What should be done to properly and effectively repair the hydraulic cylinder of a press brake? Are there any good methods? The hydraulic cylinder of a press brake consists of a piston, sleeve, piston rod, and screw. Generally, oil leaks are caused by the aging or deformation of the seals on the piston’s outer wall […]

What should be done to properly and effectively repair the hydraulic cylinder of a press brake? Are there any good methods?

The hydraulic cylinder of a press brake consists of a piston, sleeve, piston rod, and screw. Generally, oil leaks are caused by the aging or deformation of the seals on the piston’s outer wall and the sleeve’s inner wall.

Of course, the most direct method is to replace the seals. Most domestic press brake manufacturers use seals made in Taiwan and Japan, so the seals have a relatively long service life.

When customers experience oil leaks in their press brake cylinders, be sure to choose high-quality, durable seals when replacing them. This way, the replaced cylinder will not leak oil for a long time.

The steps to replace seals vary depending on the press brake design. Let me describe a common one!

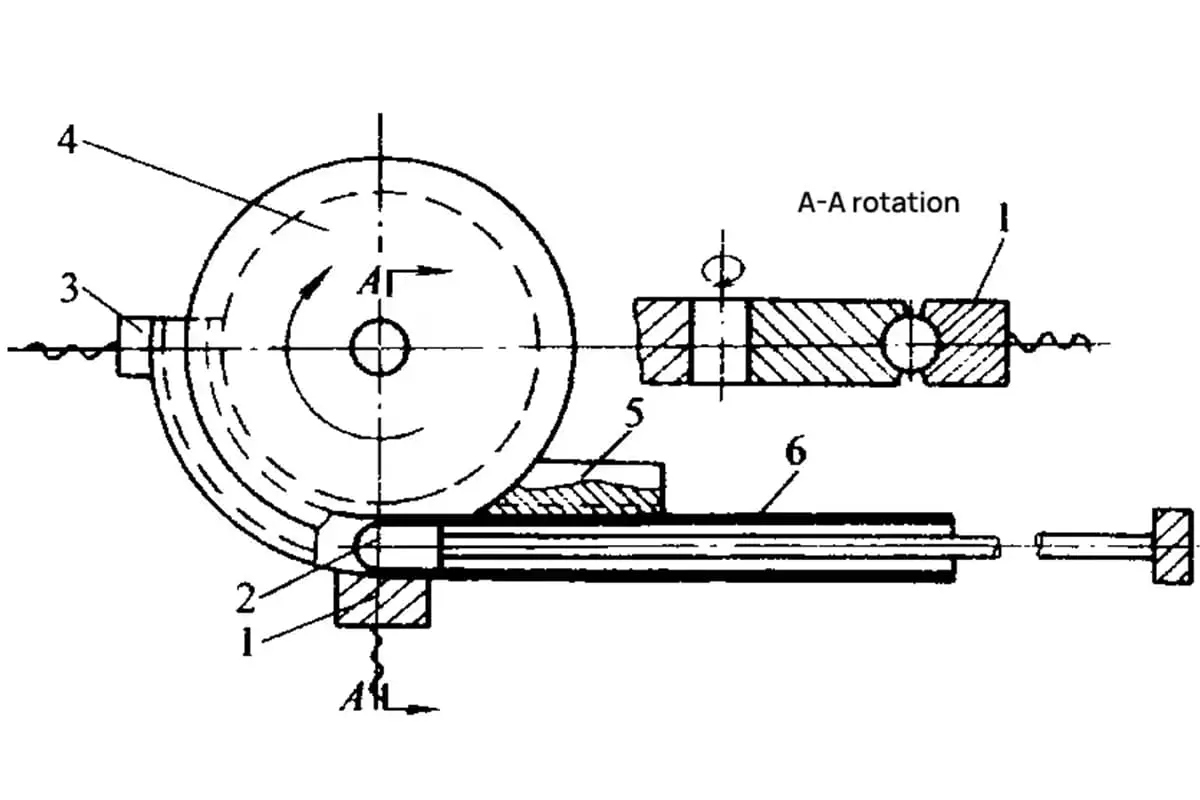

On the hydraulic cylinder of a typical press brake, there is a worm gear and worm block that houses a worm wheel and a screw connected to the piston.

First, disassemble this part, then remove the screw. At this point, you will need assistance from lifting equipment or a forklift, as it is difficult and dangerous to do manually.

Be slow when lifting the screw to avoid damaging the piston due to excessive force.

After disassembling, you will find many seals on the piston’s outer wall, usually including dust seals, O-rings, sealing rings, and gaskets.

The most important part is the sealing ring, while the others generally don’t need to be replaced unless they are severely damaged.

After replacing the seals, you will also need external assistance when reassembling the cylinder.

Once everything is installed, the most critical step is to adjust the cylinder stroke and the angles on both sides (which usually requires professional tuning).

During the adjustment, be sure to set the press brake pressure to around 5-10 MPa first, then test with a few thin plates. Repeat the tests and adjust the cylinder stroke accordingly.

Generally, the right-side cylinder serves as the reference point (depending on the actual situation), and the other cylinder is adjusted until the angles are the same.

Finally, set the pressure back to normal and test with thicker plates. This should complete the process!