Imagine transforming a lump of metal into a critical machine component, designed to withstand extreme conditions. This is the essence of forging, a vital process in manufacturing that enhances material properties and shapes metals with precision. From hot forging to die forging, this article explores the techniques and benefits, guiding you through the essentials of this powerful metalworking method. Dive in to discover how forging can eliminate defects and improve the strength and durability of metal parts, ensuring they perform reliably in the toughest environments.

Forging is a metal processing method that utilizes forging machinery to apply pressure on metal blanks, producing plastic deformation that results in forgings with specific mechanical properties, shapes, and sizes. It is one of the two components of forging, along with stamping.

Forging eliminates defects such as cast porosity in the smelting process, while optimizing the microstructure. Furthermore, since the metal’s complete streamline is preserved, the mechanical properties of forgings are generally superior to those of castings made from the same material.

Except for rolled plates, profiles, or weldments with simple shapes, forgings are mostly used for crucial components that undergo high loads and severe working conditions in relevant machinery.

The initial recrystallization temperature of steel is approximately 727℃. However, 800℃ is typically considered the threshold for hot forging. Forging above 800℃ is referred to as hot forging, while forging between 300℃ and 800℃ is referred to as warm or semi-hot forging. Room temperature forging is called cold forging.

Hot forging is the most commonly used method for manufacturing forgings in most industries. Warm and cold forging, on the other hand, are primarily used in the automotive, general machinery, and other part production industries. These methods can efficiently save materials.

As previously mentioned, forging can be classified into hot forging, warm forging, and cold forging based on temperature. Additionally, it can be categorized into free forging, die forging, ring rolling, and specialized forging based on the forming mechanism.

Free forging is a processing method that involves using simple universal tools or directly applying external force to deform a blank between the upper and lower anvil of forging equipment, to obtain the required geometry and internal quality.

Forgings produced through this method are known as free forgings and are typically produced in small batches.

To create qualified forgings, various forging equipment, such as forging hammers and hydraulic presses, are used to shape and process the blank.

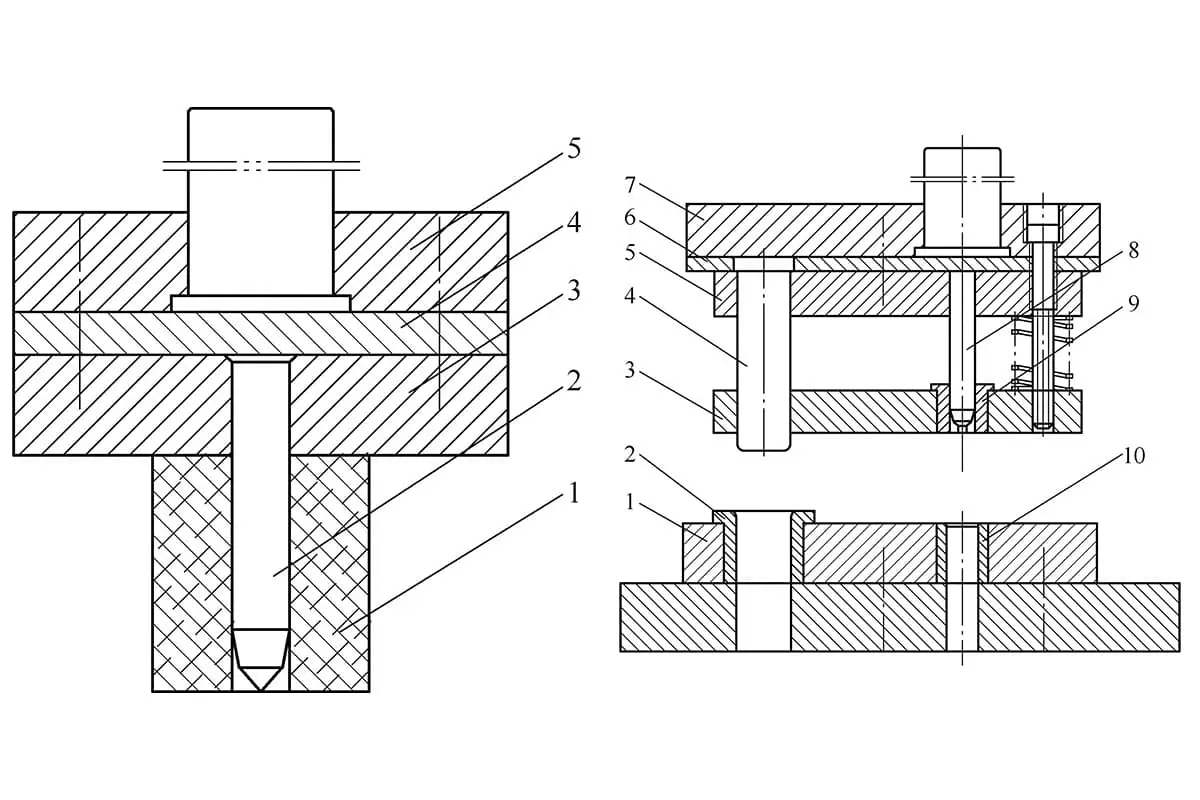

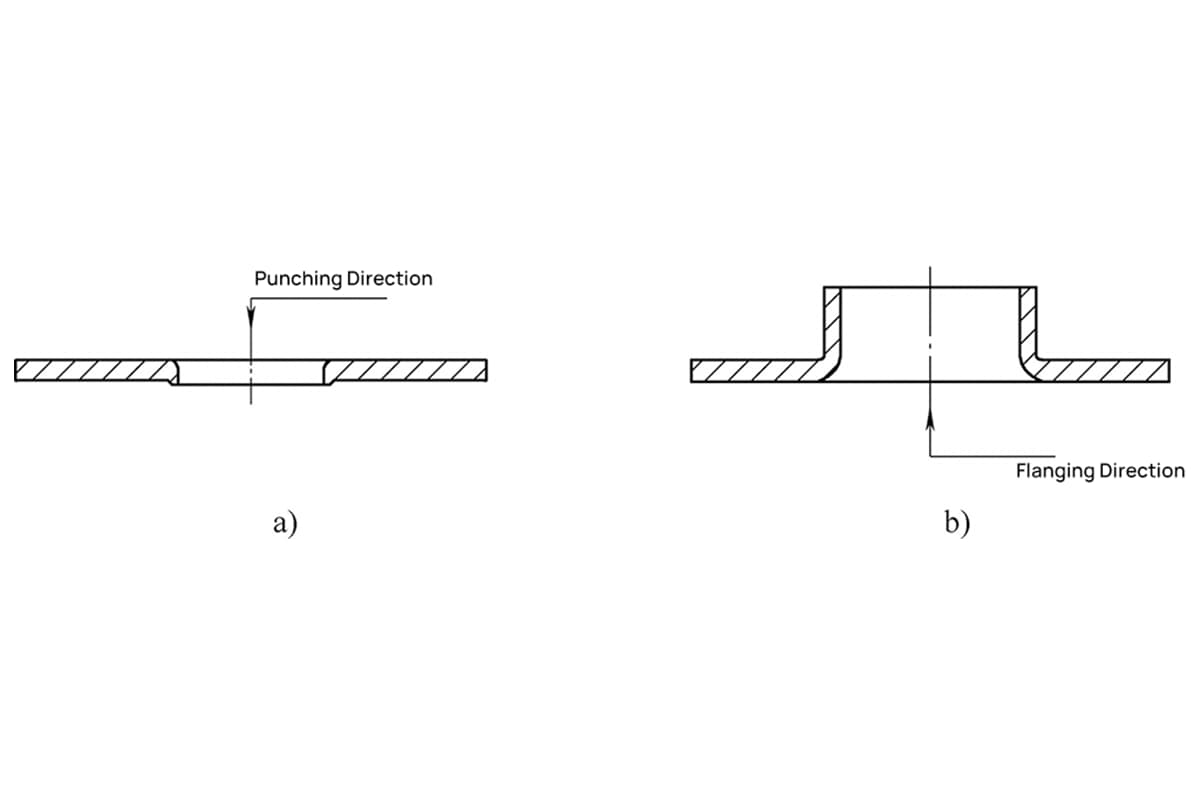

The fundamental processes of free forging include upsetting, drawing, punching, cutting, bending, torsion, dislocation, and forging. This method typically employs hot forging techniques.

Die forging can be categorized into two main types: open-die forging and closed-die forging. During this process, a metal blank is deformed and pressed in a forging die chamber of a specific shape to create forgings.

Typically, die forging is used to manufacture parts with small weights and in large batches. This process can be further divided into three types: hot die forging, warm forging, and cold forging.

Both warm forging and cold forging are considered the future direction of die forging and represent advancements in forging technology. Die forging can also be classified based on the materials used, including ferrous metal die forging, nonferrous metal die forging, and powder product forming.

Ferrous metals, such as carbon steel, nonferrous metals like copper and aluminum, and powder metallurgy materials are utilized in this process.

Related reading: Ferrous vs Non-ferrous Metals

Extrusion is a type of die forging that can be categorized into heavy metal extrusion and light metal extrusion.

Closed die forging and closed upsetting are two advanced processes of die forging. One significant advantage of these processes is the high utilization rate of materials since there is no flash.

With one or several processes, complex forgings can be completed.

Furthermore, the absence of flash reduces the stress area of the forging, ultimately resulting in lower required loads.

However, it is important to note that the blank cannot be entirely limited. Therefore, it is necessary to strictly control the volume of the blank, manage the relative position of the forging die, and measure the forging to minimize the wear of the forging die.

Ring grinding is the process of producing ring parts with varying diameters using specialized equipment, known as a ring grinding machine. It is also utilized in the production of wheel parts, including automobile hubs and train wheels.

Special forging techniques include roll forging, cross wedge rolling, radial forging, liquid die forging, and other methods that are better suited for producing certain complex-shaped parts.

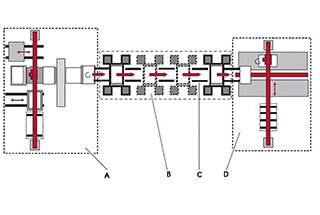

Roll forging, for instance, can serve as an efficient pre-forming process that significantly reduces the amount of pressure required for subsequent forming operations.

Cross wedge rolling is used for producing steel balls, transmission shafts, and other similar components.

Radial forging, on the other hand, is used to manufacture large barrels, step shafts, and other types of forgings.

According to the movement mode of the forging die, forging can be divided into swing rolling, swing rotary forging, roll forging, cross wedge rolling, ring rolling, and cross rolling.

Rotary forging, rotary forging, and ring rolling can also be processed by precision forging.

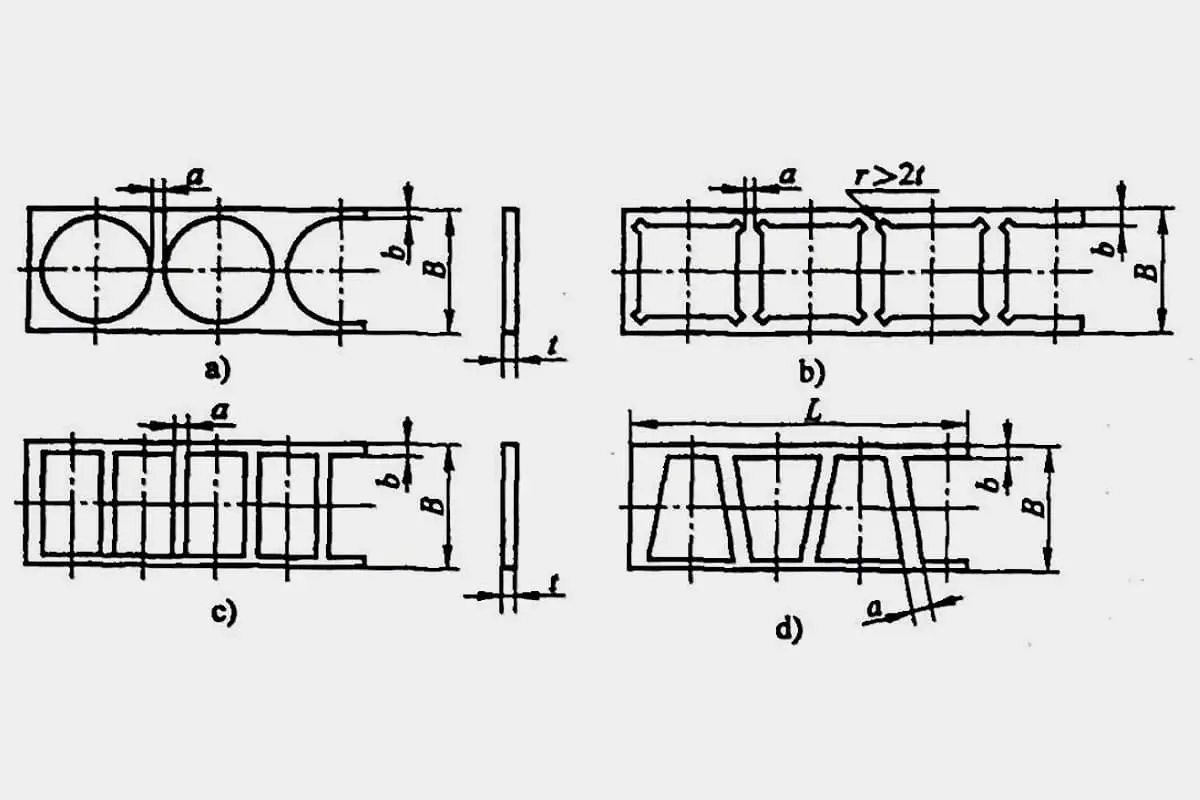

In order to improve the utilization of materials, roll forging and cross-rolling can be used as the previous process for slender materials.

Like free forging, rotary forging is also locally formed.

Its advantage is that, compared with the forging size, it can also be formed when the forging force is small.

In this forging method, including free forging, the material expands from near the die surface to the free surface during processing.

Therefore, it is difficult to ensure accuracy.

By controlling the movement direction of the forging die and the rotary forging process by computer, products with complex shapes and high accuracy can be obtained with low forging force, such as the production of forgings like steam turbine blades with many varieties and large sizes.

The movement of forging equipment may not be consistent with the degree of freedom, which can be categorized into the following four types:

To achieve high accuracy, attention must be paid to preventing overload at the bottom dead center, controlling speed and die position, as these factors can impact the forging tolerance, shape accuracy, and die life.

Additionally, maintaining accuracy requires adjusting the clearance of the sliding block guide rail, ensuring stiffness, adjusting the bottom dead center, and using an auxiliary transmission device.

For forging slender parts, lubricating cooling and forging parts for high-speed production, the slider can move vertically or horizontally. Compensating devices can also be used to increase movement in other directions.

The above methods differ in required forging force, process, material utilization, output, dimensional tolerance, and lubrication and cooling methods. These factors also affect the level of automation.

The forging materials mainly include carbon steel and alloy steel with various components, as well as aluminum, magnesium, copper, titanium, and their alloys. These materials are available in the form of bars, ingots, metal powder, and liquid metal.

The forging ratio refers to the ratio of the cross-sectional area of the metal before deformation to the cross-sectional area after deformation. The correct selection of forging ratio, reasonable heating temperature and holding time, reasonable initial and final forging temperature, and reasonable deformation and deformation speed are essential for improving product quality and reducing cost.

Round or square bars are generally used as blanks for small and medium-sized forgings. These bars have a uniform and good grain structure and mechanical properties, accurate shape and size, and good surface quality, making them convenient for mass production. With reasonable heating temperature and deformation conditions, excellent performance forgings can be produced without large forging deformation.

In comparison, ingots are only used for large forgings. Ingots have a cast structure with large columnar crystals and a loose center. Therefore, it is necessary to break the columnar crystals into fine grains and compact them through large plastic deformation to obtain excellent metal microstructure and mechanical properties.

The powder metallurgy preform can be made into powder forging by non-flash die forging in a hot state. Powder forging has properties similar to general die forgings, including good mechanical properties and high precision, and can reduce subsequent cutting. The internal structure of powder forging is uniform without segregation, making it ideal for small gears and other workpieces. However, the price of powder is much higher than that of general bars, limiting its application in production.

Liquid metal die forging is a forming method between die casting and die forging. By applying static pressure to the liquid metal poured in the die bore to make it solidify, crystallize, flow, plastic deformation, and shape under the action of pressure, die forgings with the required shape and properties can be obtained. This method is particularly suitable for complex thin-walled parts that are difficult to form by general die forging.

Finally, wrought alloys of iron-based superalloys, nickel-based superalloys, and cobalt-based superalloys can also be completed by forging or rolling. However, these alloys are relatively difficult to forge due to their narrow plastic zone. Therefore, there are strict requirements for the heating temperature, open forging temperature, and final forging temperature of different materials.

Various forging methods employ different processes, and among them, hot die forging has the lengthiest process flow.

The typical sequence is as follows: blanking of the forging blank → heating of the forging blank → preparation of the roll-forged blank → forming by die forging → trimming → punching → correction → intermediate inspection to check the size and surface defects of the forging → heat treatment of the forging to remove stress and improve metal cutting performance → cleaning to eliminate surface oxide scale → correction → inspection.

Typically, forgings undergo appearance and hardness inspections, while important forgings also undergo inspections for chemical composition analysis, mechanical properties, residual stress, and other non-destructive testing (NDT).

Compared to castings, forging can improve the microstructure and mechanical properties of metals.

When metal is deformed and recrystallized by the hot forging method, the original coarse dendritic and columnar grain structures transform into equiaxed recrystallization structures with finer and more uniform grains. This process makes the ingot’s original segregation, porosity, slag inclusion, and other imperfections more compact and welded, which improves the metal’s plasticity and mechanical properties.

The mechanical properties of castings are generally lower than those of forgings of the same material.

Furthermore, forging ensures the continuity of the metal fiber structure and maintains the fiber structure’s consistency with the shape of the forgings. The process completes the metal flow line and guarantees that parts possess good mechanical properties and a long service life.

Forgings produced by precision die forging, cold extrusion, warm extrusion, and other methods are superior to castings.

Forging involves pressing metal into the desired shape or applying an appropriate compressive force through plastic deformation, typically using a hammer or pressure. The forging process refines the particle structure and improves the metal’s physical properties. In practical applications, a correctly designed part can direct the particle flow in the direction of the primary pressure.

Casting is the process of obtaining a metal molded object using various casting methods. Molten liquid metal is injected into a prepared mold through pouring, injection, suction, or other casting techniques. The object is then cooled, sand falls off, cleaned, and undergoes post-treatment to achieve a particular shape, size, and performance.