Have you ever wondered how to ensure a successful metal stamping project? In this blog post, we’ll dive into the critical factors that can make or break your stamping process. As an experienced mechanical engineer, I’ll share insights on calculating stamping forces and selecting optimal punch and die clearances. By the end, you’ll have a solid understanding of how to plan your stamping project for the best results.

When planning a metal stamping project, one of the most critical factors to consider is the stamping force required. Calculating the correct stamping force ensures you select a press with adequate tonnage and design tooling that can withstand the forces involved.

There are several methods for calculating stamping force depending on the specific stamping process and type of force. Here we’ll cover some of the most common formulas and provide a handy stamping force calculator.

Several methods exist for calculating stamping force, and which one to use depends on the specific stamping process and the type of stamping force that needs to be calculated. Here are some common methods for calculating stamping force:

A basic formula breaks down total stamping force into the sum of several parts:

The specific components involved will depend on your particular stamping operation.

For many stamping projects, shearing and punching forces make up the bulk of the stamping force. A common formula for calculating shearing or punching force is:

𝑃 = 𝑘 × 𝑙 × 𝑡 × Г

Where:

An alternative version of this formula is:

P = ltτ

Where:

For small parts stamped with a flat punch, the formula can be simplified to:

F = Ltτ

Where F is shearing force in newtons.

To make calculating stamping force easier, here is an online calculator. Simply input your material, thickness, and part perimeter to get the required force in metric tons.

P.S: If you want to calculate hydraulic press tonnage, you can use our hydraulic press tonnage calculator.

Related calculator: V & U-shaped Bend Force Calculator

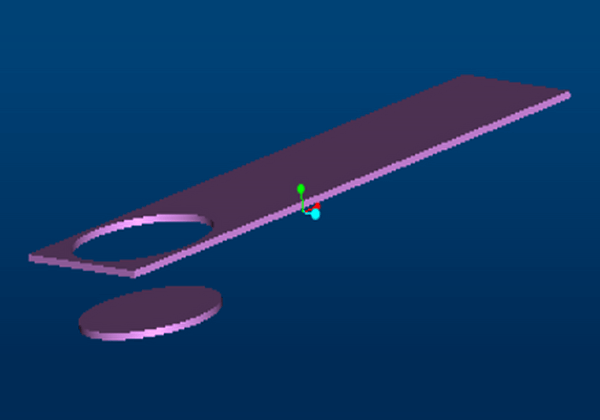

If you need to punch round, square, or any other type of hole through a given metal thickness, you’ll need to determine the punching force required to accomplish this task.

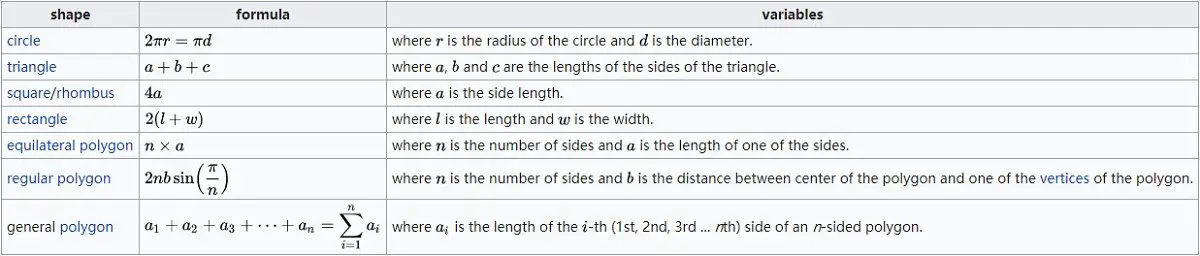

To calculate the required press tonnage, you can use the following punching force calculation formula, which is also applicable for blanking force calculation.

Press Tonnage (KN) = Perimeter (mm) * Plate Thickness (mm) * Shear Strength (kn / mm2)

Converted into metric tons: dividing the result of KN by 9.81

Common materials’ shear strength are as follows: unit: KN/mm2

| Aluminum | Brass | Low Carbon Steel | Stainless Steel |

| 0.1724 | 0.2413 | 0.3447 | 0.5171 |

For various shear strength table, you can check out the following post:

e.g: If punching one square hole in the 3mm thickness low-carbon steel plate, side length 20mm, you will get:

Punch Force (KN) = 80 x 3 x 0.3447 = 82.728 KN Convert into tonnage: 82.728 KN ÷ 9.81 = 8.43 Ton

For further information about shearing strength, including how to calculate it, you can refer to the Wikipedia article.

The formula mentioned can also be applied as the cutting force formula in press tooling or as the formula for determining the force required to punch a hole.

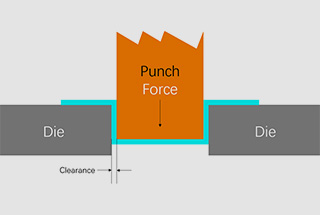

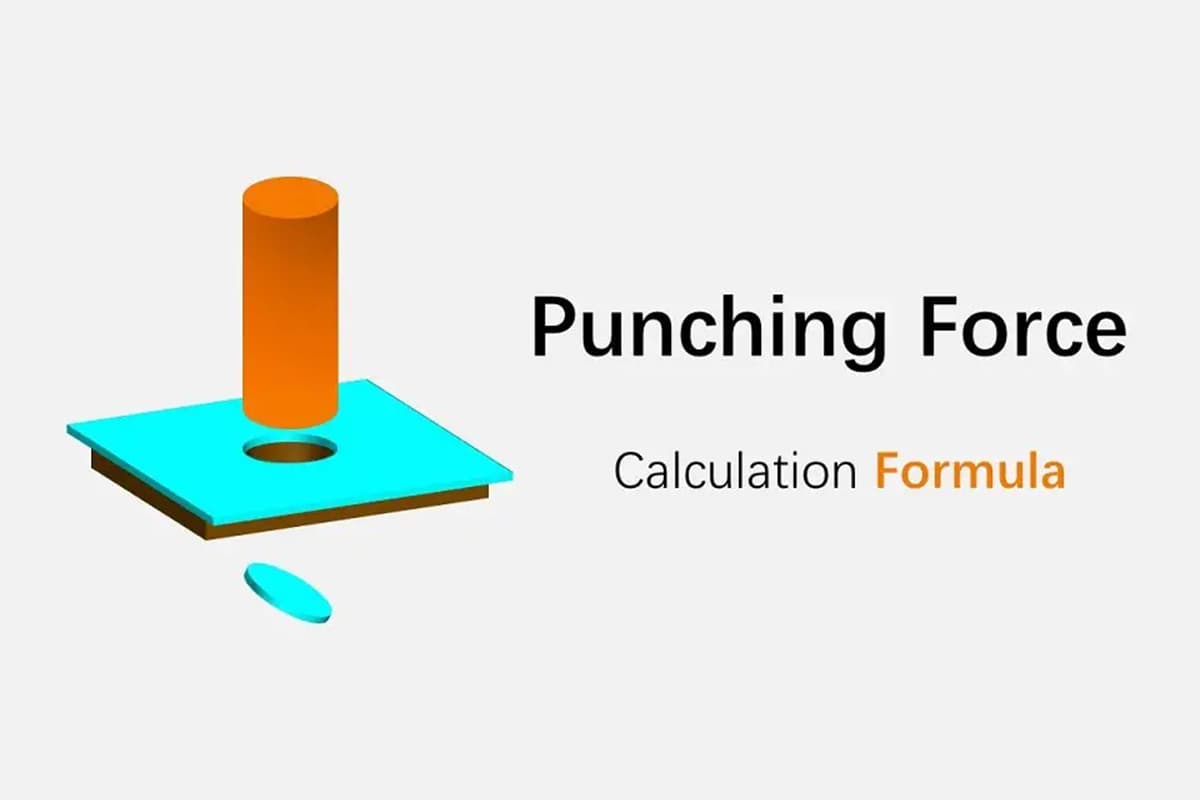

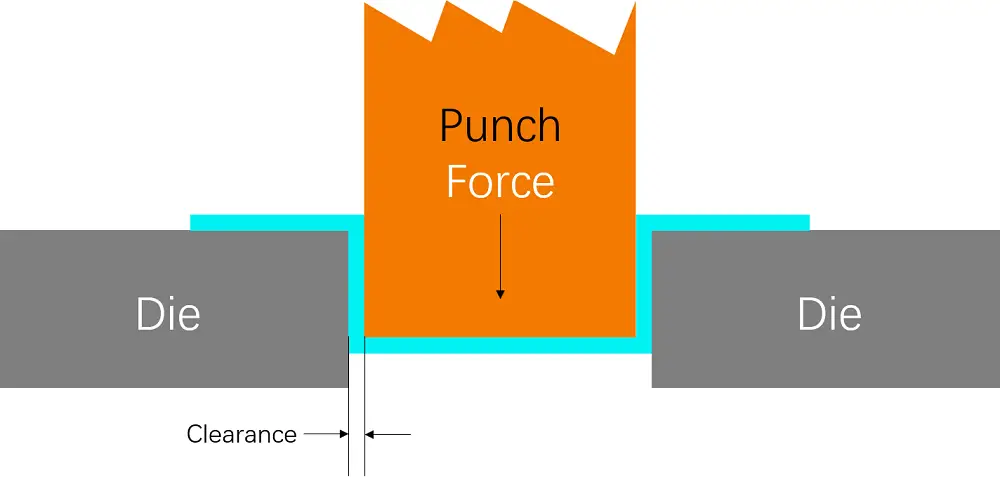

The clearance between the punch and dies is a critical factor in the punching process, and it is represented by the total difference.

For instance, suppose you are using an ø12 upper die and an ø12.25 lower die. In that case, the optimal clearance should be 0.25mm.

If the clearance is not proper, it can reduce the die’s service life, cause burrs, and lead to secondary cutting. An irregular opening can also increase the demounting force.

Moreover, the die clearance depends on the material and thickness, and for carbon steel plates, it is recommended to use a value between 12-18% of the thickness.

See also:

If there are no special requirements for the CNC punch, you can refer to the following table for selecting the die clearance.

In addition to stamping force, punch and die clearance is another key factor in successful stamping. Proper clearance, usually expressed as a percentage of material thickness, is critical to tool life, part quality and preventing secondary cutting.

Refer to this table for general clearance guidelines:

| Thickness | Mild Steel | Aluminum | Stainless Steel |

| 0.8-1.6 | 0.15-0.2 | 0.15-0.2 | 0.15-0.3 |

| 1.6-2.3 | 0.2-0.3 | 0.2-0.3 | 0.3-0.4 |

| 2.3-3.2 | 0.3-0.4 | 0.3-0.4 | 0.4-0.6 |

| 3.2-4.5 | 0.4-0.6 | 0.4-0.5 | 0.6-1.0 |

| 4.5-6.0 | 0.6-0.9 | 0.5-0.7 | / |

By calculating stamping forces and specifying proper punch and die clearance, you’ll be well on your way to a successful stamping project. Of course, many other factors are also involved, such as selecting the right material, designing optimal part geometry, and choosing appropriate lubricants and coatings.

Consult an experienced metal stamping partner to help navigate all the complexities and ensure the best results. With proper planning and expertise, you can unleash the full potential of metal stamping for your parts and products.