools.

Given the relatively low precision of high-speed steel tools, they require less stringent grinding specifications and are therefore more affordable. This is why many manufacturers have established their own in-house tool grinding workshops.

In contrast, carbide tools often need to be sent to professional grinding centers for proper maintenance.

Statistics from various domestic tool repair centers indicate that over 80% of repaired tools are made of carbide.

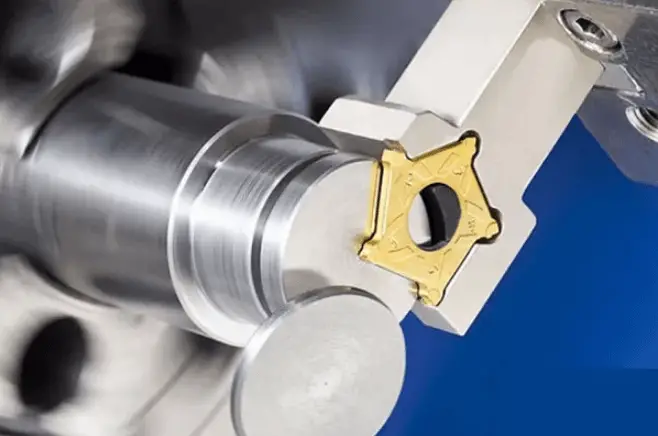

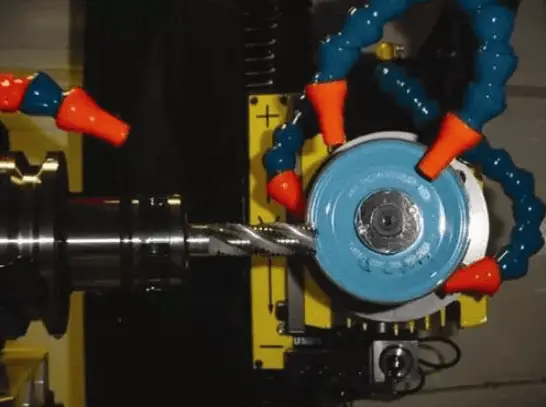

Due to the hardness of the tool material, it can typically only be reshaped through grinding. There are several common tool grinders in tool manufacturing and grinding, including:

Different materials require different abrasive particles for their grinding tools. The size of the abrasive grains must be appropriate for the specific part of the tool to achieve the optimal balance between edge protection and machining efficiency.

Alumina: This material is used for grinding high-speed steel (HSS) tools. Grinding wheels made of alumina are cost-effective and can be easily shaped to grind complex tools, such as corundum.

Silicon Carbide: This material is used to modify cubic boron nitride (CBN) and diamond grinding wheels.

CBN (Cubic Boron Nitride): CBN is utilized for grinding HSS tools. Although it is pricier, it is also more durable.

Globally, grinding wheels are designated by the letter “B”, such as B107, where 107 represents the diameter of the abrasive particle.

Diamond: This material is used for grinding high-speed steel tools and is known for its durability, despite its high cost. Diamond grinding wheels are identified by the letter “D”, such as D64, where 64 represents the diameter of the abrasive particle.

For efficient grinding of various tool components, a grinding wheel with different shapes is necessary. The two most commonly used shapes are:

It’s important to note that after using the wheel for a period of time, its shape, including its plane, angle, and rounded corners (R), may need to be modified. To maintain the wheel’s grinding ability, it’s common to use cleaning stones to remove chips that have accumulated between the abrasive grains.

Having a set of comprehensive tool grinding standards is a criterion for evaluating the professionalism of a grinding center.

Typically, the grinding standards specify the technical parameters of the cutting edge for different tools when cutting various materials, such as the blade inclination angle, apex angle, rake angle, back angle, inverted blade, and chamfer.

In cemented carbide drills, the process of passivating the cutting edge is referred to as “inverted blade,” the width of which is dependent on the material being cut and typically ranges from 0.03mm to 0.25mm.

The process of creating a chamfer on the tool tip is known as “chamfering.”

Every professional company has its own set of grinding standards that have been developed and refined over many years.

Difference between HM drill and HSS drill:

HSS Drill Bits: The vertex angle is typically 118°, but can be greater than 130° in some cases. The blade is sharp and the requirements for precision, such as blade height difference, symmetry, and circumferential run-out, are relatively low. There are numerous methods for repairing the blade.

HM Drill Bits: The top angle is usually 140°, while straight groove drills often have a 130° angle. Three-edged drills typically have a 150° angle. The blade and tip (on the edges) are not sharp and are frequently passivated through processes known as inverted blade and chamfer, which demand high precision. The chisel edge is often shaped into an S-shape to aid in chip breaking.

Back angle:

The angle at the back of the cutting edge is crucial for the effectiveness of the tool. If the angle is too steep, the blade is more prone to breaking and getting stuck, and if the angle is too shallow, the friction will be excessive and impede the cutting process.

The back angle of a tool can vary based on the material being cut, the type of tool, and the diameter of the tool.

As a general rule, the back angle decreases as the diameter of the tool increases.

Furthermore, the back angle is smaller for cutting harder materials, and larger for softer materials.

Tool inspection equipment can be classified into three categories: tool setting gauges, projectors, and universal tool measuring instruments.

Tool setting gauges are mainly utilized for preparing the tool setting length on CNC machines like machining centers, and they can also be used to detect parameters such as angle, radius, and step length.

Projectors also have the ability to detect parameters such as angle, radius, and step length.

However, neither of these two options can typically measure the back angle of a tool. On the other hand, a universal tool measuring instrument can measure most of the geometric parameters of the tool, including the back angle.

As a result, professional tool grinding centers must have a universal tool measuring instrument.

Unfortunately, there are limited suppliers of this type of equipment, and German and French products are available in the market.

Even the best equipment needs to be operated by skilled personnel. Hence, the training of grinding technicians is a crucial aspect.

Unfortunately, China’s tool manufacturing industry is relatively underdeveloped, and there is a serious shortage of vocational and technical training. As a result, the training of tool grinding technicians must be handled by individual enterprises.