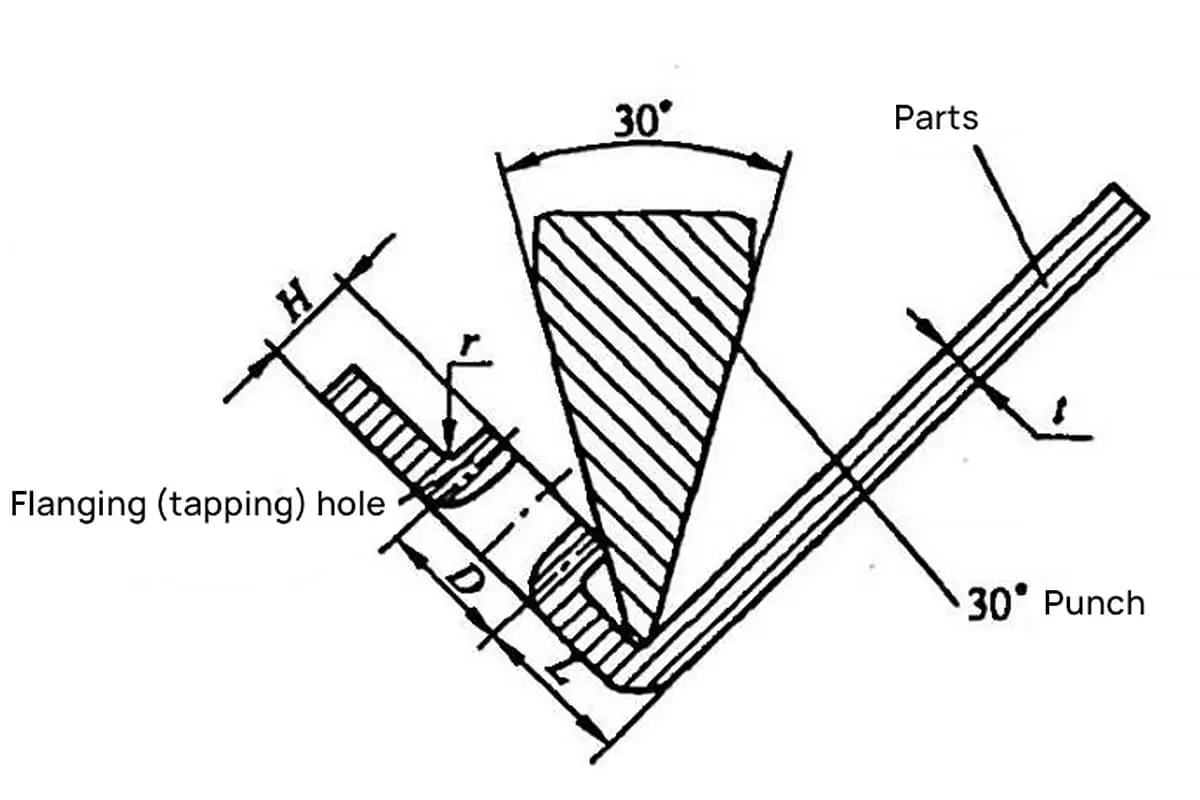

As shown in Figure 4-17. Its flanged (tapping) hole

The distance L from the hole wall to the bend edge cannot be too small, as it may damage the flange (even prevent it from forming).

Generally, it is recommended to select L > (7~8)t based on experience. When the structural requirement of the bent part requires a shorter distance from the flanged (threaded) hole wall to the bend edge, the minimum distance should be calculated or graphically determined based on parameters such as material thickness t, flange (thread M) hole (diameter D) size, flange height, folding shape, and bending radius r.

Refer to Table 4-5 for common metric thread bottom hole flange dimensions. Dimension marking examples are shown in Figure 4-18.

Table 4-5 Common Metric Thread Bottom Hole Flange Dimensions (unit: mm)

| Thread Diameter d | Material Thickness t | Flange Inner Diameter d1 | Flange Outer Diameter D | Flange Height h | Pre-punch Hole Diameter d0 | Bend Radius r |

| M2 | 0. 6 | 1.6 | 2. 6 +0.16 | 1.3±0.2 | 0.8 ±0.1 | 0.2 |

| 0. 8 | 2.7+0.16 | 1.6±0.2 | ||||

| 1 | 2. 9 +0.16 | 1.8±0.2 | 1.2 ±0.1 | 0.4 | ||

| M2.5 | 0. 6 | 2.1 | 2.9 +0.16 | 1.3±0.2 | 0.2 | |

| 0.8 | 3. 2 +0.16 | 1.7±0.2 | 1.0 ±0.1 | |||

| 1.0 | 3. 5 +0.16 | 1.9±0.2 | 0.4 | |||

| 1.2 | 3. 5 +0.16 | 2.0 ±0.2 | 1.2 ±0.1 | |||

| M3 | 0. 8 | 2.5 | 3. 6 +0.16 | 2.0 ±0.2 | 1.2 ±0.1 | 0.2 |

| 1.0 | 3. 6 +0.16 | 2.1 ±0.2 | 0.4 | |||

| 1.2 | 4. 0 +0.16 | 2.2±0.2 | ||||

| 1. 5 | 4. 2 +0.16 | 2.4±0.2 | 1.6 ±0.1 | |||

| M4 | 1.0 | 3.3 | 4.7+0.16 | 2.6 ±0.2 | 1.6 ±0.1 | 0.4 |

| 1.2 | 5 +0.16 | 2.8 ±0.2 | ||||

| 1.5 | 5. 4 +0.16 | 3.0±0.2 | ||||

| 2.0 | 6 +0.16 | 3.2 ±0.2 | 0.6 |

Note: This table is applicable for flanging thread bottom holes of low carbon steel, brass, pure and aluminum. The data in the table is for reference only.

Example 4-1 illustrates a bent part as shown in Figure 4-17. The sheet thickness is t=1.5mm, the thread M4 is tapped on the flange, and the required flange height is H=3.3mm. Calculate the minimum distance from the flange (thread tapping) hole wall to the bending edge.

Solution: Use a 30° bending knife for processing, and the graphical method to calculate the minimum distance from the flange (thread tapping) hole wall to the bending edge.

From the graphical method, we get L=6mm.

Refer to Table 4-6 for the commonly suggested minimum distances from the flange (thread tapping) hole wall to the bending edge.

Table 4-6 Suggested minimum distances from the flange (thread tapping) hole wall to the bending edge (unit: mm)

| Thread Diameter d | Material thickness t | |||

| 1.0 | 1.2 | 1.5 | 2.0 | |

| M3 | 4.9 | 5.1 | – | – |

| M4 | – | 5.7 | 6.0 | – |

| M5 | – | 5.9 | 6.4 | – |

Note: The data in the table is for reference. The minimum values are generally not used.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.