1. Double suction pump

The impeller of the double-suction pump is comprised of two back-to-back impellers, and the water that flows out of the impeller converges into a volute. With improved structure, the double-suction pump is widely used in engineering due to its high head and large flow.

The double-suction pump has two suction chambers. Many people think that one is for the water inlet and the other is for the outlet. In reality, the suction and inlet of the pump are perpendicular to the lower part of the axis, mainly due to the direction of the impeller.

The advantage of the double-suction pump is that it is less prone to cavitation due to reduced inlet flow, under the same speed and flow.

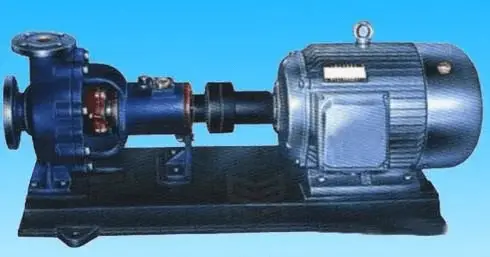

2. Single suction pump

The single suction pump sucks in horizontally and axially and discharges upwards and radially. It is of a suspended structure. During maintenance, it is not necessary to dismantle the inlet and outlet pipelines, as the rotor components can be removed for maintenance. The pump is connected to the motor through an ordinary or extended elastic coupling, and the shaft seal of the pump is sealed with soft packing. The bearing is a single row radial ball bearing, which is lubricated with oil. When viewed from the motor end, the pump rotates clockwise.

Working principle

When a single suction pump starts, the shaft drives the impeller to rotate at a high speed, causing the liquid that was pre-filled between the blades to rotate. Under the influence of the centrifugal force, the liquid moves radially from the center of the impeller to the periphery. As the liquid flows through the impeller, it gains energy and its static pressure energy increases, resulting in an increase in flow rate.

When the liquid leaves the impeller and enters the pump casing, it decelerates due to the gradual expansion of the flow channel, converting some of its kinetic energy into static pressure energy before finally flowing into the discharge pipeline in a tangential direction. The volute pump casing not only serves as a component that collects the liquid that flows out of the impeller, but also as a device for energy conversion.

As the liquid is thrown from the center of the impeller to the outside, a low-pressure area is formed in the center. The total potential energy difference between the liquid level of the storage tank and the center of the impeller causes the liquid to be drawn into the center of the impeller. The impeller’s continuous operation results in the continuous intake and discharge of liquid. The mechanical energy gained by the liquid in the centrifugal pump is finally demonstrated as an improvement in static pressure energy.

3. Double suction pump vs single suction pump:

- Different Inflow

Single suction pump refers to an impeller that is filled with water at only one end, while double suction pump refers to an impeller that is filled with water at both ends, that is, with two inlets.

- Different Flow

Double suction pump is more suitable for conveying large flows and requires stable operation. When the pump’s flow requirement is very high, a single suction pump should have a large inlet and outlet diameter and a speed that is not too high, and should be stable at around 1450 RPM.

If a double suction pump is used, the size and weight of the pump can be reduced, the rotational speed can be increased, and the volumetric efficiency can be improved.

- Cavitation Resistance

The anti-cavitation ability of a double suction pump is stronger than that of a single suction pump. The symmetrical action of the impeller on both ends of the pump creates a more stable hydraulic balance than a single axial suction pump. Additionally, the flow rate of the medium is low, making the impeller less prone to cavitation.

- Different Price

Double suction pumps are more expensive, with a slightly higher price than single suction pumps. Single suction pumps are less expensive and have a wide range of uses, but double suction pumps are better in many aspects. The specific requirements should be based on the actual operating conditions of the user.