Ever wondered why young mechanical engineers struggle to climb the career ladder? This article dives into the contrasting experiences of young and senior engineers in the mechanical industry. It highlights the systemic issues in training and mentorship, and how these impact career progression. Discover the hidden challenges and learn what it takes to bridge the gap between generations, offering insights that could shape the future of engineering careers.

Many young people feel a sense of frustration and dissatisfaction, believing they have no choice but to accept their circumstances, unable to surpass their seniors.

In the mechanical industry, there’s a well-known rule that “the older, the more valuable.” Whether you acknowledge this rule or not, the reality is that key technical departments and positions in companies are dominated by experienced veterans. They not only hold pivotal roles but also control most of the company’s resources. This leaves many young professionals without opportunities for advancement, unable to see a future or a path forward.

Let’s analyze the reasons behind this situation. Understanding the cause and effect is crucial to recognizing the gaps and finding solutions.

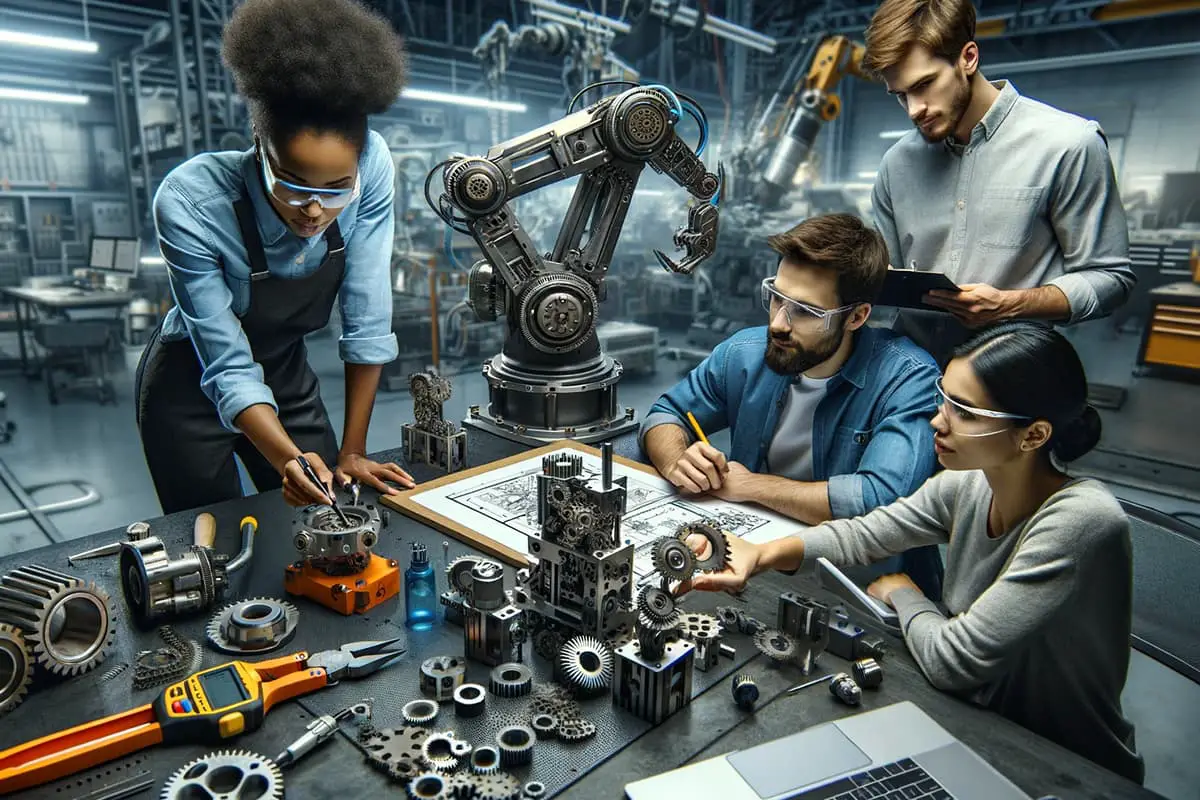

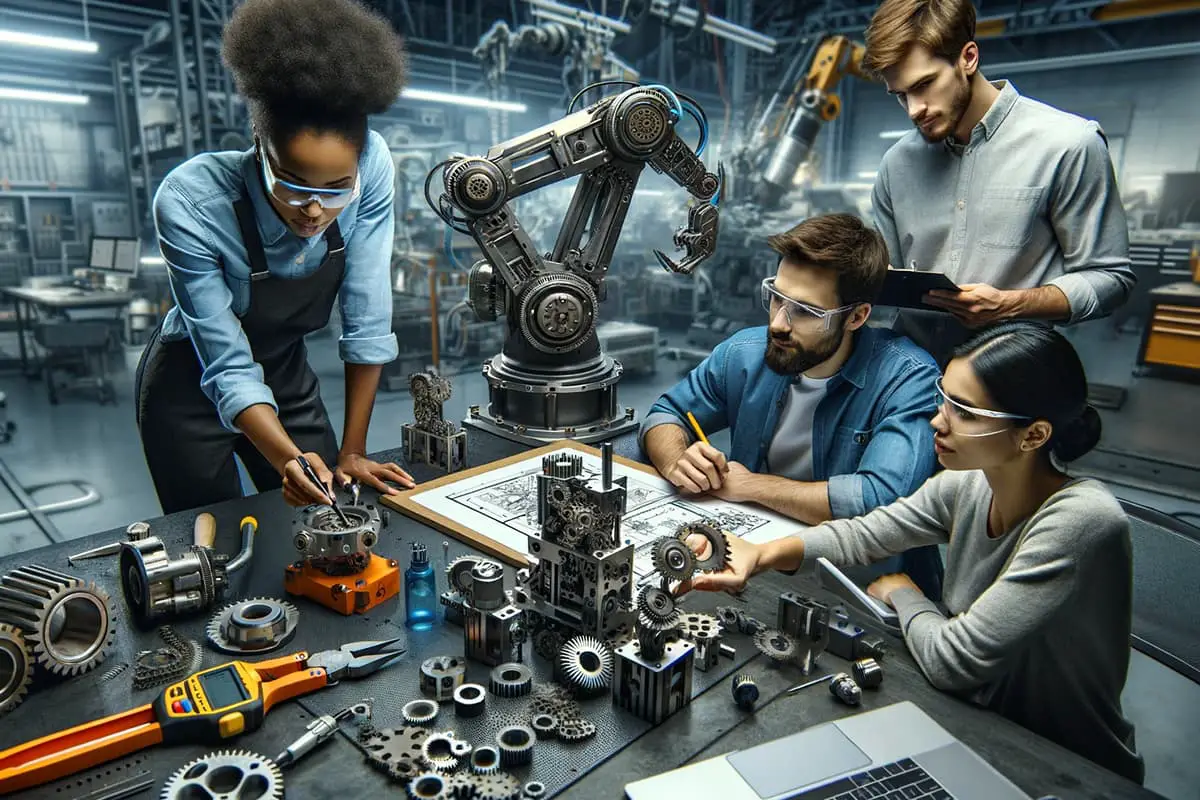

Even though we are in the so-called Industry 4.0 era, the training mechanisms for mechanical engineers haven’t evolved significantly. Regardless of whether it’s a traditional state-owned enterprise, a modern private company, or a foreign enterprise touted as an industry benchmark, the training of new engineers still heavily relies on the old “master-apprentice” method, lacking a systematic and scientific approach.

Moreover, if a mentor intentionally withholds knowledge, it becomes even harder for a newcomer to stand out in this field. They might never get their chance to shine. The saying “a master leads the way, but it’s up to the individual to follow through” sometimes feels like a platitude. Without a mentor willing to share crucial industry knowledge, personal effort alone may lead one to face greater challenges without guidance.

It’s often said that “all roads lead to Rome,” and while theoretically true, this overlooks the factor of time. Time is infinite, but our personal time is not. What could be taught in a moment by a mentor might take an individual an endless journey of hardships to learn. One might eventually reach “Rome” through personal effort, but it might be too late to matter.

There’s an unfortunate tendency in the sciences and engineering fields, similar to the saying “scholars belittle each other.” This attitude exists here too, not just in the form of mutual disdain but also in the fear of “training an apprentice to starve the master.” This results in communication barriers and reluctance in training phases. On one hand, mentors may be unwilling to fully educate their apprentices, and on the other, apprentices might undervalue their mentors, failing to show due respect. This is one of the reasons why young professionals struggle to advance while the veterans remain indispensable.

However, there are exceptions. My personal experience is one such case. My mentor was incredibly supportive, sharing knowledge generously both in technical and personal matters. I’ve respected and appreciated him for over a decade. Even though we no longer work together, I still visit him every Mid-Autumn Festival and Spring Festival, showing my respect as a student should.

As mechanical design engineers, we might not be able to change the “old guiding the new” system of technical transfer immediately, but we can still make the most of it. A society built on relationships, getting the personal aspect right often leads to everything else falling into place. Otherwise, you’ll find yourself enviously watching the older generation enjoy their successes, while feeling helpless despite your potential.

“Sharpshooters are forged through bullets,” a line I recall from a movie, aptly applies to mechanical design engineers, particularly the exceptional ones, who are essentially “nurtured” through financial investment.

An outstanding mechanical design engineer develops their design capabilities and thought processes through a multitude of diverse design projects. It’s in these projects where they refine their skills and techniques, learning from both successes and failures, eventually crafting their unique design philosophy. The linchpin of these design projects is, ultimately, funding. This underscores the principle that a mechanical engineer’s prowess is proportionate to the financial investment in their work.

Experience, not age, determines an engineer’s value. Engineers with a rich project history are more valuable than those without. Age simply facilitates more opportunities to engage in design projects. Without the backing of projects, decades in the industry don’t equate to significant utility or value.

Mechanical design projects, from market research to conceptualization, production, refinement, and finally market launch, encompass a lengthy process. A significant project can span years, during which an engineer evolves from a naive youth to a mature professional. As time strips away youth and vigor, it compensates by enriching technical skills and capabilities, laying the foundation of knowledge and capital upon which seasoned engineers rely for their worth.

If your company provides numerous opportunities to engage in and lead projects, cherish them. Leveraging company resources to build personal capabilities is a rare opportunity. Don’t dwell too much on the success or failure of these projects. All experiences, including failures, are part of the company’s investment and can be a form of success for your personal development, as they ensure you won’t make the same mistakes again. This experience is invaluable.

This is why I often encourage young professionals to join startup or smaller companies. They offer abundant opportunities to engage in various design projects and platforms for trial and error, fostering personal capabilities and wisdom.

Personally, I have been involved in and led the design of over 50 products. For many engineers in state-owned enterprises, reaching this number is unlikely. They often oversee mature products that dominate market shares but offer limited design and innovation scope. This hinders the development of a mechanical engineer’s personal skills. Without project experience, their practical value remains unexplored.

I’ve been hesitant to say this, but mechanical engineering is indeed a profession where natural talent plays a crucial role. Many people inherently possess a knack for handling mechanical structures. Among the newcomers I’ve mentored, one stood out remarkably. With just a little guidance, he could produce surprisingly creative designs, especially in structural handling, often yielding unexpected results that impressed me. However, some individuals seem notably less adept, at least in mechanical design, making it difficult for me to see their potential in this field.

Receptiveness is a two-way street, encompassing both the mentor’s guidance and the apprentice’s willingness to learn and understand. While communication skills can be developed over time, innate talent in this area can significantly fast-track a career. No one prefers to interact with those who struggle to grasp concepts; communicating with such individuals requires endless patience and tolerance, a trait not everyone possesses.

Especially from a position of advantage, it’s easy to disengage from less capable individuals, as there’s no personal loss. This can hinder young professionals from rapidly acquiring industry experience and technical knowledge, seemingly delaying their chance to shine.

I advise every newcomer to assess their intuitive understanding of the field. This intuition isn’t necessarily linked to intelligence; you might simply be unsuited for this industry. In that case, it’s better to switch careers early. You deserve to find your right fit.

Previously, I’ve always encouraged newcomers, especially those finding it challenging to pursue a career in this industry. I told them that with hard work, there’s always hope. Deep down, I didn’t fully believe this but refrained from discouraging them, as every young person needs encouragement. I couldn’t dampen their spirits. However, today, I apologize for my earlier statements. To those who feel out of place in this industry, if you find designing or drafting challenging, consider switching fields. Don’t limit yourself to one option or give up on the entire forest for one crooked tree.

Moreover, this industry demands not just talent but also years of perseverance to achieve a state of relative freedom. The accumulation phase in mechanical engineering is considerably longer than in fields like IT. While IT might promise a tough today and tomorrow but a bright future, mechanical engineering can be relentlessly challenging for years before yielding rewarding outcomes. Consider if you have the patience and time to endure this wait.

The value of an engineer stems from their professional experiences, particularly the project-based experiences I previously mentioned, rather than the length of their career. Therefore, when starting a job, it’s crucial to thoroughly understand the platform you’re joining. Assess whether this employment platform can provide sufficient project support, offer adequate resources for trial and error, and allow enough room for growth.

Many companies tend to lag in product innovation and research and development projects, focusing more on optimizing and upgrading existing products rather than continuously introducing new ones. While these companies may have a rich technical heritage, they don’t significantly contribute to personal skill enhancement. As a soldier in the mechanical industry, you need to be on the front lines, hearing the gunfire, and engaging in battles to carve out your own glory.

In this field, very few become true technical experts, as the real project resources are always monopolized by a select few. Only they can fully leverage the company’s resources to enhance their skills and use these skills to influence the company’s staffing policies and increase their own marketability and value. Your goal should be to become one of these influential individuals.

If you aim to become valuable in the mechanical industry, the key is not to wait decades to accumulate experience but to engage in as many technical projects as possible in the shortest time. These experiences are what will enhance your self-worth and ultimately enable you to realize that value. The older engineers still active in the field have simply had more such experiences and opportunities. While some may have actively sought these experiences, I believe most have achieved them passively. However, as a young professional, you have the choice to actively pursue these opportunities.