Have you ever wondered how complex hydraulic systems maintain stability under varying loads? The balance valve plays a crucial role. This article explains the structure and working principle of balance valves, essential for load control and safety in hydraulic systems. By the end, you’ll understand how these valves prevent unwanted movements, ensure safety, and improve efficiency.

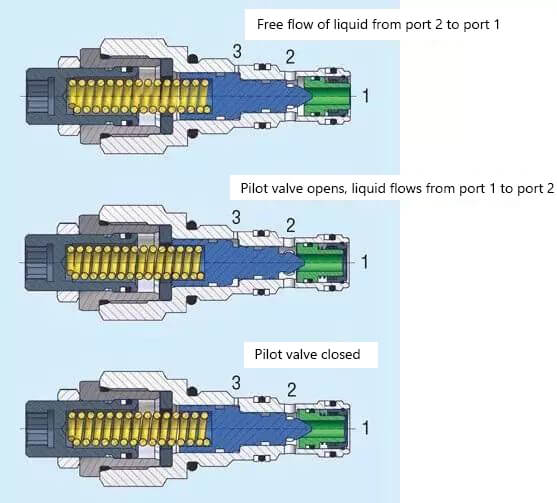

The hydraulic balancing valve enables the unrestricted flow of oil from port 2 to port 1, as evidenced by the schematic diagram at the top of the figure below.

When the oil pressure at port 2 is higher than the pressure at port 1, the green part of the spool moves towards port 1 due to the force of the oil pressure, causing the check valve to open and allowing oil to flow freely from port 2 to port 1.

However, the flow of liquid from port 1 to port 2 is blocked until the pressure at the pilot port reaches a certain level, causing the blue spool to move to the left and opening the valve port. This allows oil to flow from port 1 to port 2.

If the pilot pressure is not strong enough to open the blue spool, the valve port closes and the flow of fluid from valve port 1 to valve port 2 is shut off.

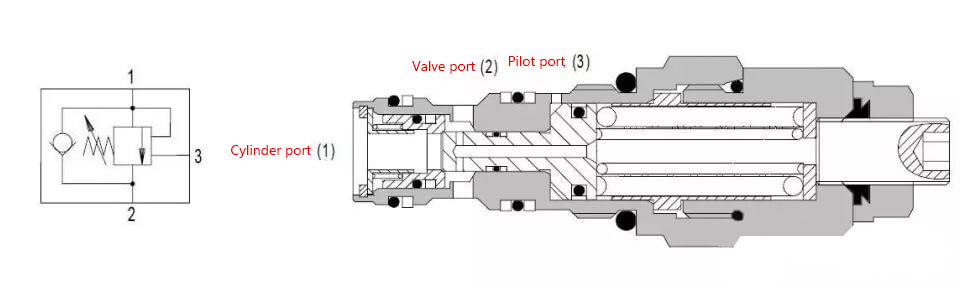

The symbol for the balancing valve is shown below:

Load Holding:

The balancing valve helps to prevent the unintended downward movement of the hydraulic cylinder. This allows the operator to lift heavy objects at a specific speed and keep them in a fixed position.

Load Control:

The balancing valve prevents the actuator from moving before the hydraulic pump has had a chance to respond. This helps to eliminate cavitation of the actuator and reduce the risk of losing control of the load.

Safety Load:

In the event of a line in the hydraulic system bursting or leaking severely, a balancing valve installed on the actuator helps to prevent the loss of control over the moving load.

The typical relief setting for balancing valves is usually 1.3 times the maximum operating pressure. However, the pressure required to activate a pilot valve depends on the pilot ratio.

The pilot pressure can be calculated using the following formula:

Pilot Pressure = (Relief Pressure Set Point – Load Pressure) / Pilot Ratio

To optimize load control and energy efficiency, the pilot ratio can be selected based on the following guidelines: