How can the sheet metal fabrication industry stay ahead of rising labor costs and production challenges? Enter the Flexible Manufacturing System (FMS). This article explores how FMS integrates automated technologies to revolutionize sheet metal production, boosting efficiency and reducing costs. Readers will learn about various production methods, the benefits of FMS, and its impact on the future of manufacturing. Get ready to discover how automation and flexibility are reshaping the industry, providing practical solutions for modern manufacturing needs.

With the growth of the world economy and advancements in technology, human manufacturing processes have become increasingly sophisticated and efficient. This has resulted in a rapid upgrade in various industries.

The sheet metal manufacturing industry has undergone a significant transformation, moving from a small variety of mass production to a large variety of small-batch production, from an inventory-based production mode to JIT (Just-In-Time) production, and from human-based to automated equipment-based production.

However, the increasing demand for better production management, technology advancements, and upgrading of technology has led to a shortage of corresponding human resources. Despite companies offering high salaries and using various recruitment methods, the rising labor costs and shortage of workers remain a major challenge.

What is the solution to these problems while still maintaining the advancements in technology? How can the industry keep pace with the times while making the necessary transition steps? These are important questions that need to be addressed in the sheet metal industry.

Sheet metal automation and flexibility are constantly evolving and each company has unique requirements based on their product type, production mode, and factory size. Finding the most suitable automatic and flexible processing line for their specific needs is a way for companies to improve their technology and reduce costs.

As a member of the sheet metal industry, we are proud to share our knowledge on sheet metal automation and flexible manufacturing systems. Our aim is to provide you with reference and guidance.

Currently, server cabinets are produced by sheet metal shops or cabinet factories. The primary methods of blanking and stamping are as follows:

This is a traditional method. It involves manually feeding the material by hand. Due to the large size of the sheet metal parts and the numerous stamping features, often a single sheet metal part requires multiple sets of tooling to be processed on various punch presses.

In the process of sheet metal fabrication, this method not only struggles to achieve high production efficiency but also poses safety risks.

It requires a substantial workforce to complete the task, resulting in intense labor demands. With economic growth and the significant rise in labor costs, this method is gradually becoming obsolete.

This is currently the mainstream production method in sheet metal shops.

CNC punch presses, through programmed stamping, can produce sheet metal parts ranging from single pieces and small batches to medium-sized batches. They aren’t particularly selective about the materials used, making them widely applicable.

However, CNC punch presses are expensive, demand skilled operators, have lower material utilization rates, and their production efficiency and cost-effectiveness are average.

This method is rapidly gaining traction. With the substantial decline in the cost of laser cutting machines, they are suitable for producing sheet metal parts from single pieces and small to medium-sized batches.

They are progressively replacing CNC punch presses in sheet metal fabrication.

However, there are concerns regarding their efficiency in large-scale production.

The flexible sheet metal stamping production line, centered on the flat feeder and pneumatic combination mold, is a low-cost, innovative stamping line capable of addressing efficiency and cost issues for medium to large-scale sheet metal production. It has seen rapid development lately.

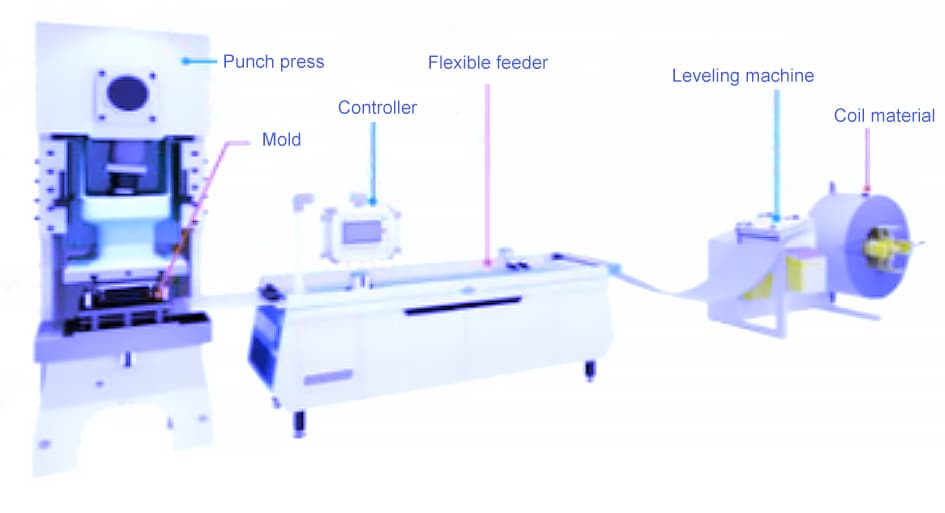

The flexible sheet metal stamping line consists of a flexible flat CNC feeder (or flexible roller feeder), pneumatic combination die, coil straightener, and a conventional punch press.

As shown in Figure 1, by coordinating the feeder with the pneumatic combination mold, it provides coil feed and performs continuous stamping and forming on parts. This greatly enhances operational efficiency and is suitable for medium and large batch sheet metal parts, especially various network cabinets, power cabinets, large appliances, express cabinets, same-hole panels, etc.

The flexible flat CNC feeder is the core of the stamping production line. It utilizes an industrial motion control PC to master the feed positioning, punch press operation, pneumatic combination mold switching, and coil material release.

Using CNC punch press clamping feed method, the straightened coil material is fed flatly, effectively solving the precision issues of coil feeding. The overall feed progress can reach ±0.2m, with dual-axis alternating feeding, improving the feed efficiency.

Under precision assurance, the punch press speed can reach up to 100 strokes per minute, and it can control up to 20 punch heads, fully meeting the needs of sheet metal stamping.

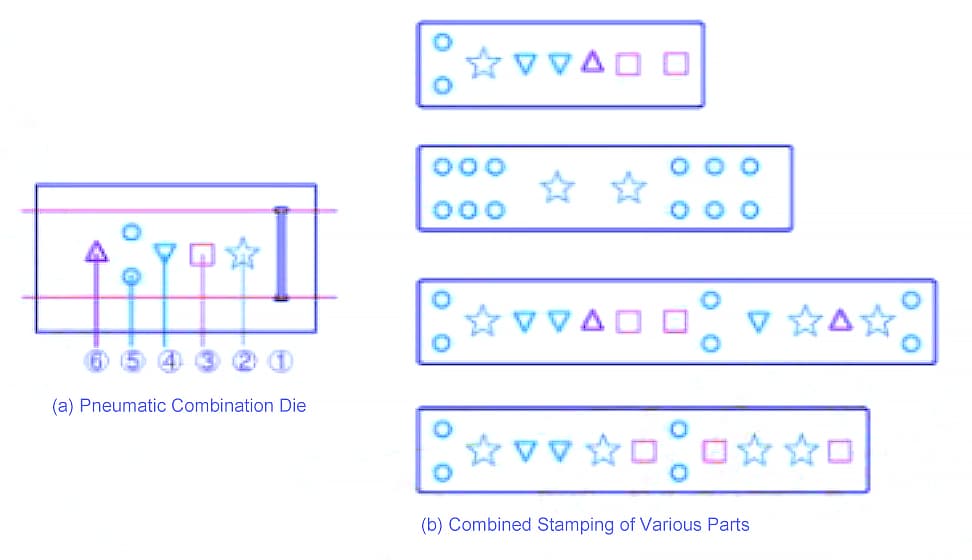

The pneumatic combination mold, an essential component of the flexible sheet metal stamping line as shown in Figure 2, deconstructs various features of the stamped sheet metal parts, creating individual punch heads arranged on one mold set.

Each punch head is controlled by its own cylinder and mechanism. When a specific punch head is needed for stamping, the cylinder and mechanism will push it out.

After completing the feature stamping, the punch head retracts, and another punch head(s) will stamp under system allocation. This mold is flexible and controllable, significantly reducing mold size.

By using punch head combinations for different parts, it not only reduces mold costs but also enhances stamping efficiency.

Advantages of the Flexible Sheet Metal Stamping Production Line:

The flexibility of the sheet metal stamping production line primarily lies in the material width, which can vary between 50-1000mm, requiring only clamp position adjustment during loading.

Using the pneumatic combination mold, any punch head can be programmed for product combinations, unrestricted by part length or punch hole position (vertically).

This allows convenient production of multiple clients’ sheet metal part series with just one set of molds. For a comparison of sheet metal production methods, refer to Table 1.

Table 1 Comparison of Sheet Metal Production Methods

| Production Methods | Advantages | Disadvantages | Applications |

| Standard Punch Press | Equipment is cheap | 1. Low efficiency, quality is hard to control 2. High labor cost | Simple sheet metal production |

| CNC Punch Press | Flexible and convenient use: Suitable for production from single pieces to mid-batch | 1. Expensive equipment 2. Requires CNC mold 3. Average efficiency | Various sheet metal material blanking |

| Laser Cutter or Material Blanking Line Component | 1. Flexible and convenient use, suitable for production from single pieces to mid-batch 2. No mold required | 1. Not suitable for complex multi-hole sheet metal parts 2. Some plates require consumption of protective gas 3. Average efficiency | Various sheet metal material blanking |

| Flexible Sheet Metal Stamping Production Line | 1. High production efficiency, some sheet metal parts can improve efficiency up to tenfold (compared to CNC punching and laser cutting) 2. High material utilization, no scrap, saving 10% to 20% of materials 3. Some sheet metal parts can be bent and formed in the production line, reducing subsequent processes 4. Coil feeding, reducing process and handling 5. Low production line cost, if a punch press is available, the entire production line can cost less than 200,000 yuan | 1. High cost of pneumatic combination mold 2. Not suitable for single piece or small batch production | Various mid-batch, large batch complex sheet metal material drops and forming, especially suitable for machine cabinet pillars, crossbeams, mesh doors, etc. |

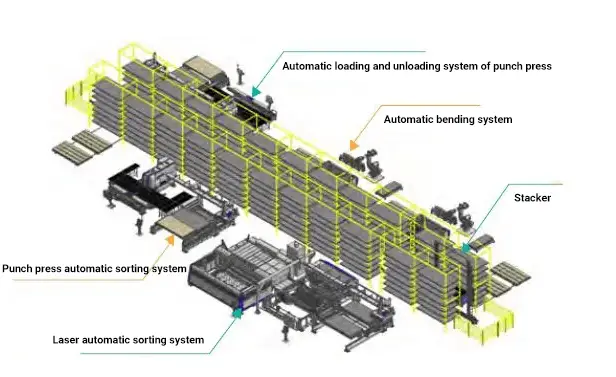

The multi-column automatic intelligent warehouse serves as the center, integrating the processes of shearing, punching, folding, and cutting.

The central control system and the customer production management system exchange information, allowing for automatic scheduling of sheet metal products based on the order quantity. This results in the formulation of production and processing plans, and the automatic programming of these plans is then pushed to the processing equipment.

The equipment communicates with the automatic intelligent warehouse according to the processing plan determined by the upper system, processing the necessary materials or semi-finished products to achieve automated production.

A monitoring system feeds back real-time processing information from each piece of equipment to the upper system, allowing for the management of the entire process.

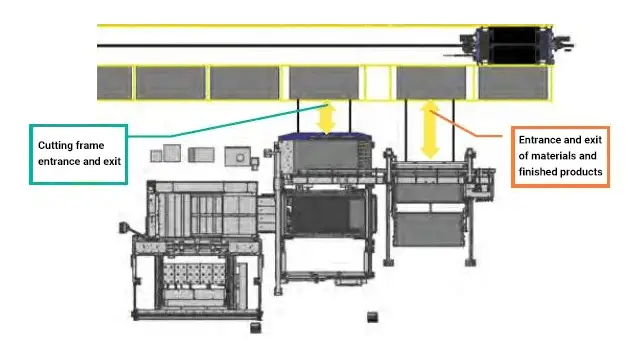

Figure 1 illustrates an example of an automatic intelligent warehouse FMS system.

Fig. 1 Schematic diagram of FMS processing line in the automatic intelligent warehouse

The automatic intelligent warehouse serves as the storage, buffer, and handling unit for materials, semi-finished products, and finished products, thereby realizing the physical integration of the FMS (Flexible Manufacturing System) system.

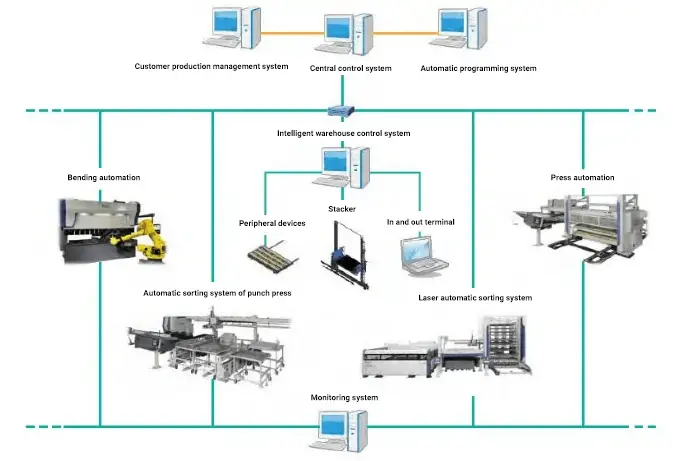

Figure 2 provides an overview of the FMS system.

Fig. 2 Schematic diagram of the automatic intelligent warehouse FMS system

The central control system, the intelligent warehouse control system, the customer’s upper production management system, and each unit are integrated through a network connection consisting of PLC (Programmable Logic Controller). This allows for the exchange of information between all systems.

The above FMS system consists of the following parts:

Features of the FMS system

However, not all customers are ideal candidates for this system. The FMS system is relatively complex and requires a high initial investment and a long delivery time. Additionally, without sufficient management personnel and a sufficient scale of production, it can be challenging to operate this system effectively.

It has been reported that some customers who have adopted similar systems have discontinued their use for various reasons.

To meet the varying needs of customers, each sheet metal unit connected to the automatic intelligent warehouse can be used as an independent sheet metal automation unit, effectively addressing the above difficulties.

The process of automatic sorting involves connecting a punch or laser cutting machine through automatic programming software, CAMPATH. This allows for the automatic identification of the shape of parts nested within a large plate. After processing, the parts are automatically sorted and stacked to a designated location.

(1) Saves Labor and Time:

By eliminating the need for manual micro-connection and palletizing, the automatic sorting process reduces the number of intermediary steps and saves time.

(2) Suitable for High-Value Variations:

This system is ideal for high-value-added varieties and Just-In-Time production modes.

(3) Prevents Scratches and Marks:

The automatic sorting device uses fine control and multiple suction cups to handle finished products gently, avoiding scratches and marks.

(4) Intelligent Visualization:

The system can automatically sort and monitor the processing quantity based on different processes or product types, providing intelligent visualization.

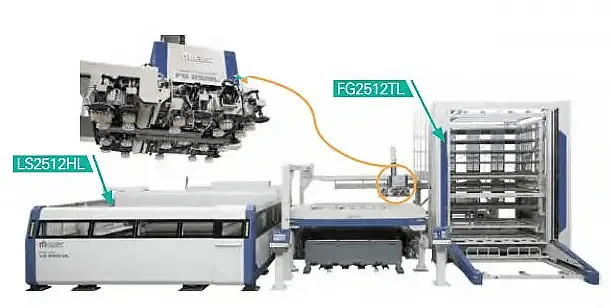

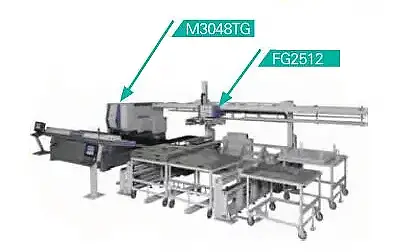

Figure 3 shows the connection between the automatic sorting system of the laser compound processing machine and the automatic intelligent warehouse.

Fig. 3 Docking of the automatic sorting system of laser compound processing machine with automatic intelligent warehouse

The central control system organizes the processing plan based on the customer’s upper management system. This, in turn, instructs the automatic intelligent warehouse and each sheet metal processing unit to begin processing.

Once the sheet metal is prepared, the cycle of automated processing begins.

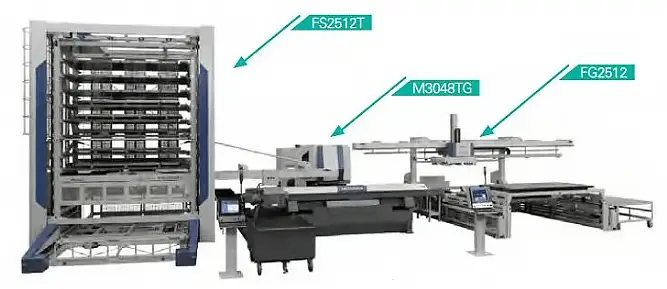

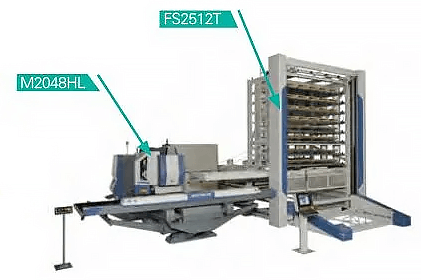

The difference between the automatic sorting stereoscopic warehouse unit (shown in Figure 4) and the previous solution is that the supply of raw materials and finished products is not handled through the automatic intelligent warehouse, but rather through the 8-layer or 10-layer independent warehouse and loading and unloading sorting tooling.

Fig. 4 Automatic sorting stereoscopic material warehouse unit of fiber laser combined processing machine

The laser sorting system is capable of sorting workpieces that are at least 250mm x 100mm and plates that weigh up to 235kg.

Once the processing plan is created on the laser cutting machine’s operation interface, the material warehouse will automatically enter and exit the warehouse based on the specified material layer and finished product layer in the processing plan. Loading and unloading sorting and palletizing will be performed through the loading and unloading sorting tooling.

The material warehouse unit is user-friendly, takes up minimal space, and has a relatively low investment cost.

Unlike the laser sorting system, the automatic sorting system for CNC punch requires the use of an auxiliary punch at the end of the sorting process. This is because CNC punches do not have an exchange table, and therefore must be in standby mode during sorting execution.

The CNC punch sorting system is capable of sorting workpieces that are at least 100mm x 80mm and handling plates that weigh up to 110kg.

Once the processing plan is created on the CNC punch’s operation interface, the material warehouse will automatically enter and exit the warehouse based on the specified material layer and finished product layer in the processing plan. Loading and unloading sorting and palletizing will be performed through the loading and unloading sorting tooling.

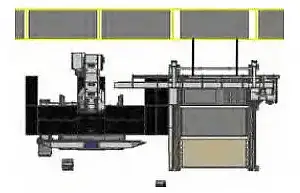

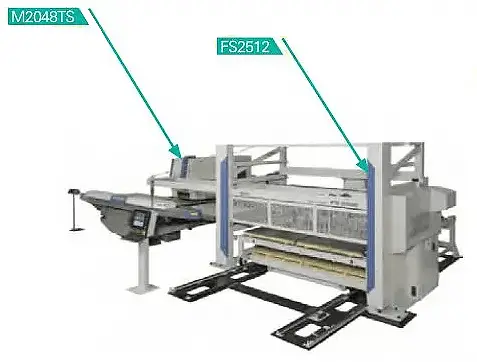

The system can be connected to an automatic warehouse (as shown in Figure 5), a stereoscopic material warehouse unit (as shown in Figure 6), or operate as an independent unit (as shown in Figure 7).

Fig. 5 Docking of automatic sorting and automatic warehouse of CNC punch

Fig. 6 Automatic sorting stereoscopic material warehouse unit of CNC punch

The manual trolley in Figure 7 is designed for the automatic sorting of different processes or products.

Fig. 7 Automatic sorting independent unit of CNC punch

The automatic loading and unloading system for CNC punch/laser cutting machines can be utilized for the automatic loading and unloading of fixed-length timber, both with large plate nesting and without nesting.

CNC punch/laser cutting machines can be paired with an automatic warehouse, a three-dimensional material warehouse, and an FG automatic sorting system, as illustrated in Figure 8 and Figure 9.

Fig. 8 Automatic loading and unloading stereoscopic material storehouse unit of laser compound machine of CNC punch

Fig. 9 Automatic loading and unloading unit of CNC punch

Compared to the automatic sorting system, the system offers the advantages of simple operation, flexible application, and a lower initial investment.

Enterprises can choose to use it in semi-automatic operation mode or as a standalone operation mode for CNC punches and laser cutting machines, depending on their specific operational needs.

The application of the automatic bending system in conjunction with the intelligent automatic warehouse (as shown in Figure 10) is similar to the sheet metal processing unit system described above.

Fig. 10 Docking of automatic bending loading and unloading and automatic intelligent warehouse

When not linked with the automatic warehouse, the system can function as an independent automatic bending unit. Additionally, the bending machine can be operated manually as a standalone machine.

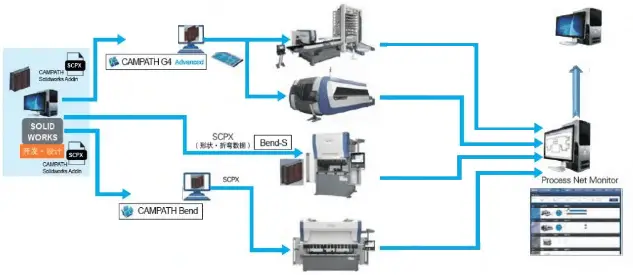

The application process of sheet metal software is shown in Figure 11.

Fig. 11 Flow chart of sheet metal software application

From the automatic processing of customer-designed 3D products to the automatic batch processing of punch/laser sorting nesting, bending, and other processing programs, the automatic push to each processing unit system can achieve full automation of the production process.

At the same time, the system monitors the actual processing status of each equipment, collects processing data in real-time, and provides feedback to the customer’s MES and other upper production management systems.

With the advancements in science and technology, sheet metal equipment has entered the era of the Internet of Things (IoT) and big data. Many leading companies in the sheet metal manufacturing industry have a large number of automatic and flexible processing lines and have come to realize that a good sheet metal equipment requires a matching intelligent sheet metal software.

Sheet metal automation equipment is like a smartphone; without the right software system, it cannot reach its full potential and value. As a result, when purchasing sheet metal automation equipment, it is critical to choose a matching intelligent sheet metal software.

In conclusion, it is recommended that before purchasing sheet metal automation equipment, enterprises should clarify as much as possible the specifications, applications, and processes needed for the automation and flexible processing line.

While communicating with the technicians of sheet metal equipment manufacturers, it is important to also seek the opinions and suggestions of industry experts and peers.

By choosing a suitable sheet metal processing line, enterprises can effectively address practical problems such as personnel changes, production capacity changes, product changes, process changes, and application changes, laying a strong foundation for future growth and development.