What makes induction heating quenching essential in modern metalworking? Imagine transforming high-speed steel in seconds, achieving optimal hardness and efficiency without the environmental impact of traditional methods. This article delves into the rapid heating process, its advantages, and the precise control it offers over microstructures. By the end, you’ll understand how this technique can enhance production efficiency and material performance, revolutionizing your approach to metal hardening.

Induction heating has a heating rate ranging from tens to hundreds of degrees per second, and pulse quenching can reach thousands of degrees per second (2000-3000 ℃/s). Due to the rapid heating speed and short duration, the quenching temperature is higher than that of the general salt bath quenching temperature. This results in the structure being transformed into austenite and homogenized.

Table 1 presents relevant data indicating that the AC1 point of T10 steel and GCr15 steel increases with the heating speed during rapid heating.

Table 1 Relationship between induction heating speed and critical point AC1

| Steel grade | Heating speed / (℃ / s) | ||||||

| Original state | 10 | 50 | 100 | 150 | 200 | 300 | |

| T10 | annealing | 745 | 760 | 765 | 760 | 765 | 765 |

| quench | 735 | 745 | 755 | 755 | 760 | 765 | |

| GCr15 | annealing | 770 | 810 | 825 | 830 | 835 | 830 |

| quench | 740 | 750 | 785 | 800 | 815 | 810 | |

From practice, we know that the quenching temperature of induction heating is 80 ~ 150 ℃ higher than that of conventional quenching.

Table 2 is the recommended heating temperature for high-frequency quenching of common steel.

Table 2 heating temperature of common steel for high frequency quenching

| Steel grade | Heating temperature / ℃ |

| 45 | 860~920 |

| 50 | 860~900 |

| 40Cr | 940~980 |

| T7, T7A | 880~960 |

| T8, T8A | 860~960 |

| Steel grade | Heating temperature / ℃ |

| T10, T10A | 850~960 |

| GCr15 | 920~1020 |

| GCr9 | 900~1000 |

| CrWMn | 850~960 |

| 9SiCr | 880~1000 |

Induction heating has a significantly higher power output than furnace heating, resulting in faster heating speeds and shorter times needed to promote the transformation of pearlite to austenite.

The original structure of steel has a considerable influence on the nucleation, growth, and homogenization of austenite during rapid heating, which in turn affects the temperature of induction quenching, as well as the resulting microstructure and properties.

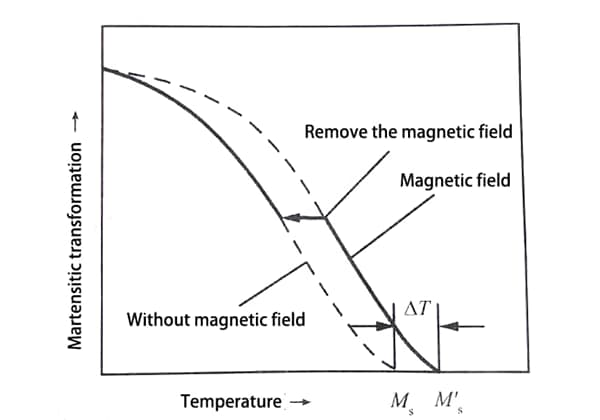

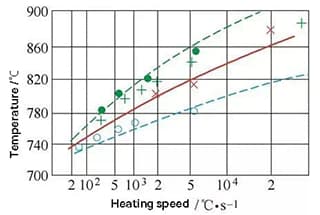

Figure 1 illustrates the relationship between the critical point of T8 steel, the heating speed, and various original structures.

Flake pearlite is more susceptible to structural transformation during heating than spherical pearlite.

Therefore, the induction quenching temperature of steel with different original structures should be as follows: t quenching (annealing state) > t quenching (normalizing state) > t quenching [quenching and tempering (annealing + high temperature tempering)].

The physical significance of α0 in the figure is:

Pearlite represents half the distance between two adjacent cementites, whereas free ferrite represents half the distance between the nodes of the dislocation network (refer to Fig. 1).

As the heating temperature increases, the AC3 point also increases rapidly (refer to Fig. 1).

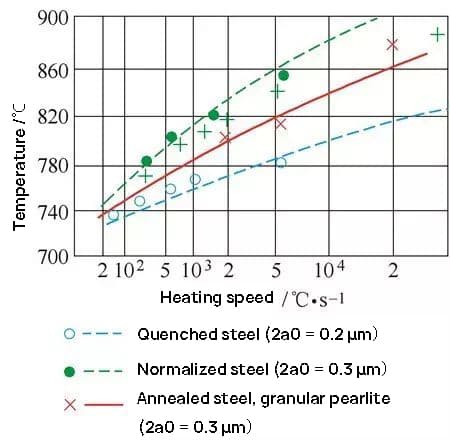

Fig. 2 shows the temperature required for complete quenching of hypoeutectoid steel at different heating speeds.

Fig. 2

At low heating speeds, the initial grain of austenite formed just after austenitizing decreases significantly with an increase in heating speed. However, at high heating speeds, the initial grain of austenite hardly decreases with an increase in heating speed.

Studies have shown that under the actual conditions of induction heating, the heating speed is very high and the initial grain obtained is very small. It has been determined that the size of the initial grain has nothing to do with the heating speed.

Nonetheless, the growth of the formed austenite grains is related to the heating rate. As heating continues to a certain temperature, the actual size of the austenite grain formed increases with a decrease in heating speed, as shown in Fig. 3.

Therefore, as long as the heating temperature and time are properly controlled, induction heating will not result in overheating.

Fig. 3

As early as 1923-1924, Vologgin from the former Soviet Union began studying the high-frequency quenching of high-speed steel tools, but it was unsuccessful.

The reason for this was that high-speed steel tools need to be completely quenched to obtain a hardened layer with high thermal hardness and strength, which can be relatively thick.

There was also concern that poor dissolution of high-frequency quenching carbides might affect other properties.

However, this was a superficial perception, and induction quenching had not been thoroughly studied.

It was not until 1952 that a breakthrough was achieved.

Gedeberge and others finally succeeded in quenching a 3-10mm W18Cr4V (P18) blade.

Unfortunately, it was not put into industrial production, but it demonstrated that high-speed steel tools could be induction-hardened.

Rod-shaped tools, such as high-speed steel taper shank drills and end mills, can be heated rapidly using techniques such as flash welding or friction welding. These methods are capable of heating steel parts to temperatures exceeding 1000 ℃ in just a few seconds.

The author recommends direct heating of the φ60mm high-speed steel billet in the high-temperature zone. This means that the cold material should be heated directly in the 1150-1200℃ zone without preheating.

This method has been used in production for many years, and the forging quality has remained stable.

There is a quenching parameter formula in the heat treatment of high speed steel tools

That is,

P = t (37 + lg τ)

Where

The symbol P in the formula represents the combined impact of quenching heating temperature and heating time.

During the quenching process, regardless of the variations in the quenching heating temperature and heating time, the degree of austenitization remains the same as long as the quenching parameters are identical.

This implies that the quenching quality of the tool will remain consistent if P remains constant, whether it is achieved through rapid heating at high temperature for a short period or slow heating at low temperature for a longer duration.

In the late 1950s, new technology for rapid heating and energy-efficient heat treatment was introduced in Beijing, Tianjin, Shanghai, and other places with the assistance of heat treatment experts from the Soviet Union. The implementation of this technology resulted in numerous successful experiences, but unfortunately, only a limited amount of data remains.

The author possesses data only on the rapid heating of a φ14mm taper shank drill and slot milling cutter made of W18Cr4V Steel from the Shanghai tool factory. According to reports, the quenching heating temperature of W18Cr4V Steel increased from 1270 to 1310 ℃, while the heating coefficient reduced from 10 to 6s/mm. Surprisingly, the tool life increased slightly instead of decreasing.

In recent years, there have been continuous reports on the surface modification of high-speed steel using lasers. These reports point out that high-speed steel can be rapidly heated using this method.

The technical method involves applying plasma with high energy density to the surface of M42 steel at high speed. This results in local rapid temperature rise and rapid cooling on the surface of the material. The temperature rise and cooling speed can reach 104-108k °/s.

As a result, a crystal structure modification layer can be formed on the surface of the workpiece, improving the material’s performance.

In the past century since the introduction of high-speed steel, innovation and reform of its heat treatment process have been ongoing.

Some individuals in the former Soviet Union claimed that steel could be heated at any speed. However, due to the limited conditions of the time, this was only achievable through salt bath furnaces and high-frequency heating. Moreover, the quenched parts were no longer limited to simple rods or pieces, but still lacked universality.

Relatively successful results have been achieved in the rapid heating application of high-speed steel forging billets. Most people believe that the heating speed of high-speed steel material after pressure processing and annealing can be unrestricted before forging.

Furthermore, with the emergence of new technologies and processes such as laser and electron beam, there are many reports on the surface modification of high-speed steel through rapid heating. This suggests that rapid heating of high-speed steel has now entered a substantial application stage.

High-speed steel is known as “wind steel” because of its good hardenability, which allows it to be quenched in air.

It can be quenched to a hardness of above 64HRC in air, which makes it ideal for producing sharp edges. For this reason, it is also referred to as “blade steel”.

Induction heating quenching of high-speed steel is a form of self-cooling quenching that is both energy-efficient and environmentally friendly. It also offers high production efficiency.

Regardless of the type of steel being quenched, there are two basic conditions that must be met. First, it must be austenitized, and second, it must be cooled immediately.

The cooling rate should be higher than the critical cooling rate of the steel (V).

Induction heating has the unique characteristic of heating the surface of the workpiece. If heating is stopped immediately after the surface layer is austenitized, and the adjacent unheated metal can quickly conduct the heat of the heating layer, the surface will be hardened if its cooling speed is greater than V.

The cooling process does not involve spraying a quenching liquid on the surface but relies on the cooling of the metal inside. This unique cooling process can only be achieved with high-energy density heating. Induction heating is one of the methods that provide high-energy density heating.

Due to the extremely high power density and short heating time, induction heating is also known as pulse heating. The temperature of the workpiece during induction heating can be measured using an infrared photoelectric pyrometer or an optical pyrometer. Alternatively, the quenching temperature can be determined through visual inspection by examining the color of the heated workpiece.

During the induction heating process, the heat generated by the eddy current is primarily used in heating the surface layer of the workpiece. Nonetheless, there are two types of heat released from the workpiece during this process.

There are two types of heat losses during the heating process: radiant heat, which is emitted from the heating surface to the air, and heat conduction, which is conducted from the heating layer of the workpiece to the center.

The impact of internal heat conduction, particularly on the heating layer, deepens the theoretical understanding of the process. The depth of the heating layer is denoted by d and is equal to 0.2 mm, where t represents the heating time in seconds. The heat loss increases as the power density decreases and the heating time is extended.

If the workpiece is relatively thin, the heat conduction will quickly transmit from the surface to the core, resulting in the entire section becoming uniformly heated.

High-speed steel is a self-hardening material, which means that it will harden immediately after the heating process is stopped.