Have you ever wondered why laser cutting precision sometimes falters? Thermal lens effects, caused by heat-induced changes in optical elements, can disrupt laser focus and accuracy. This article delves into how thermal lensing impacts laser applications like marking, welding, and cutting, and offers practical solutions to mitigate these issues. By understanding and addressing these effects, you can significantly enhance the performance and reliability of laser-based processes. Dive in to learn how to maintain optimal laser functionality and improve your results.

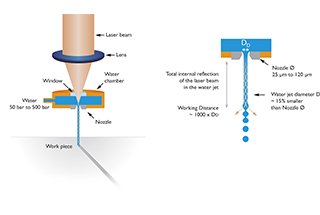

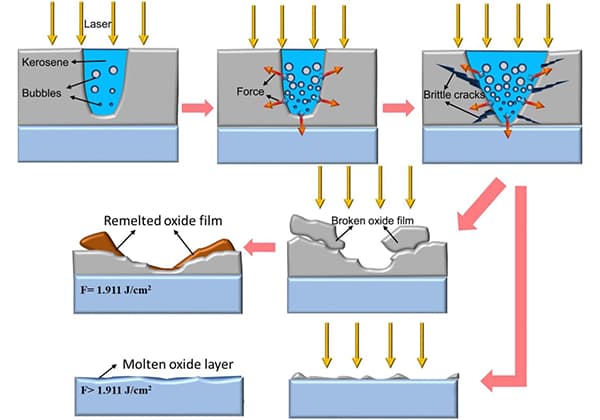

The laser absorptivity increases due to poor quality, dirt, and damage of the optical elements. Continuous exposure to laser beams for a prolonged period of time can cause thermal deformation, altering the refractive index of the transmission optical element and changing the reflection direction of the reflective optical element.

This results in a change in the position of the laser focus (beam waist), affecting its application. The transparent optical elements have a higher laser absorptivity and a greater temperature increase, making the thermal lens effect more pronounced.

In this article, we will analyze the optical elements that are susceptible to thermal lens problems in various laser application equipment.

The faster the thermal expansion of an optical element, the more prominent its thermal lens effect, as a result of high power and advanced processing of inverse materials.

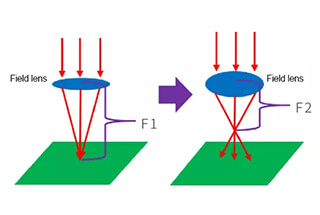

The thermal lens effect occurs when heat causes the optical element to expand, leading to an increase in focusing power, a reduction in focal spot size, and a shorter focal length and depth.

These phenomena can lead to instability during laser processing, ultimately impacting its effectiveness.

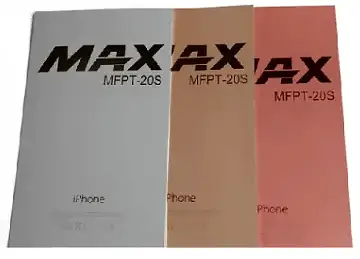

(1) Alumina blackening:

When the thermal lens effect takes place, the focal length shortens, the surface energy density of the material decreases, and blackening of alumina becomes impossible. In severe cases, the blackening effect at the center and edge may become inconsistent.

(2) Deep metal carving:

Metal deep sculptures typically utilize field mirrors with a shallow focal length (depth of focus).

During high-power deep carving, the thermal lens effect causes the energy density of the material to rapidly decrease, resulting in a shallower depth in the metal.

Due to the greater expansion at the center of the optical element compared to the edge, the center is shallower and the depth around it is uneven.

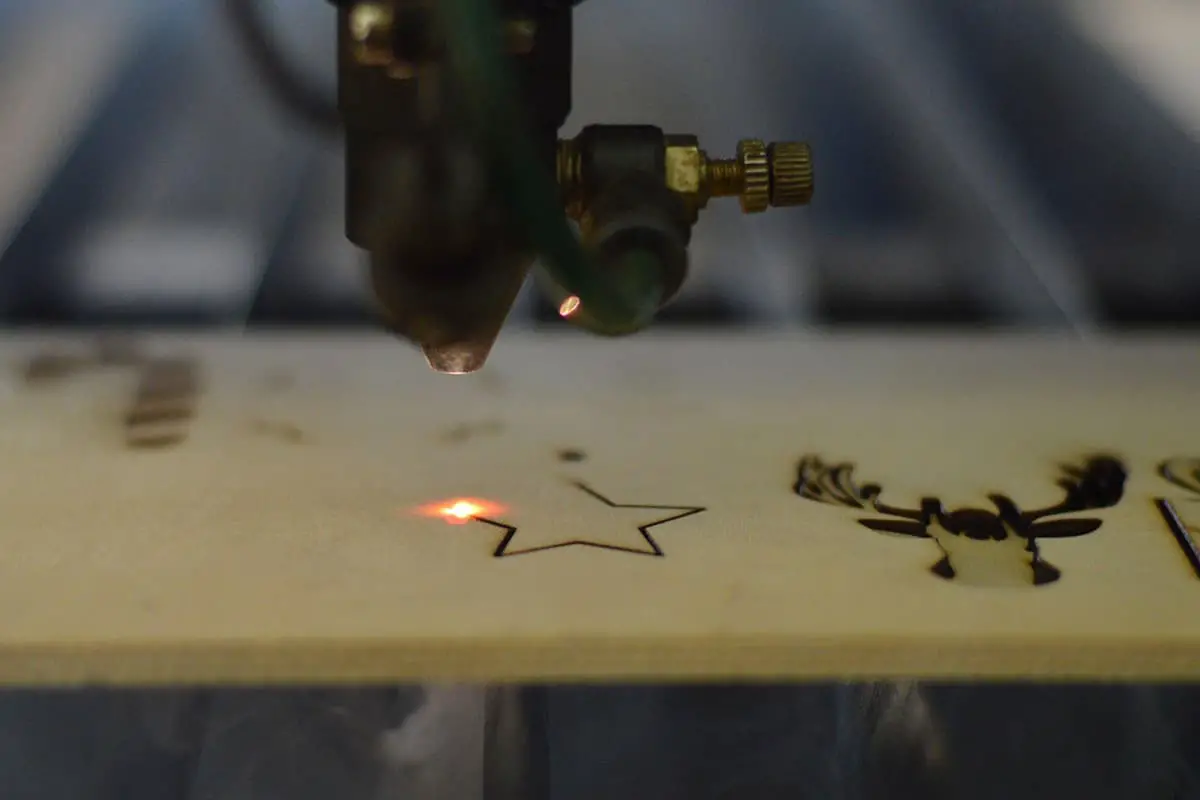

(3) Sheet cutting:

Pulsed fiber lasers use either a single slow speed or multiple fast cutting methods, depending on the type of material being processed.

Due to the rapid thermal expansion and cooling retraction that occurs in a very short time frame (< 1s), the starting position of the cutting can be successfully cut through, while other positions may not be able to be cut.

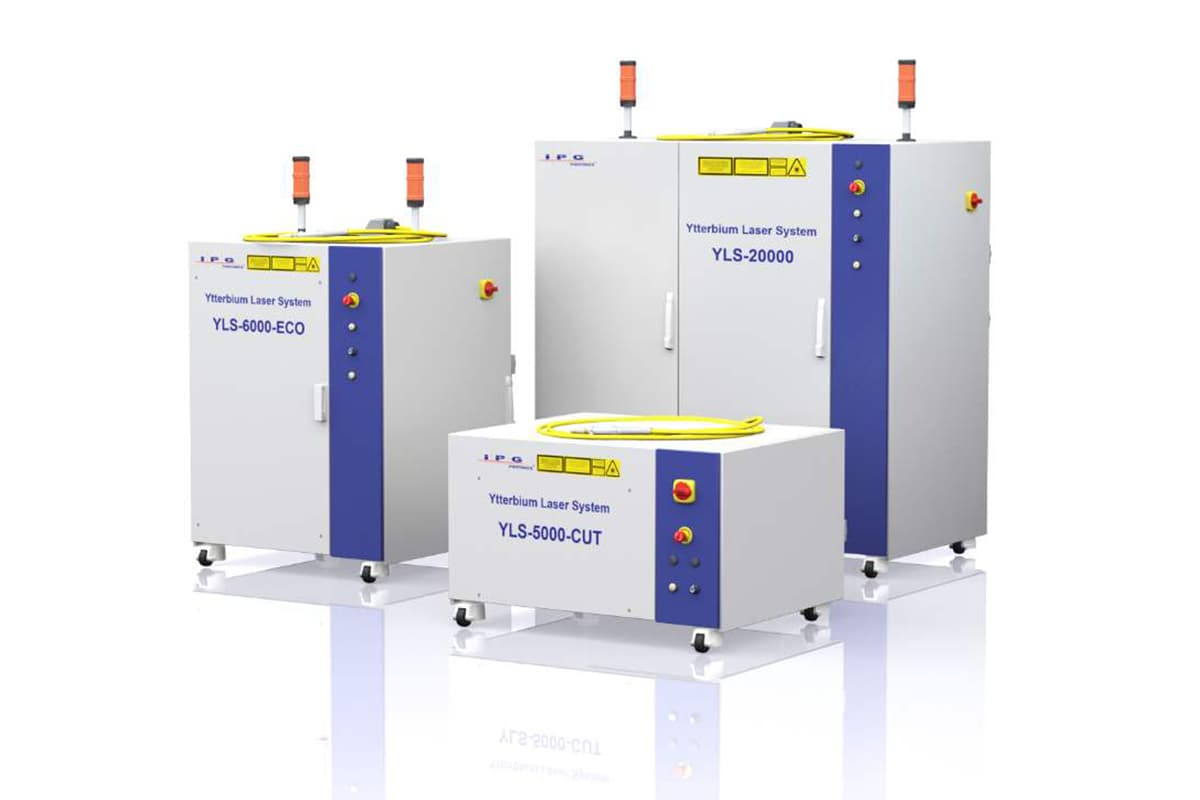

(1) Metal sheet spot welding:

When using a high-power fiber laser for spot welding metal sheets, the thermal lens effect can result in inconsistent joint sizes, unstable welding, and insufficient drawing force.

(2) Continuous metal welding:

The reflectivity of metal during continuous light welding is higher compared to that during cutting.

In high-power welding, the thermal lens effect can cause the front portion of the weld to be normal, while the back portion may be shallow or completely impenetrable.

The thermal lens effect is particularly pronounced when welding aluminum and copper, which are high-reflective materials.

(1) Stainless steel cutting:

When cutting stainless steel, the thermal lens effect can lead to inconsistent cutting surfaces, an increase in slag, and even difficulties in maintaining a continuous cut.

(2) Carbon steel cutting:

When cutting carbon steel, the thermal lens effect can result in an increase in slag at the bottom and difficulties in maintaining a continuous cut.

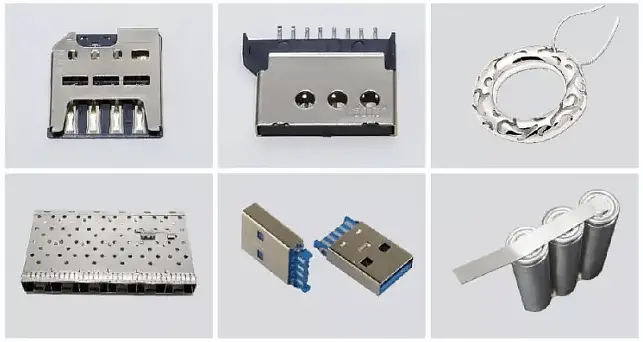

Galvanometer

| Optical element | Causes of thermal lens | Solution of thermal lens effect |

| Laser output head | Dirty or damaged output head lens or crystal | Inspection and cleaning before installation |

| Collimator (for CW lasers) | Poor quality, dirt and damage of collimating lens | Clean the collimating lens or replace the collimator with good lens quality |

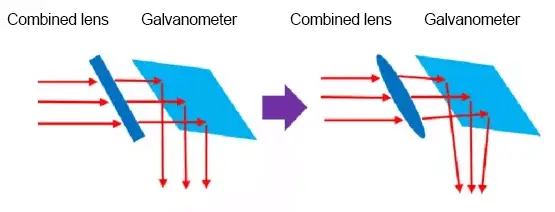

| Combined lens | Poor quality, dirt and damage of combined lens | Select the self-contained red laser or replace the beam combining lens with good quality |

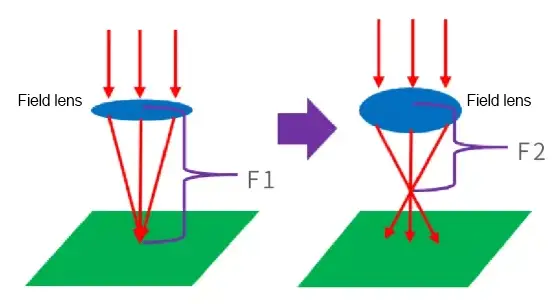

| Field mirror | Poor quality, dirt and damage of field lens | Clean the field lens or replace the quartz field lens |

Comparison of red photosynthetic lens and thermal lens

Comparison of field lens and thermal lens

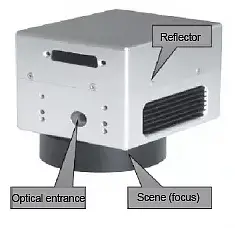

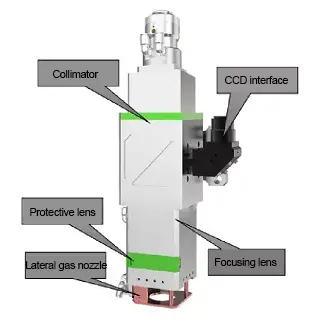

Laser welding head

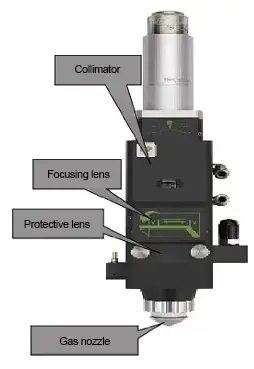

Laser cutting head

| Optical element | Causes of thermal lens | Solution of thermal lens effect | |

|---|---|---|---|

| Laser output head | Dirty or damaged output head lens or crystal | Inspection and cleaning before installation | |

| Cutting head / welding head | Upper protective lens | Poor quality, dirt and damage of lens | Clean the lens or replace the lens with good quality |

| collimating lens | |||

| Focusing lens group | |||

| Lower protective lens | |||

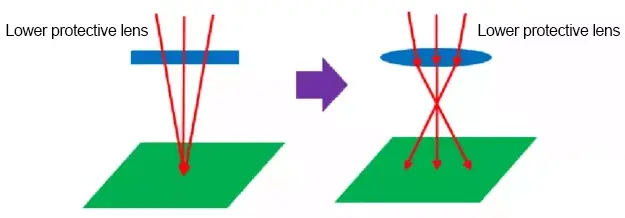

Front and rear comparison of lower protective lens and thermal lens

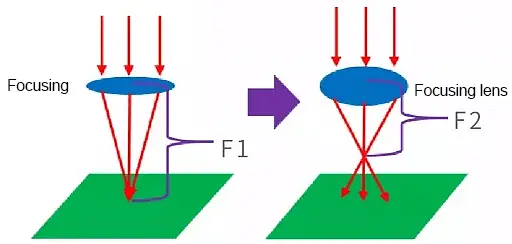

Front and rear contrast of focusing lens and thermal lens