Choosing the right milling tools can be a game-changer for your machining projects, but what factors should you consider? This article delves into three crucial principles: selecting the correct tool diameter, blade type, and tool body based on your equipment and material. Understanding these elements will help you achieve better precision, efficiency, and tool longevity in your machining tasks. Read on to discover the essential tips for optimizing your milling operations.

GUIDE

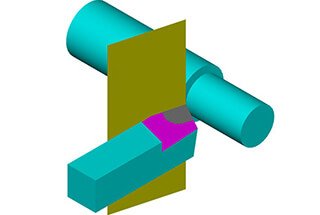

Milling tools are rotating tools with one or more cutting edges for machining. During operation, each cutting tooth removes a portion of the workpiece in intervals. The milling tool is mainly utilized for machining flat surfaces, stepped surfaces, grooves, formed surfaces, and cutting workpieces.

And I believe that when selecting a milling tool, you need to pay attention to both the milling tool body and tool holder:

When using CNC machining centers, it is recommended to use solid carbide tools. On the other hand, white steel can be used for ordinary milling machines.

White steel milling tools have a softer composition compared to hard alloy tools. High-speed steel blades are cost-effective and have good toughness, but their strength is not as high and they are more prone to wear and heat damage.

The high-speed steel milling tool has a thermal stability of around 600 degrees and a hardness of approximately 65HRC.

It is important to note that when milling hard materials with white steel, the lack of coolant can easily lead to blade burn, which contributes to its low thermal stability.

In contrast, cemented carbide tools have a high thermal stability and resistance to abrasion, but they have a lower impact resistance and can break if dropped. Cemented carbide is a material produced through powder metallurgy and has a hardness of around 90 HRA and a thermal stability of 900-1000 degrees.

In conclusion, white steel milling tools are appropriate for use with ordinary milling machines, while alloy milling tools are better suited for CNC machining centers.

The selection of the milling tool diameter varies greatly based on the product and the size of the production batch. The choice of the cutter diameter primarily depends on the specifications of the equipment and the size of the workpiece that is being processed.

When selecting the diameter of a face milling tool, it is important to ensure that the tool’s power requirements fall within the capabilities of the machine tool. The diameter of the machine tool spindle can also serve as a reference for this selection.

A general rule of thumb is to choose the diameter of the face milling tool as 1.5 times the spindle diameter (D = 1.5d).

In mass production, the tool diameter can also be selected based on 1.6 times the width of the material being cut.

When choosing the diameter of an end mill, the primary consideration should be the size of the workpiece being processed and ensuring that the tool’s power requirements are within the capability of the machine tool.

If the end mill has a small diameter, it is crucial to consider if the machine’s maximum rotational speed can reach the minimum cutting speed of the tool, which is 60 meters per minute.

The diameter and width of a slot milling tool should be selected based on the size of the workpiece to be processed and make sure that the tool’s cutting power falls within the power range of the machine tool.

(1). For fine milling, it is advisable to use a grinding insert. This type of insert has a higher dimensional accuracy, leading to better positioning accuracy of the cutting edge, resulting in improved machining accuracy and surface finish.

In addition, the trend in grinding and milling inserts for finishing is to grind the chip flute to form a large positive rake angle cutting edge, allowing the insert to cut at a low feed rate and depth of cut. Without sharp rake angles, carbide inserts may rub against the workpiece during low feed rates and cutting depths, leading to a short tool life.

(2). In some machining situations, a pressed insert may be more appropriate, and in others, a ground insert is necessary. For roughing operations, a pressed insert is recommended to reduce processing costs.

Although the dimensional accuracy and sharpness of a pressed insert are not as good as those of a ground insert, the edge strength of a pressed insert is better and can withstand impacts during rough machining and large cutting depths and feeds. Some pressed inserts also have chip flutes on the rake face, which can lower cutting forces and reduce friction with the workpiece and chips, thereby reducing power requirements.

(3). However, the surface of a pressed insert is not as close as that of a ground insert, the dimensional accuracy is poor, and the height of the tips on the milling tool body can vary greatly. Due to their low cost, pressed inserts are widely used in production.

(4). Sharp large rake angle inserts can be used for milling viscous materials such as stainless steel. The sharp blade reduces friction between the blade and the workpiece, allowing chips to leave the front of the blade more quickly.

(5). Another option is to install a pressed insert in the blade seat of most milling tools and configure a grinding scraping insert. Using a scraping insert to remove rough machining marks can achieve better surface roughness than using only a pressed insert.

In addition, the use of a scraping insert can reduce cycle time and cost. Scraping technology is an advanced technology that has been widely used in turning, grooving, and drilling.

Milling tools are relatively expensive, with a face milling tool body of 100mm diameter costing over $600. It is important to choose carefully to meet specific processing needs.

(1). When selecting a milling tool, the number of teeth must be considered. For example, a 100mm diameter coarse-tooth milling tool may only have 6 teeth, while a 100mm diameter dense-tooth milling tool may have 8 teeth. The size of the tooth pitch affects the number of cutter teeth involved in cutting at the same time during milling, which in turn impacts the smoothness of the cut and the requirements for the machine tool’s cutting rate. Each milling tool manufacturer has its own series of coarse and dense-tooth milling tools.

(2). Coarse-tooth milling tools are mainly used for rough machining because they have a large chip flute. A small chip flute can cause difficulty in chip curling or increase friction between the chip, the cutter body, and the workpiece. At the same feed rate, the cutting load per tooth of a coarse-tooth milling tool is larger than that of a dense-tooth milling tool.

(3). During fine milling, the cutting depth is typically shallow, from 0.25 to 0.64mm, and the cutting load per tooth is small (about 0.05 to 0.15mm). The required power is not high, so a close-tooth milling tool can be chosen with a larger feed rate. Since metal removal is always limited in fine milling, a small chip flute in the dense-tooth milling tool is not a problem.

(4). For spindles with larger taper holes and better rigidity, rough milling can also be performed with close-tooth milling tools. However, when using a large cutting depth (1.27 to 5mm), it is important to consider the machine tool’s power and rigidity and the size of the milling tool chip flute. Chip removal should be verified through testing and adjustments made if necessary.

(5). During heavy-duty rough milling, excessive cutting forces can cause chattering on less rigid machines, leading to chipping of carbide inserts and reduced tool life. The use of coarse-tooth milling tools can reduce the machine’s power requirements. Therefore, when the spindle hole size is small (such as R8, 30#, 40# taper holes), a coarse-tooth milling tool can be effectively used.