Imagine working with a laser welding machine, where one wrong move could lead to serious injuries or equipment damage. This article covers essential safety precautions for using these powerful devices, detailing steps for safe operation, necessary personal protective equipment, and proper emergency responses. By following these guidelines, you’ll ensure a secure working environment and prevent accidents, safeguarding both personnel and machinery. Dive in to learn the critical safety measures that every operator should know.

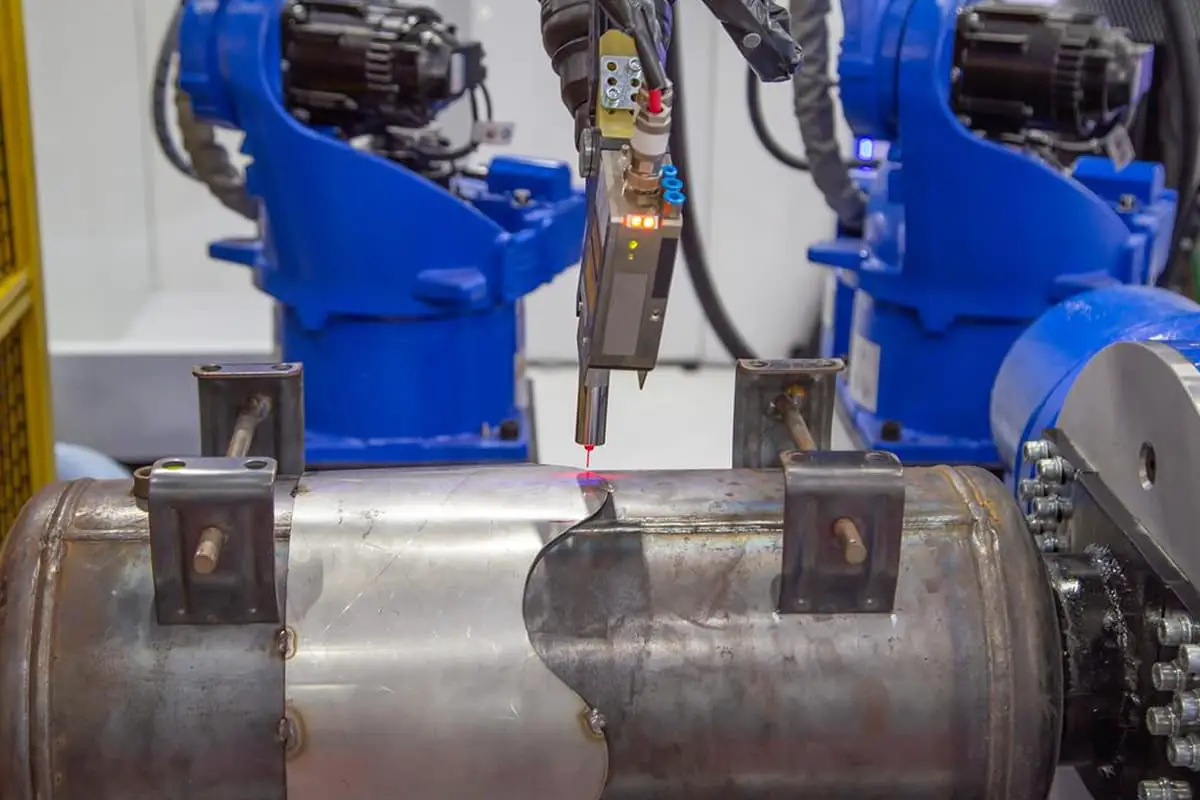

Laser welding machines are commonly utilized for butt welding and repair welding of metal materials. The operating principle of laser welding involves using high-energy laser pulses to heat a small area of the material. The heat energy diffuses from the material surface to its interior, creating a specific molten pool after melting. During the entire process, the materials are kept in a high-temperature state.

So, how can we safely operate a laser welding machine?

The laser of a laser welding machine has biological effects, such as the ripening effect, light effect, pressure effect, and electromagnetic field effect, similar to ordinary light.

However, if proper protection measures are not in place or if protection is inadequate, these biological effects can lead to direct or indirect harm to human tissues, such as the eyes, skin, and nervous system.

To ensure the safe and protective use of laser welding, it is important to strictly control laser hazards and to properly implement engineering controls, personal protection, and safety management.

Engineering controls refer to structural safety measures taken for laser or laser processing systems, mainly including:

Protective Cover: Used to prevent workers from receiving more than the maximum allowable exposure.

Safety Interlock: A device that automatically connects with the protective cover and prevents radiation when the cover is removed.

Safe Optical Path: Closes the optical path that may cause combustion or secondary radiation by irradiation.

Key Switch: Generally refers to the ability to turn off the laser when the key is removed.

Beam Terminator: To prevent the laser beam from exceeding the controlled processing area, an attenuator can be used as a beam terminator.

Personal Protective Equipment (PPE) plays a crucial role in ensuring laser safety. To stay protected, it is important to wear fire-resistant and heat-resistant laser protective clothing, use laser protective glasses that effectively reduce specific laser wavelengths, wear a laser protective mask for UV laser sources, and put on laser protective gloves to prevent damage from direct or scattered laser beams.

Effective safety management involves establishing dedicated organizations or personnel, clearly defining responsibilities and rights, conducting safety training, and providing ongoing supervision.

Before starting a laser welding operation, inspect all parts of the laser welding machine to ensure they are functioning normally. After the operation, check both the machine and the work site to eliminate any potential hazards and guarantee a safe work environment.

Direct exposure to the laser beam or strong reflection can cause ignition and fire. Additionally, the laser contains thousands to tens of thousands of volts of high voltage, which can pose a risk of electric shock. To prevent direct exposure, the optical path system of the laser must be completely enclosed in metal. Additionally, the laser welding worktable must be shielded to prevent radiation.

The laser welding machine uses a high power density (units: g/cm3 or kg/m3) and a thin beam, which can easily cause damage to the eyes and skin. To protect the eyes, professional laser protective glasses must be worn during the operation.

Direct exposure of the skin to the laser beam can result in burns. Additionally, long-term exposure to diffuse reflection can cause skin aging, inflammation, and even skin cancer in the operator. To reduce the effects of diffuse reflection, field operators should wear protective clothing.

Laser welding is a process in which a high-efficiency laser single pulse is used to heat specific areas of raw materials. The kinetic energy of the laser radiation source is transferred to the interior of the raw materials through heat conduction, causing the raw materials to melt and form a specialized pool of solution.

Laser welding is a cutting-edge welding method that is particularly well-suited for electric welding of thick-walled raw materials and high-precision parts. It can perform various types of welding, such as butt welding, overlap welding, and sealing welding, with a high depth-to-length ratio, minimal total welding width, small heat-affected area, and minimal deformation.

Laser welding is also faster than traditional electric welding and produces a smooth and attractive finish. Additionally, it requires no post-welding cleanup and produces high-quality results with no air holes. With its accurate operation and small focus spot, laser welding offers a high level of precision and can be easily automated.

How to use laser welding machine properly?

Safety analysis of common problems in proper application of laser welding machine:

Laser welding machine start:

Laser welding machine standby: