In the rapidly evolving world of manufacturing, cost-cutting is king. Waterjets have emerged as a game-changer, offering unparalleled versatility and efficiency. But how can you harness their full potential to minimize costs and maximize profits? In this article, a seasoned mechanical engineer shares insider tips and expert insights to help you master the art of waterjet cutting. Discover the secrets to optimizing your operations and staying ahead of the competition.

Engineers and manufacturers constantly strive to find ways to reduce costs, and waterjets have proven to be highly effective in achieving this goal and increasing profits.

To take full advantage of this cost-saving technology, it is crucial to gain a deeper understanding of how to effectively apply waterjet cutting methods to minimize costs and maximize profits.

The waterjet cutting industry is regarded as one of the most versatile and rapidly growing industries in terms of cost-cutting measures.

See also:

Furthermore, the waterjet cutter is among the most efficient machines globally. It surpasses other cutting technologies such as flame cutting, plasma machining, laser machining, EDM machining, turning, milling, and planing.

Additionally, waterjet cutting is a versatile, efficient, and environmentally friendly process as it does not produce harmful gases or liquids and generates no heat on the workpiece surface.

This cutting method offers unique capabilities that cannot be achieved through other simple processes. For instance, it can cut holes in titanium and produce intricate patterns on stone or glass.

Moreover, the waterjet cutting process is truly cold as it generates no heat when cutting materials.

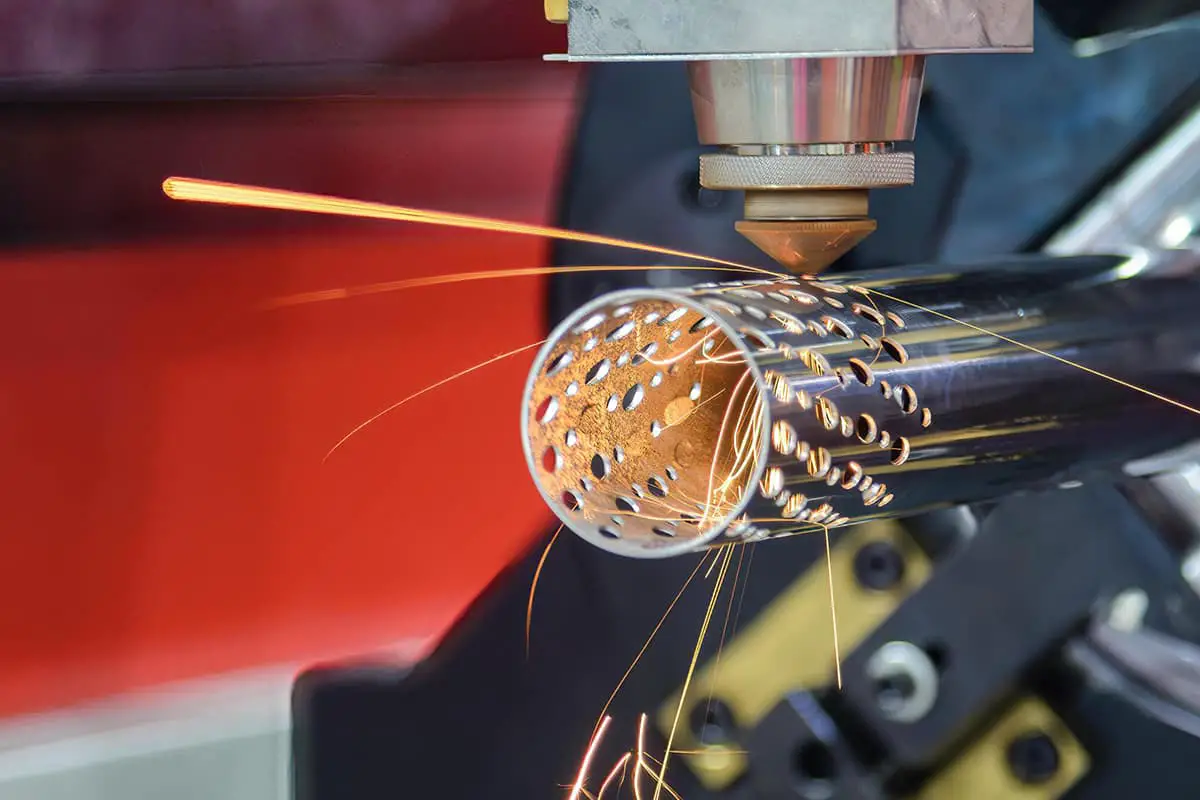

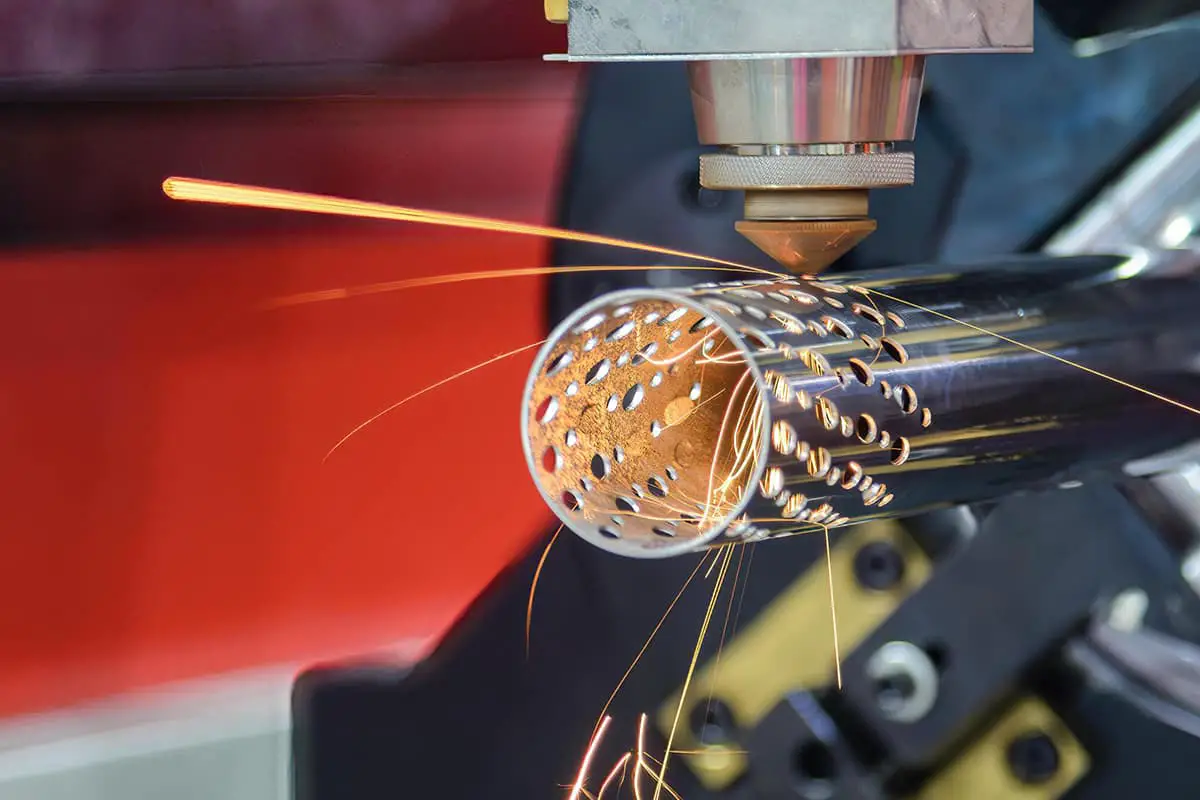

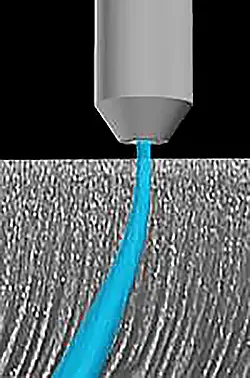

The supersonic water arrows that are produced during the cutting process result in excellent outcomes when directed at the cutting material’s surface, and the combination of water and sand enhances its cutting power even further.

Waterjet, also known as “water as the knife,” is the original name for high-pressure water jet cutting technology. This technology originated in the United States and was initially used in the aerospace and military industries.

Its popularity stems from the fact that it does not alter the physical and chemical properties of the material due to its cold cutting method.

Over time, with continuous technical advancements, the addition of abrasives such as garnet sand, diamond sand, and others to high-pressure water greatly improved the cutting speed and thickness of waterjet cutting.

Waterjet technology has been widely adopted across a range of industries, including ceramics, stone, glass, metal, composite materials, and others.

In China, the maximum pressure of waterjets has reached 420MPa. Some technologically advanced companies have even developed 3-axis and 4-axis waterjets, with 5-axis waterjets being a rapidly developing technology.

Waterjet, also known as waterjet cutting, is a machine that uses high-pressure water for cutting purposes. It allows for precise cutting controlled by a computer and is not greatly affected by the texture of the material.

Due to its low cost, ease of operation, and high yield, waterjet cutting is becoming the preferred cutting method in industrial technology.

It can cut any material into any shape in a single process, which sets it apart from other cutting methods that are limited by material restrictions.

The cutting process generates no heat, and the high-speed flow of waterjet immediately removes any heat generated. It also does not produce any harmful substances and has no thermal effect on the material, making it an environmentally friendly, safe, and efficient method of cutting.

Additionally, there is no need for secondary processing, and it offers flexible, versatile cutting capabilities that can be used to achieve any desired shape.

UHP water cutting, also known as waterjet or water jets, is a high-energy (380MPa) water flow generated by multi-stage pressurization of ordinary water.

This water is then expelled at a speed of nearly 1,000 meters per second through a highly precise ruby nozzle (Φ0.1-0.35mm), making it a highly efficient cutting method. This cutting process is referred to as UHP water cutting.

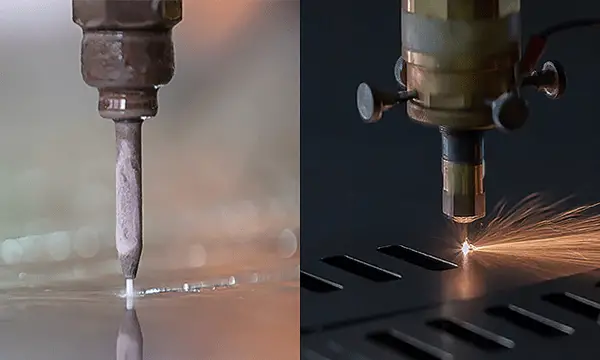

Waterjet can be divided into pure waterjet and abrasive waterjet.

The pure waterjet was the first method of water cutting, with its first commercial application starting in the mid-1970s for cutting corrugated cardboard.

The largest applications for pure water waterjets are cutting disposable diapers, cotton paper, and automotive upholstery.

For cotton paper and disposable diapers, waterjet technology provides the least amount of water residue compared to other technologies.

Features of Pure Water Waterjet:

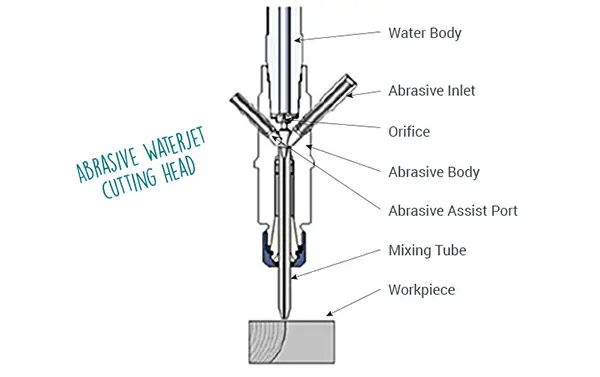

Abrasive waterjets differ from pure waterjets in only a few ways. In pure waterjet, the material is eroded by supersonic water flow, while in abrasive waterjet, particles of abrasive material are accelerated by water jets, eroding the material.

Abrasive waterjets are hundreds or thousands of times more powerful than pure waterjets and are used to cut hard materials like steel, stone, composites, and ceramics.

With standard parameters, abrasive waterjets can cut materials with a hardness equal to or slightly exceeding that of alumina ceramics (often referred to as AD 99.9).

Features of Abrasive Waterjet

Water cutting can be divided into different categories based on various factors. These include:

Experiments have shown that when water pressure exceeds a certain threshold, even pure water can cause certain sensitive chemicals to detonate. Sand-containing water cutting can also cause instability of special chemicals because of the potential energy and impact generated by the abrasive sand and object collision. The threshold was determined to be around 237.6 MPa after much experimentation and argumentation.

As a result, water cutting with a pressure of over 200MPa is primarily used in the machining industry.

Table1 Water jet cutting speed for common materials

| Material | Cutting thickness | Water pressure MPa | Nozzle aperture water abrasive mm | Cutting speed m/min |

|---|---|---|---|---|

| Carbon Steel | 12 , 50 | 350 | 0.25/0.76 | 0.4, 0.1 |

| Stainless Steel | 13, 25 | 350 | 0.25/0.76 | 0.4, 0.2 |

| Titanium | 3.2, 6.4 | 350 | 0.25/0.76 | 0.8, 0.6 |

| Aluminum | 12 , 100 | 350 | 0.25/0.76 | 0.6, 0.12 |

| Ductile Iron | 15 | 350 | 0.25/0.76 | 0.4 |

| Laminated paper | 12 | 309 | 0.25 | 3.5 |

| Gypsum board | 15 | 294 | 0.15 | 20 |

| Rubber | 15 | 377 | 0.17 | 12 |

| Silicone rubber | 12 | 377 | 0.12 | 3 |

| Hard rubber | 19 | 309 | 0.25 | 6 |

| Fabric | 20 | 309 | 0.18 | 3 |

| Fiber fabric | 20 | 377 | 0.20 | 6 |

| Leather | 1 | 343 | 0.15 | 30 |

Dr. Norman Franz is widely recognized as the father of the waterjet technology.

He was the first person to research ultra-high pressure (UHP) waterjet cutting tools, which are defined as higher than 30,000 psi. As a forestry engineer, Dr. Franz aimed to find a new method for cutting large tree trunks into lumber.

In 1950, he first used heavy weights to apply pressure to a column of water, forcing it through a small nozzle and producing a brief high-pressure jet that could cut wood and other materials.

Despite the difficulties he faced in obtaining a continuous stream of high pressure and the limited lifespan of parts at the time, he showed that high-speed convergent water flow has tremendous cutting power.

Today, wood cutting is one of the least significant applications for UHP technology, but Dr. Franz’s discovery has far-reaching applications beyond what he could have imagined.

In 1979, Dr. Mohamed Hashish of Flow Research began investigating ways to enhance the cutting power of waterjets for cutting metals and other hard materials.

Dr. Mohamed Hashish is widely regarded as the father of the abrasive waterjet, having developed the method of adding abrasives, such as garnet, to a regular waterjet, enabling it to cut almost any material.

In 1980, abrasive waterjets were first used to cut metal, glass, and concrete. In 1983, the world’s first commercially available abrasive waterjet cutting system was introduced and was initially used to cut automotive glass.

The aerospace industry was one of the first users of this technology, recognizing its benefits for cutting stainless steel, titanium, high-strength lightweight composites used in military aircraft, and carbon fiber composites in civilian aircraft.

Over time, abrasive waterjets have been adopted by many other industries such as fabricators, stone and tile, glass, jet engines, construction, nuclear, shipyards, and more.

The development of water cutting can be roughly divided into several stages: the early 1960s exploration and experimental stage, mainly used in low-pressure waterjet mining and oil pipeline cleaning; the late 1960s to early 1970s stage of basic equipment development and research, focused on developing high-pressure pumps, boosters, and high-pressure pipe fittings and promoting high-pressure waterjet cleaning technology; the early 1970s to early 1980s stage of industrial experiments and applications, characterized by the emergence of a large number of high-pressure waterjet coal mining machines, cutting machines, and cleaning machines; and the rapid development of high-pressure waterjets since the 1980s, featuring further advancements in high-pressure waterjet research, as well as the rapid development of new technologies such as abrasive waterjet, abrasive jet, cavitation jet, and self-excited shock jet.

At present, more than 40 countries are involved in researching and applying waterjet processing technology, including the United States, Russia, Japan, Germany, Switzerland, the United Kingdom, France, Canada, Australia, India, South Korea, and Singapore.

The application of waterjet technology is quite broad and encompasses industries such as industrial cutting, excavation and drilling, rock cutting, surface cleaning, material crushing, and more.

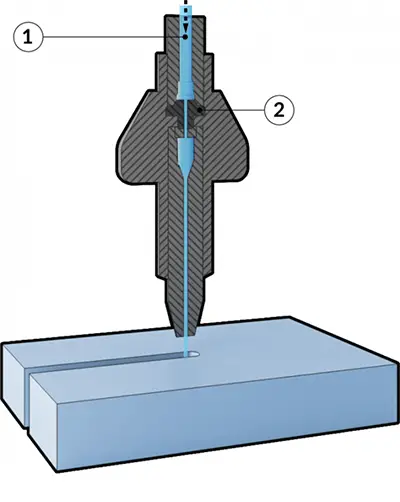

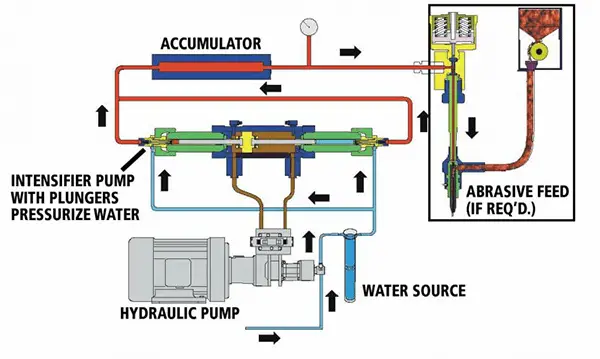

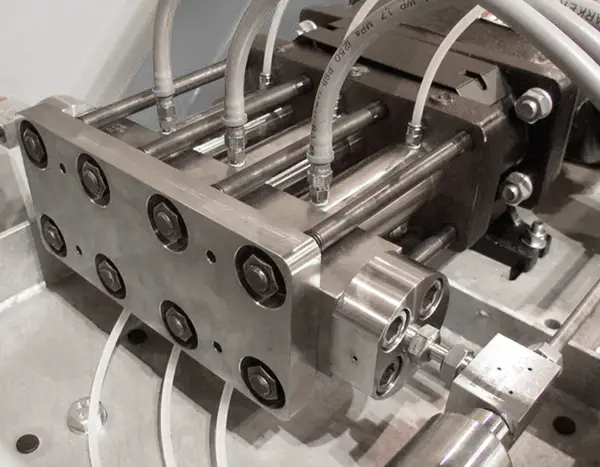

The basic principle behind a water jet cutter is both straightforward and complex. The process starts with a pressurized pump that feeds water into a high-pressure tube, which then exits through a cutting nozzle.

Although the explanation is simple, the design of the cutter is intricate and precise, capable of producing 60,000 PSI of pressure.

A small leak in the system can cause lasting damage to the parts through erosion, which is why manufacturers and engineers take great care in handling high-pressure materials and using specialized technology to assemble the machine. Users only need to have a basic understanding of how to operate the cutter.

Abrasive cutters have been used in various industries, including the automotive, aerospace, and glass industries, since 1982, with the first ones appearing in 1970. Over time, the precision of cutting has continuously improved.

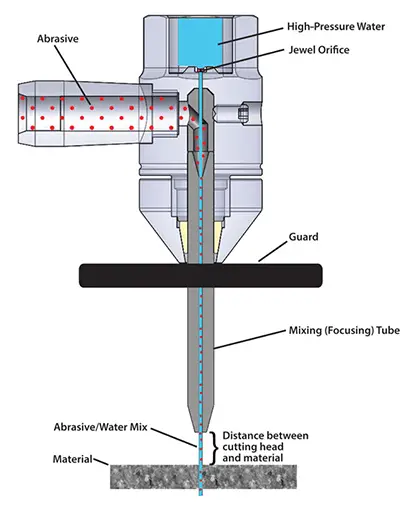

The pressure of an abrasive cutter can reach 55,000 PSI, and the high-pressure water exits a tiny nozzle at a speed of 762m/s, which is 2.5 times faster than the speed of sound.

By mixing garnet sand into the high-velocity water jet, the cutting process becomes a grinding and cutting process. The force and action are generated by the water, which is directed at the material being processed at 305M/s.

In summary, the water jet cutter works by converting mechanical energy from a power source (motor) into pressure energy using a specific device (such as a booster port or high-pressure pump).

The pressurized water then passes through a small nozzle, converting the pressure energy into kinetic energy to form a high-speed jet stream. This is why the cutter is often referred to as a high-speed water jet.

Regarding water quality, there are two forms of ultra-high-pressure (UHP) water cutting: pure water cutting, which produces a cutting slit of about 0.1-1.1mm, and abrasive cutting, which produces a cutting slit of about 0.8-1.8mm.

In terms of structure, UHP water cutting can take on various forms such as a gantry structure or cantilever structure with two to three CNC axes, which are typically used for cutting plates.

There is also a robot structure with five to six CNC axes, which is mostly used for cutting automotive interior parts and car interiors.

Advantages:

Disadvantages:

High-pressure Water Jet Machining

High-pressure water jet machining involves using water or a liquid with added substances that is pressurized by a supercharger through a water pump.

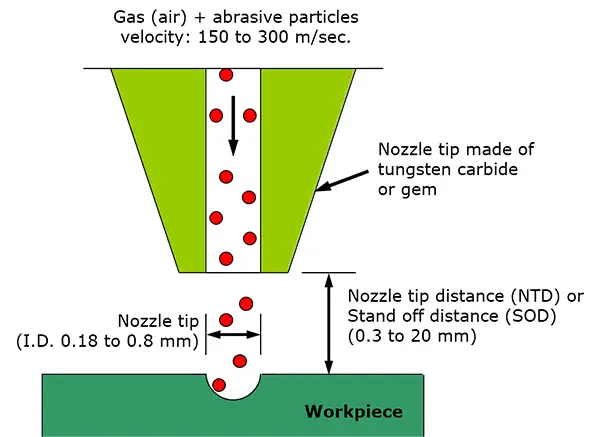

This high-pressure liquid is then made to flow steadily through a liquid storage accumulator and finally forms a high-speed liquid flow of 300-900 meters per second through the nozzle, which is then sprayed onto the surface of the workpiece for material removal and modification.

Abrasive jet machining

Abrasive Jet Machining (AWM) is a process that involves the use of a high-speed jet flow composed of micro-abrasives and high-pressure air or other gases.

The material on the surface of the workpiece is removed and modified by the high-speed impact and erosion of the abrasives, which are delivered through a specially designed nozzle.

Abrasive Water Jet Machining

Abrasive Water Jet Machining (AWJ) is a method that utilizes water as a medium and generates high pressure through a high-pressure generating device.

The high-pressure water beam is then mixed with abrasive through a feeding and mixing device to form a two-phase liquid-solid jet. It removes and modifies the surface material of the workpiece through the high-speed impact and scouring of the abrasive and high-pressure water beam.

The advantages of AWJ include its strong adaptability, wide cutting range, availability of water and abrasive sources, and low cost. It also has the benefits of being environmentally friendly with no harmful gas, dust, smoke or pollution.

Multiple cutting heads can operate simultaneously for fast and efficient cutting, and the process is flexible and versatile for machining complex parts.

Additionally, there is a good working environment with no fixtures, easy operation, and a smooth cutting surface without burrs. The cold processing will not affect the physical and mechanical properties or intergranular structure of the material.

Overall, AWJ combines the benefits of abrasive jet and water jet, expanding the processing range and providing excellent results.

Water jet can be divided into the following three types:

Classification of Jet Techniques:

The pulse jet is an intermittent jet, with an appearance similar to that of a bullet. It is produced through the following methods:

(1) A sudden release of stored energy or water from a cannon;

(2) Pressure extrusion;

(3) Flow regulation, also known as “water hammer.”

The performance of this type of jet depends on factors such as the frequency of water hammer formation, the ratio of the water hammer length to the jet diameter, and the energy of the water hammer.

The cavitating jet is a type of continuous jet that generates cavitation bubbles naturally within the jet. This process stimulates the growth of cavitation nuclei, or bubbles in the fluid, which are pulled into the jet and continue to grow until they collide with the surface being cleaned or cut, causing them to break.

During the breaking process, extremely high pressure and micro jets are produced with stresses exceeding the tensile strength of most materials.

The advantages of abrasive water jet machining are:

Ultra high-pressure water jet can cut all kinds of thick and hard materials, such as stainless steel, aluminum, copper, steel, marble, alloy metal, glass, plastic, ceramics, tiles and all kinds of visible materials.

High-pressure water jet cutting involves using a high-speed jet with high kinetic energy, also known as high-speed water jet processing. It is a type of high-energy beam processing, similar to laser, ion beam, and electron beam processing.

As a new and innovative technology, high-pressure water jet cutting has revolutionized the cutting industry and has a vast range of applications.

With the advancement of technology and the overcoming of certain limitations, high-pressure water jet cutting has become a complement to other cutting processes.

The technology is widely used across various industries, including aerospace, automobile, machinery manufacturing, construction, medical equipment, electronic power, chemical, sporting goods, military, and new materials-related fields.

In the aerospace industry, high-pressure water jet cutting is used to cut a variety of alloy materials and new materials, such as carbon fiber composites and plastic glass, without causing thermal effects or damaging material properties.

In the automobile industry, it is used to cut a range of non-metal and composite materials, including body outer panels and door frames.

In the military industry, it is used to destroy weapons and cut inflammable and explosive facilities.

In machinery manufacturing and construction, it can be used to cut all types of metal, non-metal, brittle plastic materials, and challenging-to-process materials, such as ceramics and concrete, with high efficiency and accuracy.

Water jet technology is also used in the paper industry and rubber industry, while abrasive waterjet is used in the stone industry, ceramics industry, aerospace industry, and metal processing industry.

In particular, the application of water jet technology in the automotive manufacturing industry has been on the rise, with the development of the industry and the need for high efficiency and accuracy.

The combination of water jet equipment and robots has been particularly effective in processing automotive interior parts. The high-pressure water pipe is wound around the robot arm, and the robot arm and wrist can move the nozzle of the water jet head in a straight line or arc for 3-dimensional processing.

Application of water jet technology in industrial cleaning

The Water Jet Technology has various applications including the cleaning of spray booths in the automobile industry, the cleaning of heat exchanger tubes in the petrochemical industry, rubber cleaning of aircraft runways, surface treatment for industrial rust removal and anti-corrosion engineering, engine parts cleaning in the aerospace industry, and radiation pollution cleaning in nuclear power plants.

In recent years, some companies have embraced ultra-high-pressure technology for food preservation, with great success. For example, the American Hemell Company has earned a good reputation in the food preservation industry with its ultra-high-pressure equipment.

Water Jet technology can be used for cleaning cars, high-rise buildings, airport runways, heat exchangers in chemical plants, and more. Many cleaning machines and facilities have been introduced to the market, and various cleaning companies and service providers have emerged to meet user needs.

According to recent research from Missouri Rolla University, high-pressure water jet has enormous potential. It can crush coal into fine particles for cleaning purposes and produce clean fuel, and it can also separate wood fibers through hydraulic pulping.

In 2002, the Flow Company in the United States took ultra-high-pressure technology to a new level with the release of the ultra-high-pressure water jet equipment, with a maximum pressure of 87000mpa, which significantly improved production efficiency and reduced costs by 40% compared to previous methods.

As water jet technology continues to develop and expand, its potential for growth and application is limitless.

System parameters: Water Jet System Pressure;

Nozzle Structure Parameters: Nozzle Diameter, Chamfer Radius, Mixing Pipe Length, Mixing Pipe Diameter;

Abrasive Parameters: Abrasive Material, Particle Diameter, Abrasive Flow, Particle Shape;

Mixing Mode: Pressure Drive or Negative Pressure Suction;

Mixing State of Abrasive: Dry Powder or Slurry;

Cutting Parameters: Feed Speed, Target Distance, Number of Cuttings, Jet Angle;

Material Parameters: Strength, Hardness, Density, etc.

The cutting accuracy of water jet cutting is typically between 0.1 mm and 0.25 mm, which depends on several factors including the accuracy of the machine, the size range of the workpiece being cut, and the thickness and material of the workpiece.

Typically, the positioning accuracy of the machine system is in the range of 0.01 mm to 0.03 mm.

The size and thickness of the material to be cut, as well as the nozzle used, will determine the width of the kerf.

Typically, the kerf for abrasive cutting is around 1.0 to 1.2 mm. As the diameter of the abrasive nozzle increases, the kerf becomes wider.

The quality of the beveled edge depends on the cutting speed, and a good cutting quality is generally around 0.1 mm.

The abrasives used in water cutting include quartz sand, garnet, river sand, and diamond sand. The grain size of the abrasives is generally between 40-70 mesh, with the hardness of the abrasive affecting the grain size and cutting ability.

Generally, the higher the hardness of the abrasive, the larger the grain size and the stronger the cutting ability.

Generally speaking, materials with complex patterns, thickness, and difficulty in cutting, along with being fragile and heat-sensitive, are most suitable for water jet cutting.

For cutting and drilling the edges of a workpiece, using an abrasive cutter is much faster, easier to organize, and cost-effective compared to blind holes, drilling, and threading.

This is because we can cut the workpiece in a single pass with a waterjet, without having to grind the metal into pieces.

When precise workpieces need to be cut, the abrasive cutter is a tool that can be used to produce nearly finished products in one pass without any thermal effects.

Furthermore, the waste produced by an abrasive cutter is often valuable as it is in the form of whole pieces rather than chips and can be recycled.

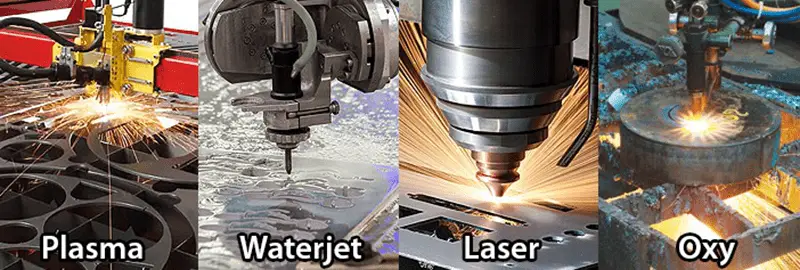

Obviously, the process of flame cutting is hot and results in thermal effects on the final product. In contrast, abrasive cutting usually results in a better surface finish, with no slag on the back of the workpiece, reducing the need for secondary processing.

Additionally, there is no limit to the thickness that can be cut, and the spacing of the cutting pattern can be reduced to conserve material costs.

The investment required for laser cutting equipment is substantial. Currently, it is mainly utilized for cutting thin steel plates and some non-metallic materials. The cutting speed is fast, and the precision is high, however, it also causes an arc mark and thermal effect at the cutting seam.

Additionally, laser cutting may not be suitable for some materials such as aluminum, copper, and other non-ferrous metals and alloys, particularly for cutting thicker metal plates, as the cutting surface may not be ideal or even unable to be cut.

Related reading: Ferrous vs Non-ferrous Metals

At present, research into high-power laser generators aims to solve the challenge of cutting thick steel plates, but the cost of equipment investment, maintenance, and operation is significant.

In contrast, water cutting has several advantages including low investment cost, economical operation, the ability to cut a wide range of materials, high efficiency, and easy operation and maintenance.

Water jet is better than laser in some aspects

There is no limit on the cutting thickness with water jet cutting.

Reflective materials, such as brass and aluminum, can also be cut effectively.

No heat energy is required, so there is no risk of burning or producing thermal effects.

When adjusting cutting speed, only the cutting speed needs to be changed, without the need to modify the gas, focus, or other components.

Production capacity can easily be increased by installing multiple cutting heads.

Maintenance for laser equipment is more specialized and challenging, while water jet equipment requires relatively lower maintenance.

Additionally, purchasing a complete set of water jet equipment is less expensive, costing only 1/2 to 1/3 of the cost of laser cutting equipment.

Plasma cutting has a significant thermal impact, low precision, and the cut surface is not easily re-processable.

On the other hand, water cutting is a cold cutting process, which does not cause thermal deformation and results in a high-quality cutting surface with no need for secondary processing. If further processing is required, it is also easy to accomplish.

For metal processing, WEDM (Wire Electrical Discharge Machining) provides high accuracy, but is very slow in cutting speed. In some cases, additional methods such as piercing and threading are required.

Additionally, the cutting size is limited with WEDM. On the other hand, water cutting is capable of punching and cutting any material at a faster speed, with the added flexibility of having a variable processing size.

The process of punching and shearing can be used to efficiently and quickly cut some metal parts, but it requires special dies and cutters.

On the other hand, water cutting is more flexible and can be used to cut any shaped workpiece at any time. This is particularly beneficial for cutting thick and hard materials, as punching and shearing technology may be difficult or impossible to achieve in these cases.

Flame cutting is a common cutting process in the metal industry, but it has a large cutting thickness range and a significant thermal effect, poor cutting surface quality, and accuracy.

Water cutting, on the other hand, can be used to cut special materials like high melting point alloys and composites, and is highly precise when cutting normal thickness plates in the glass, stone, and ceramics industries.

It is worth noting that when laser, plasma, flame, wire cutting, sawing, milling, and other processing methods are able to meet processing requirements, water cutting is usually not appropriate.

The operation cost of water cutting is high, with imported consumables like nozzles, guide sleeves, and high-pressure seals being expensive.

In conclusion, while water cutting has its benefits, it may not be suitable in certain cases.

A complete set of water jet cutting equipment should at least include the following components: an ultra-high pressure pump, a water jet cutting head device, a CNC cutting table, and a computer control cabinet.

The details are as follows:

Due to the energy gradient effect, laser, oxy, plasma, jet and other cutting methods have a declining cutting ability as the cutting plane becomes deeper (further away from the nozzle).

As a result, the formed cutting surface is often not perpendicular to the workpiece surface, creating a cutting slope, which is an inherent flaw in all cutting methods.

Attempts have been made to reduce the cutting slope by increasing the cutting energy or reducing the cutting speed, however, the issue of non-vertical cutting cannot be completely resolved.

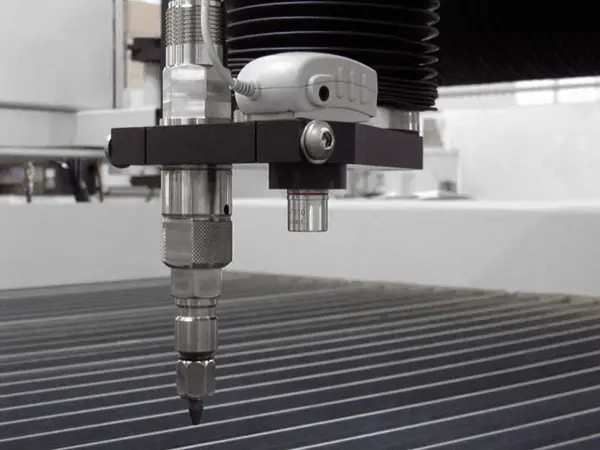

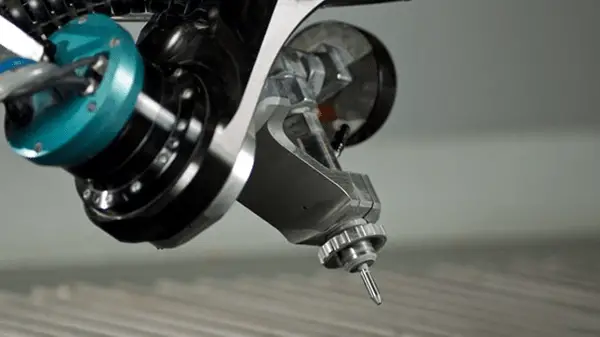

In 1997, the idea of a tiltable cutting head was proposed. Currently, there are commercially available products in the market. This method is the most direct and effective solution to the problem of cutting inclination and improving accuracy.

The tiltable cutting head works by adding two rotation axes to the original three-axis platform. The system uses a pre-set slope model and real-time calculations of the cutting trajectory.

Based on the material and thickness of the workpiece being cut, the cutting head continuously swings during the cutting process, allowing the workpiece to achieve a perfect non-interference slope state.

Pulsation: the pressure is unstable, for example, from 150MPa to 230MPa

Solution:

To resolve the issue, first check the pulsation of the water inlet transparent pipe to ensure it is normal. Once you have determined which high-pressure cylinder is causing problems, disassemble it and inspect the water inlet valve core, water outlet valve seat, and spring.

Usually, repairing these parts will solve the issue, but if it cannot be fixed, then they may need to be replaced. The spring is a common problem in this situation.

The pressure is stable at a pressure, but not in a normal state.

For example: normal 230MPa, now 170Mpa or 140MPa.

Solution:

Check the pulse of the water inlet pipe to determine if there is an impurity blocking the water inlet valve core in one of the high-pressure cylinders.

Inspect the pressure relief valve for leaks and see if it is returning water to the small water tank.

Examine all parts of the main engine for any water leaks.

The pressure is only tens of Mpa, or no pressure

① Verify if the water, electricity, and gas supply is normal

② Check if the belt is slipping or loose

③ Verify if the diamond abrasive has been added

④ Determine if any of the three high-pressure cylinders are not functioning, as when two cylinders are not working simultaneously, the pressure will be significantly reduced or nonexistent.

The abnormal noise of high-pressure cylinder of the crankcase, the large jump range of ammeter and unstable pressure.

There are two potential causes for the noise:

Solutions:

Cut glass will crack

Gemstone and sand pipe

The normal lifespan of gems is 17 hours to 7-14 days. When they have been in use for a prolonged period, the cutting quality may deteriorate and show symptoms such as a larger amount of fog around the cutting head, scattered water arrows, edge skipping, sharp teeth, and differences in the pressure display value compared to normal frequency.

As for the sand pipe, the normal lifespan is 3-8 months, depending on their quality and usage time. Over time, the nozzle may become larger or have an eccentric hole or elliptical shape, causing the cutting workpiece to have high slope, bell-mouthed edges, angle collapse, and other issues. This can result in a reduction of the workpiece size, or a decline in cutting speed.

The pressure is normal, the water line is normal, but the cutting ability is poor

Cause of failure:

Treatment method:

The system pressure is normal, but the cutting ability is poor

Cause of failure:

Treatment method:

When the high pressure is turned on, there is no water ejecting from the sand pipe, while there is water ejecting from the sand inlet pipe

Cause of failure:

Treatment method:

The water line without sand addition is normal, and the water is divergent after sand addition, and the cutting ability is decreased

Cause of failure:

Treatment method:

“Cutting Sand Flying”

“Directional Valve Not Working”

If the above factors are present, check if the relay is loose and if the striker on side 2 of the directional valve is stuck.

“Main Motor Abnormal Working”

If the machine repeatedly starts and stops in a triangular pattern, check if the upper limit pressure set by the temperature controller has been exceeded.

“Pressure Gauge Alarm”

“Cabinet Failure”

After ruling out the above conditions, try playing the emergency stop, releasing it every 15 seconds, to see if the situation has been resolved.

If not, cut the power and restart the entire machine. If the problem persists, contact the manufacturer.

“Large Valve Body”

“Cutter Head Switch“

Unable to Seal the Water: After cutting, when the switch is moved to the second position, the high pressure does not stop. This can result in grinding of the workpiece if the machine is kept running.

Troubleshooting Steps: First, verify if there is any open air. Then, check if the air valve is functioning properly.

If the problem persists after troubleshooting, disassemble the relief valve of the cutter head and inspect the needle and the seat for wear or misfit. Replace the worn parts if necessary.

“Computer“

Will Not Work: If the computer is not working, please refer to section 5 for troubleshooting. If the problem cannot be resolved, seek assistance from a computer maintenance expert.

Backup: In case of system paralysis, there is a backup available on the hard drive, which can be restored using the “one click ghost restore” feature.

Repair: For other faults, the computer can be taken to a repair shop. However, ensure that the new system installed includes the Auto CAD software and Ncstudio cutting software to ensure proper functionality.

Network Connection: The computer department must connect the network cable to the internet to avoid any potential contamination.

Dust Cleaning: Regular cleaning of the computer to remove any dust buildup is recommended.

“Cutting software“

1-1) If you encounter an error message saying “Hardware self-check error” upon opening the cutting software, follow these steps to update the driver:

Note: Do not move on to the next step until the current step is finished.

1-2) If updating the driver does not resolve the issue, try reinstalling the cutting software. If the problem persists, try again at a later time.

1-3) If the previous steps have not been successful, you may need to disassemble the computer to troubleshoot the problem.

If the issue persists, try changing the slot position and attempting the steps again.

2) If there is no error message when opening the software, but you are unable to press any buttons or install the cutting software, try the following steps:

Note: Before attempting a new system installation, be sure to back up important data and files.

3) If the software is unable to control the machine, follow these steps to troubleshoot the issue:

Note: If you are unable to resolve the issue, seek assistance from a qualified technician.

4) If the software is still not working, turn off the power and try again.

5) If the drawing cannot be opened, check if it is currently open in CAD. Close CAD and open the desired drawing.

6) Origin Position:

When checking for proper operation, pressing the emergency stop button may cause the origin to move.

If the XY axis is being tested for its limits, it may also cause the origin to move. Check if the workpiece is moving or not properly secured.

7) If the XY axis is inactive:

Note: If the issue persists, seek assistance from a qualified technician.

10. Maintenance

Improving Reliability and Longevity

Particular attention should be paid to improving the service life of key components, such as the high-pressure pump, high-pressure hose, connector, and nozzle.

This will enhance efficiency, reduce abrasive consumption, and lower energy consumption, making the cost more competitive.

Adopting Intelligent Control

The process parameters can be adjusted in real-time during machining to enhance accuracy. This approach can be used to produce parts with specific accuracy requirements, and its technical and economic effects are comparable to those of plasma and laser machining.

Expanding the Application Scope

The scope of water jet machining is continuously expanding, from two-dimensional cutting and deburring to hole machining and three-dimensional surface machining.

Enhancing Theoretical Research

Particular emphasis should be placed on establishing a water jet machining model and studying multiphase flow theory to advance the field.